Metal composite, preparation, forming method and equipment

A metal composite material and forming method technology, which is applied in the field of composite material preparation and forming, can solve the problem that the performance stability and reliability of composite materials cannot be guaranteed, it is difficult to obtain the optimal performance of materials by ordinary casting methods, and the microstructure is not repeatable and other problems, to achieve the effect of wide range of industrial applications, simple structure of equipment and molds, and high composition ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

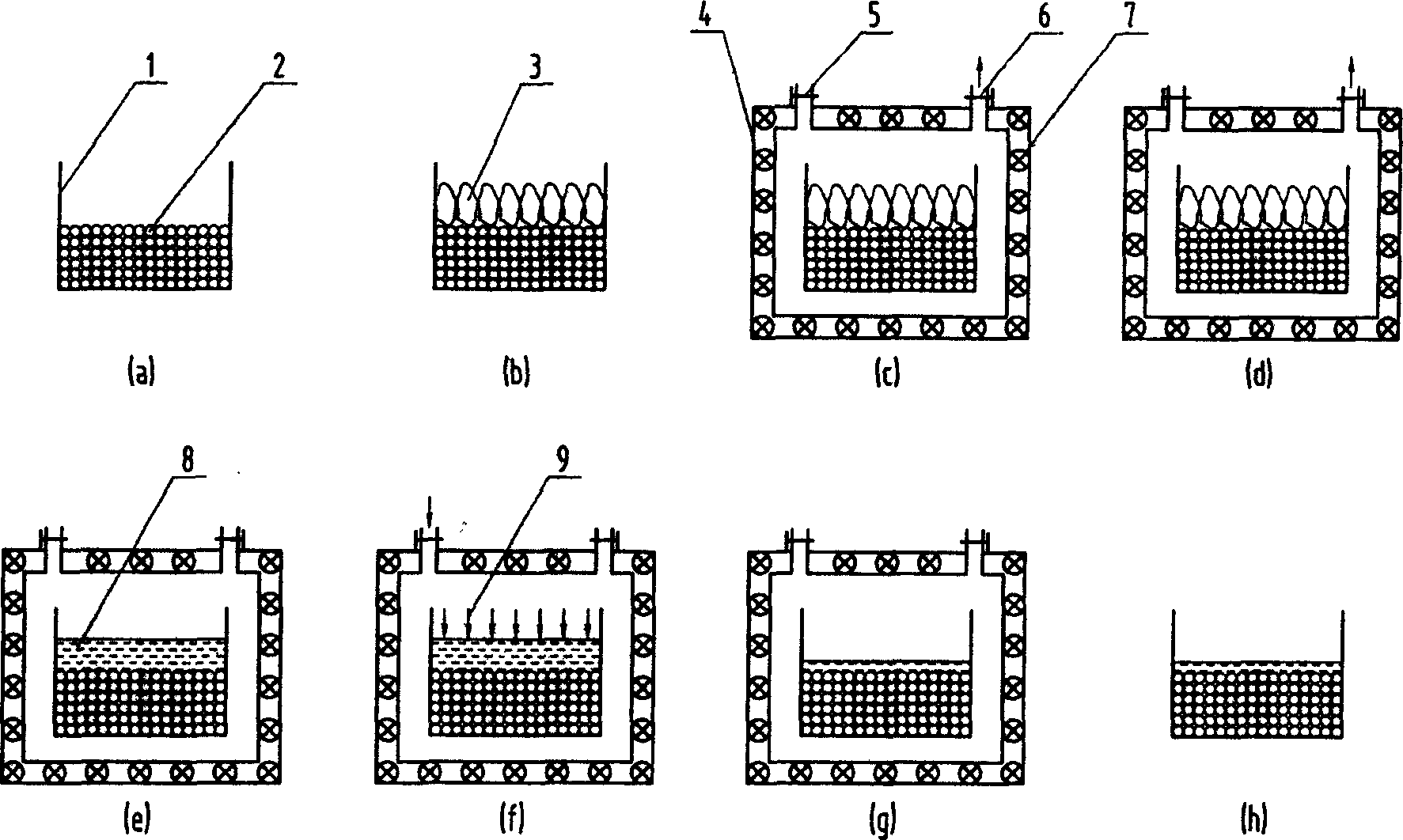

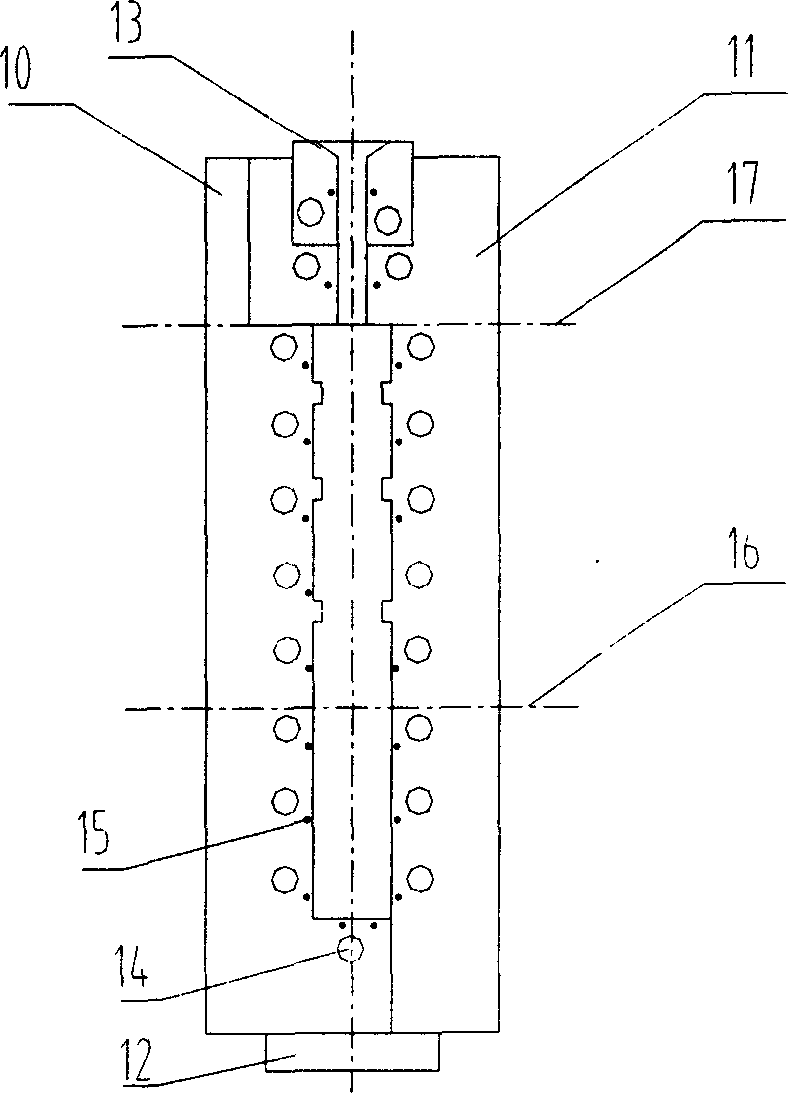

[0033] The structure of the manufacturing equipment of metal composite material of the present invention is as figure 1 shown in figure 1Among them, the impregnation container 1 is a container tank made of steel plate that can hold liquid. The liquid will not leak out when it is contained in the tank. The silicon dioxide powder with an average particle size of 10 μm is spread on the bottom of the impregnation tank to a certain thickness, and Vibrate and shake the silica powder to form a powder bed 2; place the brass block 3 for melting and infiltration on the powder bed; put the impregnation tank containing the silica powder and brass block into 4 in the heating furnace (the heating furnace can be airtightly evacuated, or can be airtightly inflated to withstand a certain air pressure), after closing the furnace door, evacuate to reach a vacuum degree of 0.01Pa; the heater 7 in the heating furnace is in the heating process Melt the brass block; when the brass block 3 on the si...

Embodiment 2

[0035] This example is basically the same as Example 1, except that the metal used is a cast aluminum block, and the temperature for heating and heat preservation is 730°C. Perform die casting.

Embodiment 3

[0037] This embodiment is basically the same as the second embodiment, except that the obtained metal composite material of aluminum alloy and silicon dioxide in solid-liquid coexistence is cooled to a semi-solid state and then put into the cavity of a squeeze casting mold for extrusion casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com