Edible detergent and preparation method thereof

A dishwashing liquid, food-grade technology, applied in the field of dishwashing liquid, can solve the problems of high price, weak washing ability and high raw material price, and achieve the effect of moderate foam, no skin allergy and lower product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with embodiment the present invention is described in further detail.

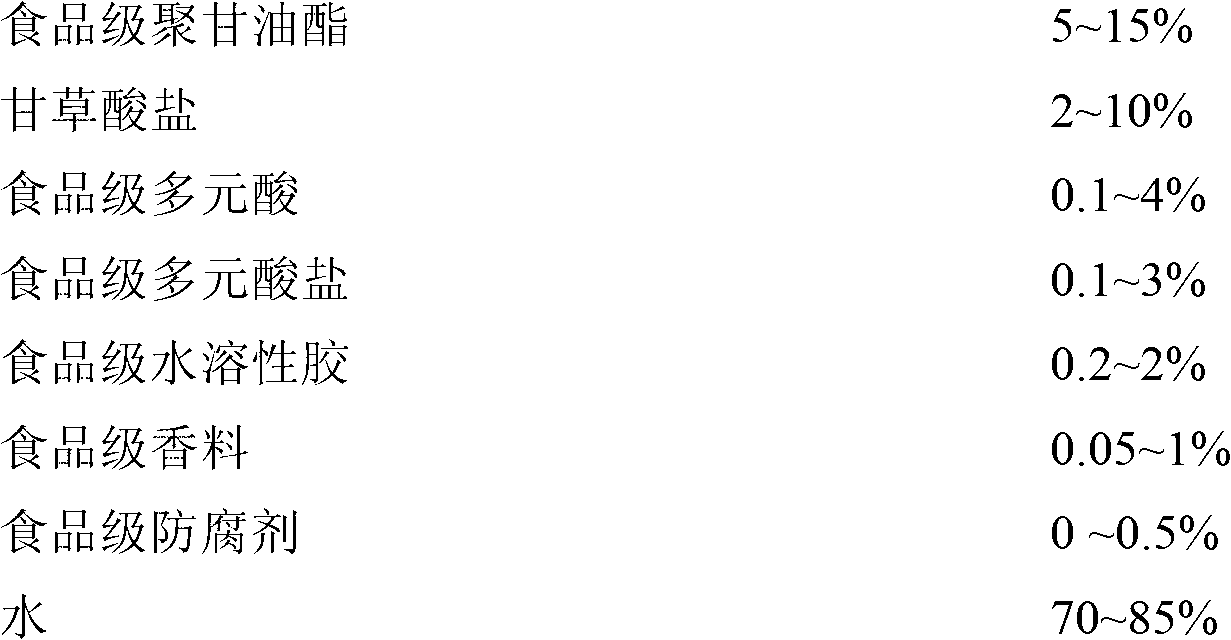

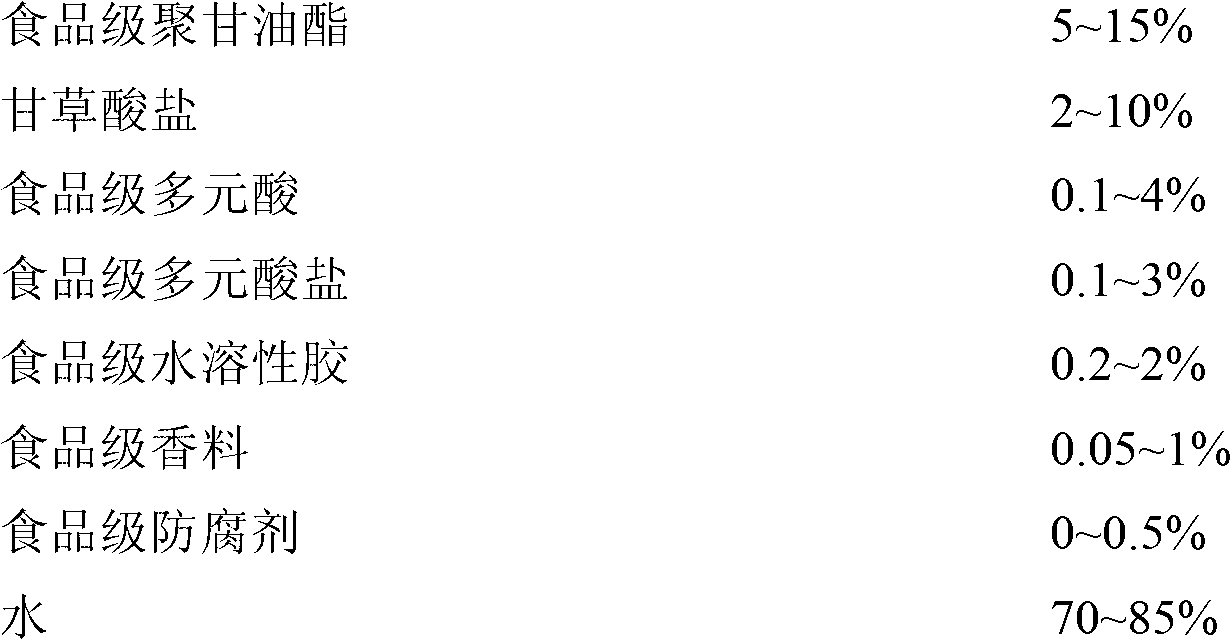

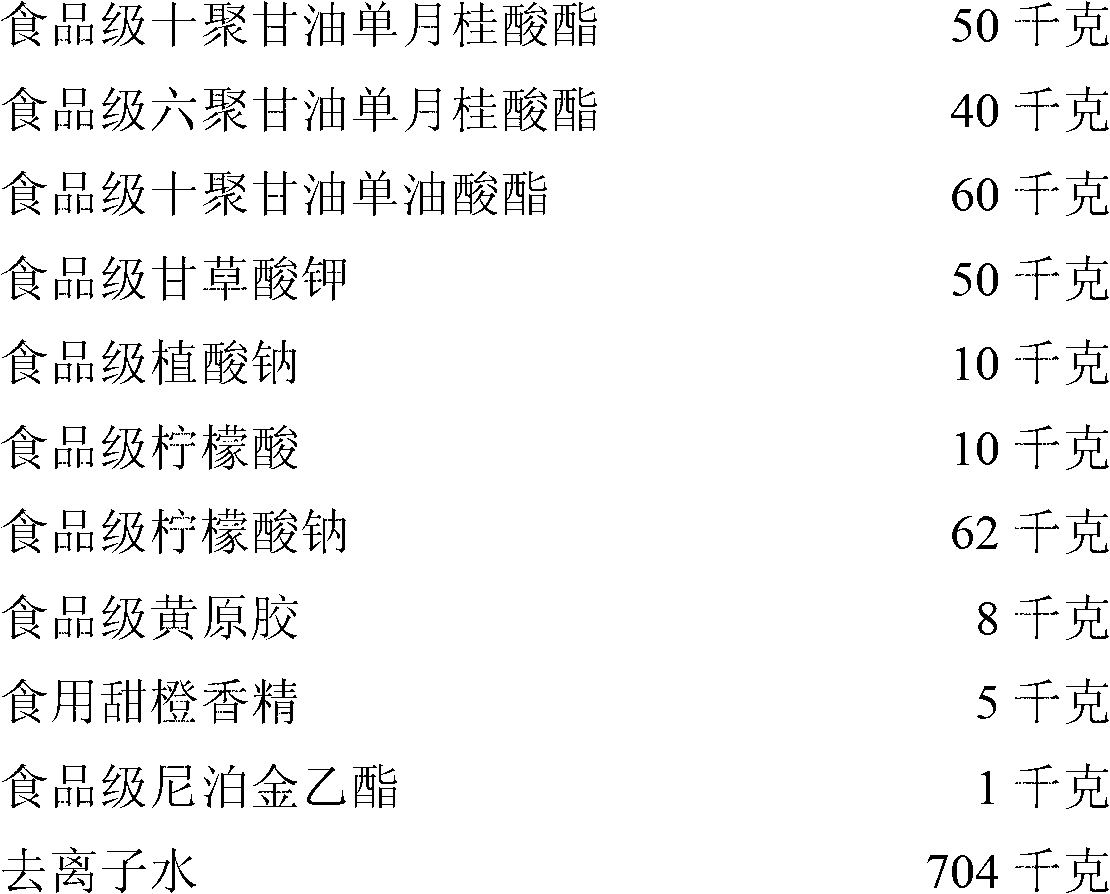

[0055] Feeding ratio:

[0056]

[0057] Preparation steps:

[0058] Inject 230 kg of deionized water into a 1000 liter conventional reaction pot, start the mixer, control the stirring speed to 180 rpm, and at the same time heat the jacket with steam, add food grade decaglycerol monooleic acid in three batches at intervals of 20 minutes 60 kg of ester, after completely melted, add 40 kg of food grade hexapolyglycerol monolaurate and 50 kg of food grade decaglycerol monolaurate in two batches at intervals of 20 minutes to prevent a large amount of foam from rising; Stir the materials in the pot evenly and heat up to 75°C, then evenly sprinkle 50 kg of food-grade potassium glycyrrhizinate in three batches at intervals of 10 minutes, and continue stirring to make the system translucent; obtain material A.

[0059] Add 62 kg of food-grade sodium citrate in two batches at interva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com