Metamaterial micro-bridge structure and preparation method thereof

A micro-bridge structure and meta-material technology, applied in the directions of micro-structure technology, micro-structure devices, manufacturing micro-structure devices, etc., can solve the problems of meta-material micro-bridge structure deformation, complex preparation process, etc. The effect of terahertz radiation absorptivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

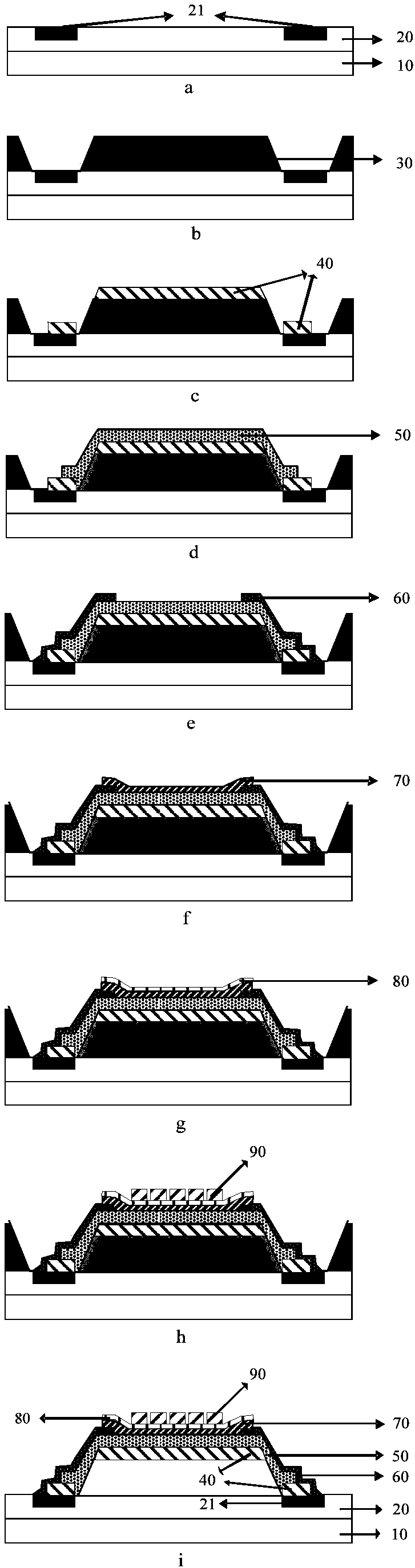

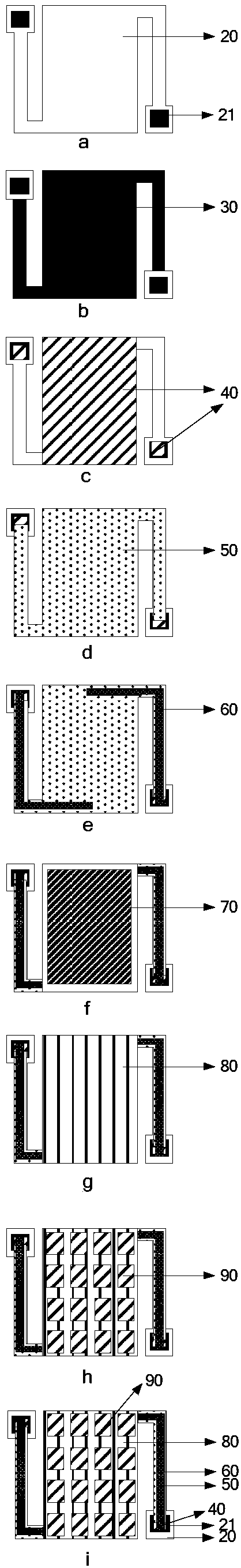

[0040] For the preparation method of the above-mentioned metamaterial microbridge structure, specifically, the following steps are included:

[0041] Step 1: grow a sacrificial layer on the substrate with the driving circuit layer 20 and pattern the sacrificial layer 30, the driving circuit layer 20 has a circuit interface 21; the material of the sacrificial layer 30 is polyimide, silicon dioxide, One of oxidized porous silicon or phosphosilicate glasses.

[0042] Step 2: Prepare an underlying metal film 40 with a thickness of 100-300 nm on the sacrificial layer 30 , and the underlying metal film 40 covers the top of the sacrificial layer 30 and part of the surface of the circuit interface 21 . The bottom metal thin film 40 is made of one or more of aluminum, tungsten, titanium, platinum, nickel, and chromium.

[0043] Step 3: Prepare an intermediate dielectric layer 50 with a thickness of 100-500 nm on the underlying metal film 40 to expose the circuit interface 21 . The ma...

Embodiment 1

[0051] Such as figure 1 with figure 2 Shown, a kind of preparation method of metamaterial microbridge structure, this microbridge structure is expanded on the substrate 10 that has prepared bottom driving circuit 20, and driving circuit 20 has flowed out of circuit interface 21, as figure 1 As shown in -a, the next steps are:

[0052] Step 1: Clean the surface of the substrate 10 to remove surface contamination, and bake the substrate 10 at 200°C to remove the moisture on the surface and enhance the bonding performance; use the automatic glue coating track to coat the sacrificial layer 30, Here, the material of the sacrificial layer 20 is photosensitive polyimide; the thickness of the polyimide film is adjusted by rotating speed, and the coated photosensitive polyimide is baked at 120°C to remove part of the solvent in the glue , which is conducive to the neatness of the exposure lines. The photosensitive polyimide is exposed by a NIKON lithography machine, and the exposed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com