Sodium ion battery positive electrode material, preparation method thereof and sodium ion battery comprising same

A technology for sodium ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of capacity fading, cycle performance difficult to meet the requirements of practical applications, etc., and achieve simple operation and suitable for large-scale Promote the effect of production and less process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Further, the present invention also provides the above chemical composition (Na 0.6 mn 0.8 co 0.2 o 2 ) The preparation method of the sodium ion battery cathode material, comprising:

[0034] (a) adding soluble carbonate, manganese salt, and cobalt salt into water to stir the reaction, and collecting the generated precipitate;

[0035] Wherein, the raw material soluble carbonate includes: sodium carbonate, or at least one of potassium carbonate;

[0036] Soluble manganese salts include: at least one of manganese sulfate, manganese nitrate, or manganese chloride;

[0037] The soluble cobalt salt includes: at least one of cobalt sulfate, cobalt chloride, or cobalt nitrate.

[0038] The molar ratio of the raw material soluble carbonate, soluble manganese salt, and soluble cobalt salt to carbonate, manganese ion and cobalt ion is: 1:a:b;

[0039] Wherein, 0.5

[0040] Preferably, the molar ratio of c...

Embodiment 1

[0055] Add sodium carbonate, manganese sulfate and cobalt nitrate into water according to the molar ratio of 1:0.9:0.1, stir at room temperature for 6 hours, filter and collect the precipitate, dry, pulverize, and then dry the precipitate and NaOH according to the mass ratio of 2 :1 ratio ball milled evenly, followed by sintering in the air at 500°C for 5 hours, and at 800°C for 6 hours to obtain the layered-tunnel structure symbiotic sodium ion battery cathode material Na 0.6 mn 0.8 co 0.2 o 2 .

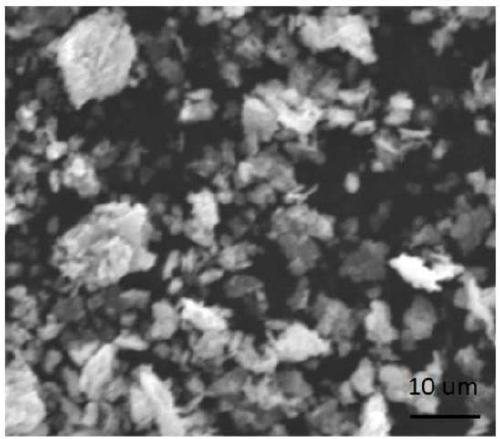

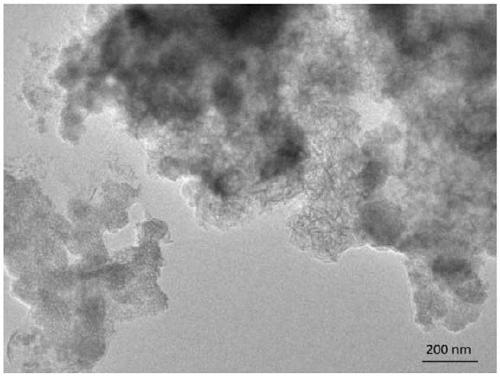

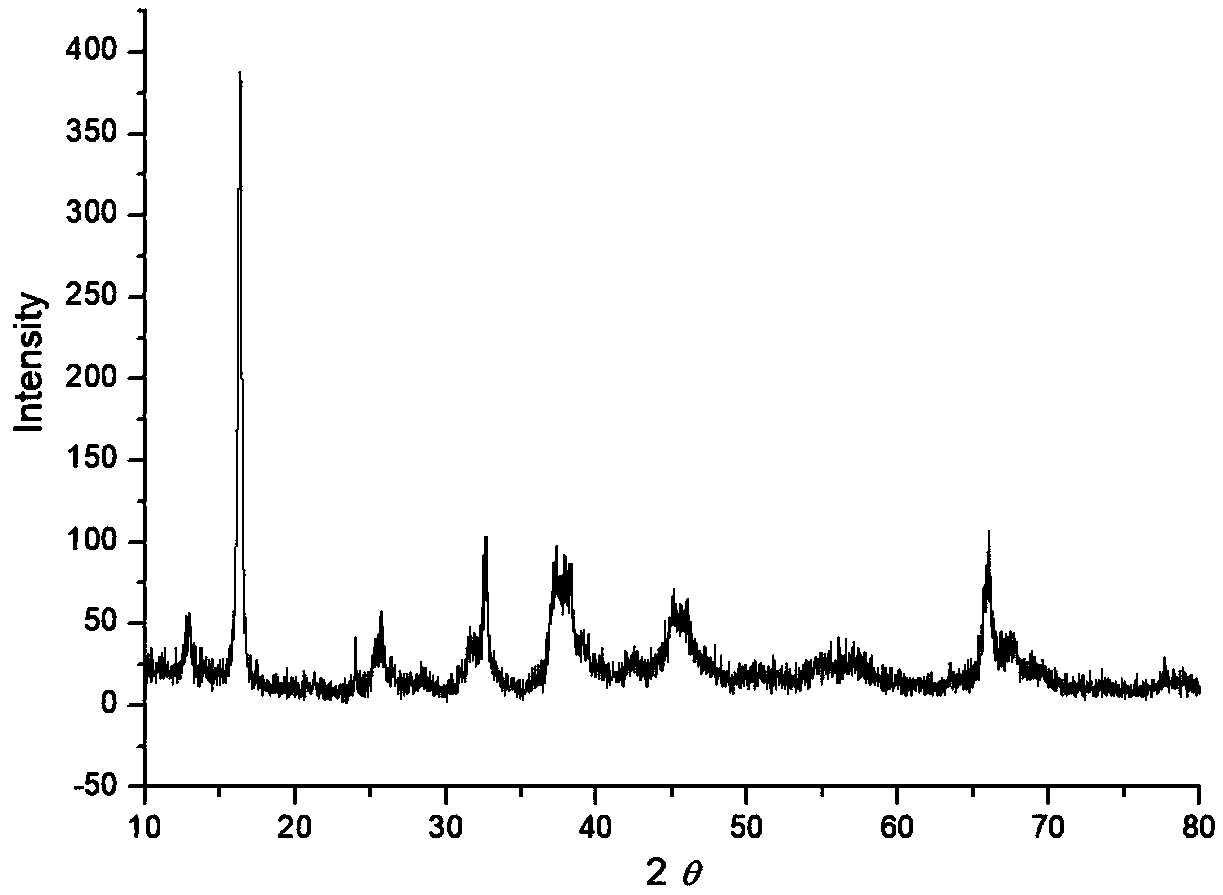

[0056] The scanning electron microscope detection figure and transmission electron microscope of the positive electrode material with layered-tunnel structure symbiosis structure prepared in embodiment 1 are as follows: figure 1 with 2 As shown, it is a nanosheet structure. Its crystal powder diffraction pattern is shown in image 3 As shown, compared with the diffraction standard card tunnel structure manganese oxide (JCPDS NO.27-0750) and the layered structure manganese oxid...

Embodiment 2

[0058] Add sodium carbonate, manganese chloride and cobalt sulfate into water according to the molar ratio of 1:0.9:0.1, stir at room temperature for 6 hours, filter and collect the precipitate, dry, pulverize, and then mix the dried precipitate with NaOH according to the mass ratio The ratio of 2:1 is ball milled evenly, followed by sintering in the air at 550°C for 5 hours, and at 900°C for 5 hours to obtain the layered-tunnel structure symbiotic sodium ion battery cathode material Na 0.6 mn 0.8 co 0.2 o 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com