Single preparation method of solid oxide fuel cell

A solid oxide and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of complex SOFC preparation steps, high manufacturing cost, time-consuming, etc., achieve uniform force, reduce production costs, and reduce preparation The effect of the process step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

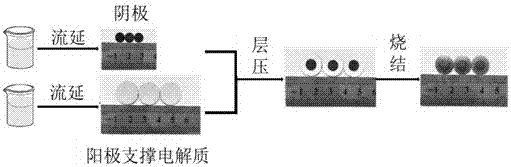

[0024] Specific Embodiment 1: This embodiment describes a simple solid oxide fuel cell preparation method, the method is as follows figure 1 As shown, it specifically includes the following steps:

[0025] Step 1: cast SSZ electrolyte layer;

[0026] Step 2: cast an anode functional layer and an anode support layer on the SSZ electrolyte layer in step 1 to form a green body A;

[0027] Step 3: cast a cathode functional layer, and cast a cathode support layer on the cathode functional layer to form a green body B;

[0028] Step 4: superimpose the SSZ electrolyte layer of green body A and the cathode functional layer of green body B, and obtain a complete full battery green body by lamination;

[0029] Step 5: Put the full cell blank obtained in Step 4 into a high-temperature furnace for sintering.

specific Embodiment approach 2

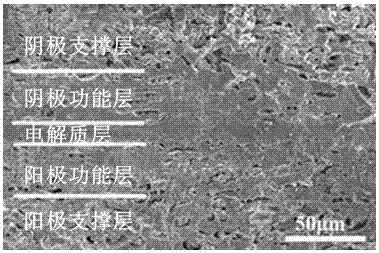

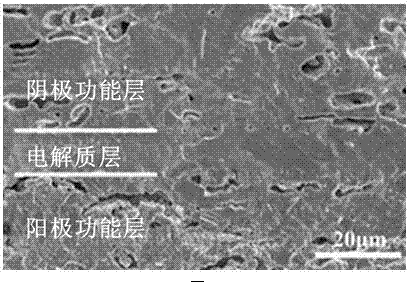

[0030] Embodiment 2: A simple solid oxide fuel cell preparation method described in Embodiment 1, the fuel cell is sequentially made of an anode support layer, an anode functional layer, an electrolyte layer, a cathode functional layer and a cathode support layer. Integral structure, the obtained solid oxide fuel cell cross-sectional scanning electron microscope picture and its enlarged picture are as follows: figure 2 , 3 shown; where:

[0031] The anode support layer is composed of NiO phase and SSZ phase, and the thickness of the anode support layer is 500-700 μm;

[0032] The anode functional layer is composed of NiO phase and SSZ phase, and the thickness of the anode functional layer is 20-35 μm;

[0033] The electrolyte layer is composed of SSZ phase, and the thickness of the electrolyte layer is 10-20 μm;

[0034] The cathode functional layer is composed of LSM phase and SSZ phase, and the thickness of the cathode functional layer is 20-35 μm;

[0035] The cathode ...

specific Embodiment approach 3

[0037] Specific embodiment three: the simple solid oxide fuel cell preparation method described in specific embodiment one or two, in step one, the casting method of the SSZ electrolyte layer is as follows:

[0038] Dissolve 0.2~1.0mL dispersant triethanolamine in a mixed solvent of 80~120mL ethanol and 50~150mL butanone, add 80~120g SSZ powder, first ball mill for 12~24 hours, then add 0.5~2.0g poly Vinyl butyral plasticizer, 0.5~2.0g polyethylene glycol and 0.5~2.0g polymethyl methacrylate toughening agent, continue ball milling for 12~24 hours, take out the slurry, vacuum defoaming, remove the air inside , cast SSZ electrolyte layer, the purity of raw materials and reagents involved are analytically pure. The scanning electron microscope image of the electrolyte surface of the simple solid oxide fuel cell is as follows Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com