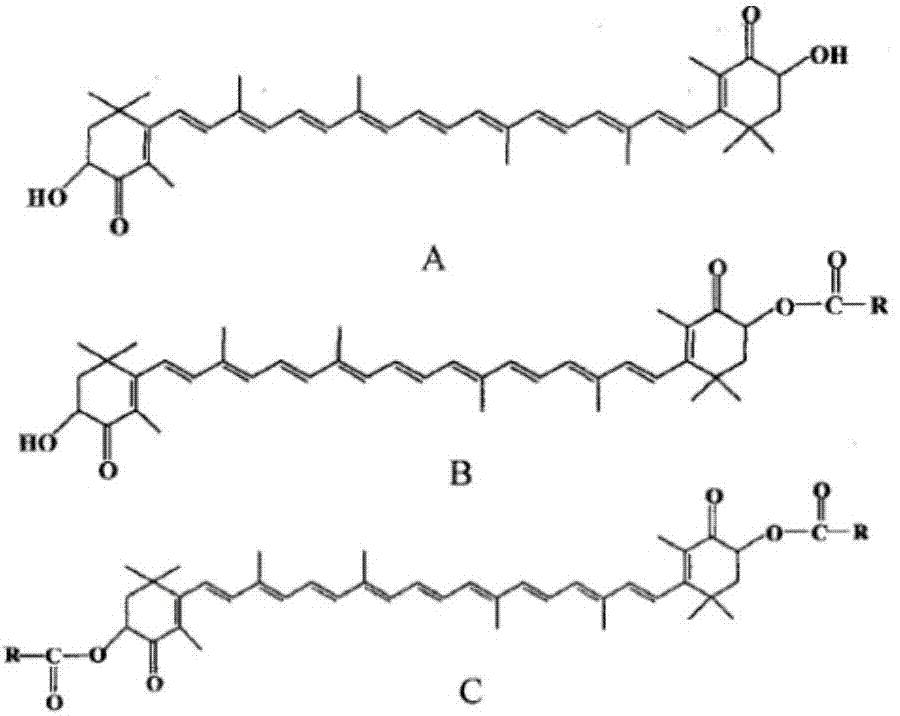

Method for breaking walls of Haematococcus pluvialis and extracting astaxanthin

A technology of Haematococcus pluvialis and Haematococcus pluvialis powder, applied in the direction of organic chemistry, can solve the problems of loss, high temperature selection, cumbersome steps, etc., reduce loss and denaturation, mild reaction conditions, and simple operation steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

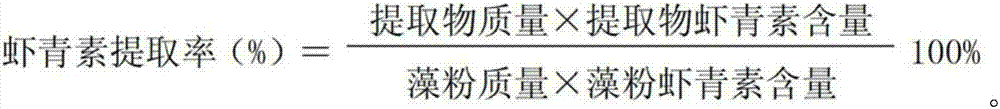

[0037] Weigh 200 mg of algae powder, put it in a reaction flask, add 5% sulfuric acid-methanol system (volume fraction, v / v) at a liquid-to-solid ratio of 10:1 (mL / g), and stir at 50 ° C for 1 h to break the wall. After the wall-breaking treatment of 5% sulfuric acid-methanol system, the extraction solvent n-hexane was added according to the liquid-to-solid ratio of 10:1 (mL / g), stirred and extracted at 30°C for 30 minutes, and the supernatant was collected by centrifugation and layered with liquid nitrogen. Blow dry and concentrate to obtain an extract rich in astaxanthin. The content of astaxanthin is determined by high performance liquid chromatography. The content of astaxanthin in the extract is 10.2%, and the extraction rate of astaxanthin is calculated to be 93.5%. It can be seen that the content of astaxanthin is 10.2%, and the content of astaxanthin in the crude extract has exceeded 10%, so the difficulty of subsequent purification can be greatly reduced, and it is mor...

Embodiment 2

[0039] Weigh 200 mg of algae powder, put it in a reaction flask, add 3% sulfuric acid-methanol system (volume fraction, v / v) at a liquid-to-solid ratio of 10:1 (mL / g), and stir at 30 ° C for 1 h to break the wall. After being treated with 3% sulfuric acid-methanol system for wall breaking, add the extraction solvent n-hexane at a liquid-to-solid ratio of 10:1 (mL / g), stir and extract at 70°C for 30 minutes, centrifuge and separate to obtain the supernatant, supernatant liquid nitrogen Dried and concentrated to obtain an extract rich in astaxanthin, the content of astaxanthin was determined by high performance liquid chromatography, and the content of astaxanthin in the extract was 10.3%, and the calculated astaxanthin extraction rate was 92.3%. The result of this embodiment is basically consistent with that of embodiment 1. The content of astaxanthin is 10.3%, and the content of astaxanthin in its crude extract has exceeded 10%. Therefore, the method for breaking the wall of ...

Embodiment 3

[0041] Weigh 200 mg of algae powder, put it in a reaction flask, add 10% sulfuric acid-methanol system (volume fraction, v / v) at a liquid-to-solid ratio of 10:1 (mL / g), and stir at 70 ° C for 1 h to break the wall. After breaking the wall with 10% sulfuric acid-methanol, add a vegetable oil extraction solvent as the extraction solvent according to the liquid-to-solid ratio of 10:1 (mL / g), stir and extract at 50°C for 30 minutes, centrifuge and separate the supernatant, and The clear liquid was blown dry with nitrogen gas, concentrated to be rich in astaxanthin extract, and the content of astaxanthin was determined by high performance liquid chromatography. The content of astaxanthin in the extract was 9.6%, and the calculated astaxanthin extraction rate was 87.5%. The content of astaxanthin in the crude extract is close to 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com