Patents

Literature

57results about How to "Delamination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

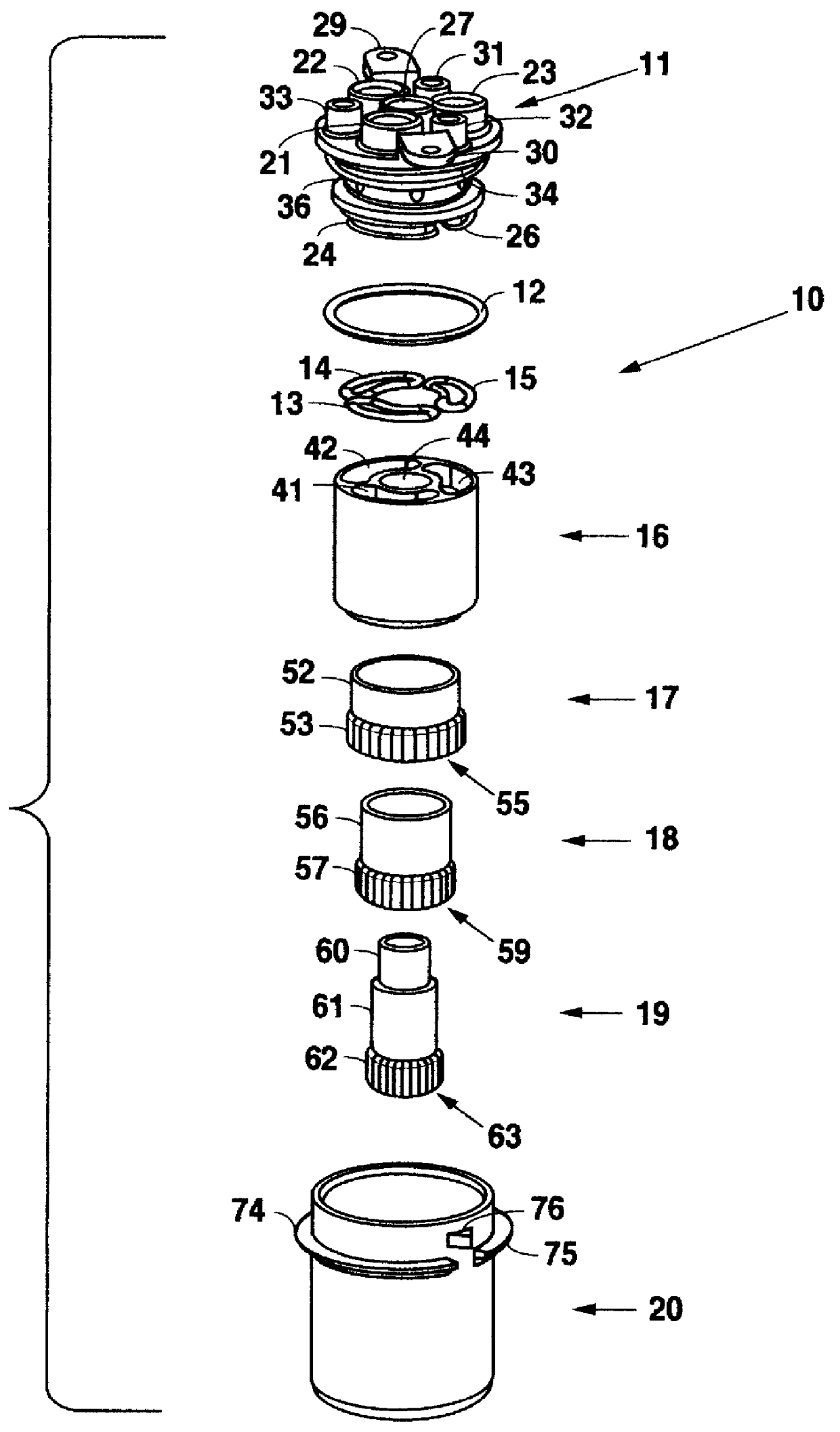

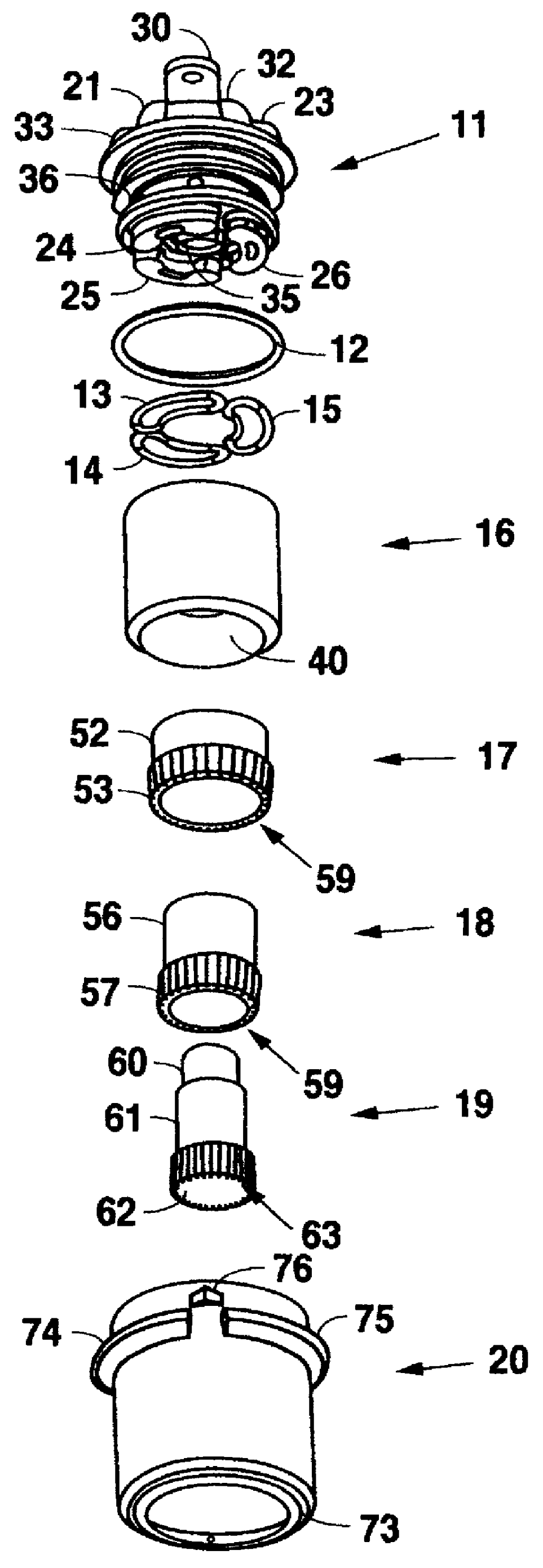

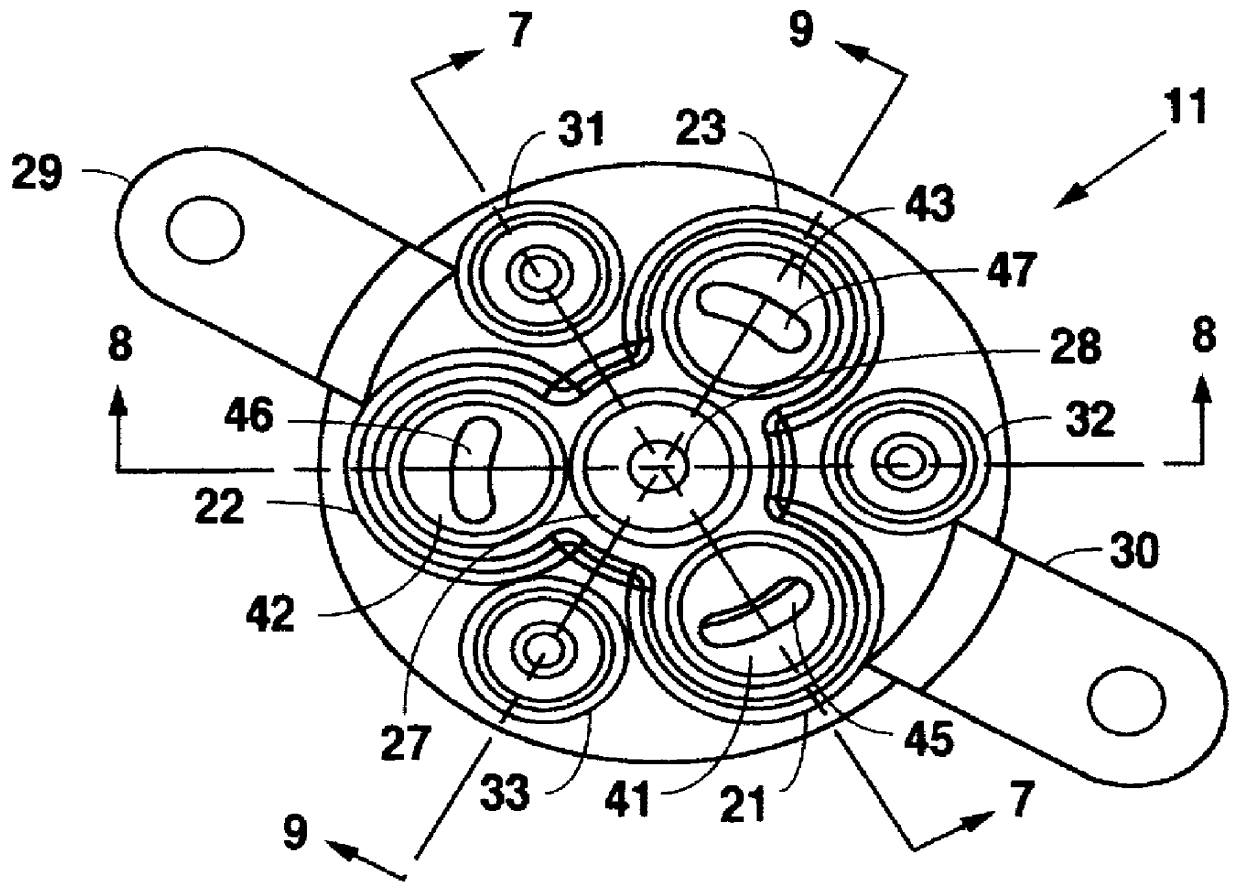

Multiple flavor beverage dispensing air-mix nozzle

InactiveUS6047859AAvoiding carbon dioxideIncrease surface areaOpening closed containersBottle/container closureEngineeringFood flavor

In a beverage dispensing nozzle, a cap member includes a first beverage syrup inlet port coupled to a first beverage syrup source and a mixing fluid inlet port coupled to a mixing fluid source. The cap member further includes a flavor additive port coupled to a flavor additive source. An inner housing including a chamber is coupled to the cap member. A first annulus disposed within the chamber of the inner housing defines a first annular beverage syrup channel with the inner housing, wherein the first beverage syrup inlet port communicates beverage syrup to the first annular beverage syrup channel for discharge from the beverage dispensing nozzle. The first annulus further includes a flavor additive passageway, wherein the flavor additive inlet port communicates flavor additive to the flavor additive passageway for discharge from the beverage dispensing nozzle. An outer housing coupled to the cap member defines a mixing fluid channel with the inner housing, wherein the mixing fluid inlet port communicates mixing fluid to the annular mixing fluid channel for discharge from the beverage dispensing nozzle in an annular flow pattern that contacts exiting beverage syrup and flavor additive to mix therewith outside the beverage dispensing nozzle.

Owner:LANCER PARTNERSHIP

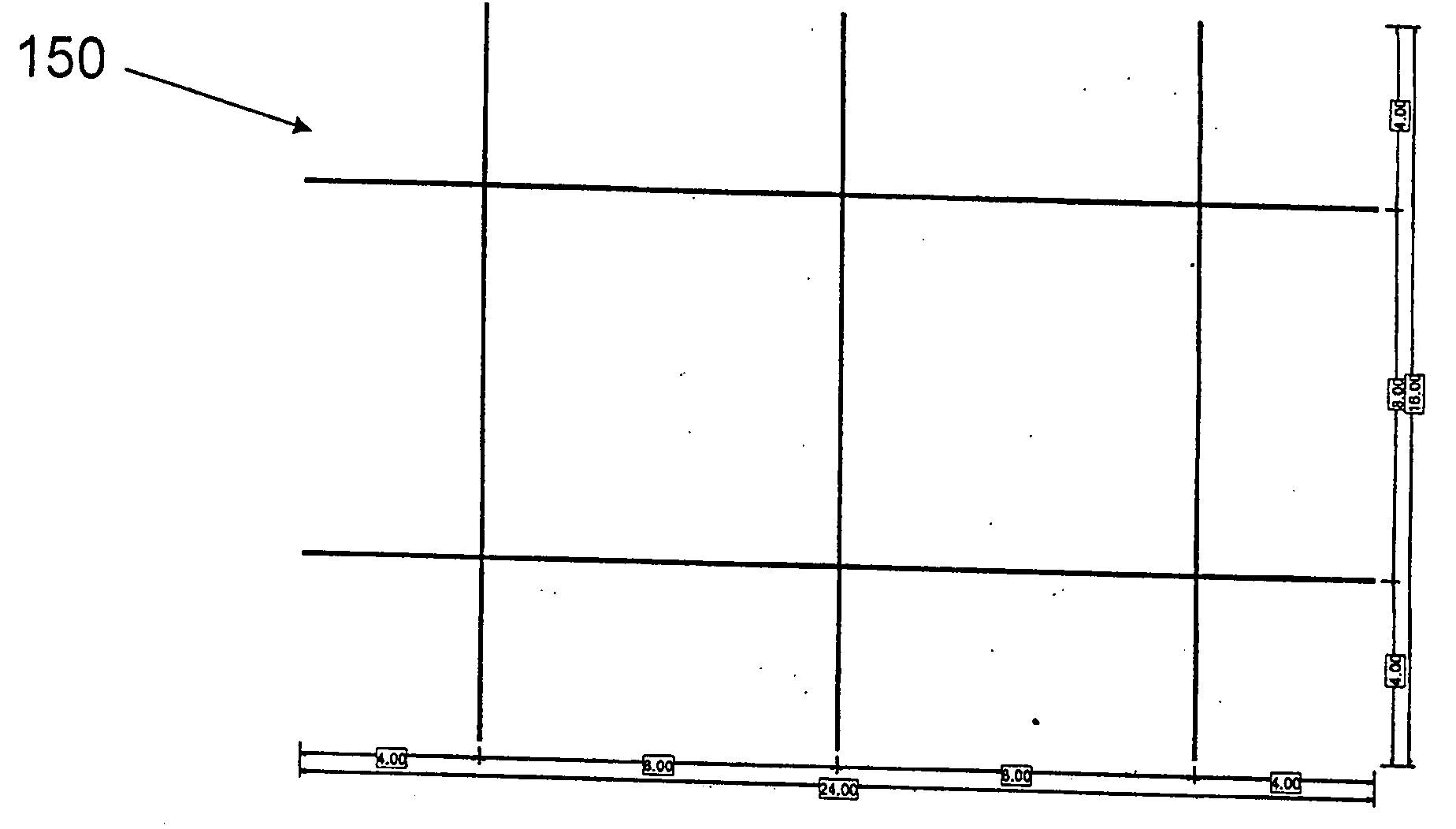

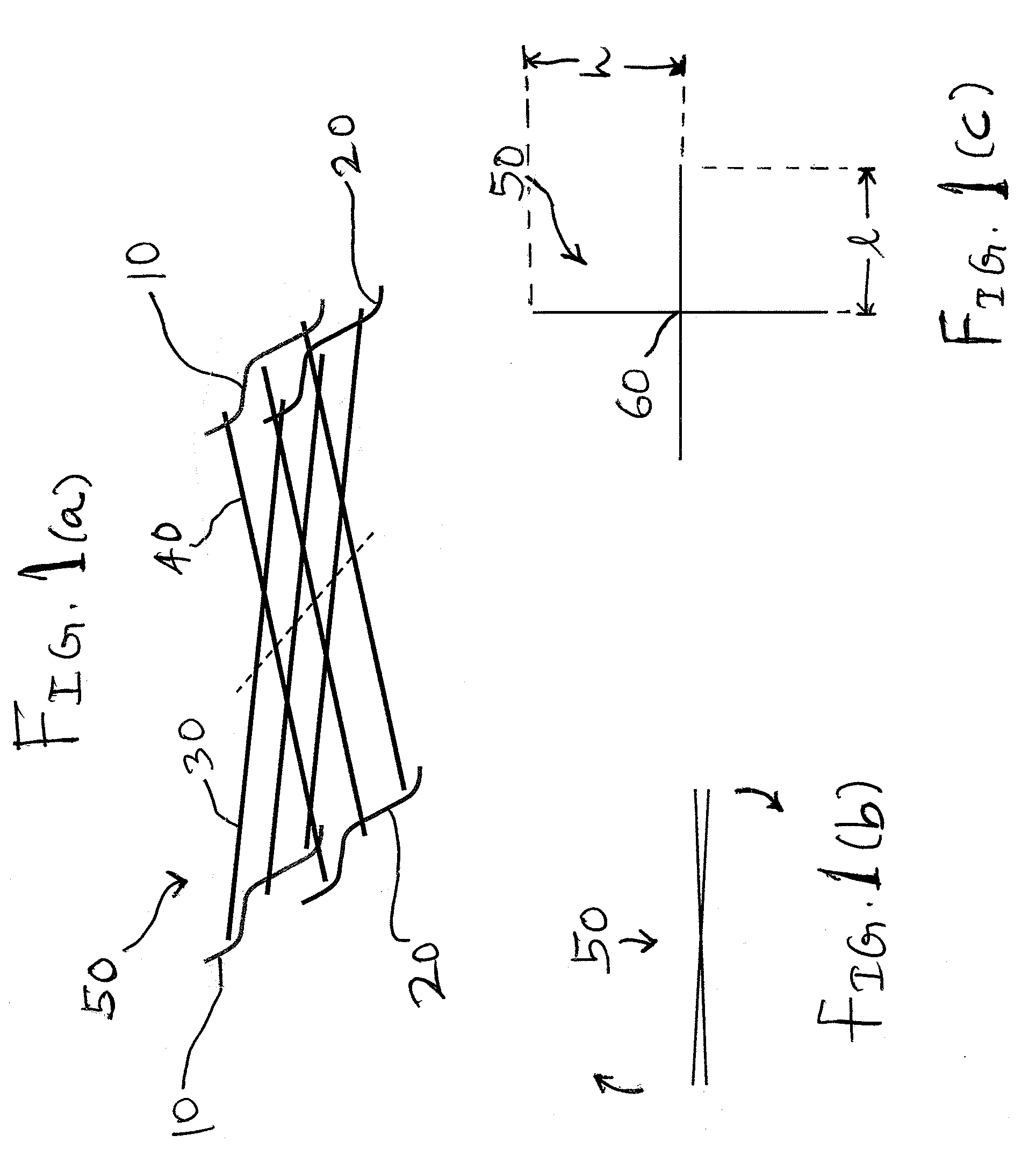

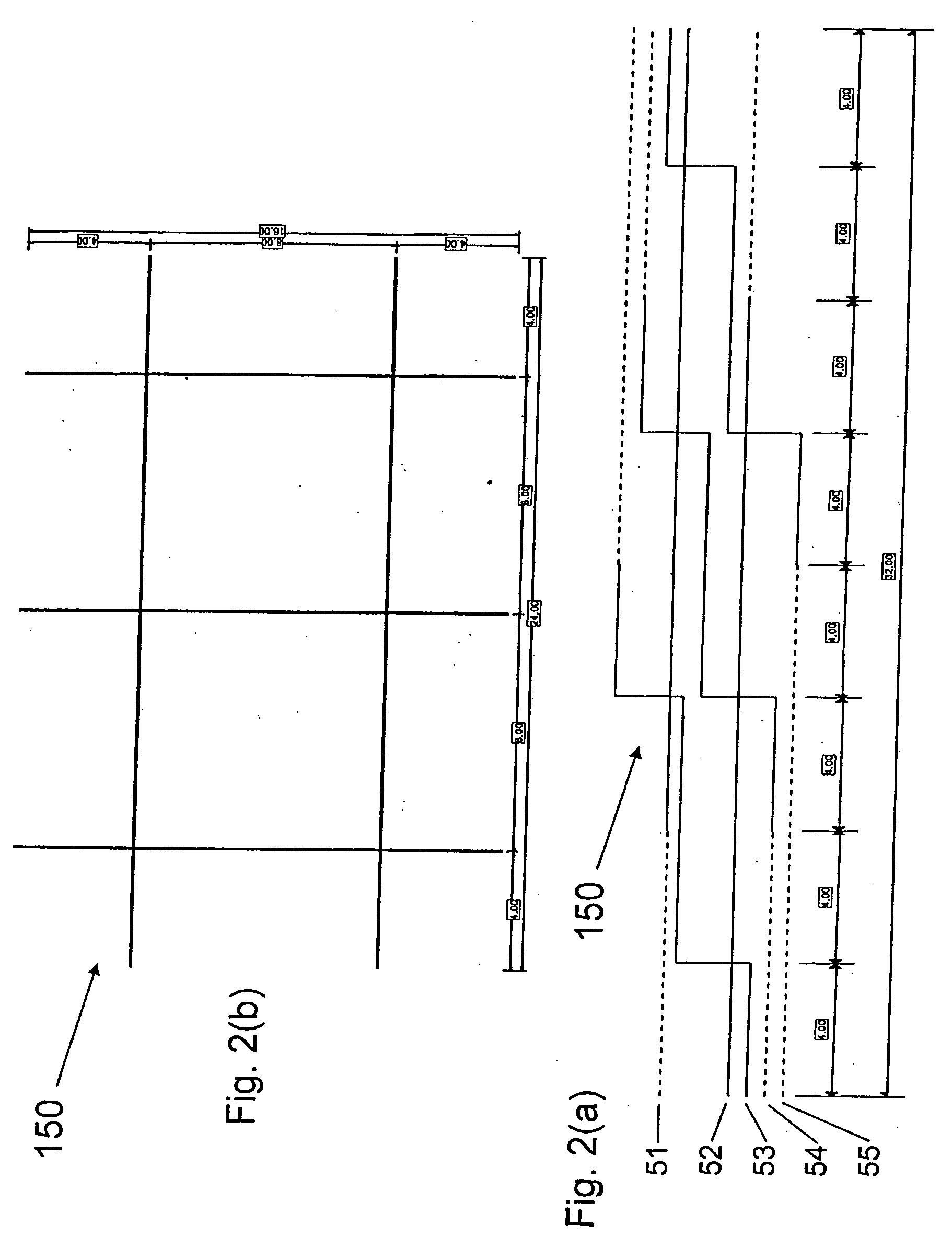

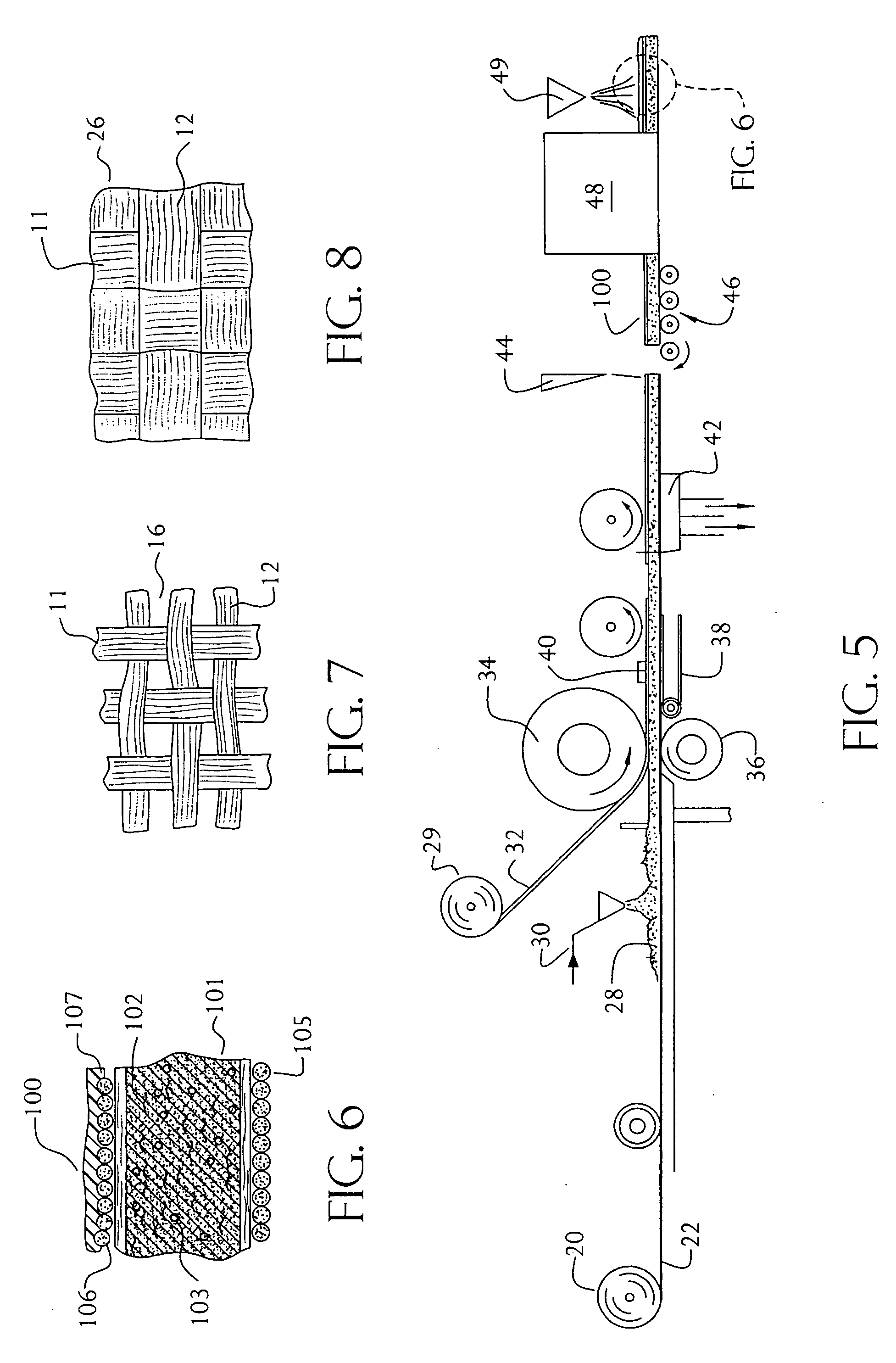

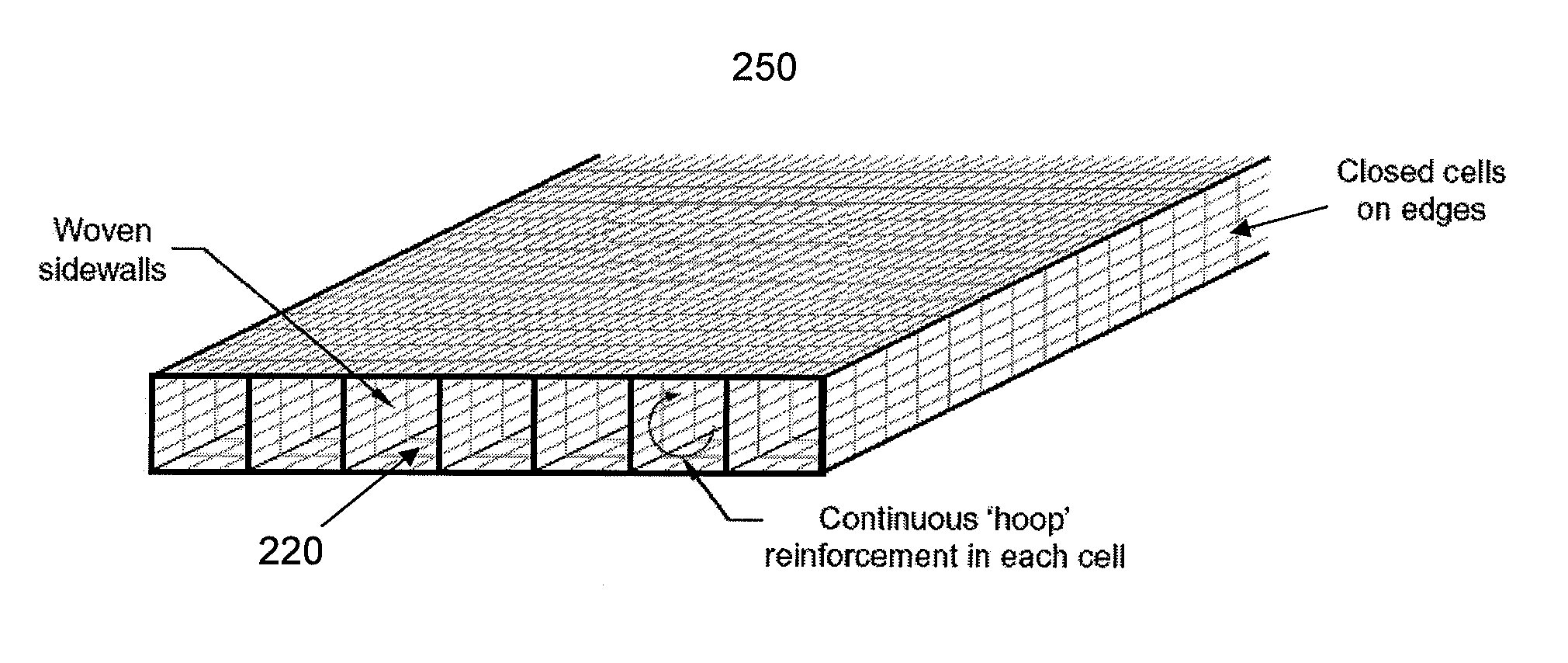

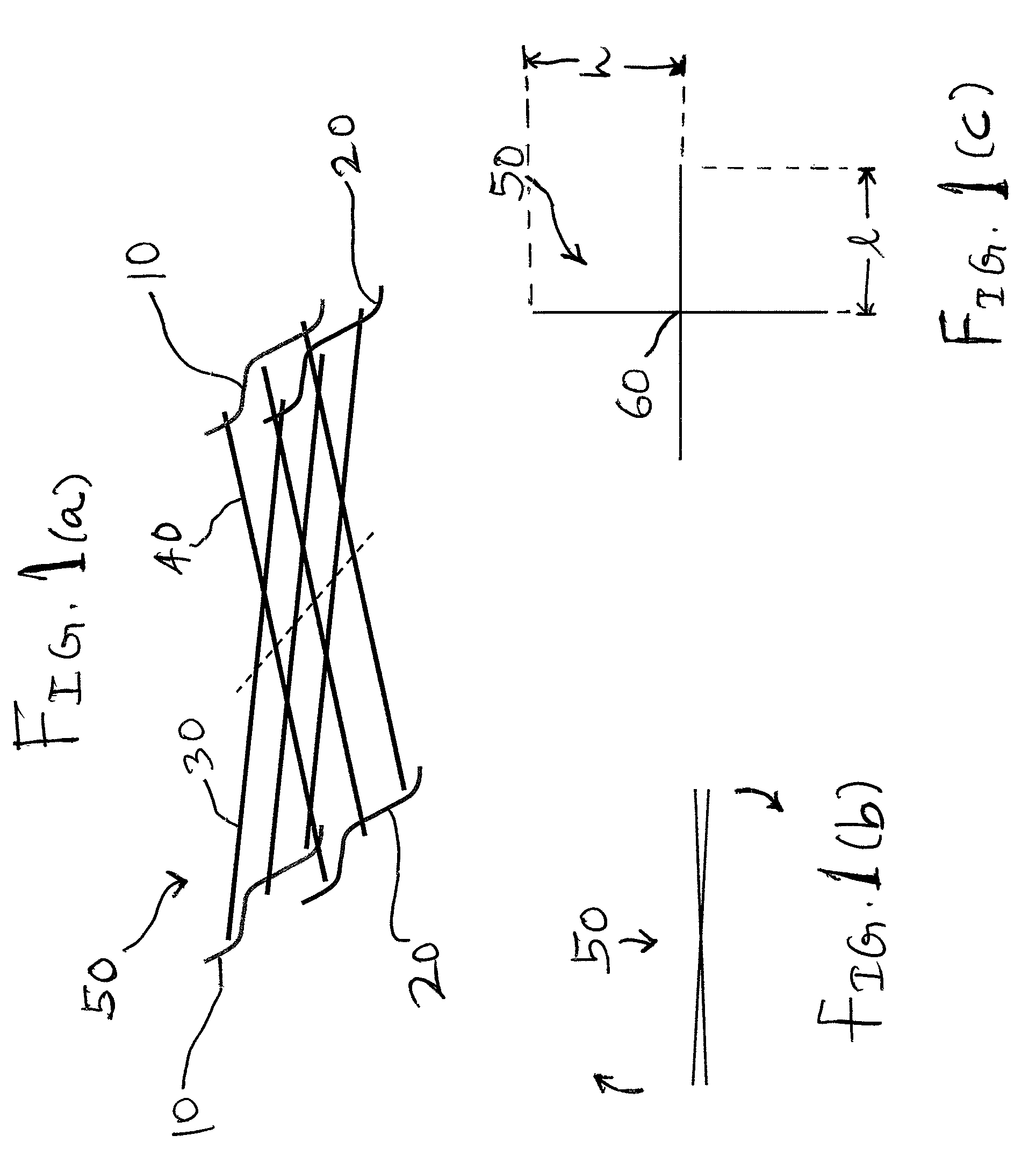

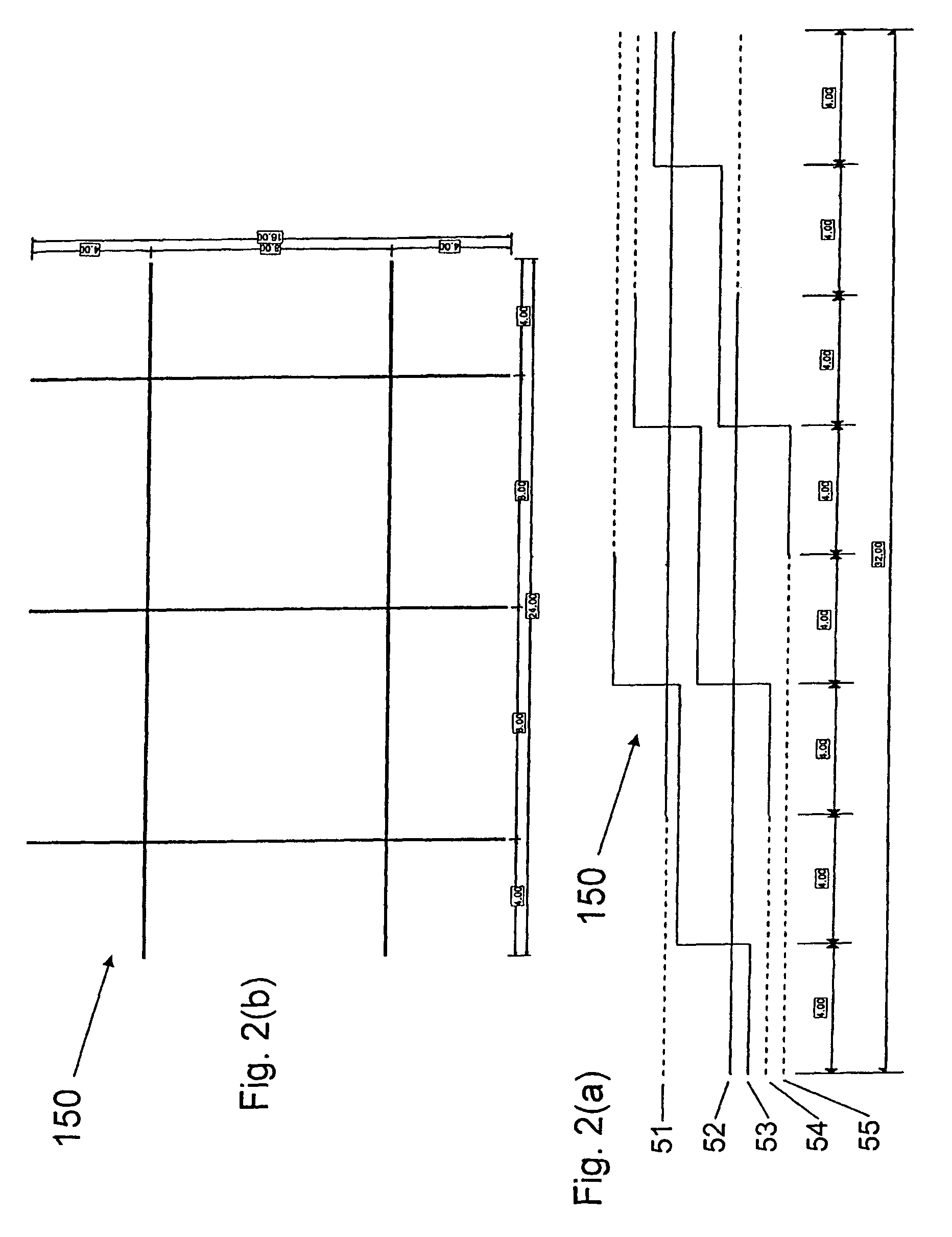

Method for Weaving Closed Structures with Intersecting Walls

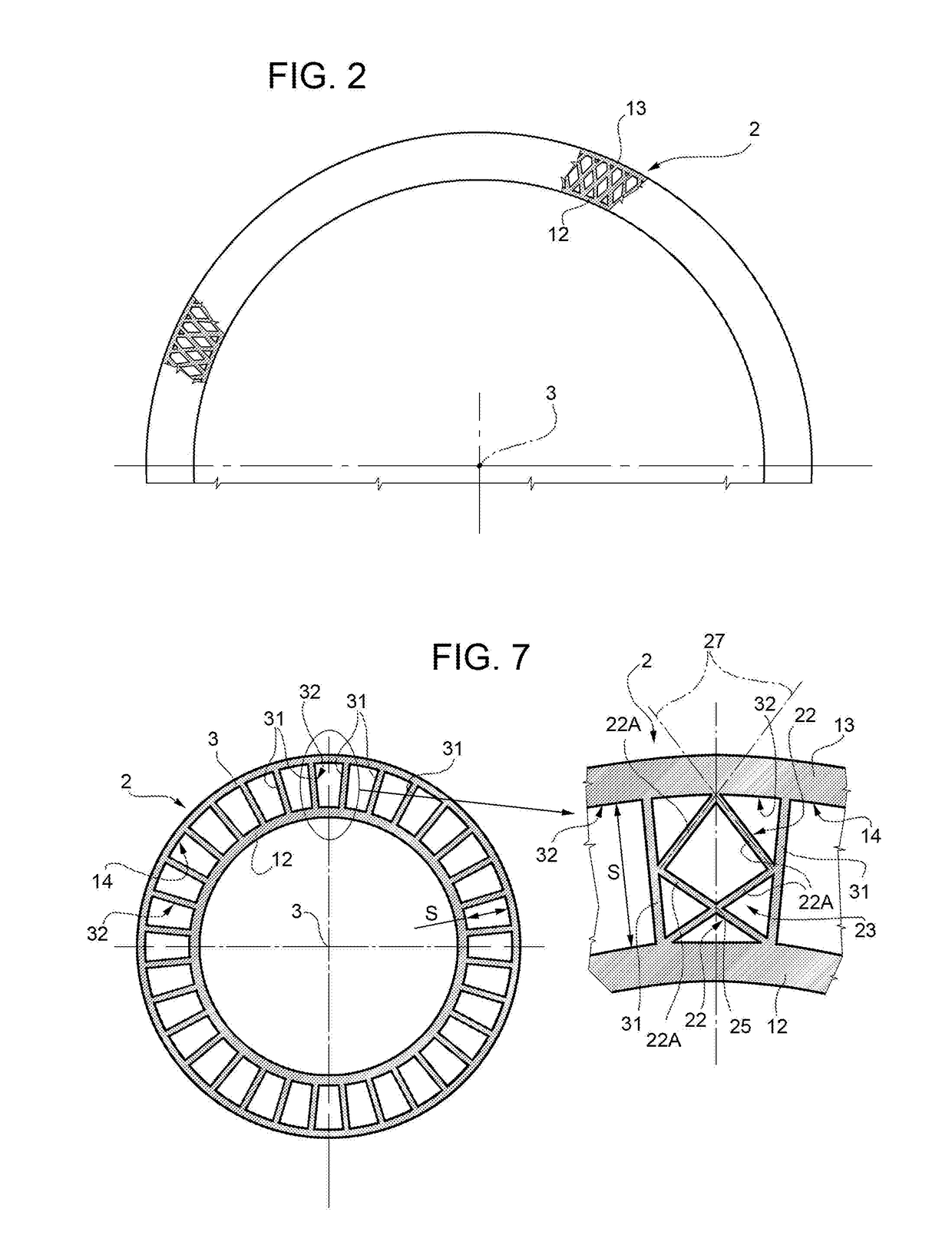

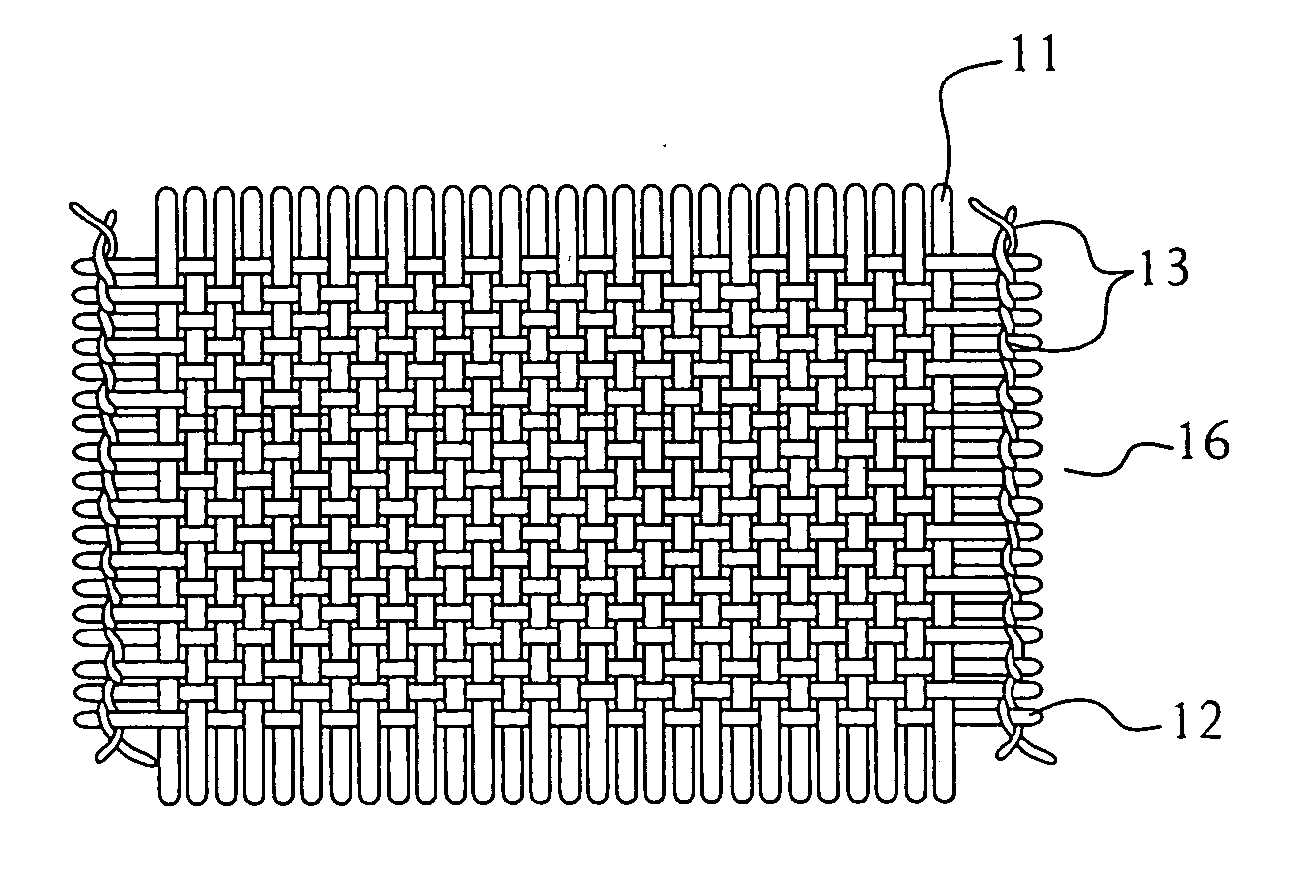

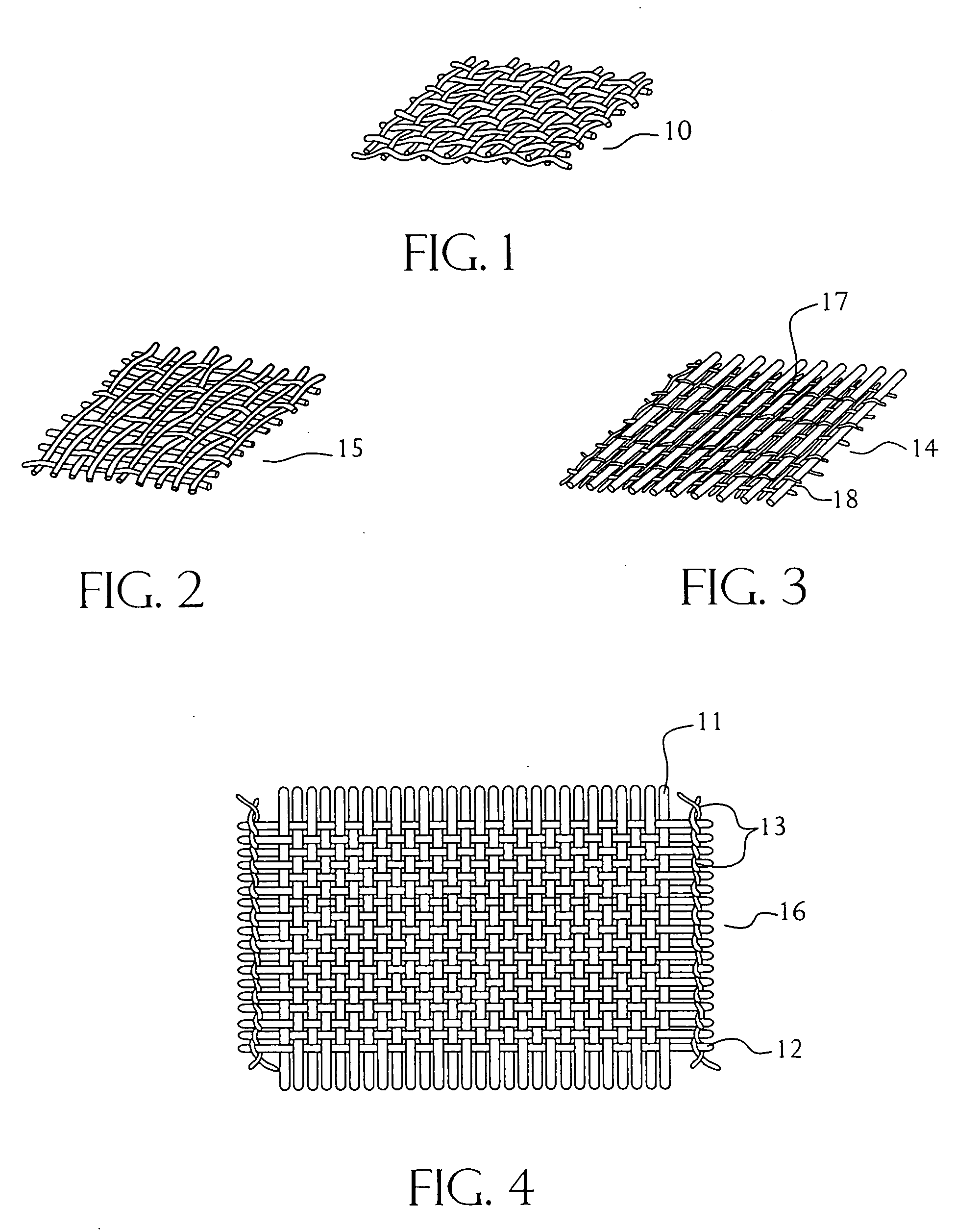

ActiveUS20090149100A1Shorten manufacturing timeLow costSmallware loomsOrnamental textile articlesShell moldingTransfer molding

The present invention generally relates to a woven preform for reinforced composite materials and a method of making thereof. Specifically, the present invention is a method of machine weaving fiber preforms for polymer matrix composites that consist of closed perimeters with multiple intersecting members in their interiors. More specifically, the invention is a woven preform and a method of forming thereof with closed cells at the outer edges with continuous hoop reinforcement in each cell of the preform. The woven preform is woven flat in both the warp and weft directions, and then unfolded to achieve the final shape of the structure, and can be processed into composite structural components using known methods such as resin transfer molding or chemical vapor infiltration. Thus, complicated shapes of all sizes can be woven on a conventional loom using the instant method.

Owner:ALBANY ENGINEERED COMPOSITES

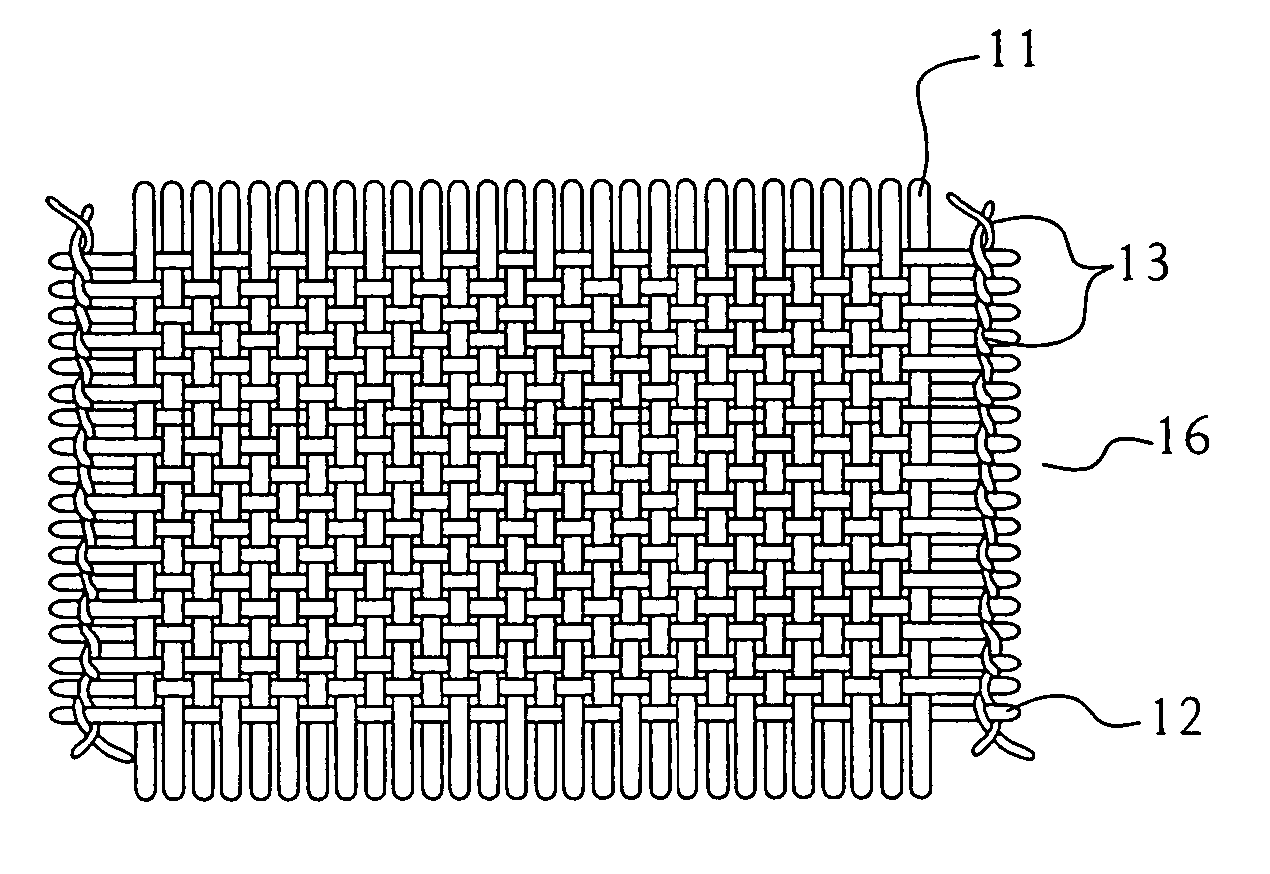

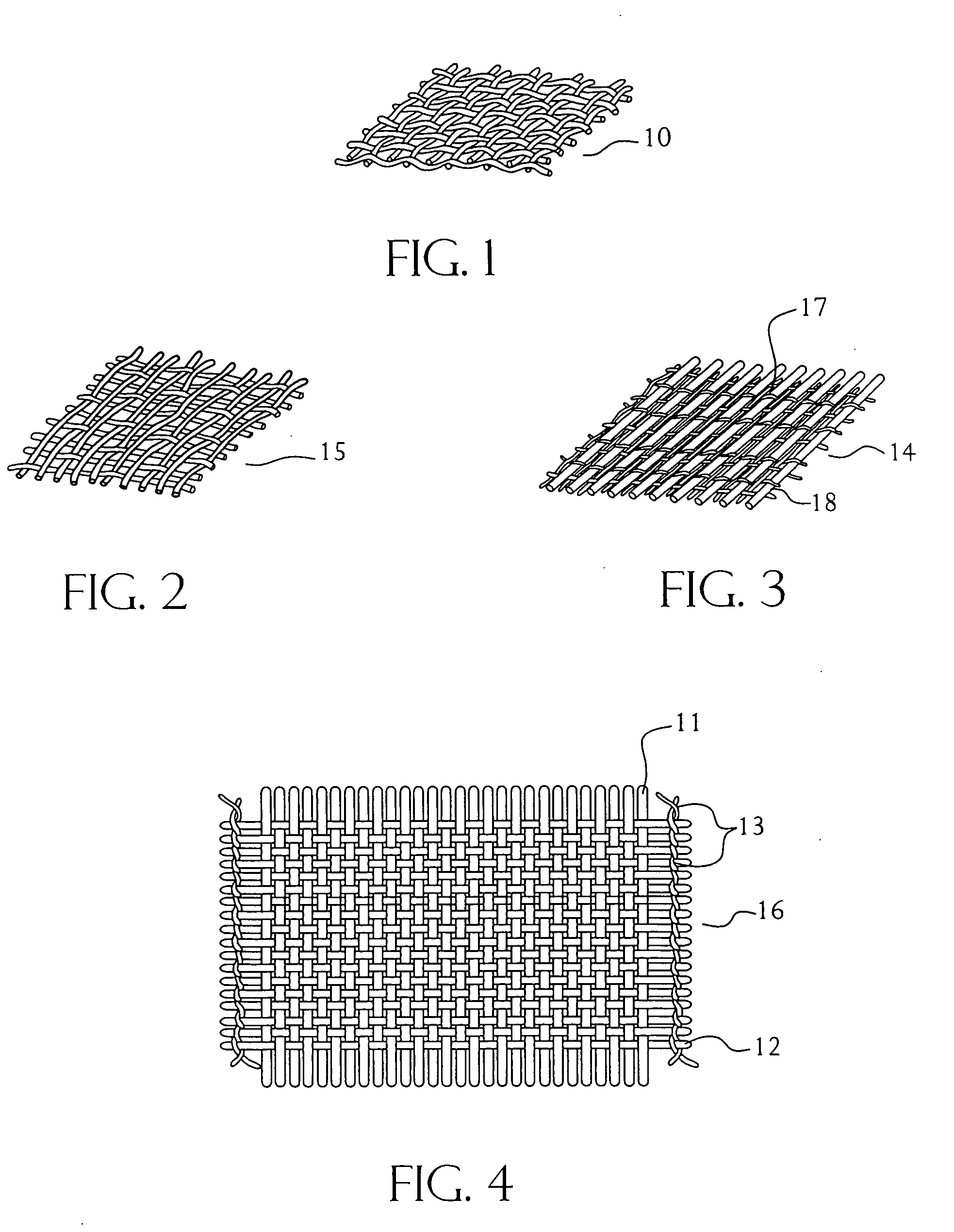

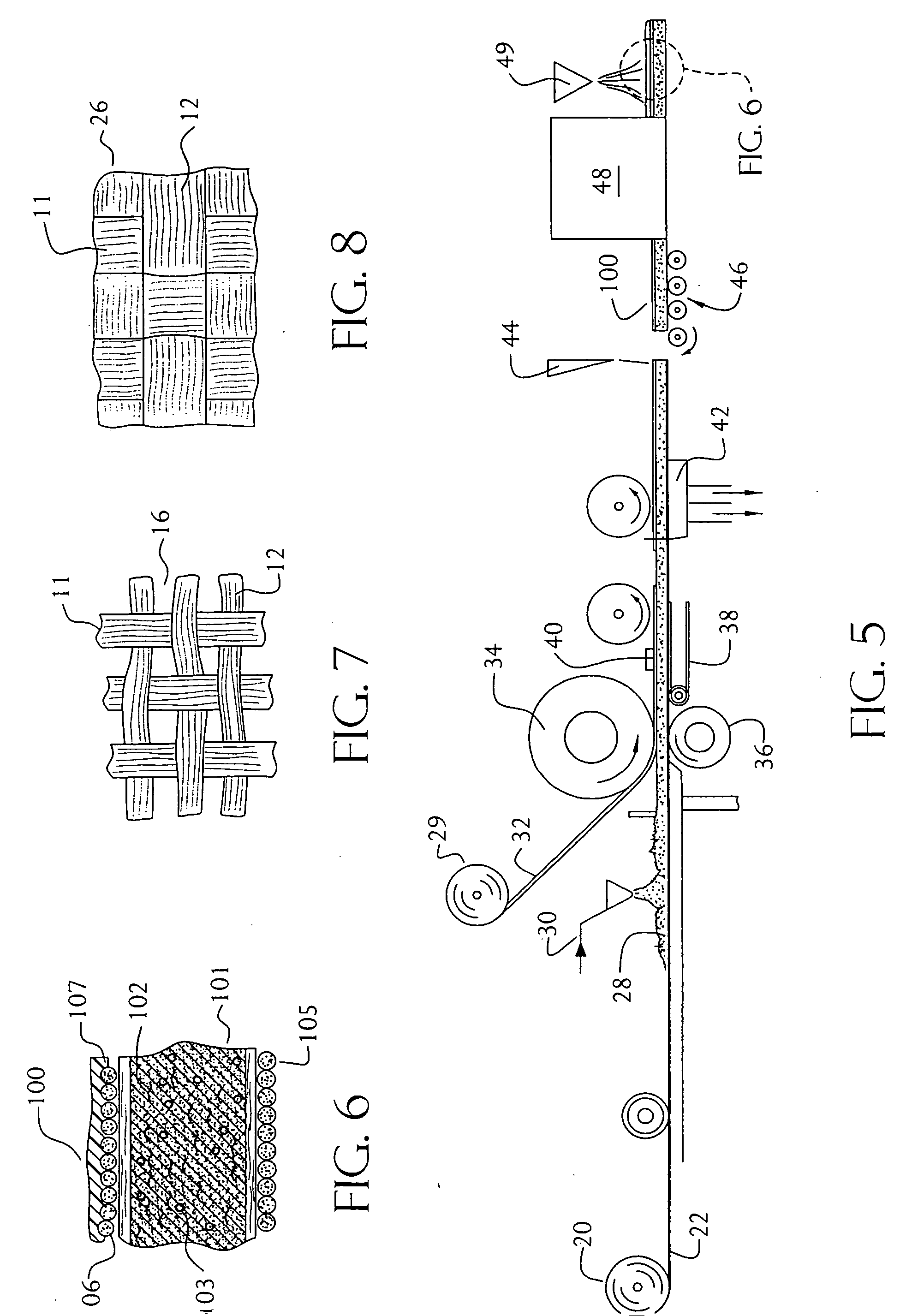

Facing material with controlled porosity for construction boards

InactiveUS20060065342A1Prevent penetrationHigh strengthConstruction materialSynthetic resin layered productsPorosityWater vapor

This invention provides facing materials for cementitious boards such as those including Portland cement or gypsum cores. The preferred facing material includes, in a first embodiment, a facing layer having an areal weight of about 300 grams / M2, and an air permeability rating of no greater than about 300 CFM / ft2 (FG 436-910 test method). The facing layer reduces the penetration of a slurry of cementitious material during the manufacture of a cementitious board, while permitting the water vapor from the slurry to pass therethrough. The facing materials of this invention can be designed to substantially eliminate the fouling of rolls used in continuous processing of such boards without the use, or with greatly reduced use, of costly viscosity control agents in the slurry. In addition, further embodiments of this invention can include binders, coatings or saturants which are designed to decrease pore size, increase or decrease the contact angle of liquids, or promote greater adhesion to cementitious cores, greater adhesion to other layers in the facing material, or greater adhesion or affinity to various types of adhesive compositions used to join cementitious boards to insulation and exterior finishing systems (EIS or EIFS).

Owner:SAINT GOBAIN ADFORS CANADA LTD

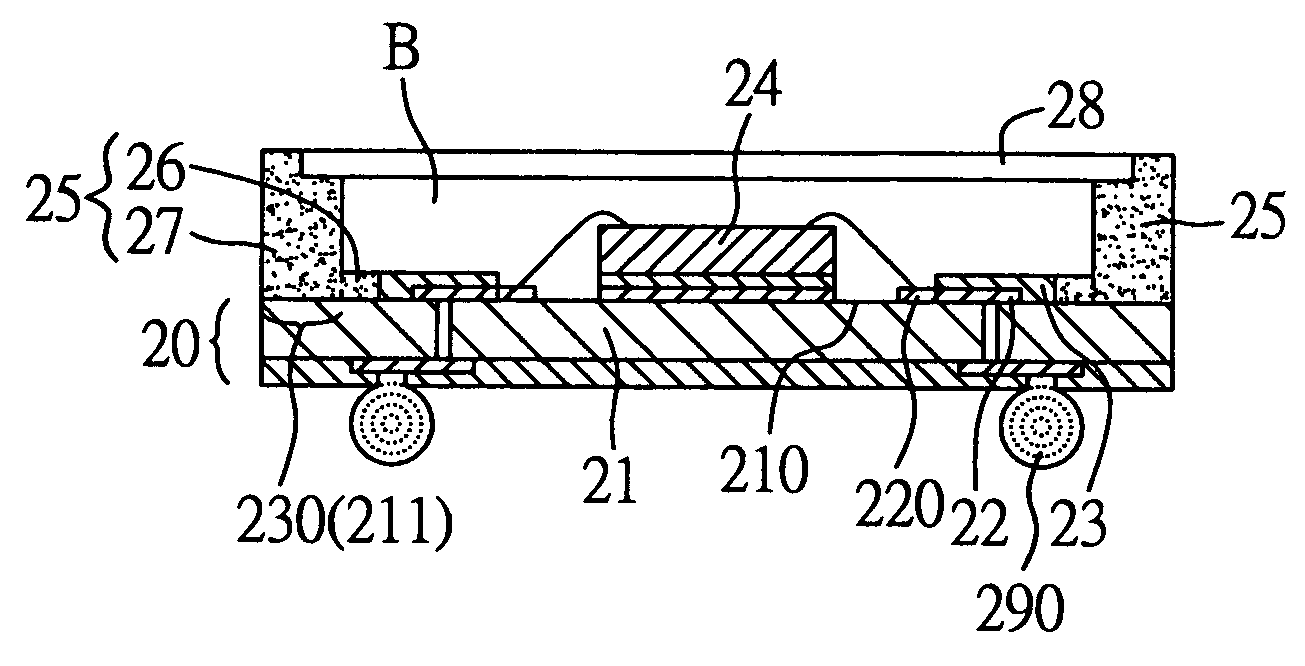

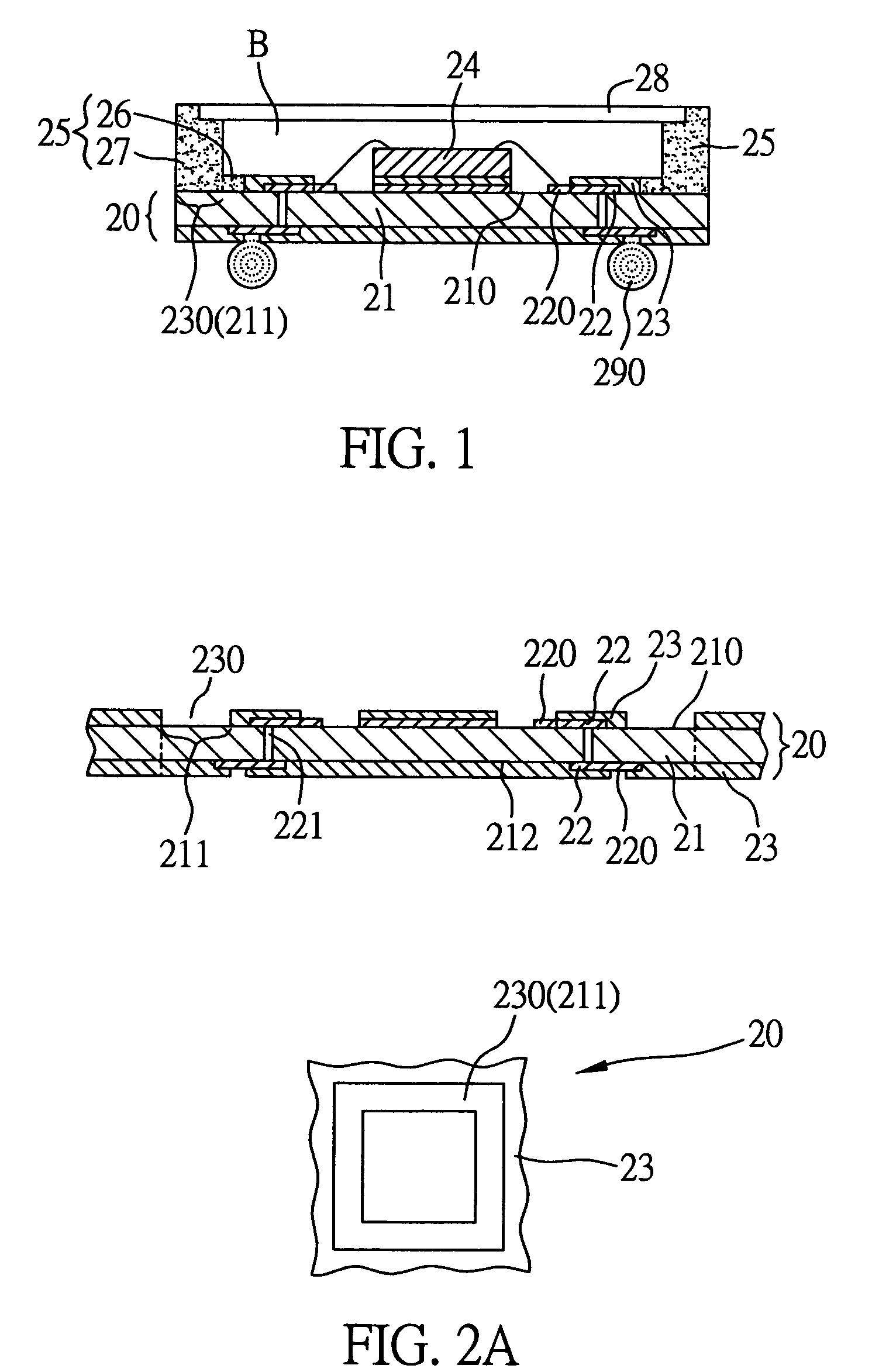

Semiconductor package with photosensitive chip and fabrication method thereof

InactiveUS7005720B2Improve adhesionAvoid layeringSemiconductor/solid-state device detailsSolid-state devicesSolder maskSemiconductor package

A semiconductor package with a photosensitive chip and a fabrication method thereof are provided. A substrate having a core is prepared. A solder mask layer is applied over a surface of the core and formed with an opening to expose a continuous peripheral portion on the surface of the core. At least one photosensitive chip is mounted on and electrically connected to the substrate. An encapsulation dam is formed on the continuous peripheral portion of the core and surrounds the chip. The dam includes a shoulder portion adjacent to and flush with the solder mask layer, and a protruded support portion surrounding the shoulder portion. A lid is attached to the support portion of the dam for sealing the dam such that the chip is received in a space defined by the substrate, the dam and the lid.

Owner:SILICONWARE PRECISION IND CO LTD

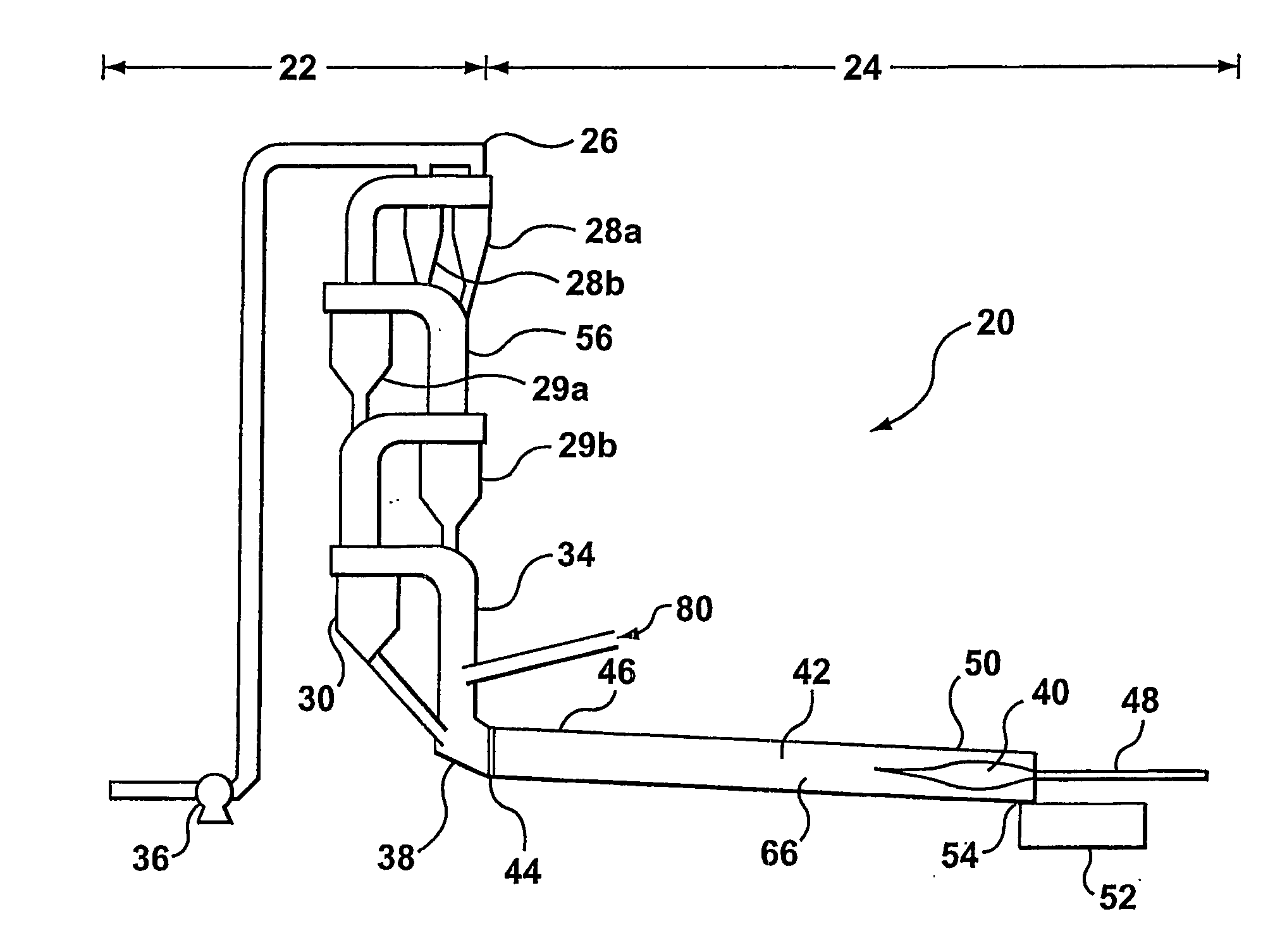

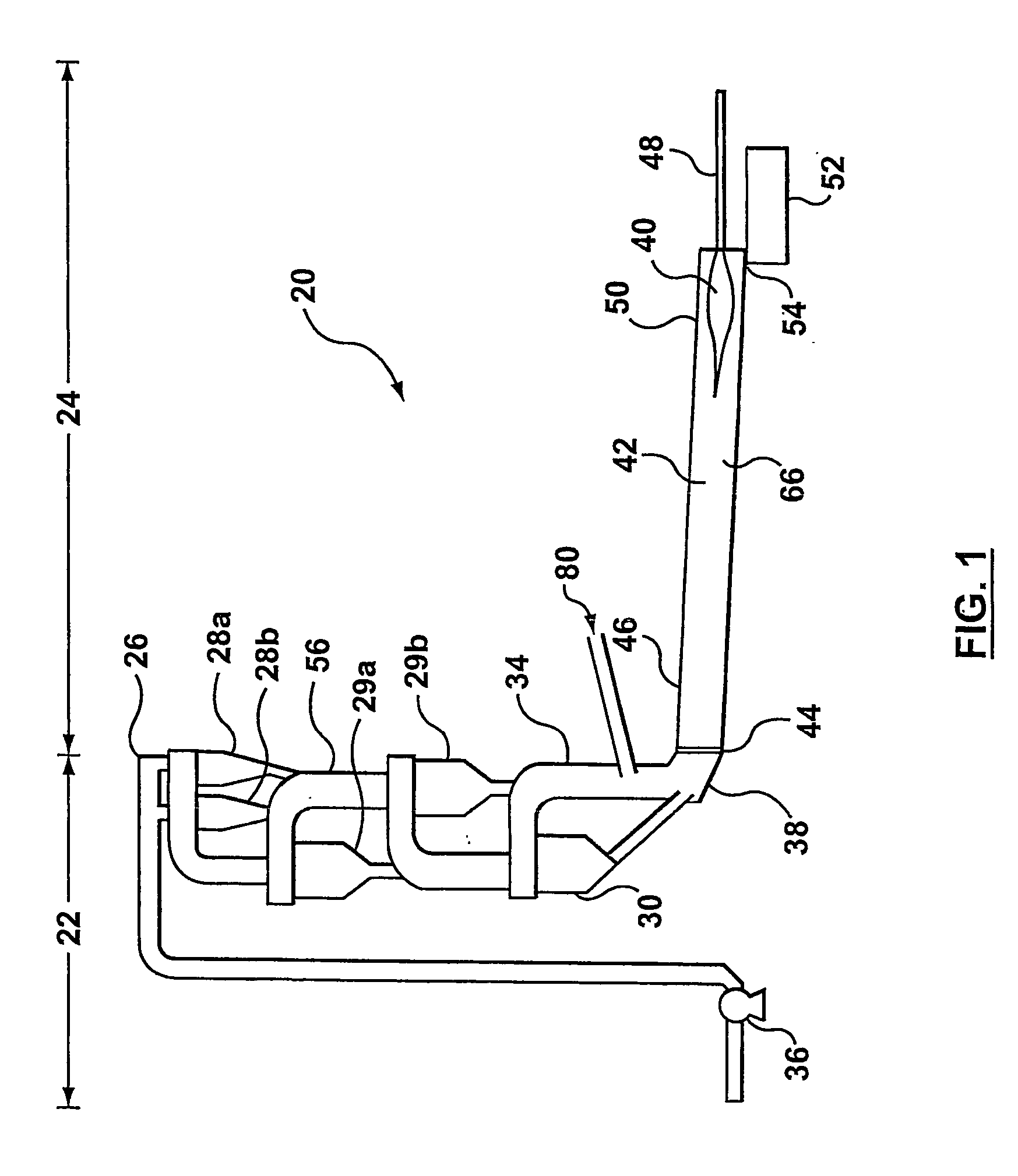

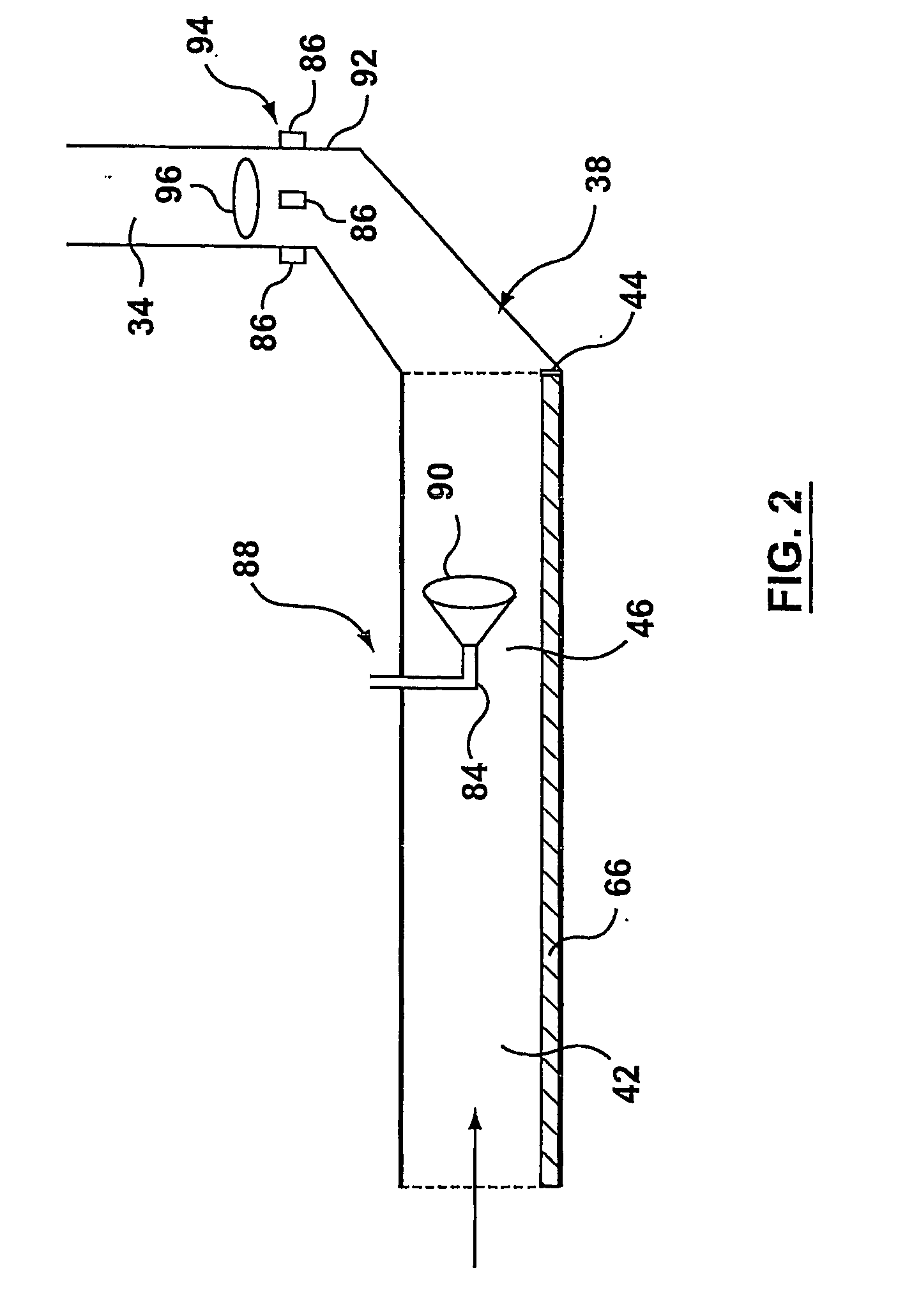

Method and system for process gas entrainment and mixing in a kiln system

InactiveUS20070184396A1Eliminate stratificationImprove mixingRotary drum furnacesMaintainance of heating chambersProcess engineeringHigh momentum

A method and system for mixing process gas flow by adding or injecting suitably-directed high momentum turbulent gas into dust-laden stratified process gas flow at approximately 850 to 1400° C. to entrain the process gas flow such that stratification is reduced and mixing of both gases and suspended solids is improved. The jet entrainment of the process gas flow by appropriate injection of gas serves to enhance the contact of reacting materials, such as residual fuel and available oxygen, and further serves to improve the completion of reactions, such as combustion of the fuel and the transfer of heat to the raw material / kiln feed.

Owner:HOLCIM

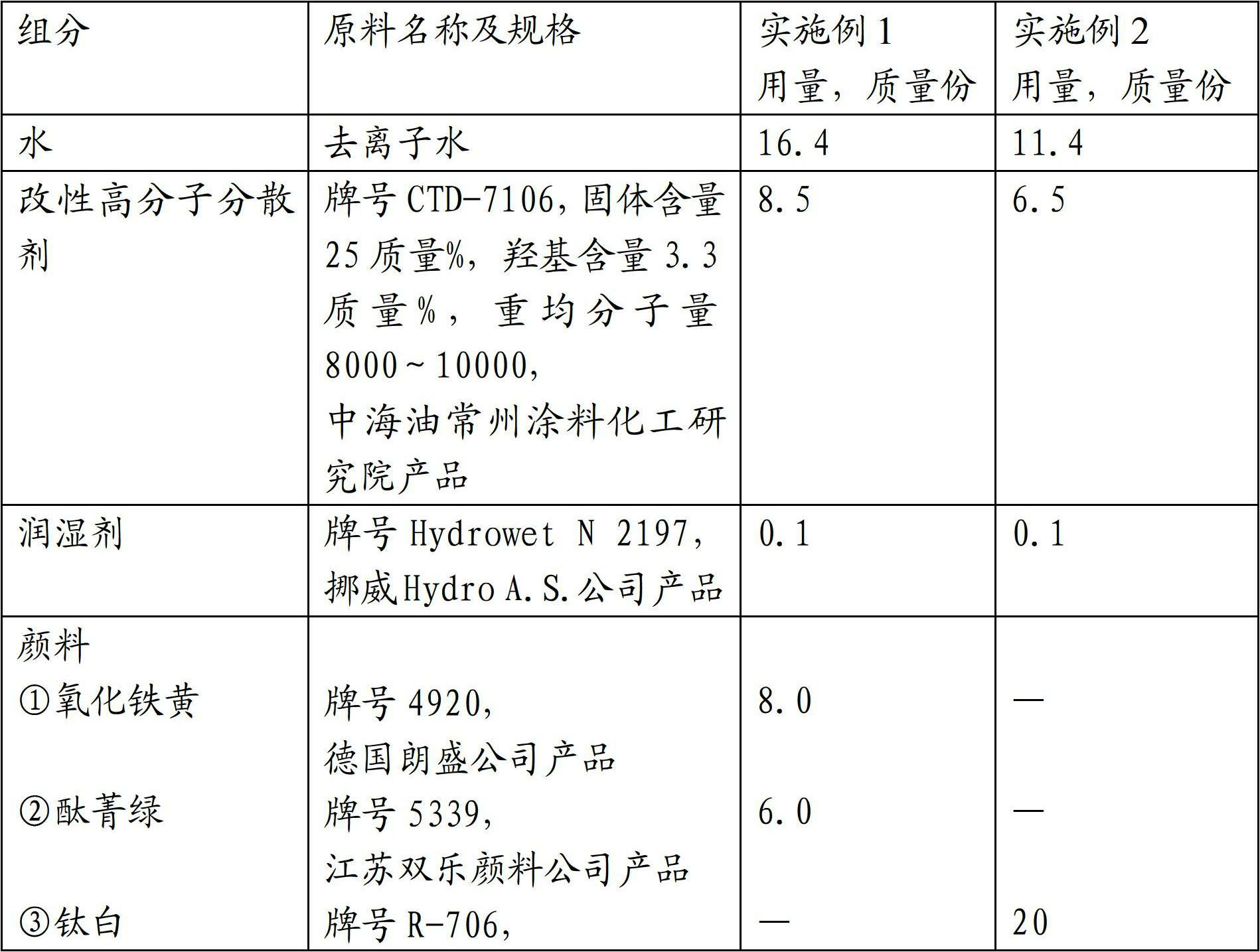

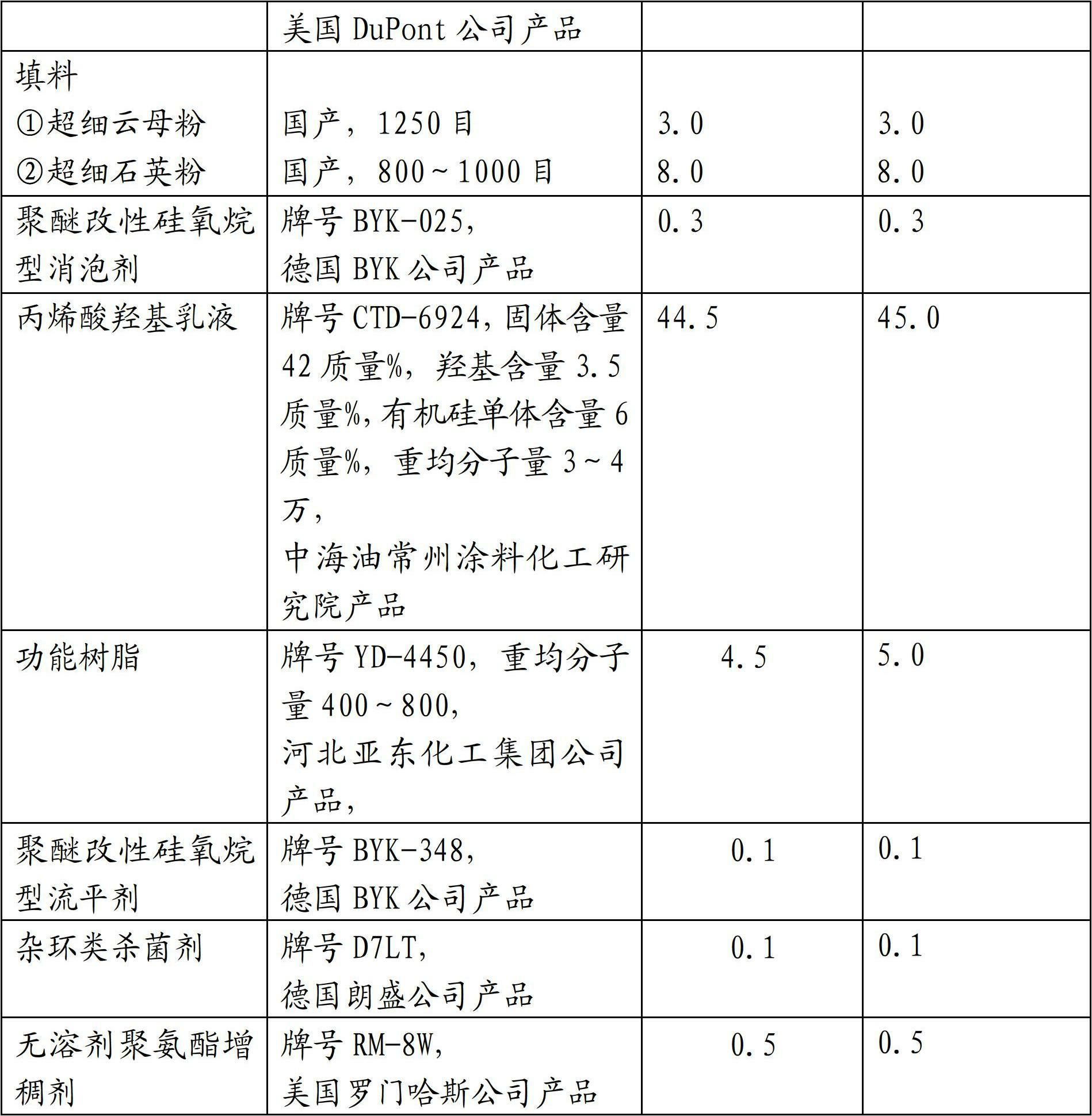

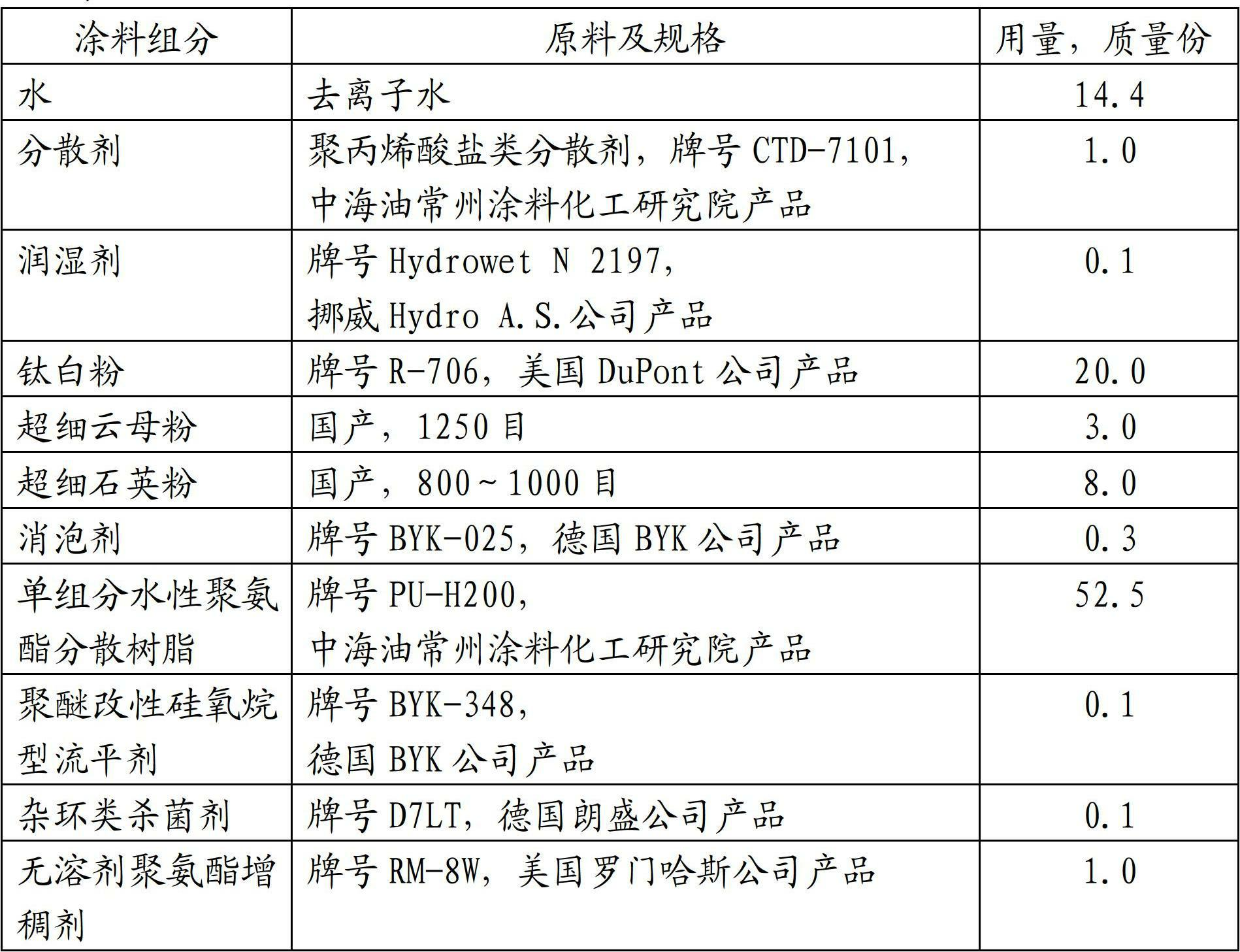

Environment-friendly water-based double-component polyurethane floor coating

ActiveCN102634273AImprove performanceImprove adhesionPolyurea/polyurethane coatingsWater basedMass ratio

The invention relates to an environment-friendly water-based double-component polyurethane floor coating. A component I is water-based aliphatic isocyanate containing 100% by mass of solid content, a component II comprises the following components by weight parts: 10-18 parts of water, 4-10 parts of modified polymeric dispersant, 0.1-0.3 parts of non-ionic and / or anionic wetting agent, 2-20 parts of pigment, 3-15 parts of filler, 40-70 parts of acrylic hydroxyl emulsion, 3-6 parts of functional resin, 0.1-0.5 parts of polyether modified siloxane defoamer, 0.1-0.3 parts of polyether modified siloxane flatting agent, 0.1-0.3 parts of heterocyclic fungicide and 0.2-1.0 part of solvent-free polyurethane thickening agent. When the floor coating is used, the component I and the component II are mixed according to the mass ratio of the component I to the component II being 1:(5-6). According to the coating, all the performances of the coating completely meet the requirements of solvent-based floor coating, the artificial aging resistance is excellent, and the volatile organic compound content in the water-based double-component polyurethane floor coating is obviously lower than that of single-component water-based polyurethane floor coating, and the environmental requirement is met.

Owner:CHINA NAT OFFSHORE OIL CORP +3

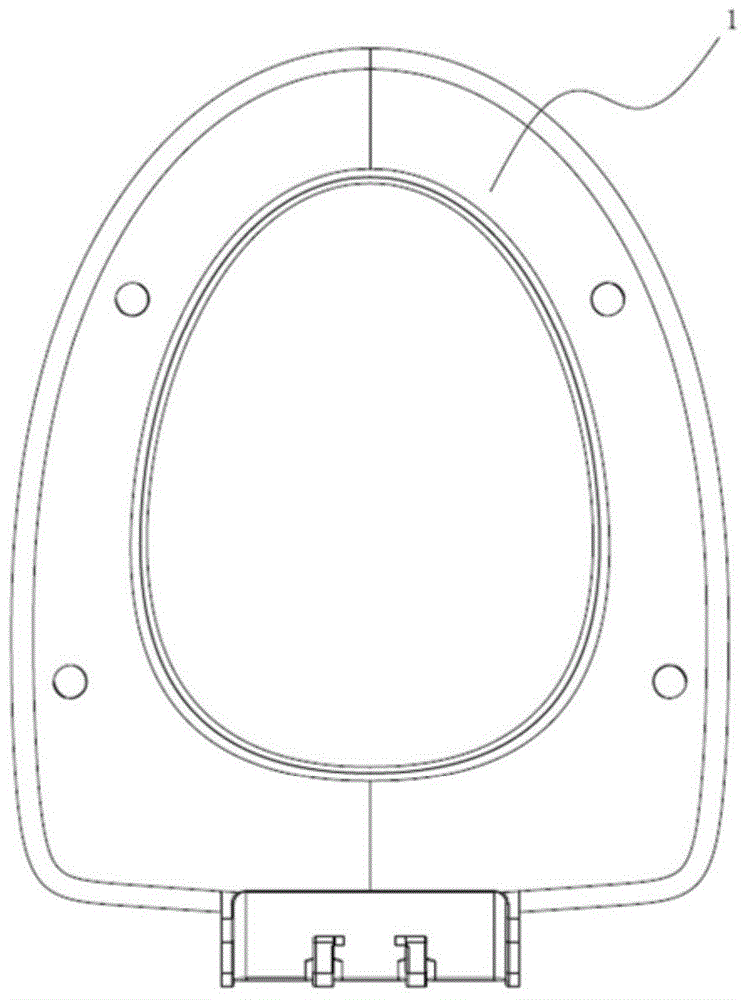

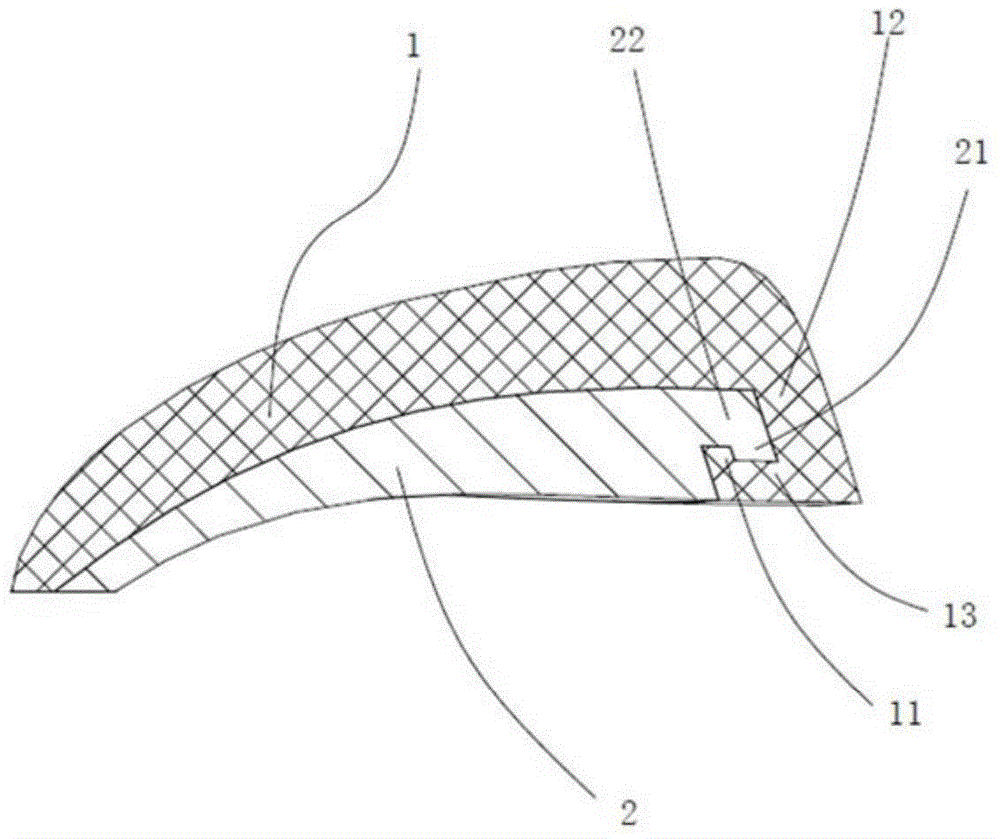

Compound type polyurethane toilet seat and preparation technology thereof

ActiveCN104545656AReduce usage costsReduce processing costsBathroom coversDomestic articlesAbrasive blastingEngineering

The invention discloses a compound type polyurethane toilet seat, including a surface coating layer, a positioning structure and a seat cushion support, wherein the surface coating layer of made of polyurethane and seamlessly wraps the outer surface of the seat cushion support by the positioning structure. The preparation technology includes the steps of: 1, spraying mold release agents and intramode paint in a mold cavity; 2, cleaning the surface of the seat cushion support; 3, polishing or abrasive blasting; 4, thermally processing seat cushion support; 5, spraying the mold release agent in the mold cavity, and installing the seat cushion support in the mold cavity; 6, injecting polyurethane material into the mold cavity, and shaking the mold; 7, foaming the polyurethane material; 8, after the polyurethane is cured in the mold, opening the mold to take out the product, and thereby completing the whole preparation technology of the product. The compound type polyurethane toilet seat achieves the one-time composite molding of the polyurethane toilet seat, optimizes the processing technology, saving the use cost, increases the bonding intensity of the product, and improves the use quality of the product.

Owner:FINEHOPE POLYUREHTHANE PROD

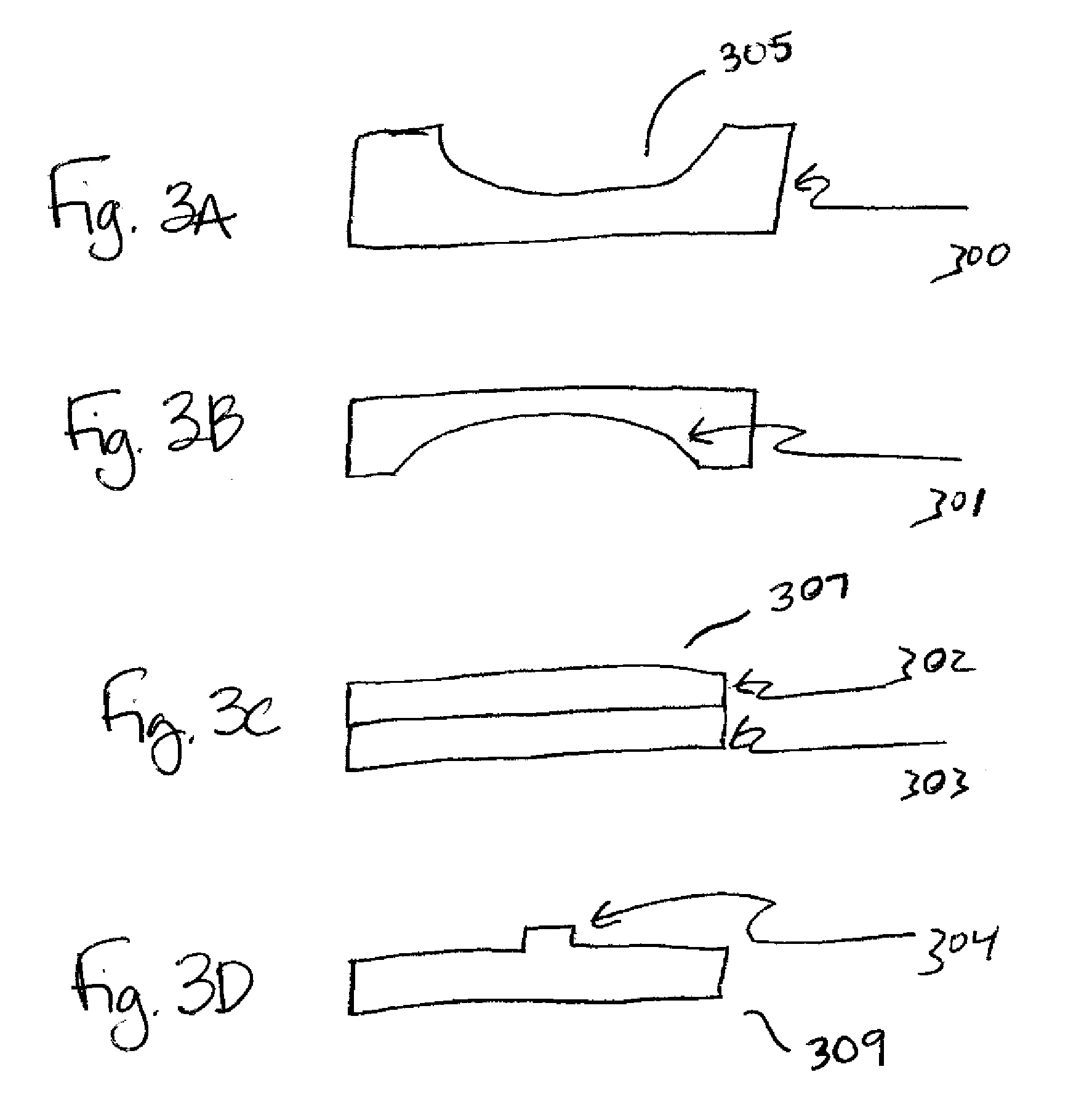

Specially shaped wood fiber molded product enclosed forming method

InactiveCN103737699AImprove thermal conductivityQuality improvementWood working apparatusDomestic articlesCompression moldingTO-18

The invention discloses a specially shaped wood fiber molded product enclosed forming method. The method sequentially includes processes of drying, blending, mat formation, pre-pressing and hot press molding. By means of the method, the moisture content of wood fibers is kept in 8% to 18%, during hot press molding, the temperature is controlled between 95 DEG C to 130 DEG C, the hot-press pressure is controlled between 30kg / cm2 to 110kg / cm2, and the hot-pressing time is controlled between 2.5 minutes to 28 minutes. According to the method, the moisture content in the wood fibers is increased so as to increase heat transfer rate in products, the time consumed by a heated object core layer which reaches curing temperature in a glue process is shortened, the producing efficiency is increased, moreover, the heating temperature is properly lowered so as to eliminate phenomena of product layering and surface bulging in the compression molding process, and qualities of wood fiber molded products are improved.

Owner:宁波新缅新材料研发有限公司

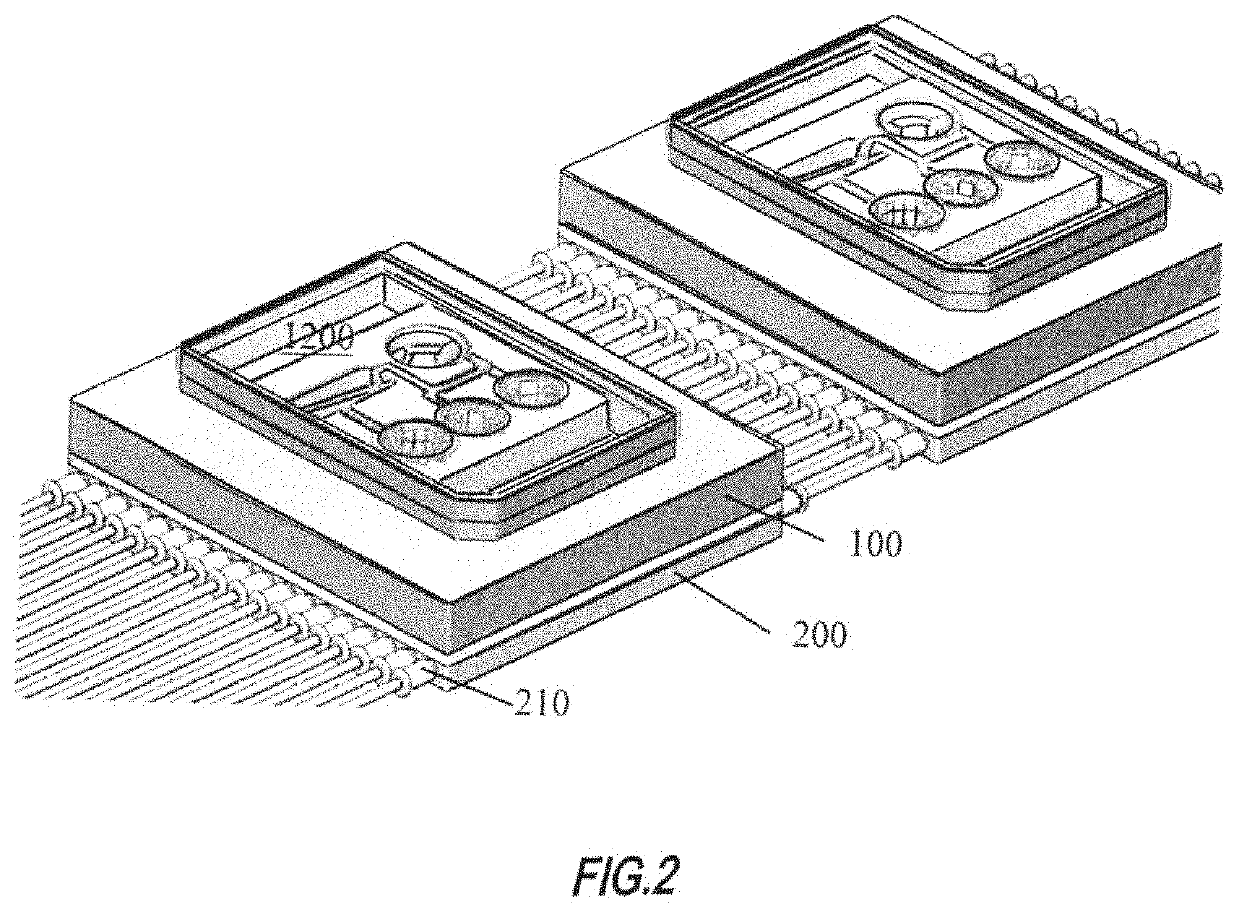

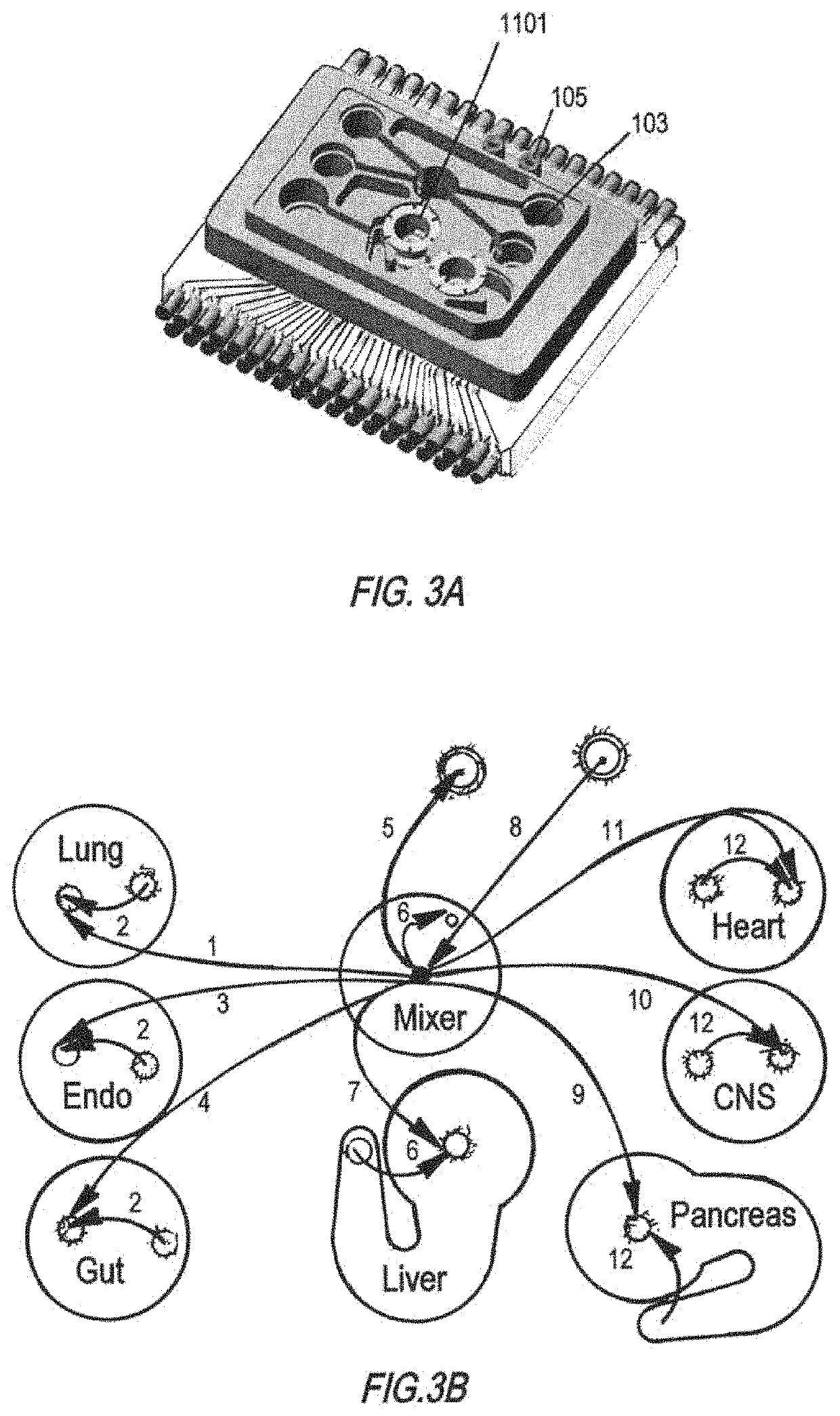

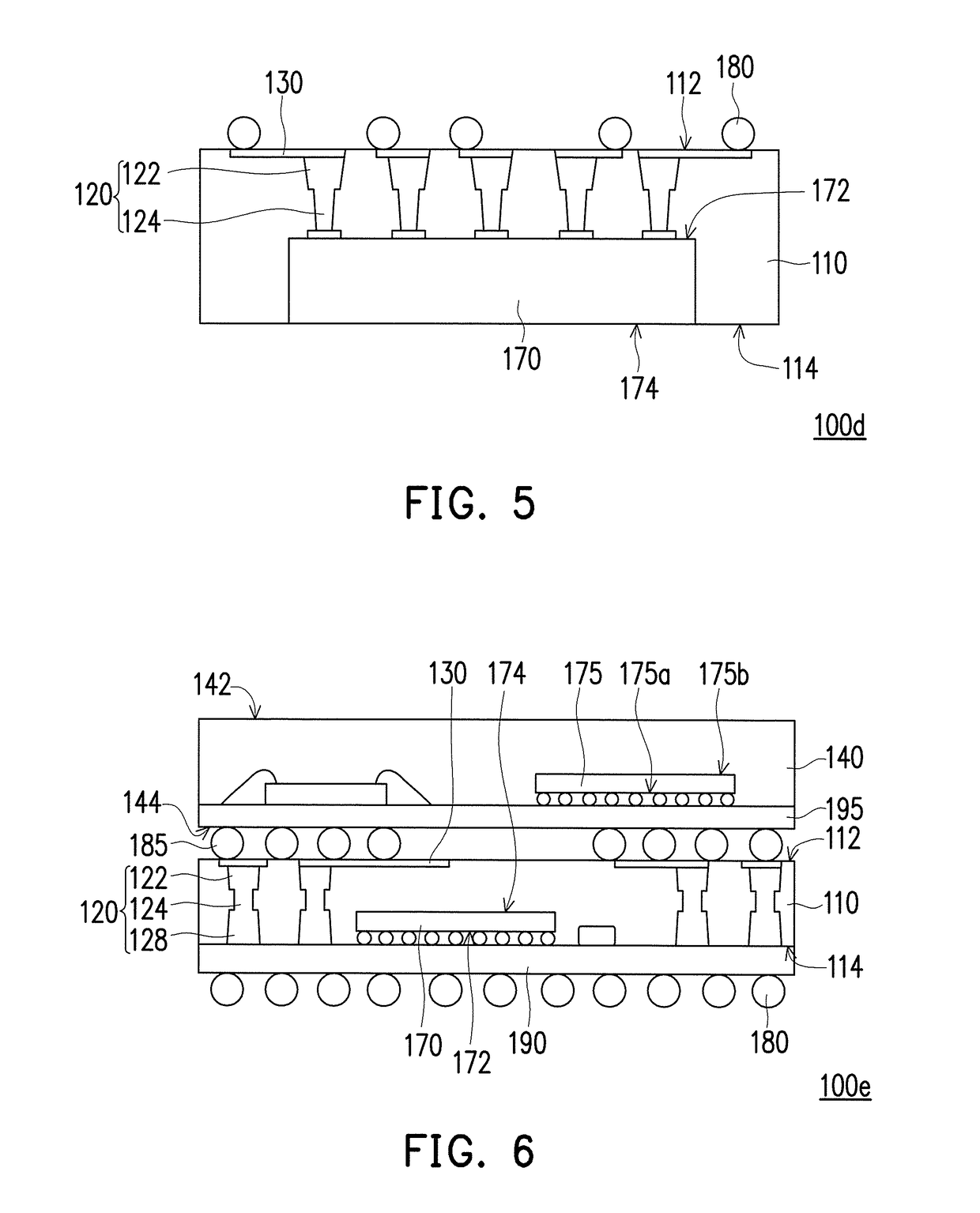

Modular organ microphysiological system with microbiome

PendingUS20180272346A1Improve reliabilityLow costFlexible member pumpsLaboratory glasswaresSource to sinkOn board

Fluidic multiwell bioreactors are provided as a microphysiological platform for in vitro investigation of multi-organ crosstalks with microbiome for an extended period of time of at least weeks and months. The platform has one or more improvements over existing bioreactors, including on-board pumping for pneumatically driven fluid flow, a redesigned spillway for self-leveling from source to sink, a non-contact built-in fluid level sensing device, precise control on fluid flow profile and partitioning, and facile reconfigurations such as daisy chaining and multilayer stacking. The platform supports the culture of multiple organs together with microbiome in a microphysiological, interacted systems, suitable for a wide range of biomedical applications including systemic toxicity studies and physiology-based pharmacokinetic and pharmacodynamic predictions. A process to fabricate the bioreactors is also provided.

Owner:MASSACHUSETTS INST OF TECH

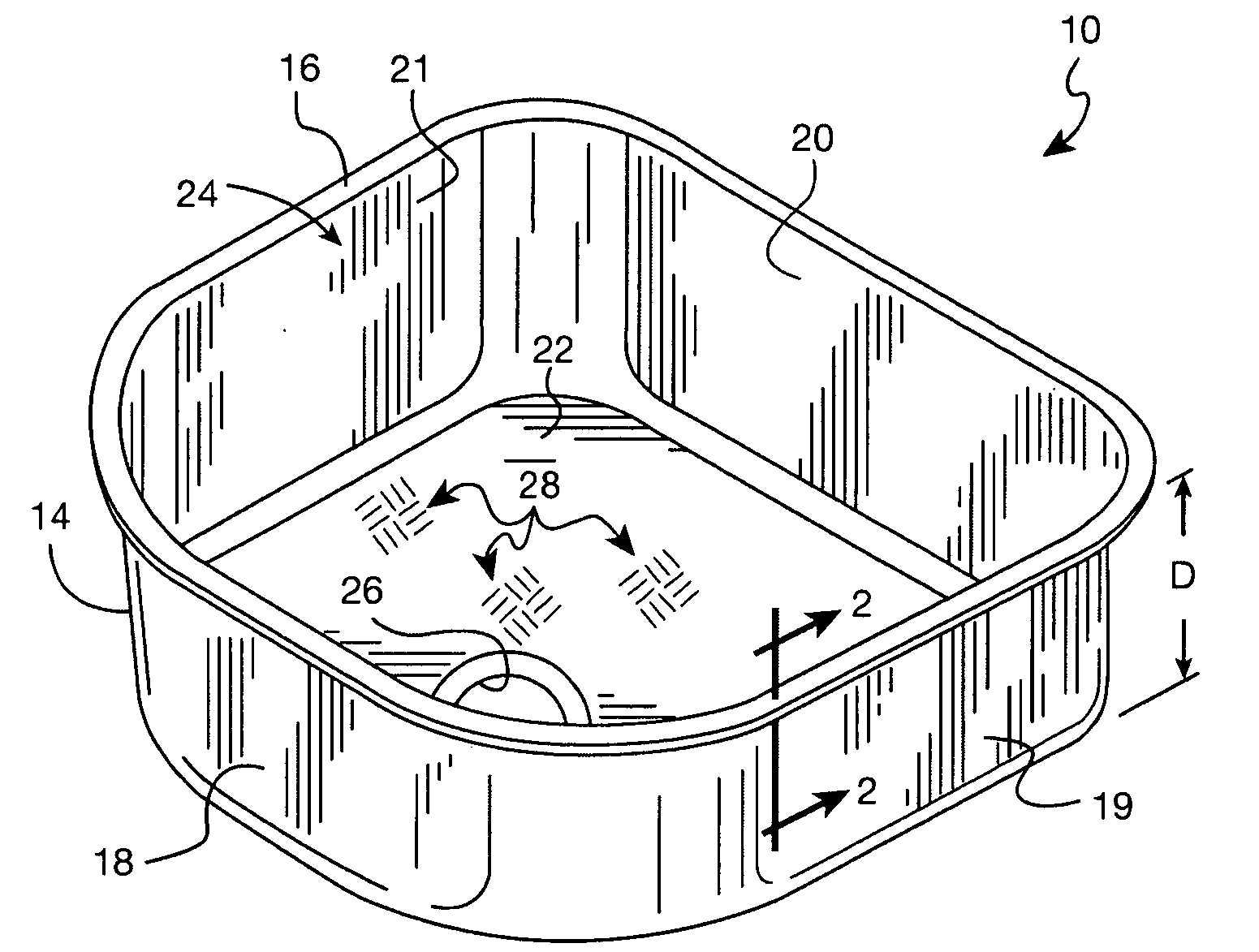

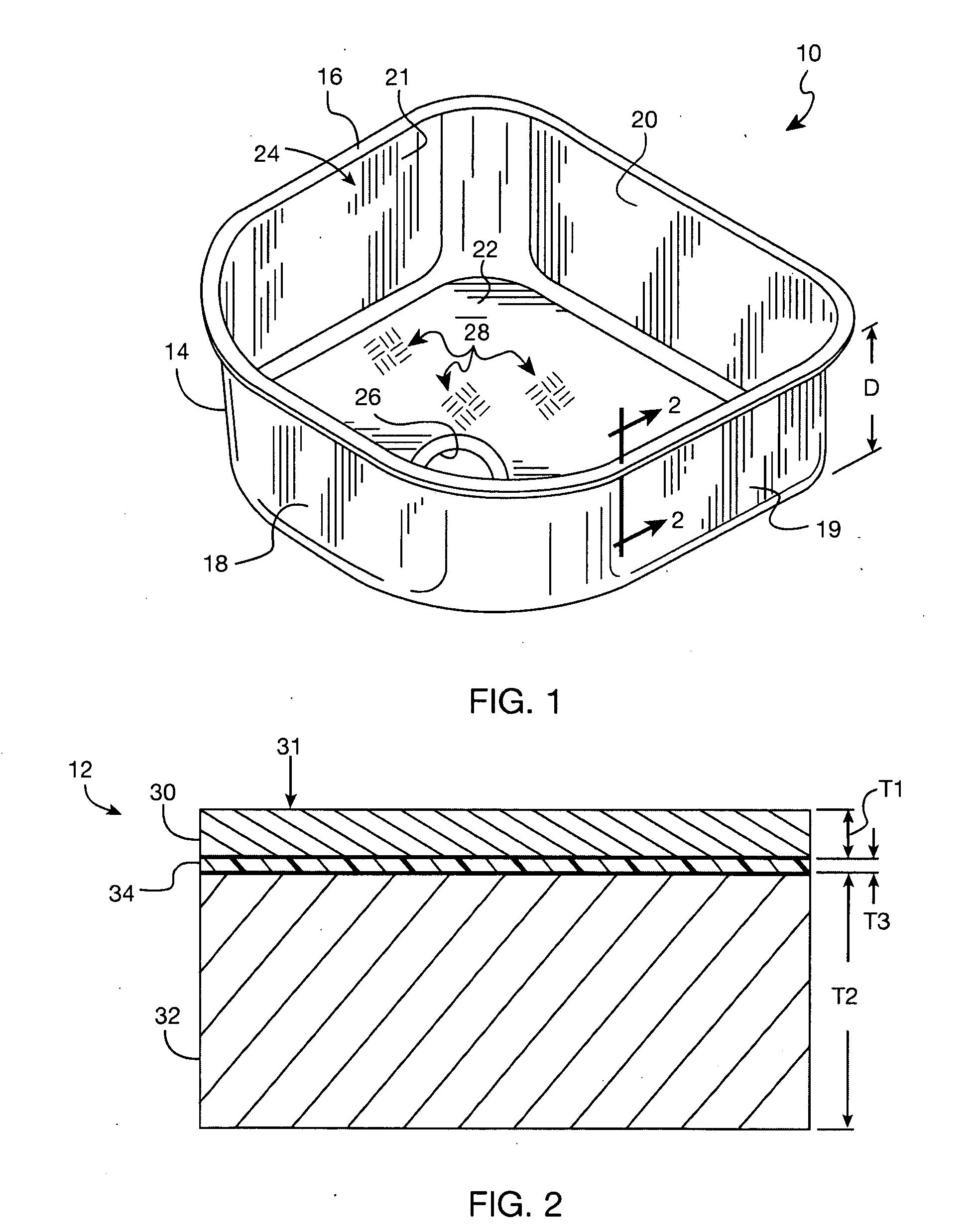

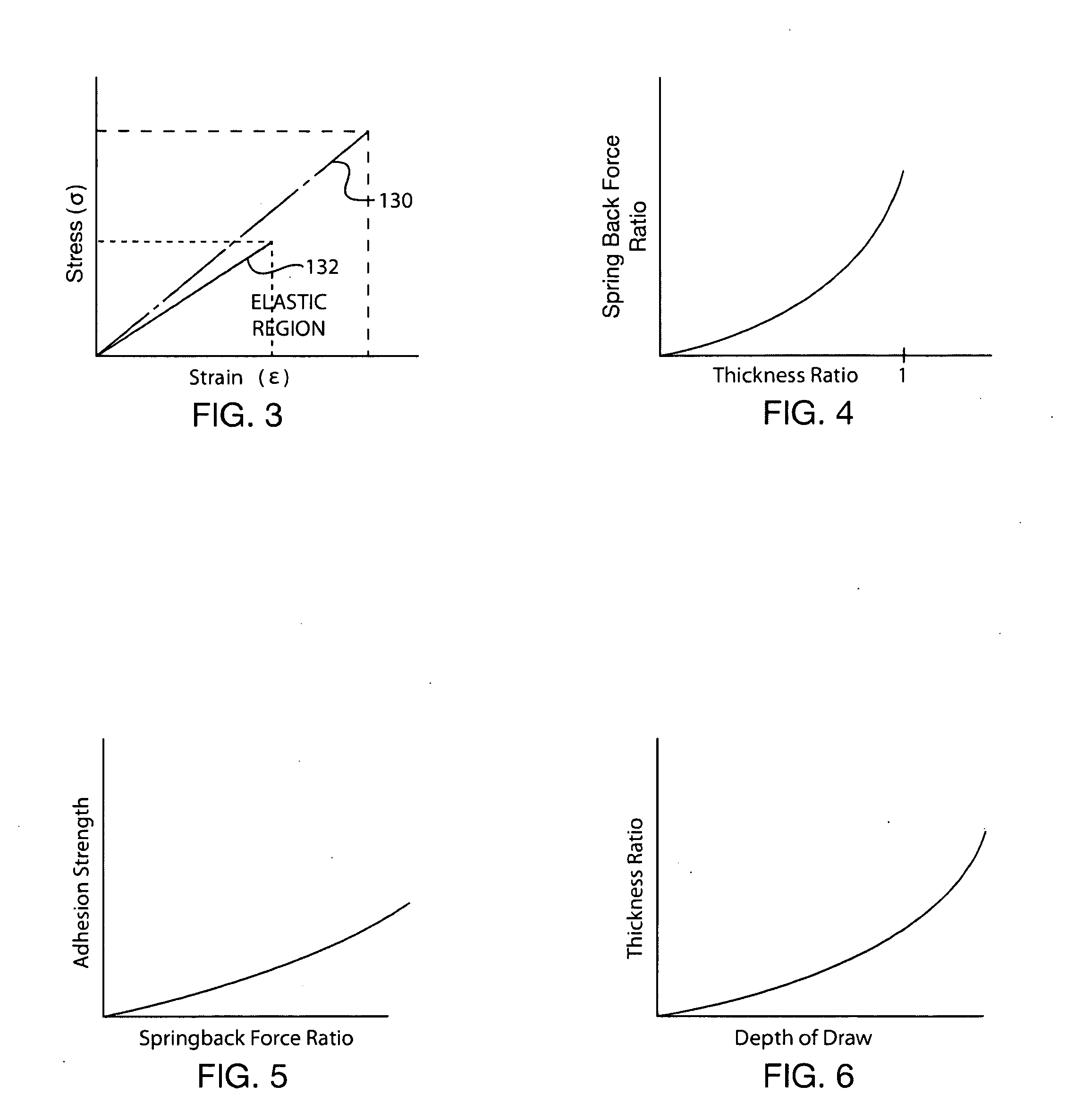

Bimetal laminate structure and method of making the same

InactiveUS20100132110A1Eliminate cracksEliminate delaminationLamination ancillary operationsLayered product treatmentMetallic materialsImproved method

Bimetal laminate structures and an improved method for manufacturing the same are provided herein. In one preferred embodiment, the laminate structure includes a first constraining layer that is fabricated from a metallic material, such as stainless steel. A second constraining layer that is appreciably thicker than the first is also included. The second constraining layer is fabricated from a different metallic material, such as low-carbon cold rolled steel. An adhesive layer spans between and rigidly bonds the first and second constraining layers. The first and second constraining layers have a thickness ratio, a yield strength ratio, and a springback ratio that are collectively optimized such that the laminate structure can be formed, preferably through a deep drawing operation, to define one or more depressions / basins of a predetermined depth without delaminating or cracking. The adhesion strength of the adhesive layer is also engineered to prevent separation of the two constraining layers.

Owner:MATERIAL SCIENCES CORPORATION

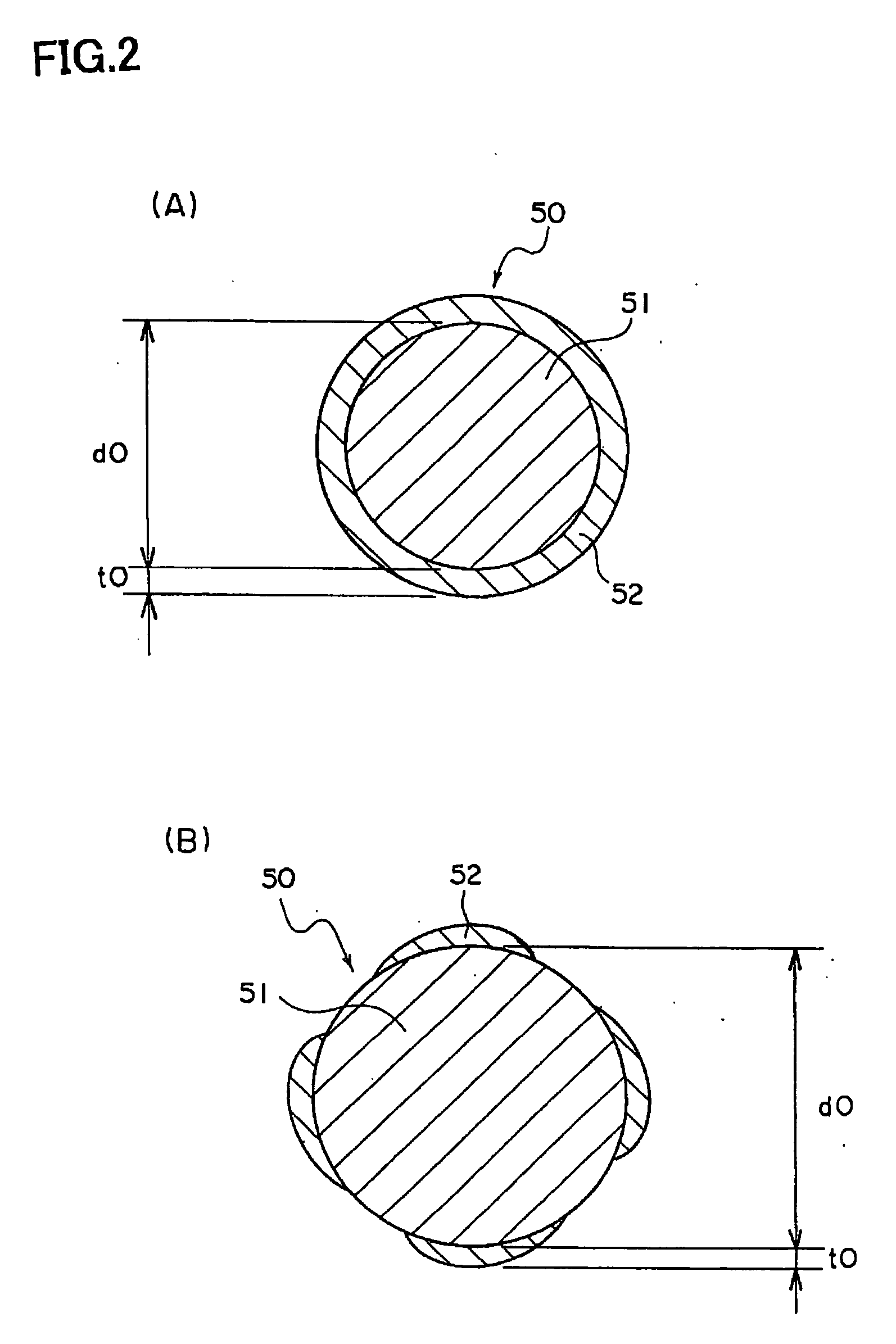

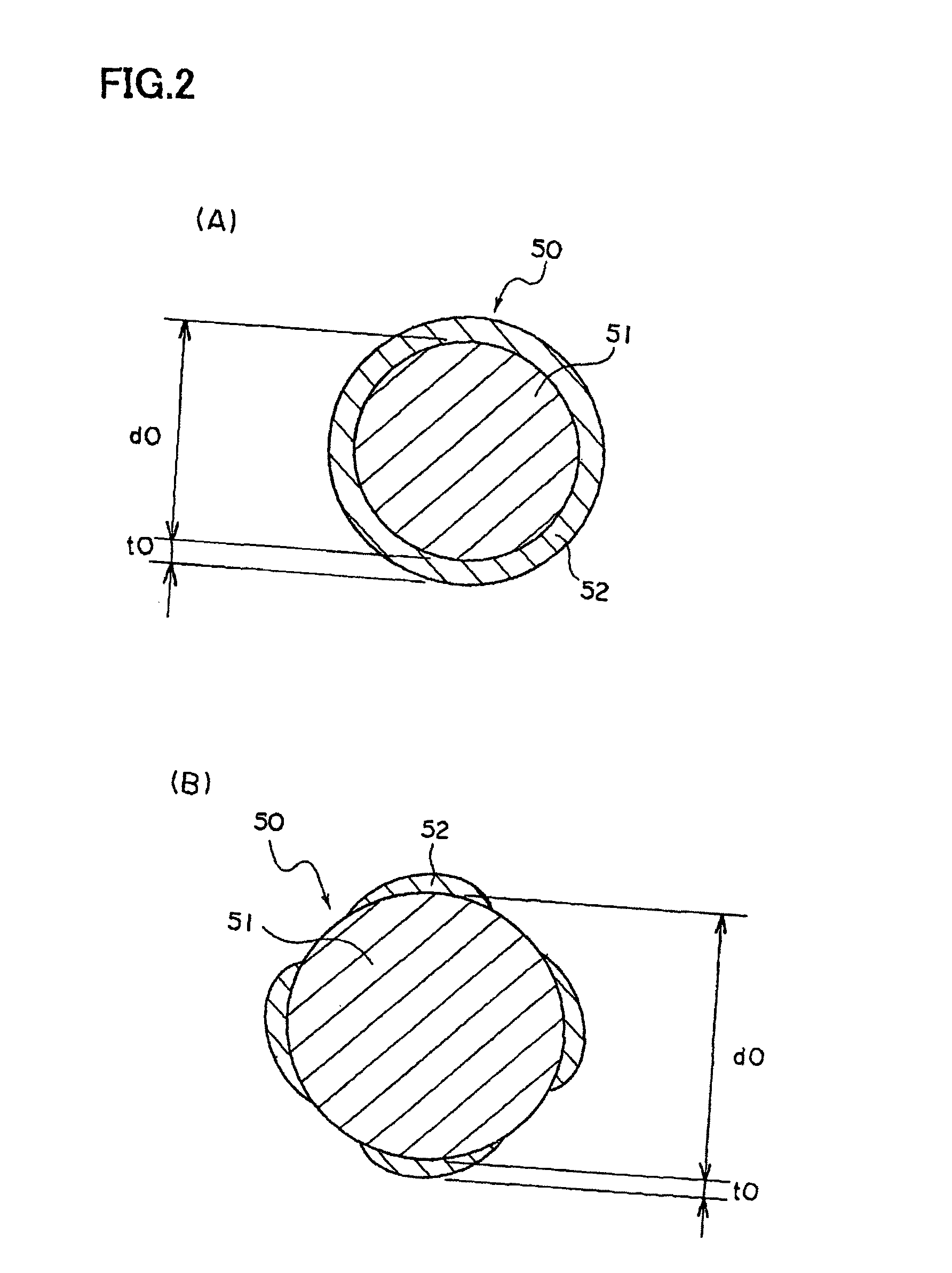

Method of Production of a Conductive Particle, Conductive Paste, and Method of Production of Electronic Device

InactiveUS20080035244A1Improve wettabilitySuperior in bondabilityLiquid surface applicatorsTransportation and packagingConductive pasteAdditive ingredient

A method of production of conductive particles able to suppress growth of the conductive particles at the firing stage, able to effectively prevent spheroidization and electrode disconnection, able to effectively suppress a drop in electrostatic capacity, and able to efficiently produce core particles covered by thin coating layers without abnormal segregation of the coating layer metal particularly even when the internal electrode layers are reduced in thickness. A method of producing conductive particles comprising cores 51 having nickel as their main ingredients and coating layers 52 covering their surroundings. A core powder, a water-soluble metal salt containing a metal or alloy forming the coating layers 52, and a surfactant (or water-soluble polymer compound) are mixed to deposite by reduction a metal or alloy for forming the coating layers 52 on the outer surfaces of the core powder. The metal or alloy forming the coating layers 52 has at least one type of elements selected from Ru, Rh, Re, and Pt as a main ingredient.

Owner:TDK CORPARATION

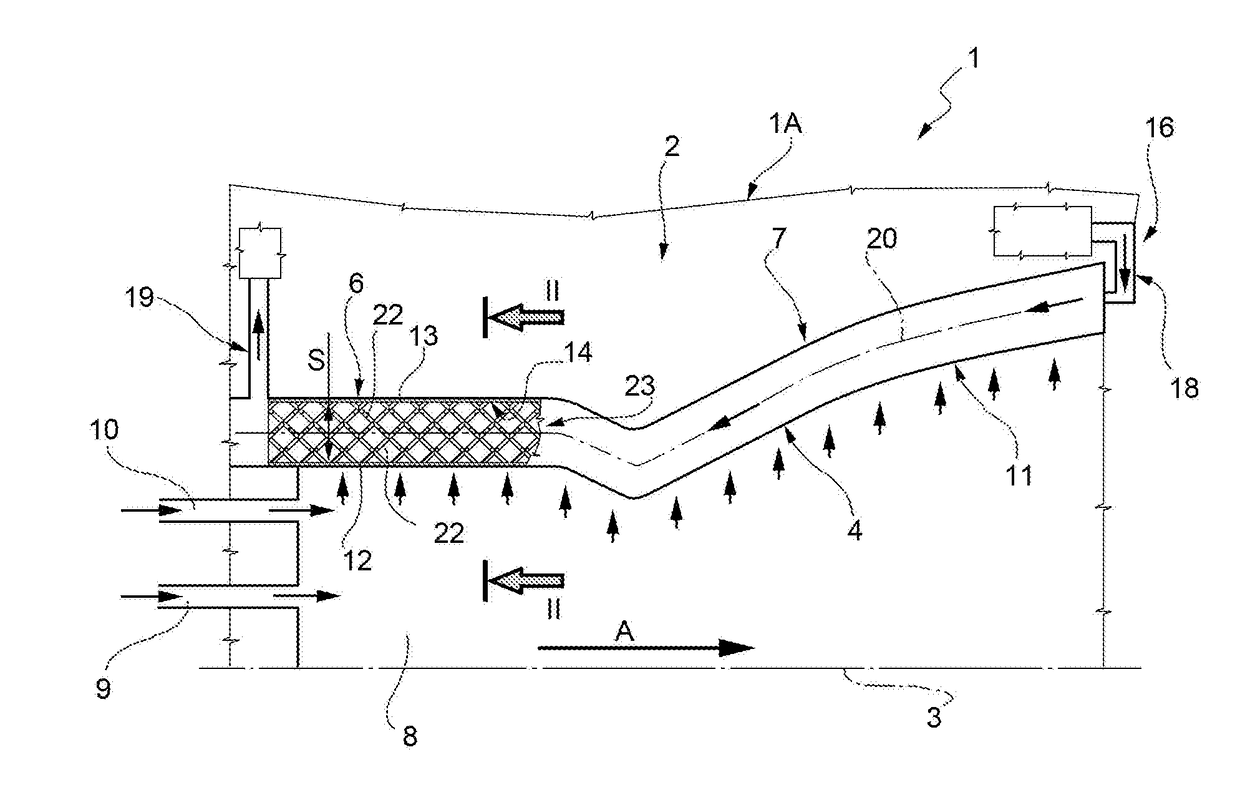

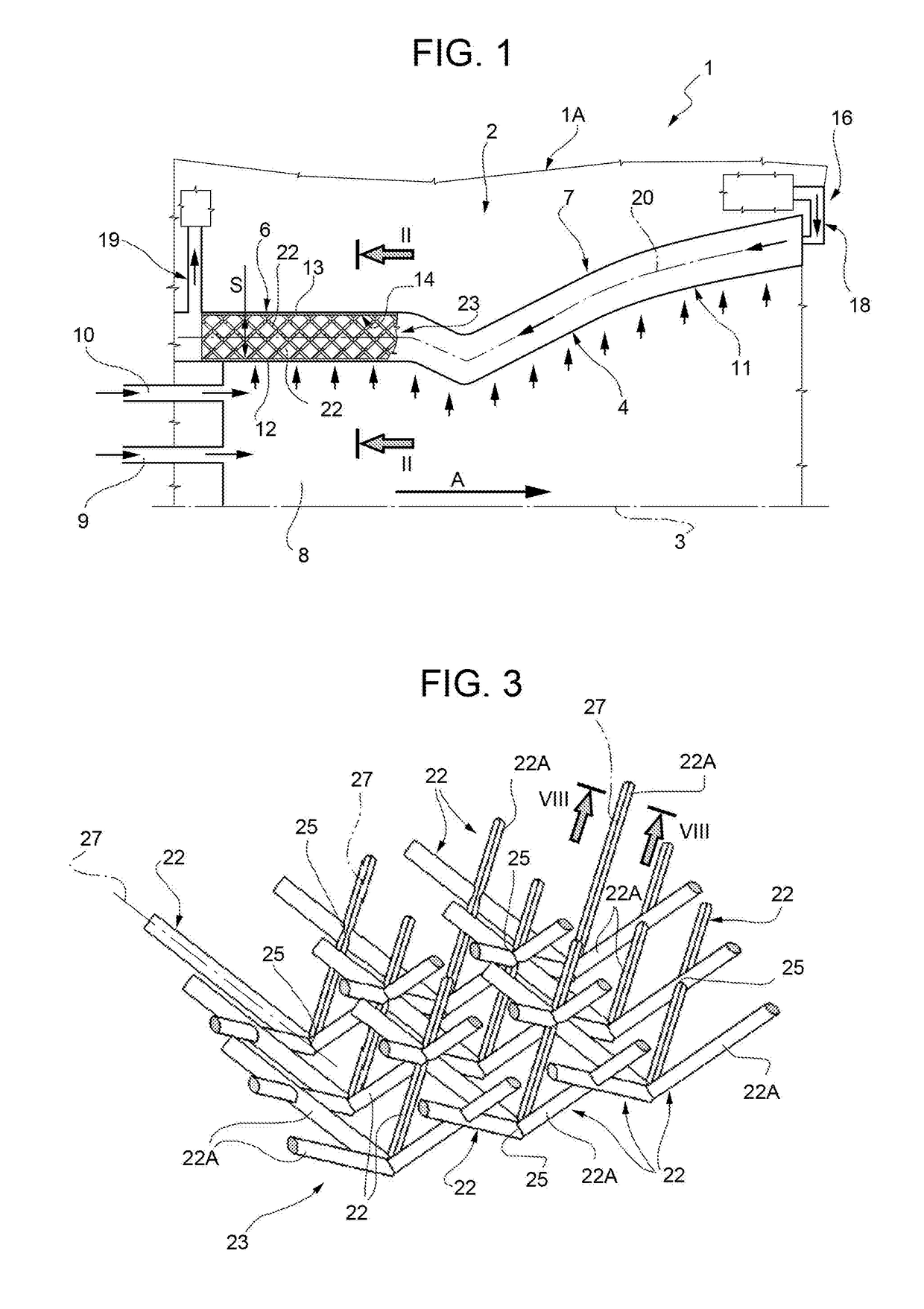

Combustor of a liquid propellent motor

InactiveUS20170122258A1High efficiency and reliabilitySimple and cost-effectiveContinuous combustion chamberHeat exhanger finsCombustion chamberCombustor

A combustor for a liquid propellent motor has an elongated hollow tubular casing having an inner wall delimiting a combustion chamber for the liquid propellent and an outlet nozzle for the combustion products, and an outer wall, both being coaxial to an axis of the casing; the inner and outer walls being spaced apart from each other in radial direction and delimiting at least one guiding conduit of a cooling fluid therebetween; a plurality of bar-shaped elements extending into the guiding conduit, which form a grid for perturbing the cooling fluid, stiffening the casing and increasing the heat exchange surface; the grid being part of a body made in one piece and of a single material along with the inner and outer walls.

Owner:AVIO

Facing material with controlled porosity for construction boards

InactiveUS20060105653A1Prevent penetrationHigh strengthConstruction materialSynthetic resin layered productsPorosityWater vapor

Owner:SAINT GOBAIN ADFORS CANADA LTD

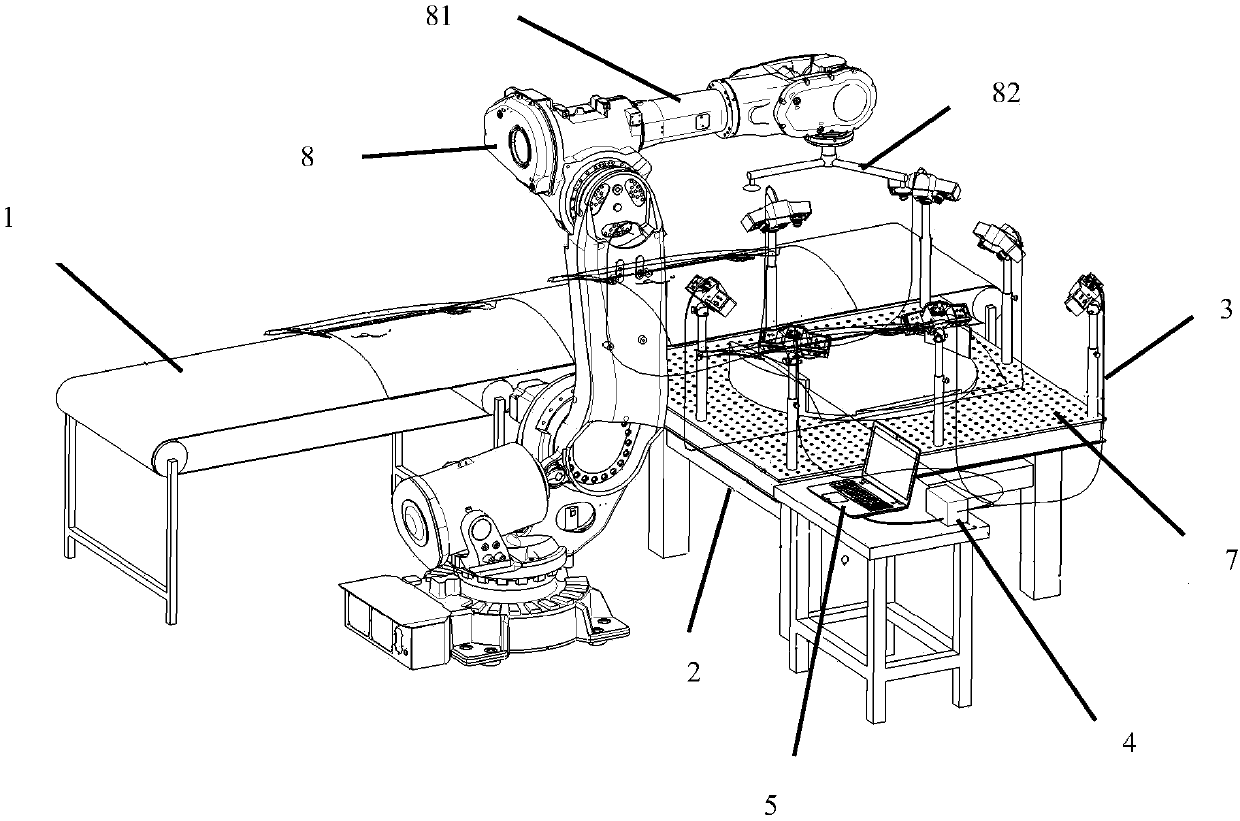

Industrial automatic three-dimensional detection system and method

The invention provides an automatic three-dimensional detection system and method. The system comprises a workpiece conveying system, a working platform, one or more three-dimensional optical scanningdevices, a data transfer station and a computer terminal. The system has the advantages that the system is applied to the industrial automatic shape detection of a plurality of production-line objects and the automatic shape scanning and detection of a non-production-line single object, a detection mode using a robot to grab a workpiece and place the workpiece on the scanning working platform ora stop and detection working mode, which does not need robot grabbing, on a production-line conveying belt is adopted, a coordinated detection mode using one or more three-dimensional optical scanningdevices arranged on the periphery of a production line is used to lower the use difficulty, maintenance cost and manpower cost of three-dimensional scanners, and detection efficiency is greatly improved.

Owner:张宇航

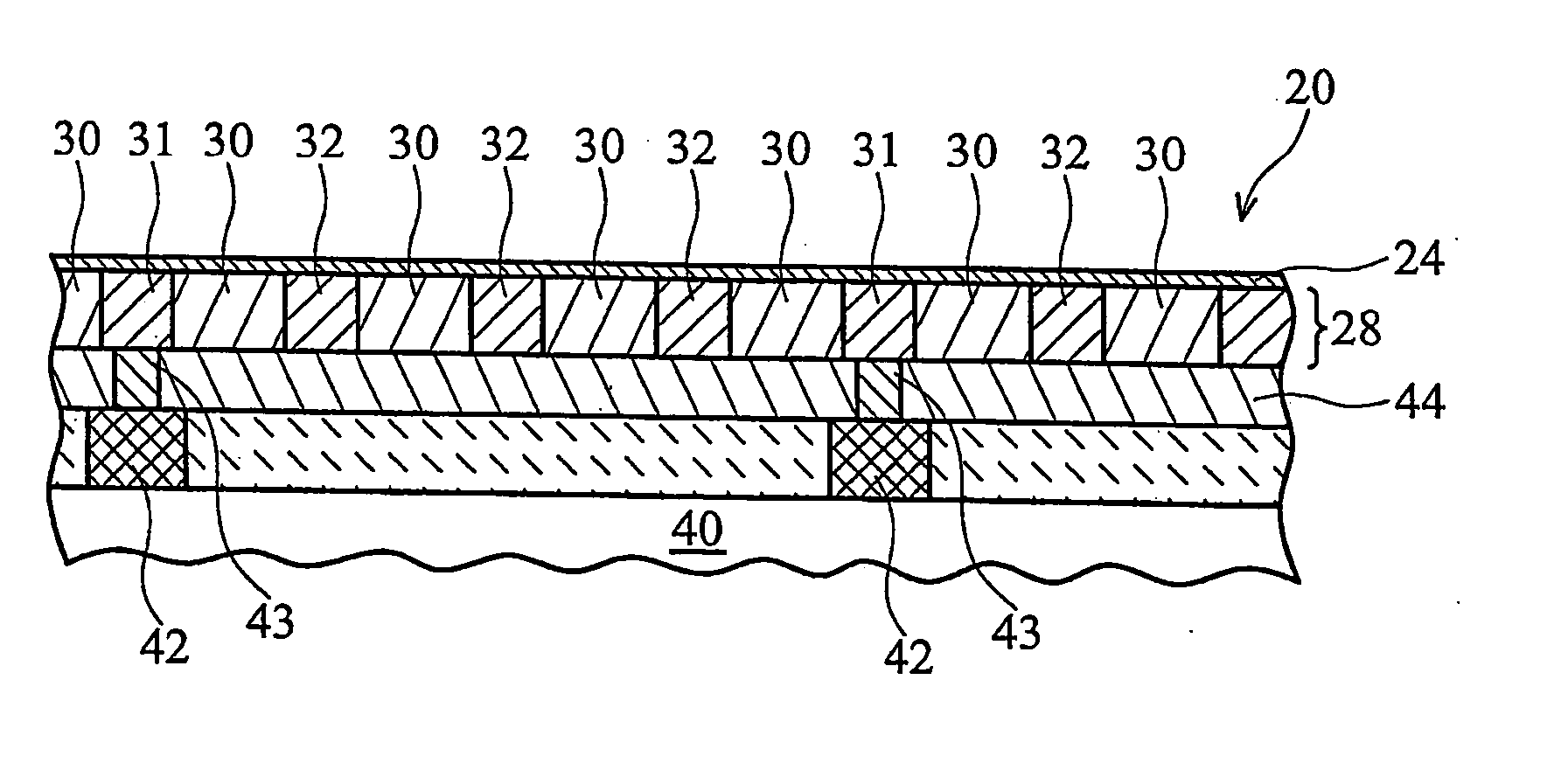

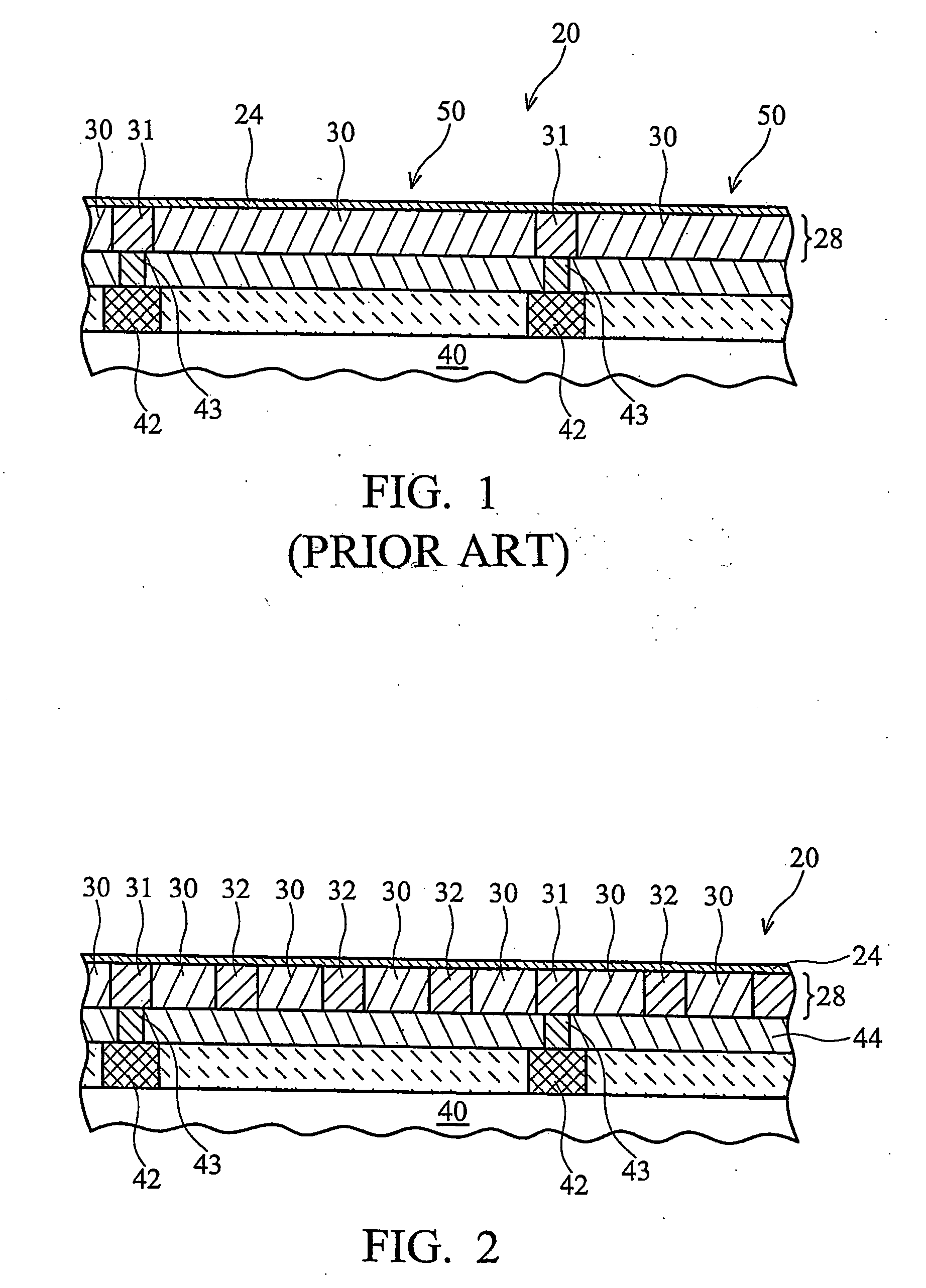

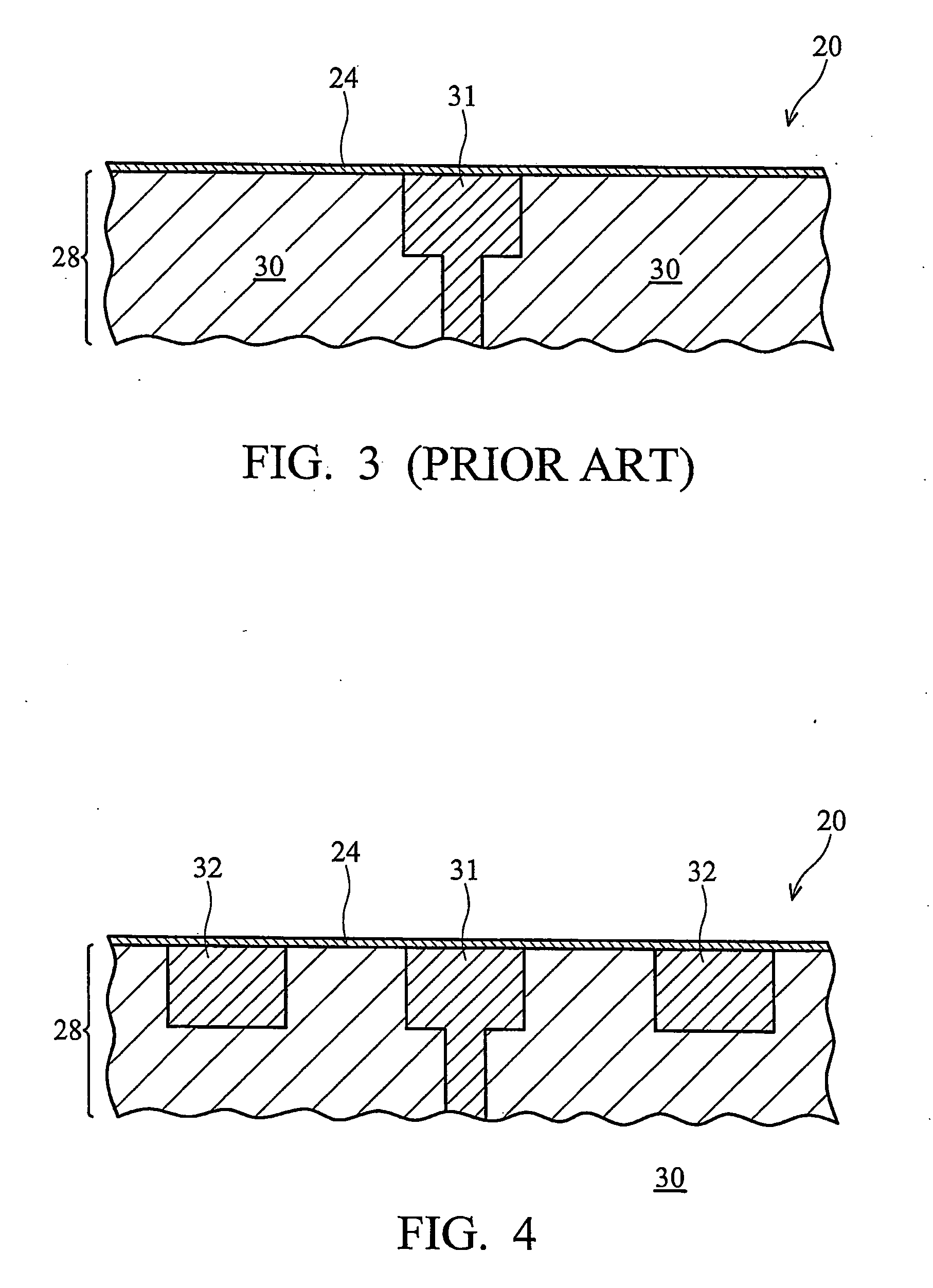

Method and structure for improving adhesion between intermetal dielectric layer and cap layer

InactiveUS20050253268A1Relieve excessive stressDelaminationSemiconductor/solid-state device detailsSolid-state devicesDevice materialAdhesion strength

A semiconductor interconnect structure including a semiconductor substrate, a semiconductor active device formed in the substrate, a layer of low-k dielectric material, a first patterned conducting layer, a second patterned conducting layer, and a cap layer formed thereon. The low-k material layer is formed over the semiconductor device. The first conducting line is formed in the low-k material layer and connected to the semiconductor active device. The second conducting line is formed in the low-k material layer but not electrically connected to the semiconductor active device. The cap layer is formed over the low-k material layer, the first and second conducting lines. The cap layer includes silicon and carbon. Since the adhesion strength between the cap layer and the patterned conducting layer is greater than the adhesion strength between the cap layer and the low-k material layer, the addition of second patterned conducting layer would eliminate the overall possibility of delamination between the surface where cap layer is in contact with the low-k material and the first and the second patterned conducting layers.

Owner:TAIWAN SEMICON MFG CO LTD

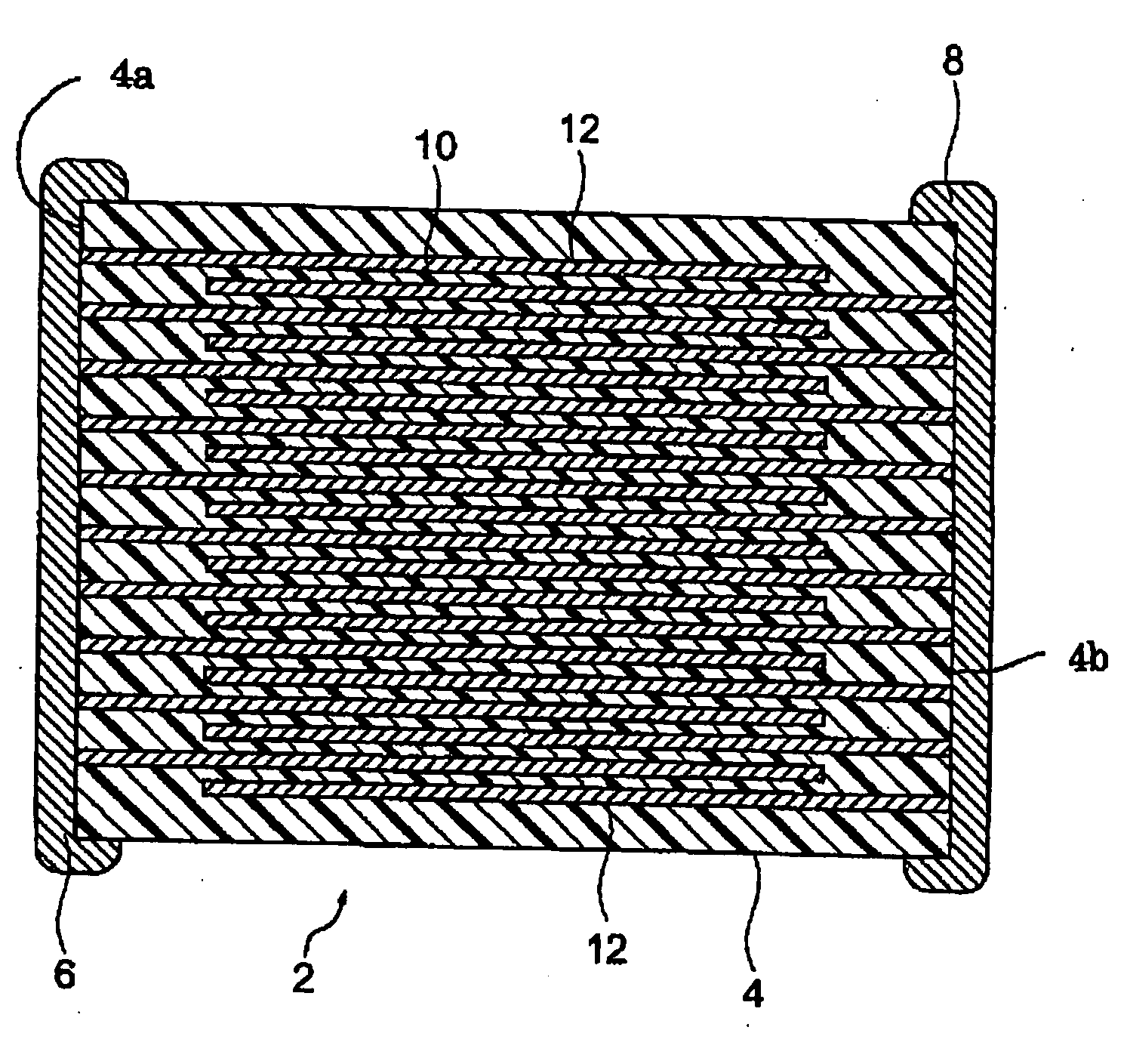

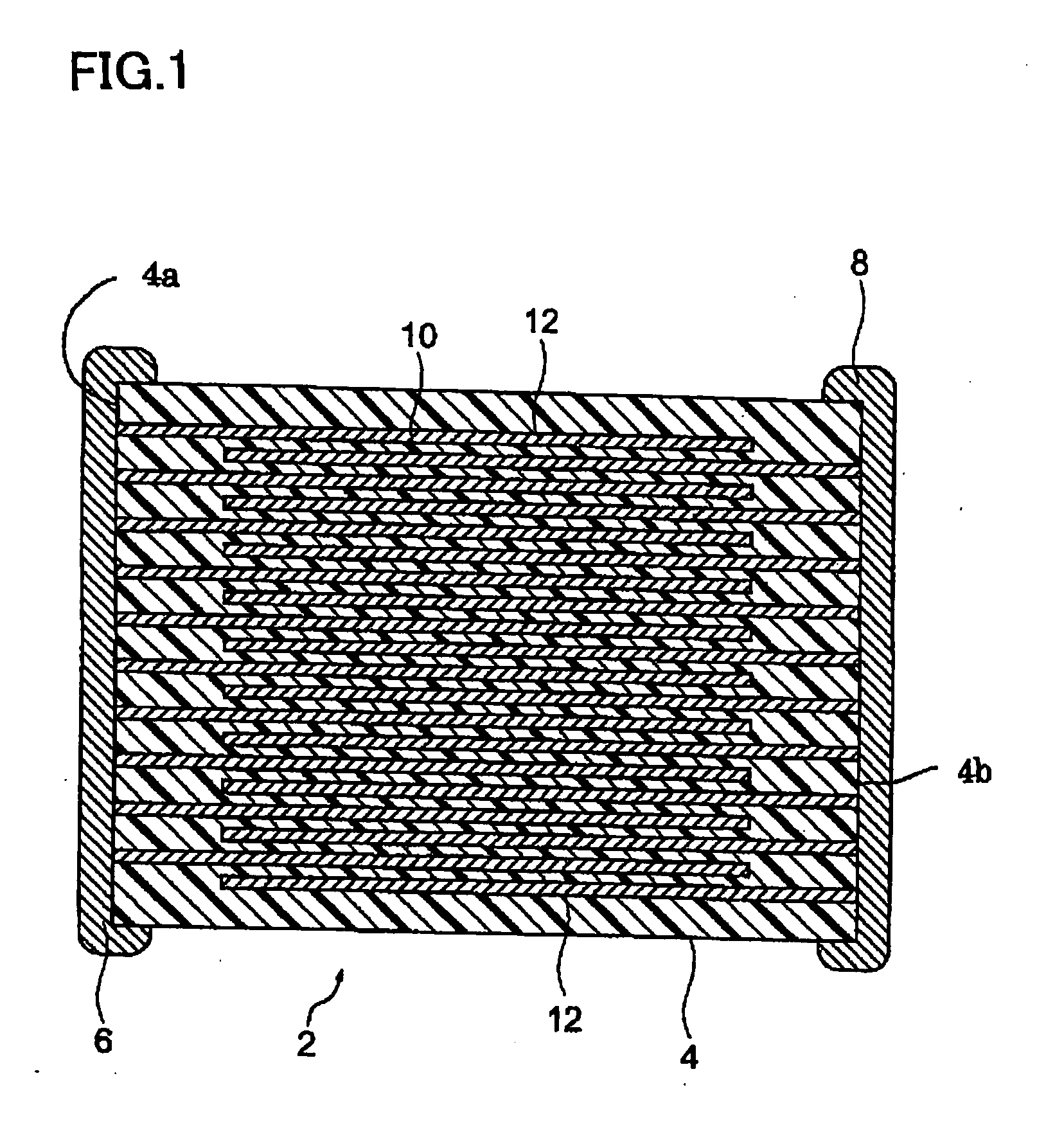

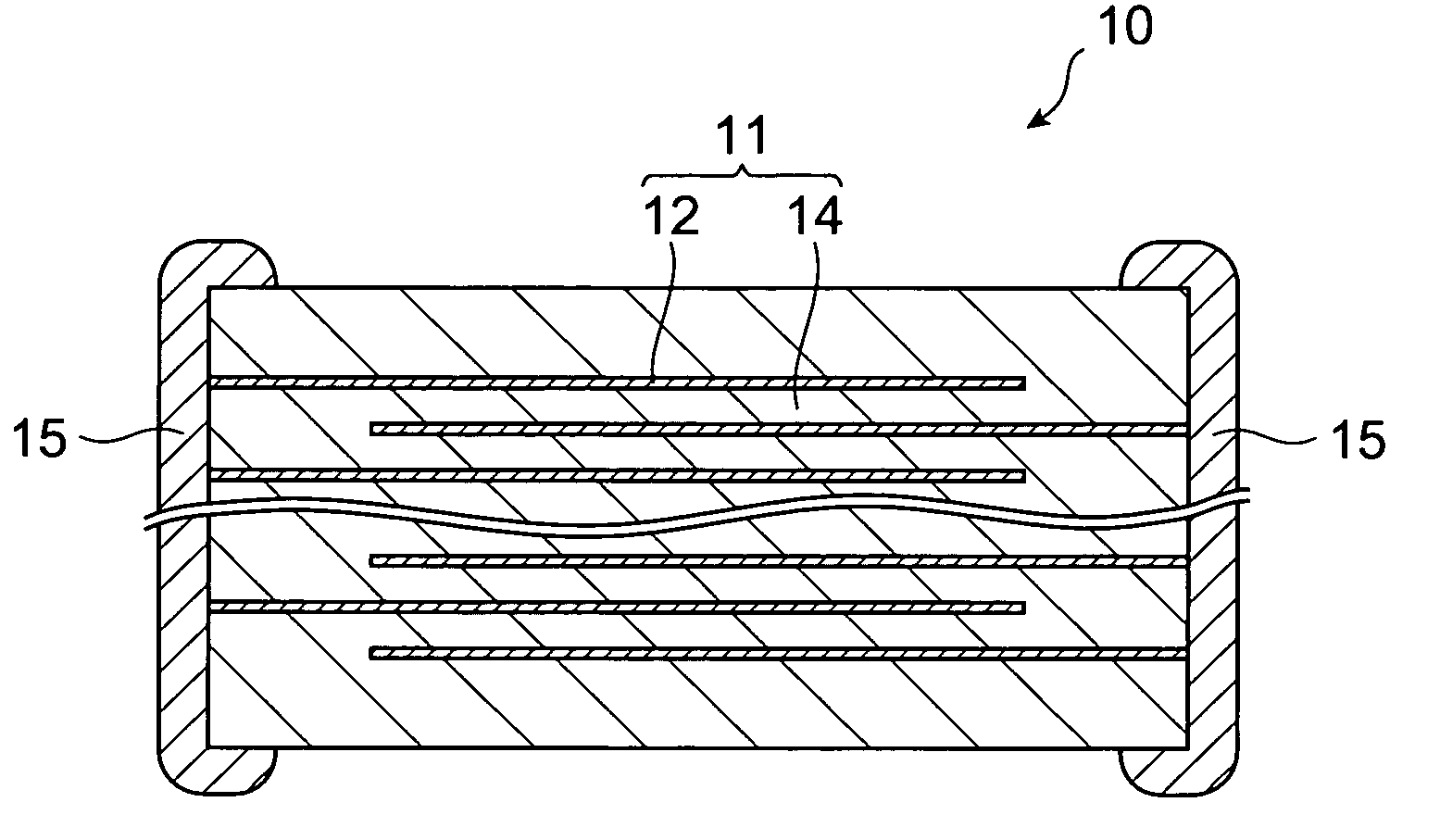

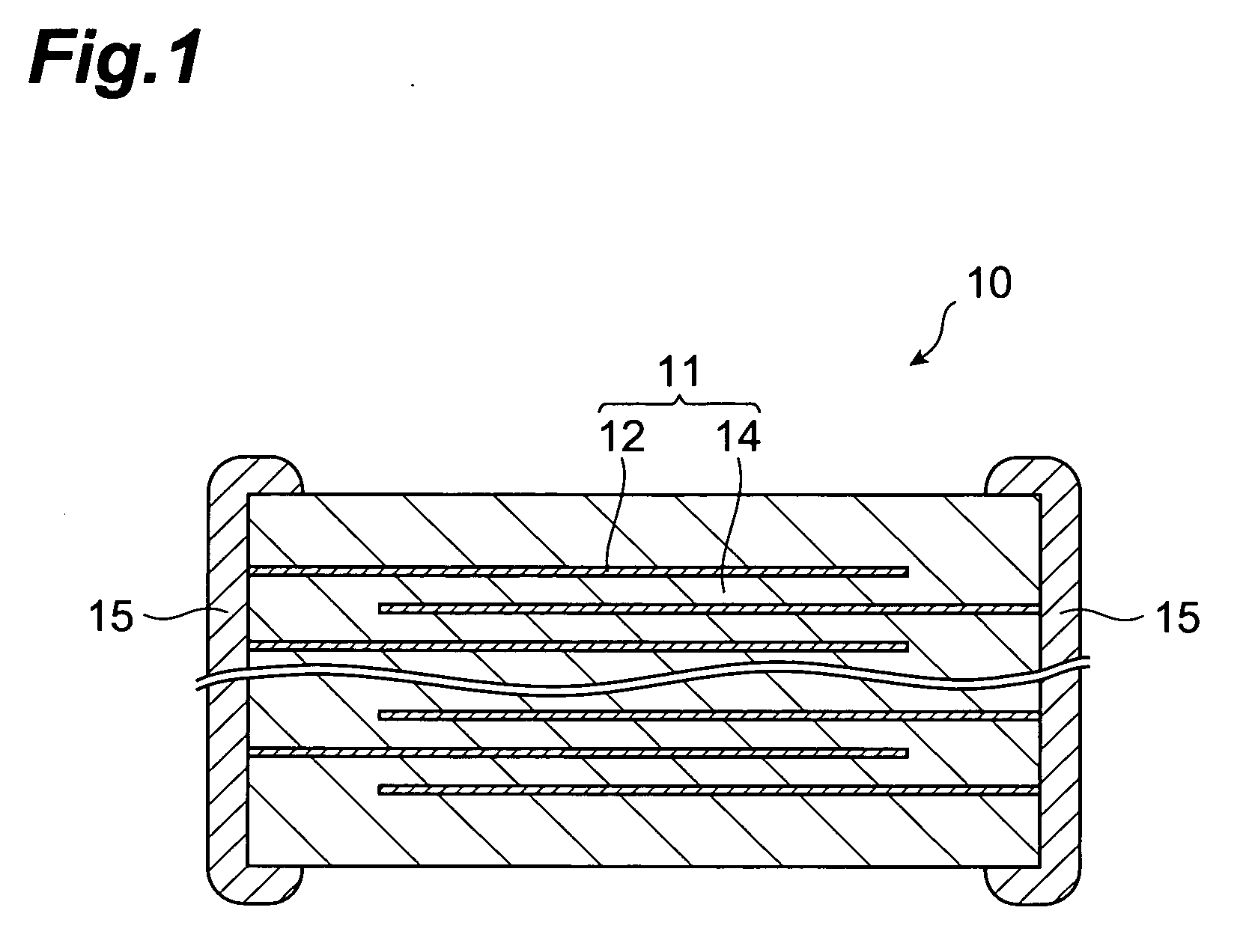

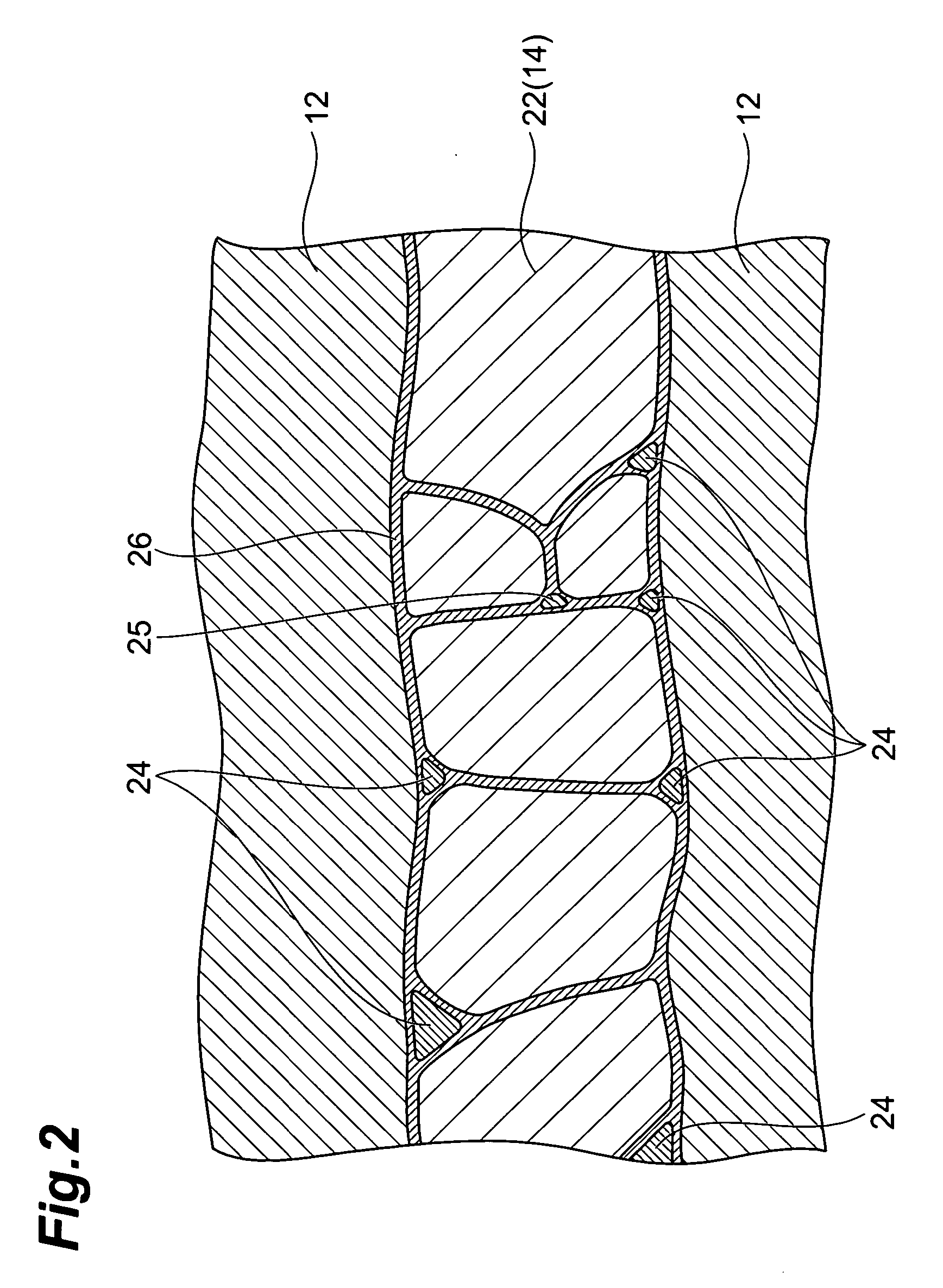

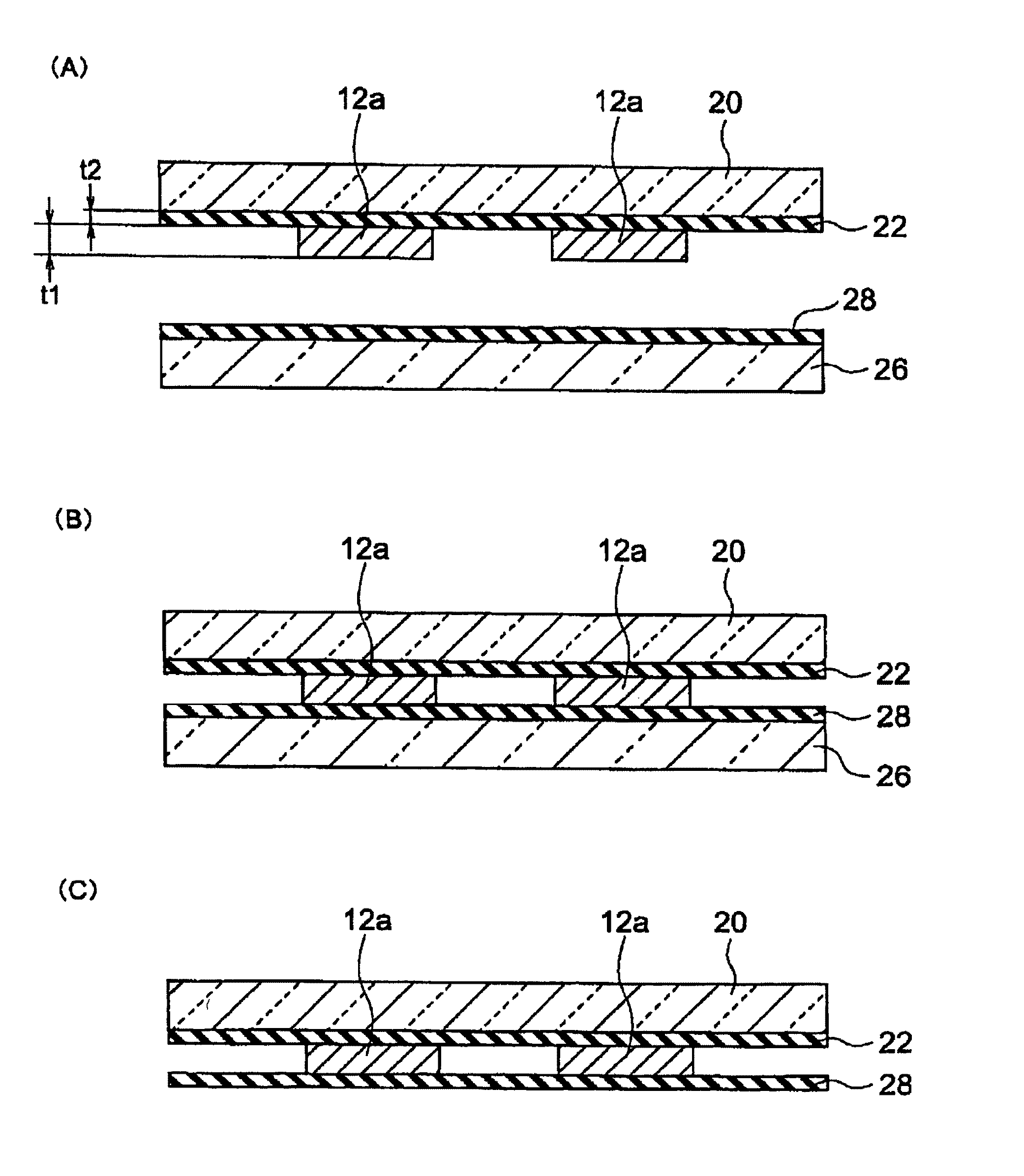

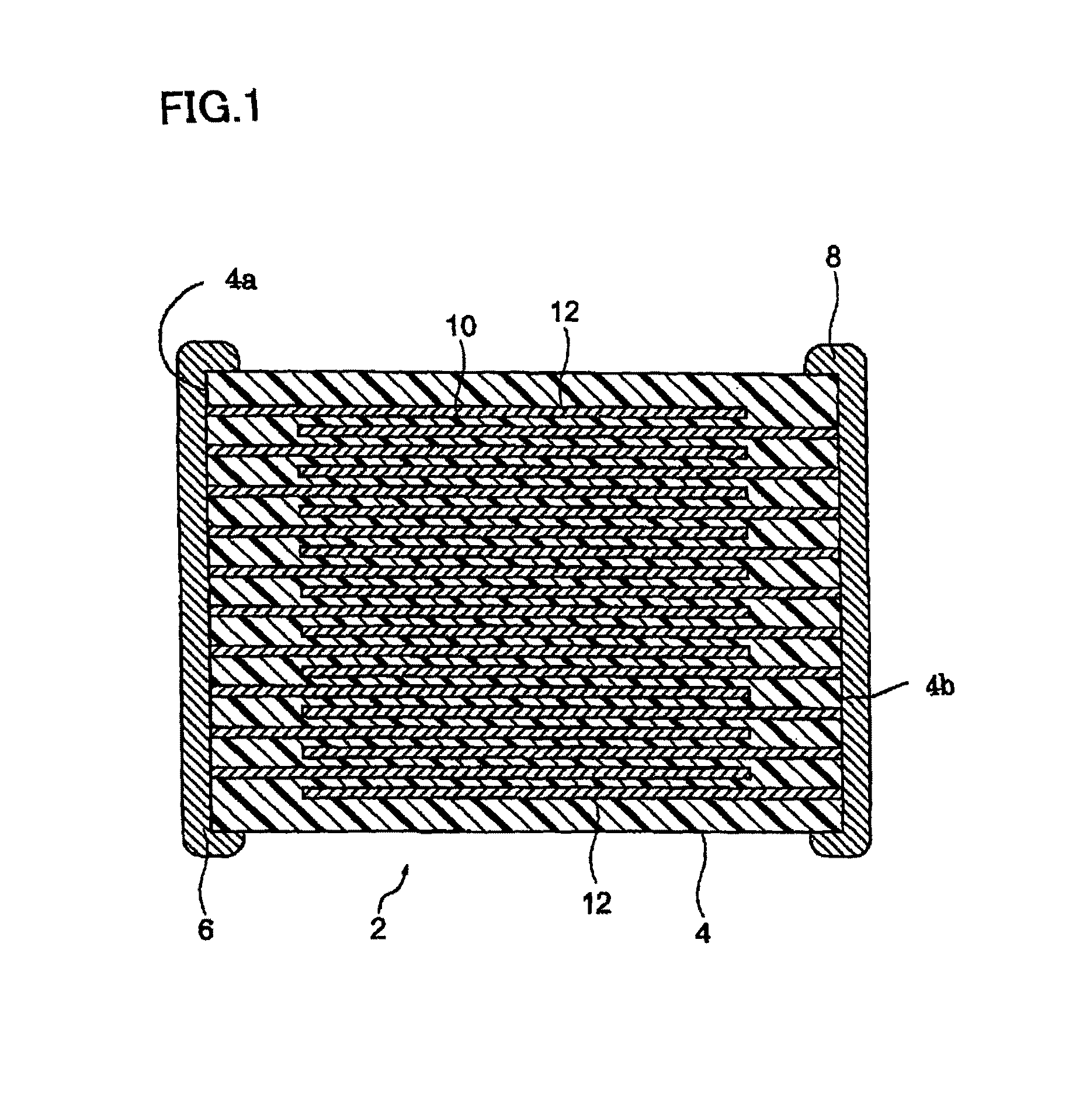

Laminated ceramic capacitor

ActiveUS20060177678A1Increase capacitanceHigh insulation resistanceTransistorFixed capacitor dielectricCeramic capacitorDielectric layer

The capacitor 10 (laminated ceramic capacitor) of the invention comprises a capacitor body 11 wherein internal electrodes 12 (electrodes) and a dielectric layer 14 are alternately laminated, and external electrodes 15 are provided on the end faces thereof. The dielectric layer 14 has a site containing particles of a dielectric material which is formed of only one of these particles in its thickness direction. Regions 24 comprising at least one element selected from a group comprising Si, Li and B are scattered between the internal electrodes 12 and dielectric layer 14.

Owner:TDK CORPARATION

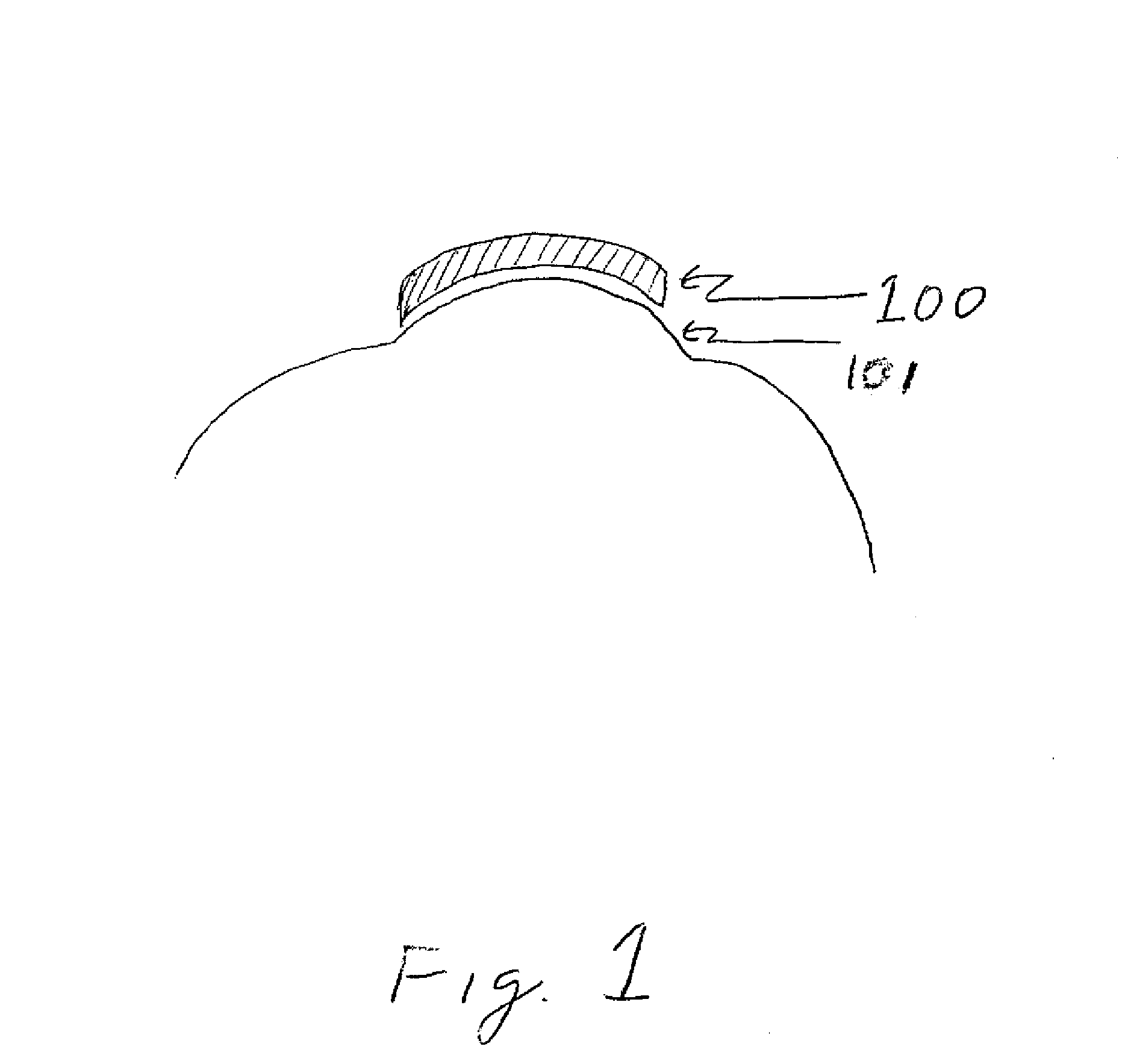

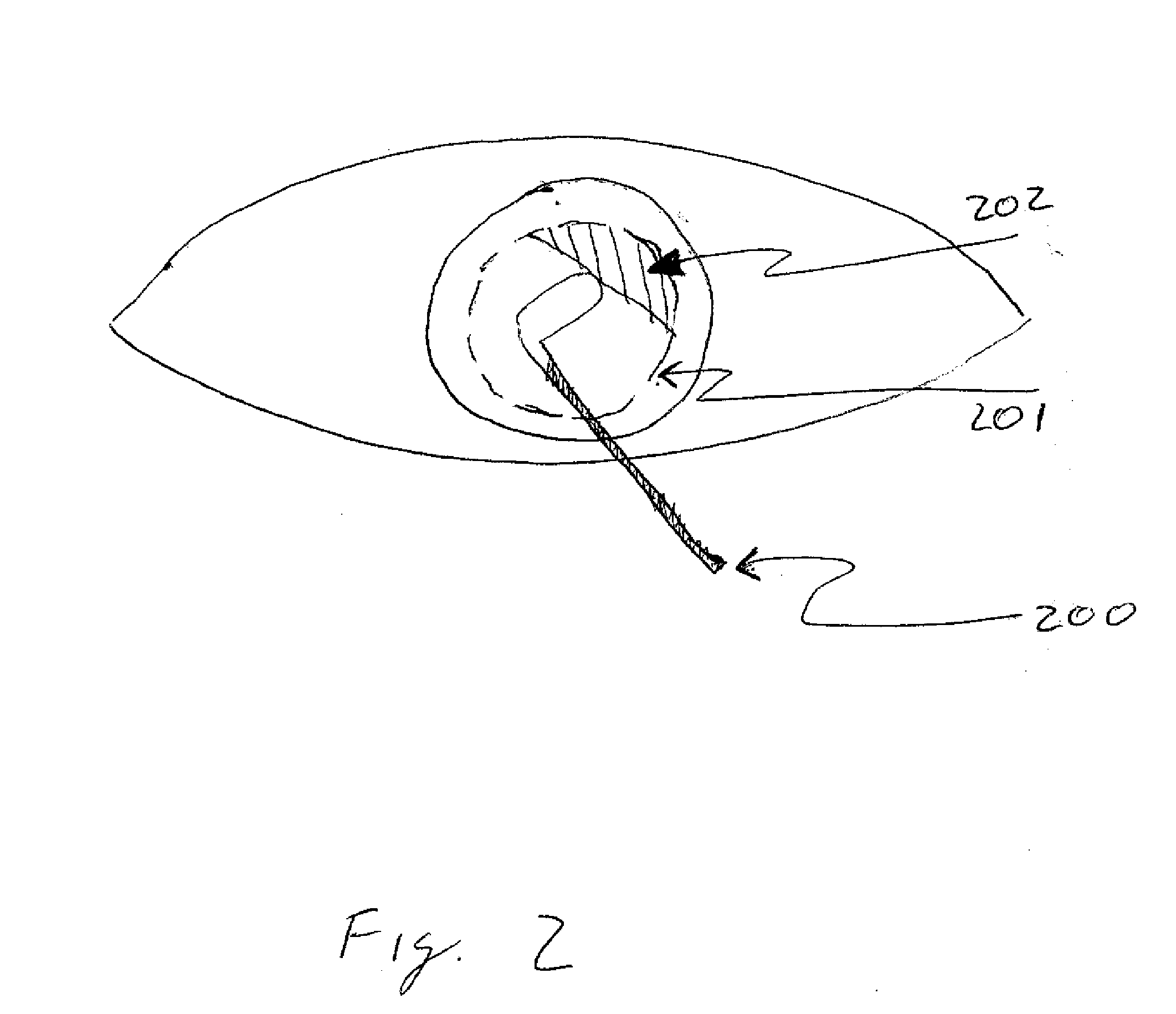

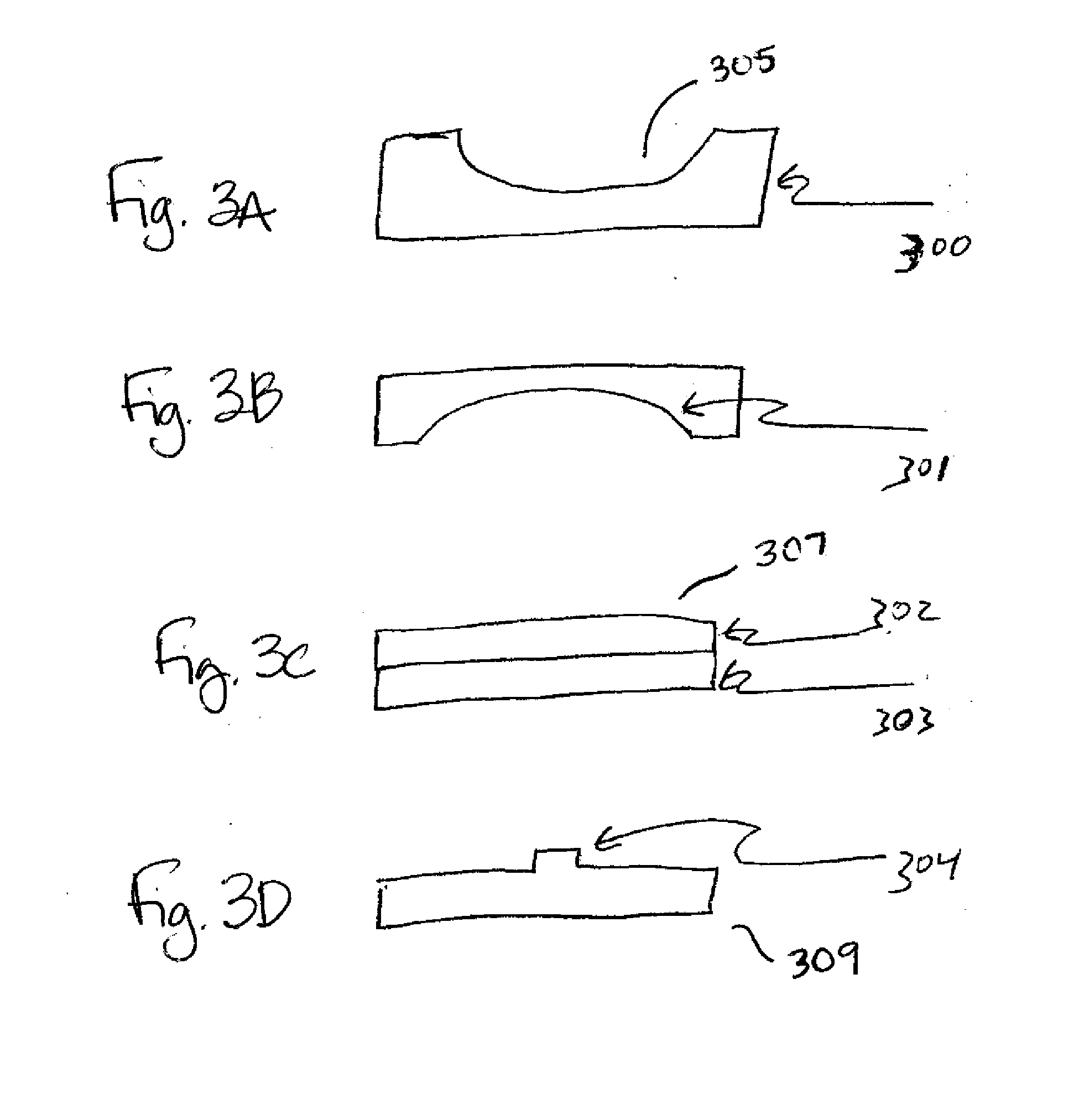

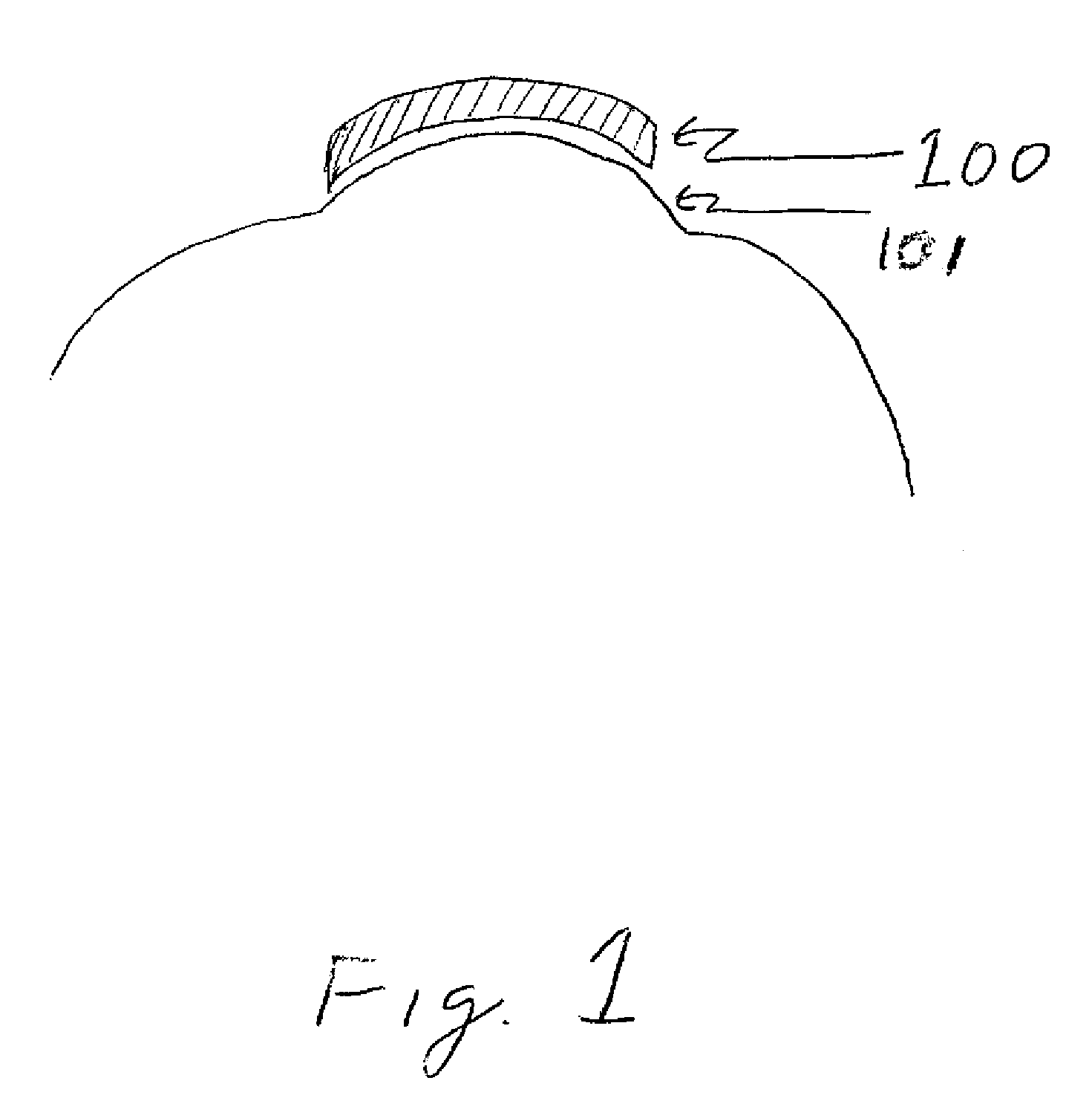

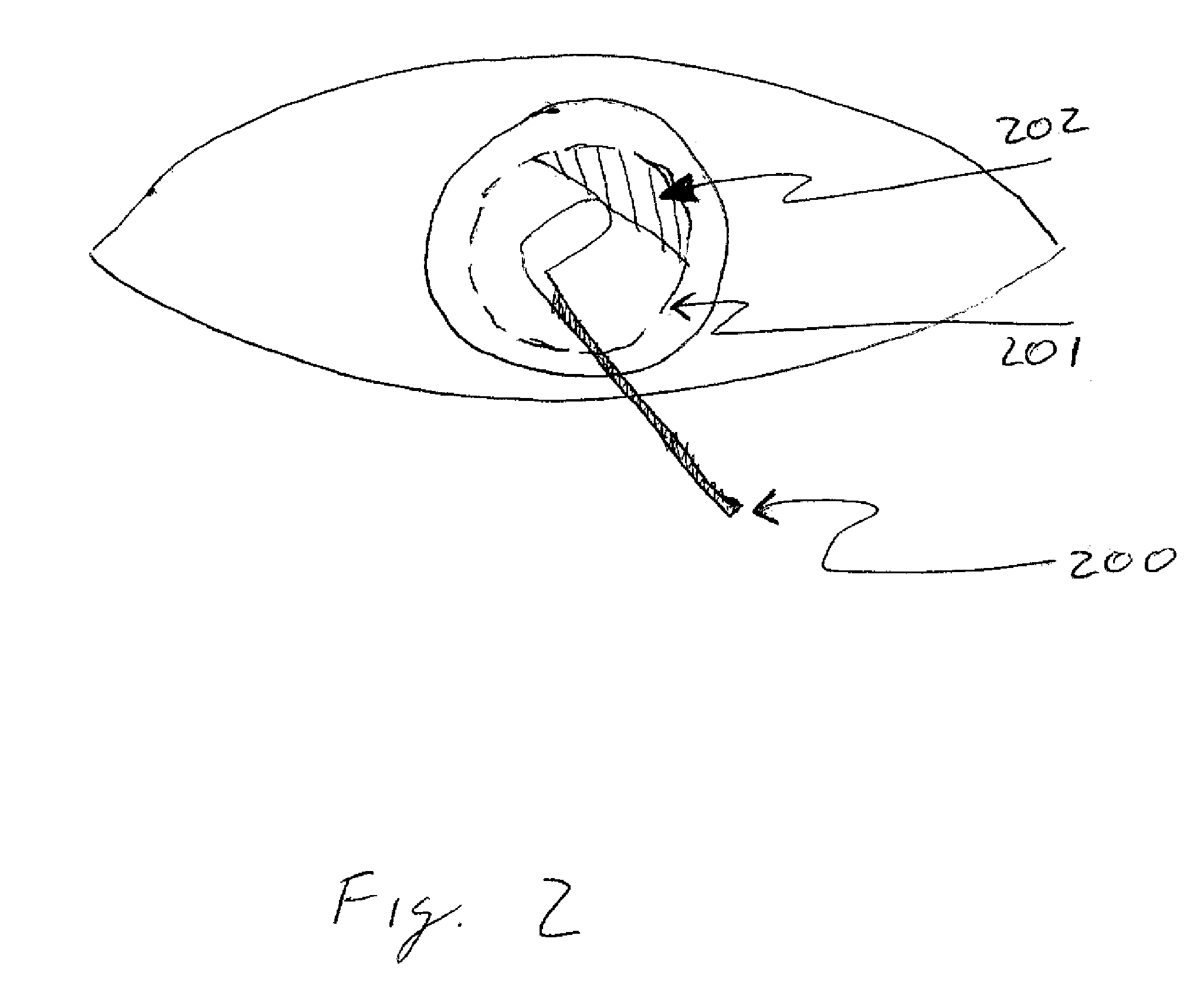

Apparatus and Method for Removing Epithelium from the Cornea

ActiveUS20120087970A1Facilitating de-epithelializationDelaminationOrganic active ingredientsBiocideMedicineCornea surface

An apparatus and a method for removing epithelium from the cornea include a fluid agent for facilitating de-epithelialization of the cornea. A disc includes a biocompatible material operable for covering a predetermined zone of a cornea. The disc is hydrated by the fluid agent, wherein the hydrated disc is pliable for conforming to a surface of the cornea. An application of the hydrated disc to the cornea substantially constrains the fluid agent to the determined zone and softens a corneal epithelium enabling delamination of the epithelium from an underlying stroma.

Owner:NEWMAN LEONARD A

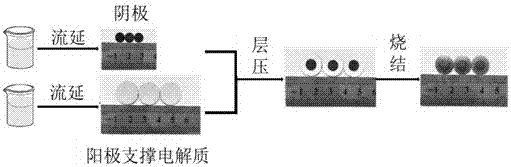

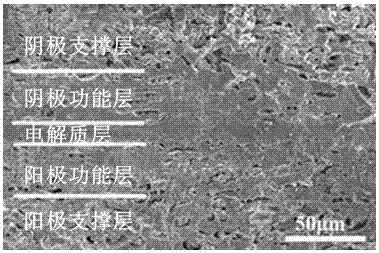

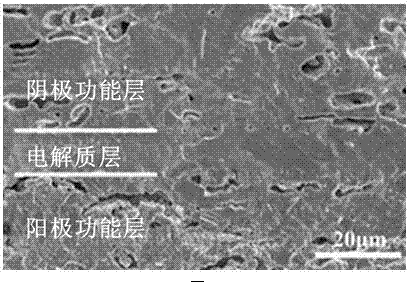

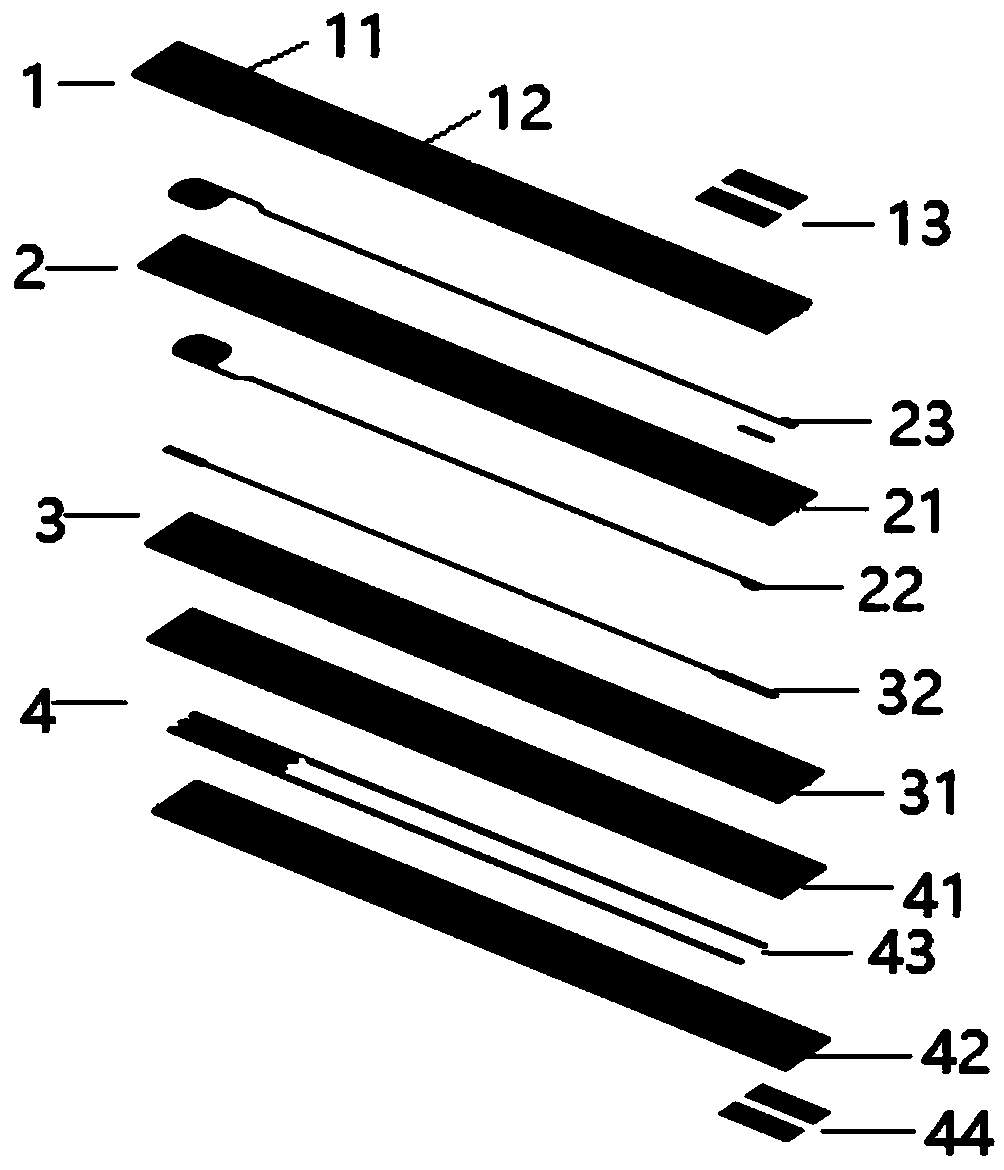

Single preparation method of solid oxide fuel cell

InactiveCN107195938AEven by forceReduce interface stressFinal product manufactureFuel cellsFuel cellsBattery cell

The invention relates to a single preparation method of a solid oxide fuel cell, and belongs to the field of a fuel cell. The method comprises the following steps of (1) casting an SSZ electrolyte layer; (2) casting a positive electrode functional layer and a positive electrode support layer on the SSZ electrolyte layer in the step (1) to form a biscuit A; (3) casting a negative electrode functional layer, and casting a negative electrode support layer on the negative electrode functional layer to form a biscuit B; (4) laminating the SSZ electrolyte layer surface of the biscuit A and a negative electrode functional layer surface of the biscuit B, and obtaining a complete all-battery biscuit by lamination; and (5) placing the all-battery biscuit obtained in the step (4) in a high-temperature furnace for sintering. The method has the advantages that uniform stress of the biscuit can be ensured by a lamination technology, so that the interface stress is reduced, and a crack and layering are eliminated; the biscuit A and the biscuit B are jointly laminated to form the all-battery biscuit by lamination, the all-battery is prepared by a one-step co-sintering technology, the step of a solid oxide full cell (SOFC) preparation process can be reduced, the production cost is reduced, and the time is saved.

Owner:HARBIN INST OF TECH

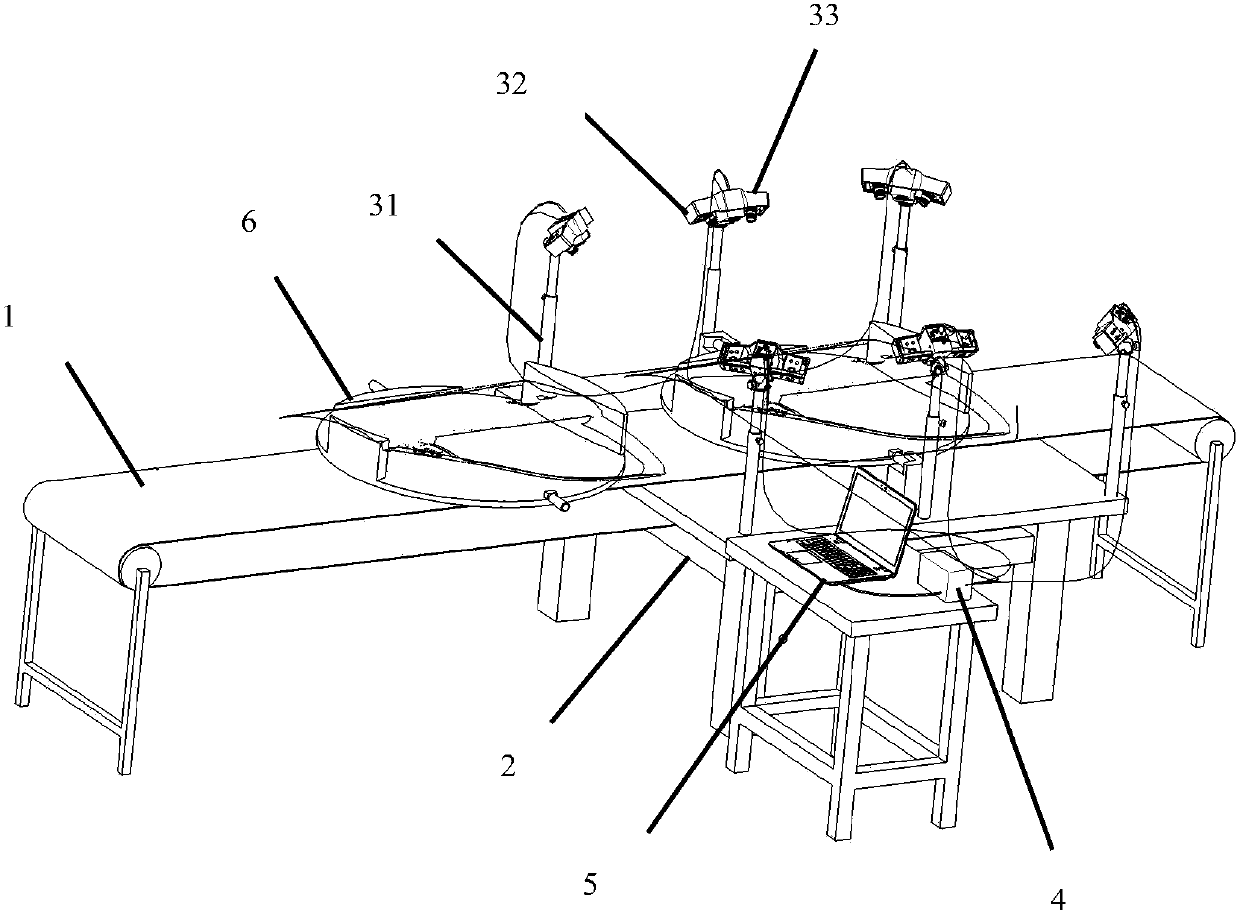

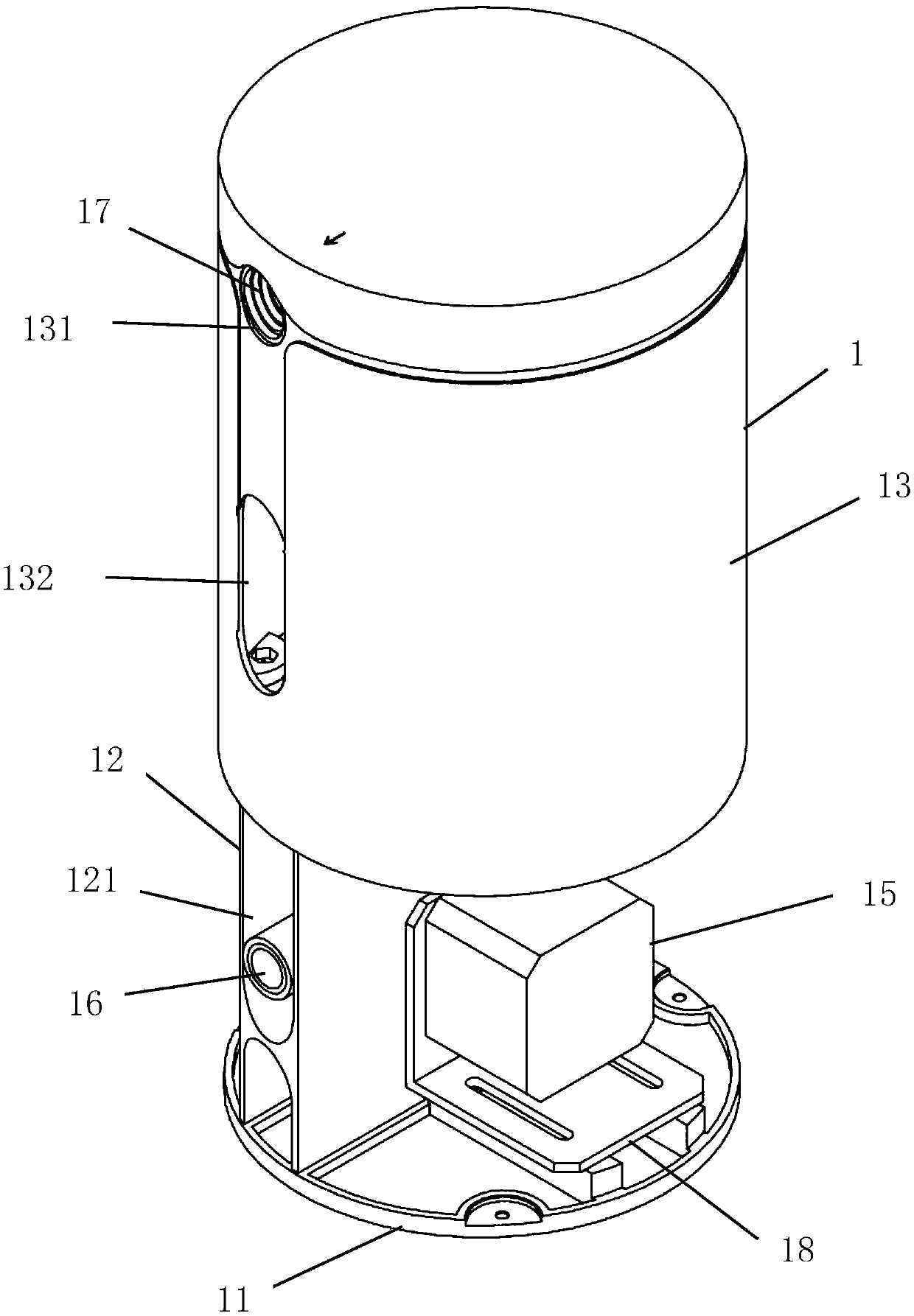

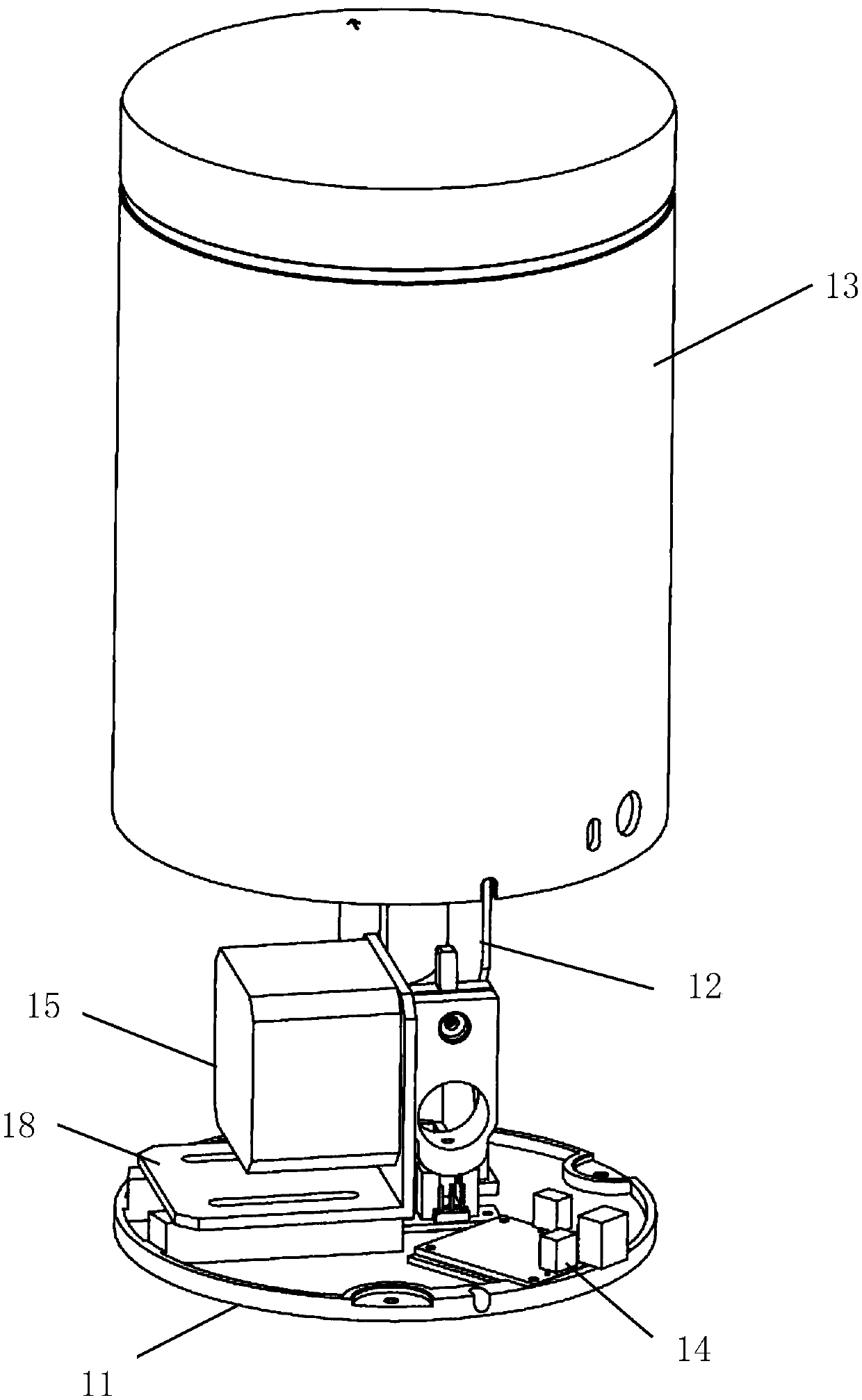

Three-dimensional laser scanner system and use method

PendingCN107869955AReduce configuration requirementsHigh positioning accuracyUsing optical meansPoint cloudLaser scanning

The invention provides a three-dimensional laser scanner system and use method. The three-dimensional laser scanner system comprises a scanner support, a camera component and a backboard, the camera component is mounted on the scanner support, an object to be scanned is placed in the front of the backboard, the camera component is connected with a computer through a USB (universal serial bus) interface, three-dimensional laser scanner software is arranged in the computer, and the camera component aligns the object to be scanned. The three-dimensional laser scanner system has the advantages that by a high-precision coding image backboard spliced algorithm, positioning accuracy is improved, accuracy and reliability of subsequent photography measurement are ensured, a laser scanner is flexible, efficient, easy to use and high in accuracy, point cloud of the surface of the object is acquired by a laser, and the space position of the laser scanner in the working process is determined according to visual image markers.

Owner:华朗三维技术(深圳)有限公司

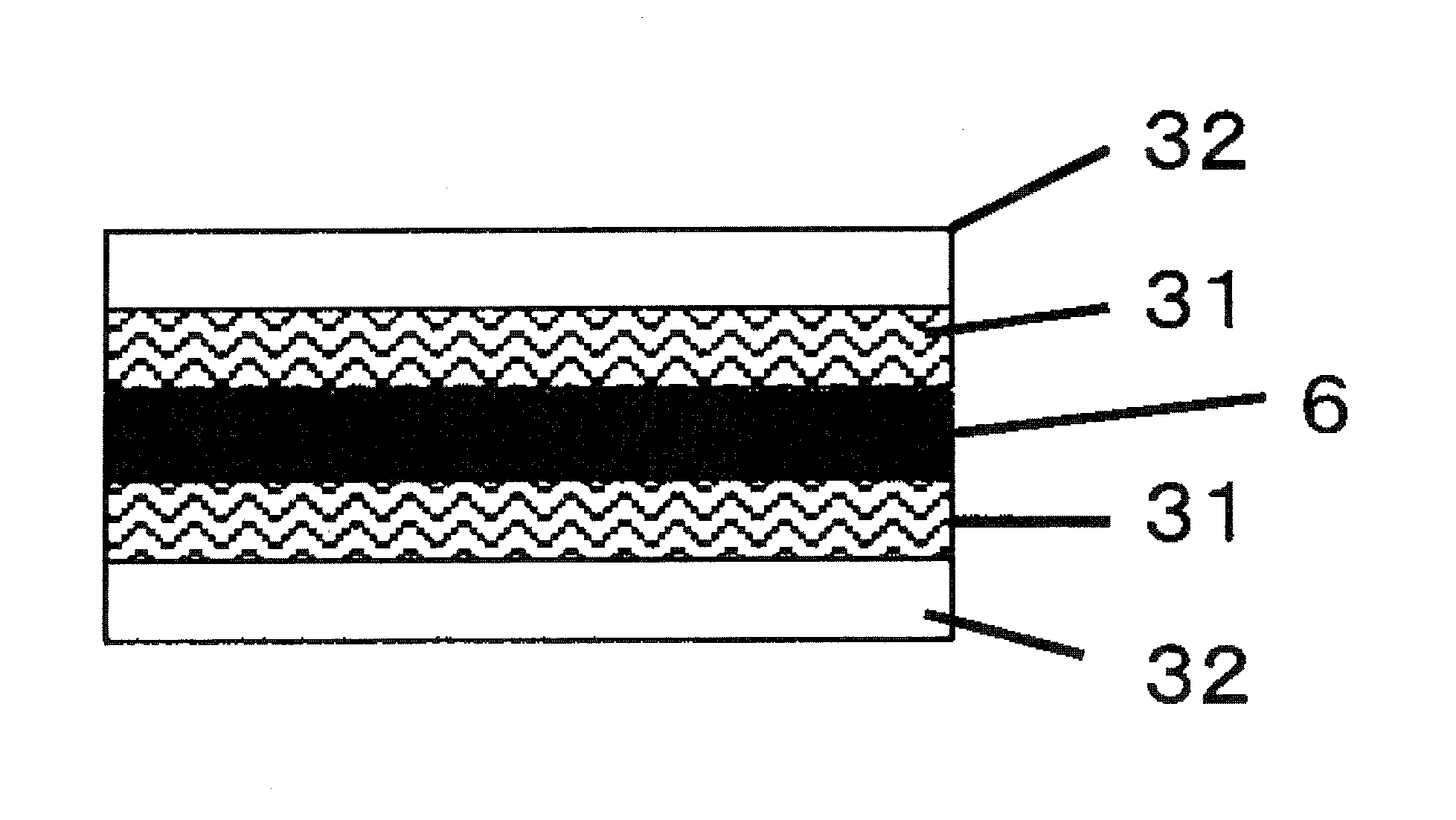

Graphite composite material

InactiveUS20150190982A1Suppress delaminationDelaminationCarbon compoundsSemiconductor/solid-state device detailsGraphite compositeMaterials science

Disclosed herein is a graphite composite material including a graphite film and a resin layer, wherein peeling-off of the resin layer from the graphite film is suppressed. The graphite composite material includes: a graphite film; and a resin layer formed on at least one surface of the graphite film, wherein the graphite film has through holes, wherein a number of the through is 100 to 1000 per cm2, and the through holes have a diameter of 0.10 mm or more but 1.00 mm or less, and wherein part of the resin layer is formed also in the through holes.

Owner:KANEKA CORP

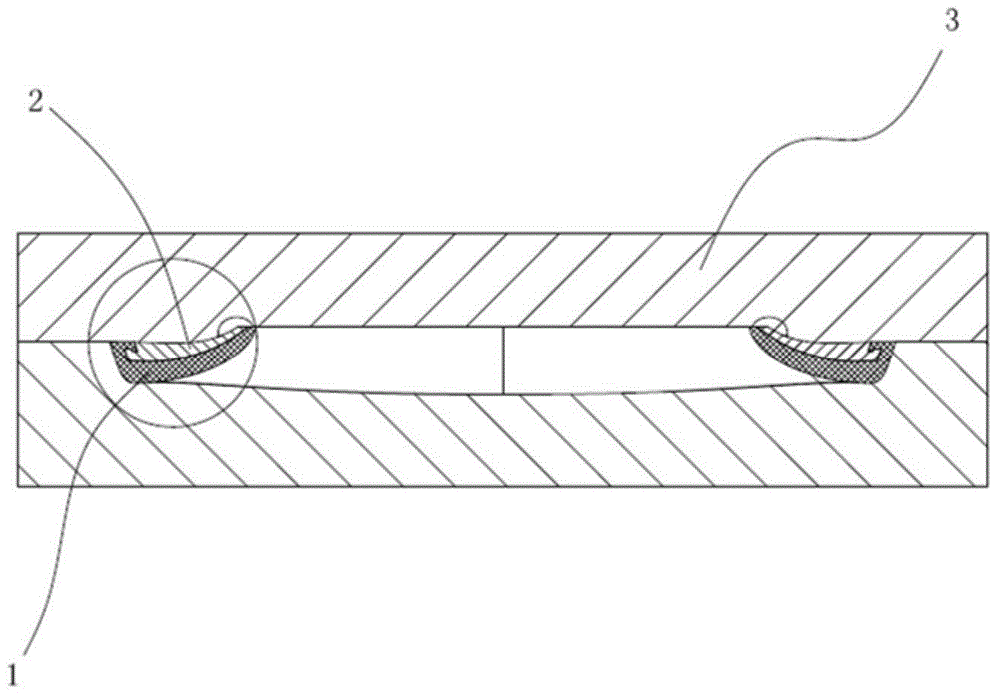

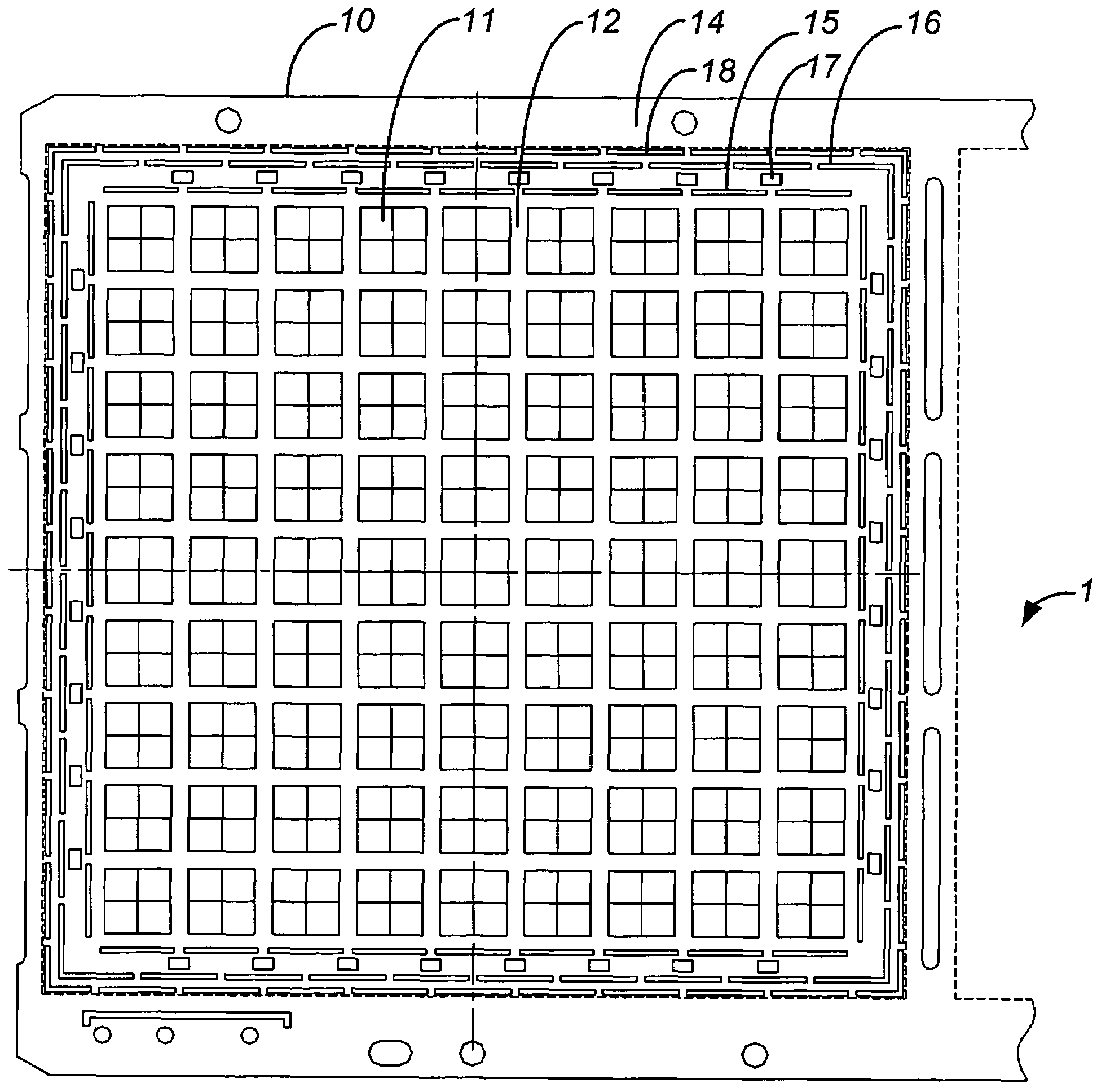

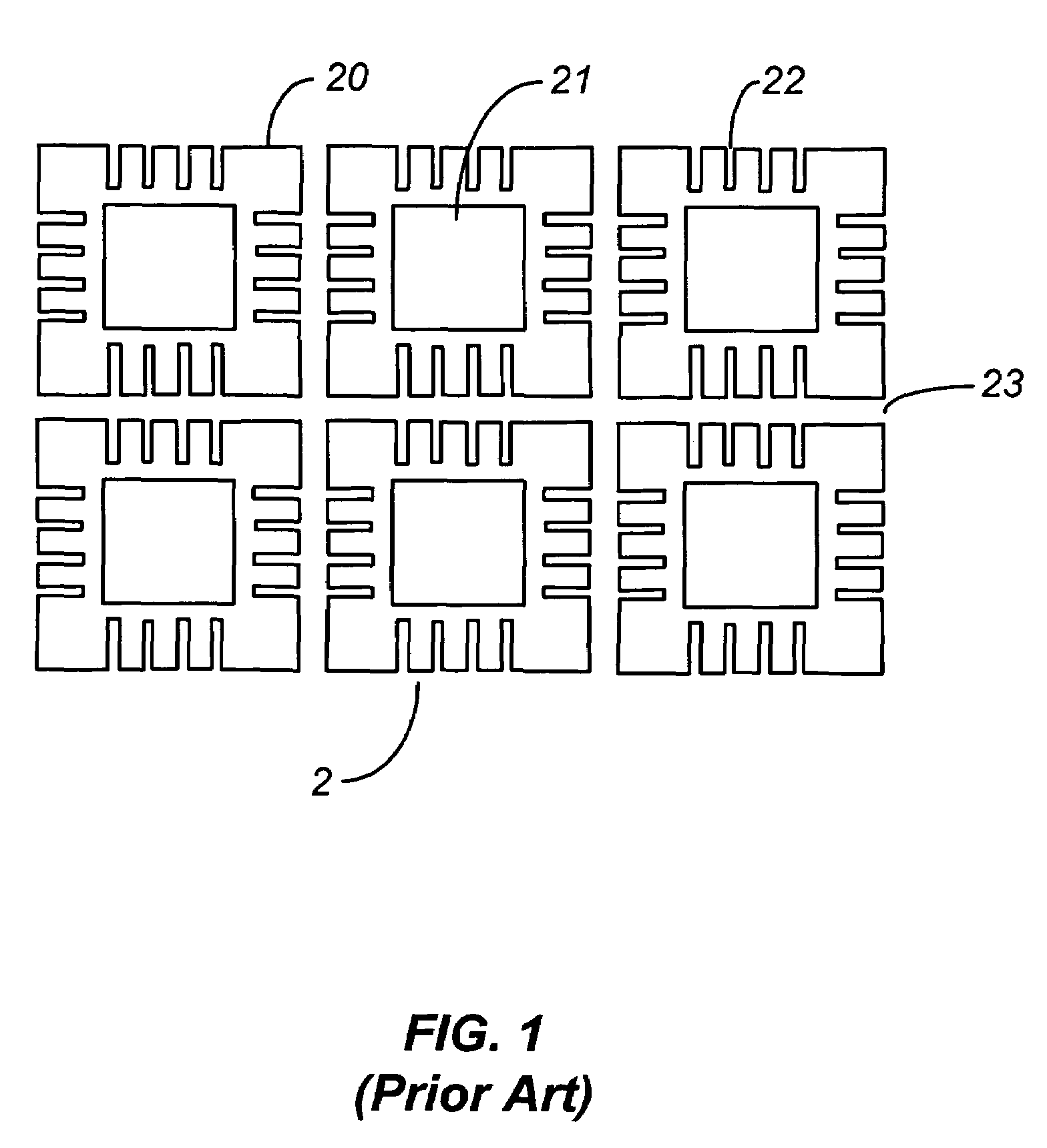

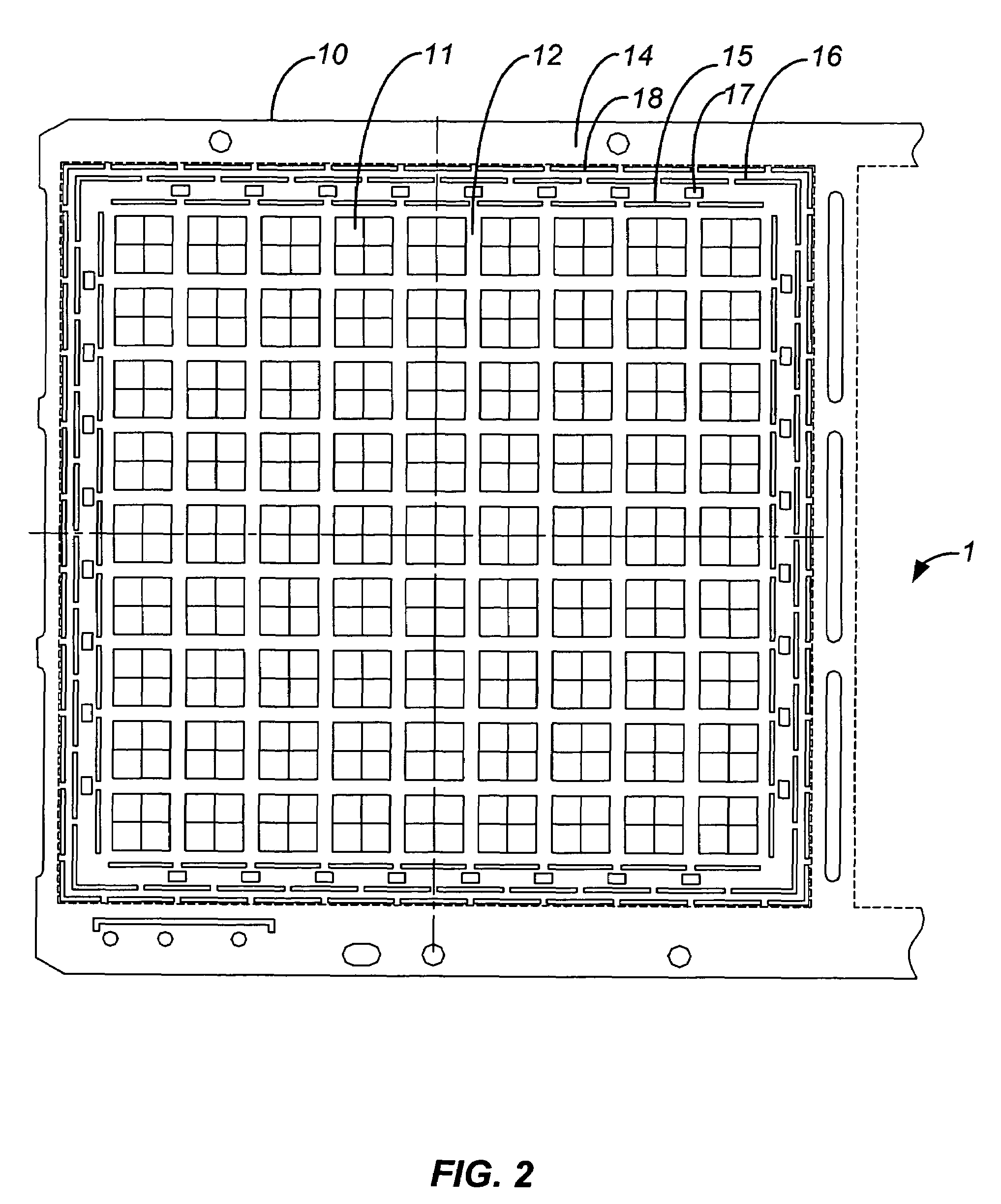

Stress-free lead frame

InactiveUS7288833B2DelaminationSimple designSemiconductor/solid-state device detailsSolid-state devicesStress reliefEngineering

The present invention relates to a stress-free lead frame (1) for a semiconductor. The stress-free lead frame (1) is provided with a stress-relief means (15) and an interlocking means (16) at the outer periphery. The stress-relief means (15) is capable of accommodating expansion and compression while the interlocking means (16) take care of shock and vibration during handling to thereby eliminate delamination of the lead frame (10).

Owner:CARSEM M

Method for weaving closed structures with intersecting walls

ActiveUS7960298B2DelaminationHigh damage toleranceOrnamental textile articlesSelvedgesShell moldingTransfer molding

The present invention generally relates to a woven preform for reinforced composite materials and a method of making thereof. Specifically, the present invention is a method of machine weaving fiber preforms for polymer matrix composites that consist of closed perimeters with multiple intersecting members in their interiors. More specifically, the invention is a woven preform and a method of forming thereof with closed cells at the outer edges with continuous hoop reinforcement in each cell of the preform. The woven preform is woven flat in both the warp and weft directions, and then unfolded to achieve the final shape of the structure, and can be processed into composite structural components using known methods such as resin transfer molding or chemical vapor infiltration. Thus, complicated shapes of all sizes can be woven on a conventional loom using the instant method.

Owner:ALBANY ENGINEERED COMPOSITES

Diamond-Covered Substrate, Filter And Electrode

InactiveUS20080014417A1Increased durabilityDelaminationDecorative surface effectsLayered productsElectrolysisCorrosion

By providing a substrate that can be used as an electrode, the invention solves the problem of corrosion of the substrate itself during an electrochemical oxidation treatment, the problem of discontinued electrolysis caused by delamination between a diamond layer and a substrate, or the problem of severely impaired electrolysis efficiency. The present invention is a diamond-covered substrate comprising a substrate and a conductive diamond layer covering the substrate, wherein the largest area of the portion where the diamond comprising the diamond layer is continuous ranges from 1 μm2 to 1,000 μm2. Preferably, the substrate is porous and has open pores, and the open pores preferably have a diameter from 0.1 μm to 1,000 μm.

Owner:SUMITOMO ELECTRIC IND LTD

Thin-shell sand culturing casting simple technology

InactiveCN104972066AAccelerated solidification coolingShorten the cooking and holding timeFoundry mouldsFoundry coresAluminium chlorideCrazing

The invention relates to a precision steel casting industry, and provides a thin-shell sand culturing casting simple technology for precision steel casting. A sodium silicate binder is adopted in shell manufacturing, quartz powder and the small amount of quartz fine sand are used in surface layer powder, a lubricating agent and an antifoaming agent are added to prepare a coating, quartz sand, two layers and a transition layer are scattered, and a coating is prepared through the sodium silicate binder, the quartz powder and mullite powder; mullite sand and a crystallization aluminium chloride solution are scattered to be hardened to prepare a thin shell; a reinforcing layer is not needed, roasting after dewaxing can shorten the heat preservation time, and burning through is easy; defects of shell layering, cracks, air holes, sand clamping, insufficient hardening and the like are overcome. Culturing sand in a dedicated sand box is put, after the sand is jolted through a vibration table, the sand is casted, and an abrasive disc upper cover box is lifted after 15 minutes to 30 minutes, and the culturing sand can fall in a sand collection hopper; sequential solidification cooling is accelerated, and the function of reinforcing the shell in a multilayer manner is achieved; the production period is short, the technology is simple, and the cost is low; compared with an original reinforcing layer shell casting, the cost of a casting of each tonnage is reduced by about 200 yuan; and the technology is suitable for manufacturing pump valve type fine castings of large specifications.

Owner:江苏万恒铸业有限公司

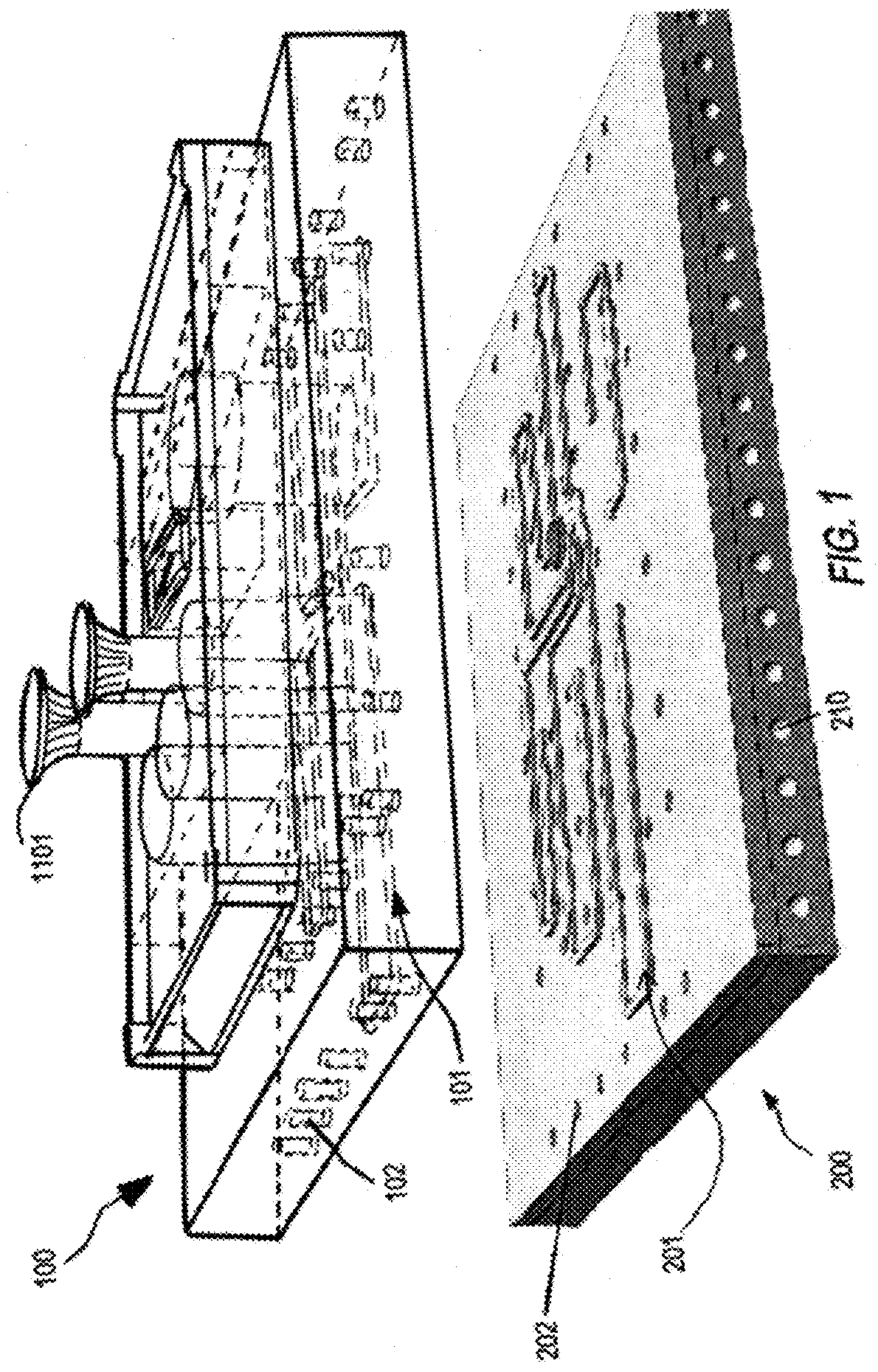

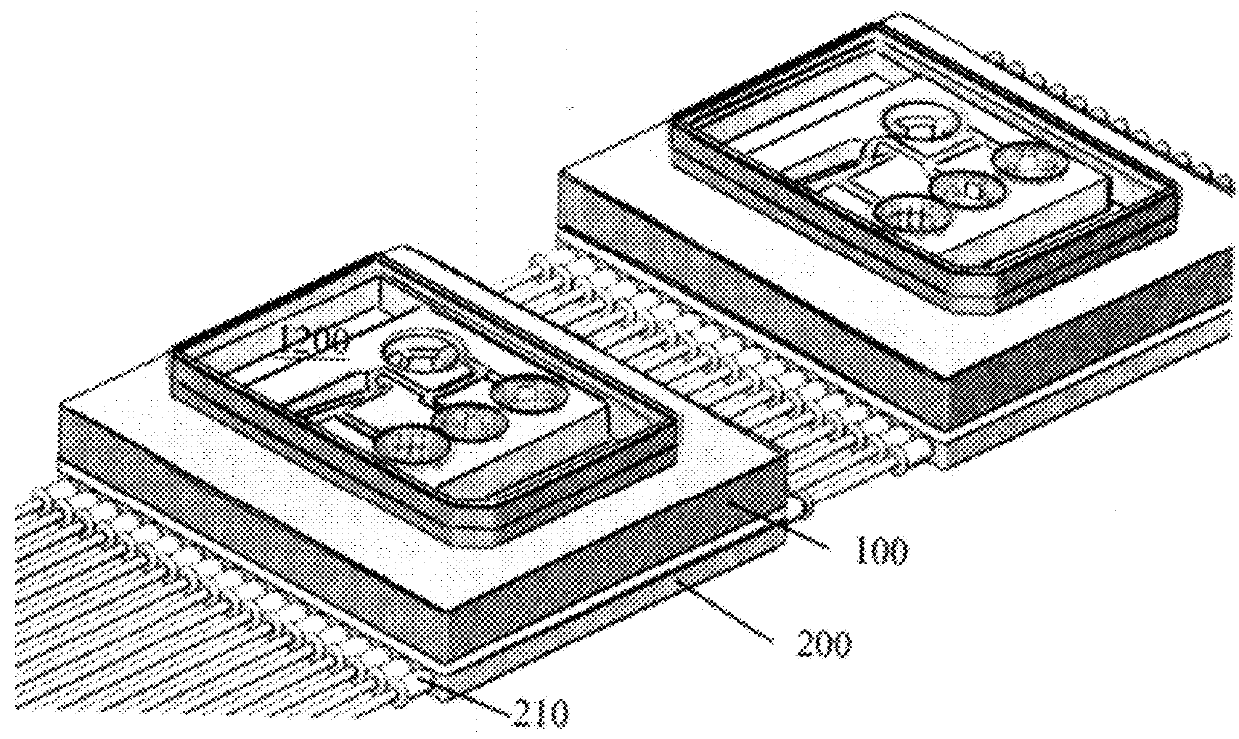

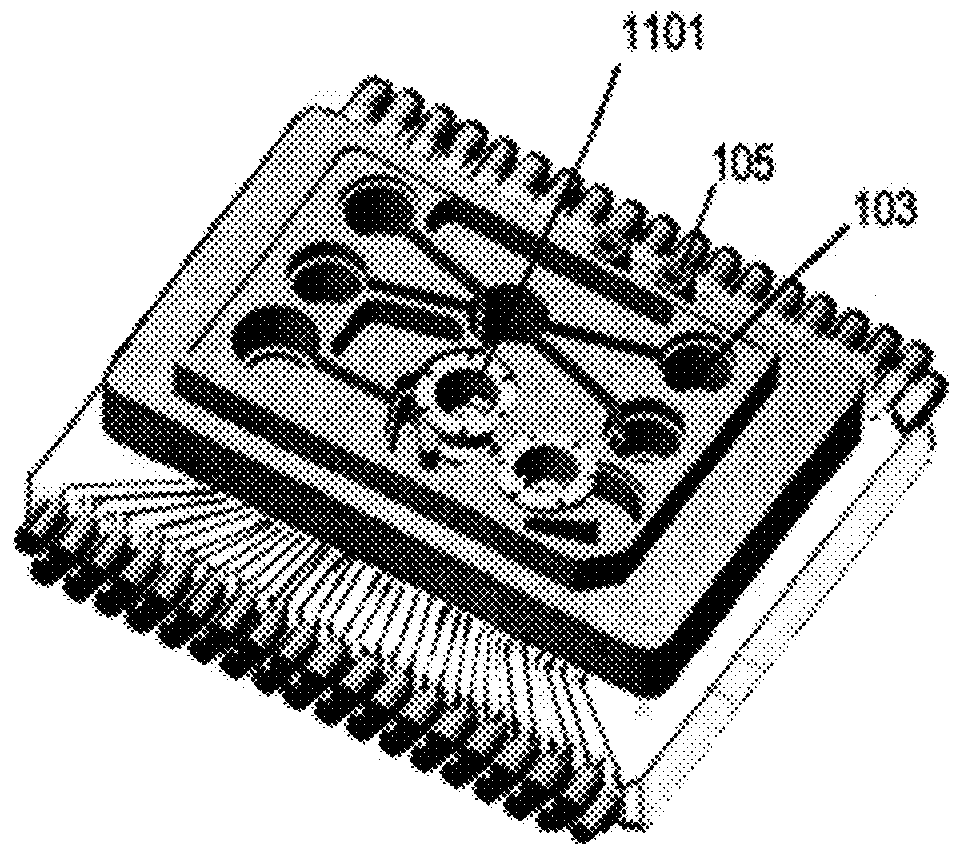

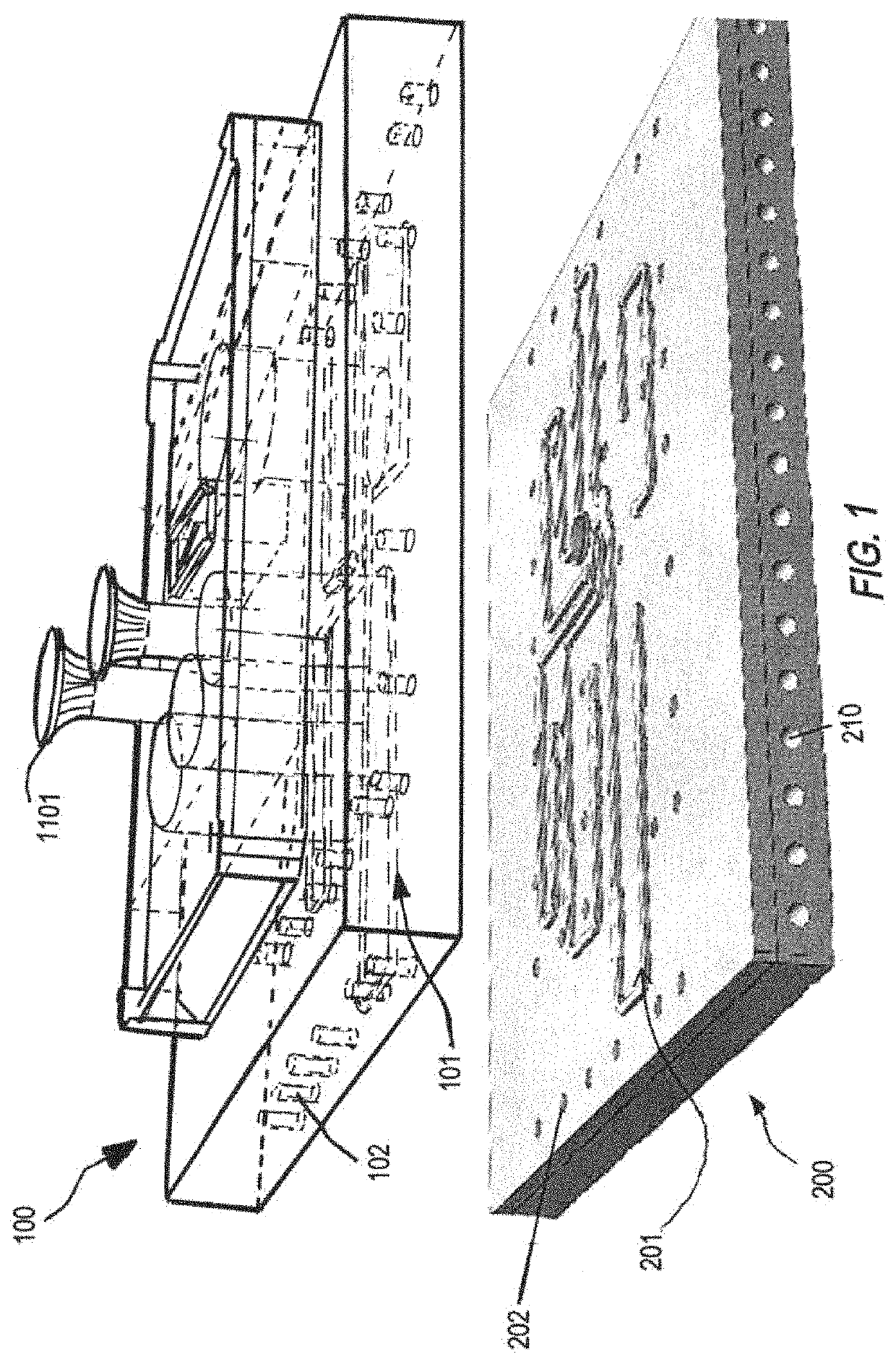

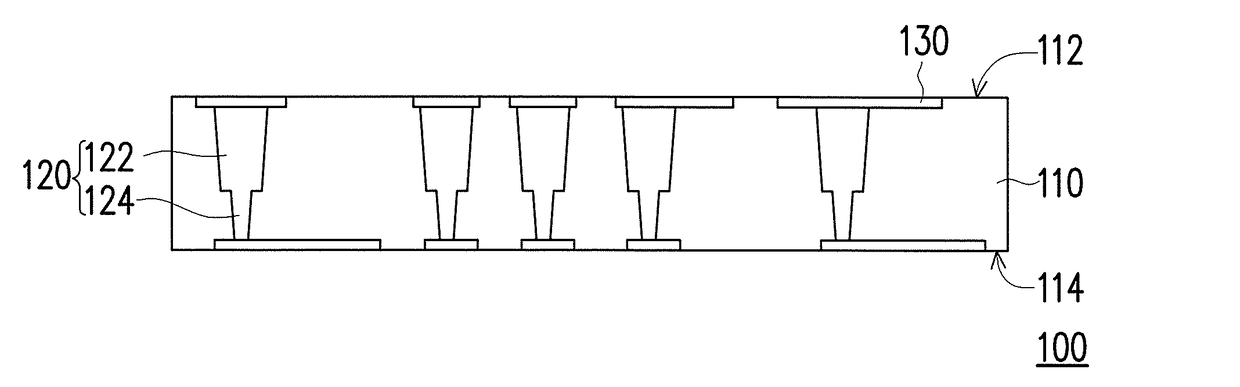

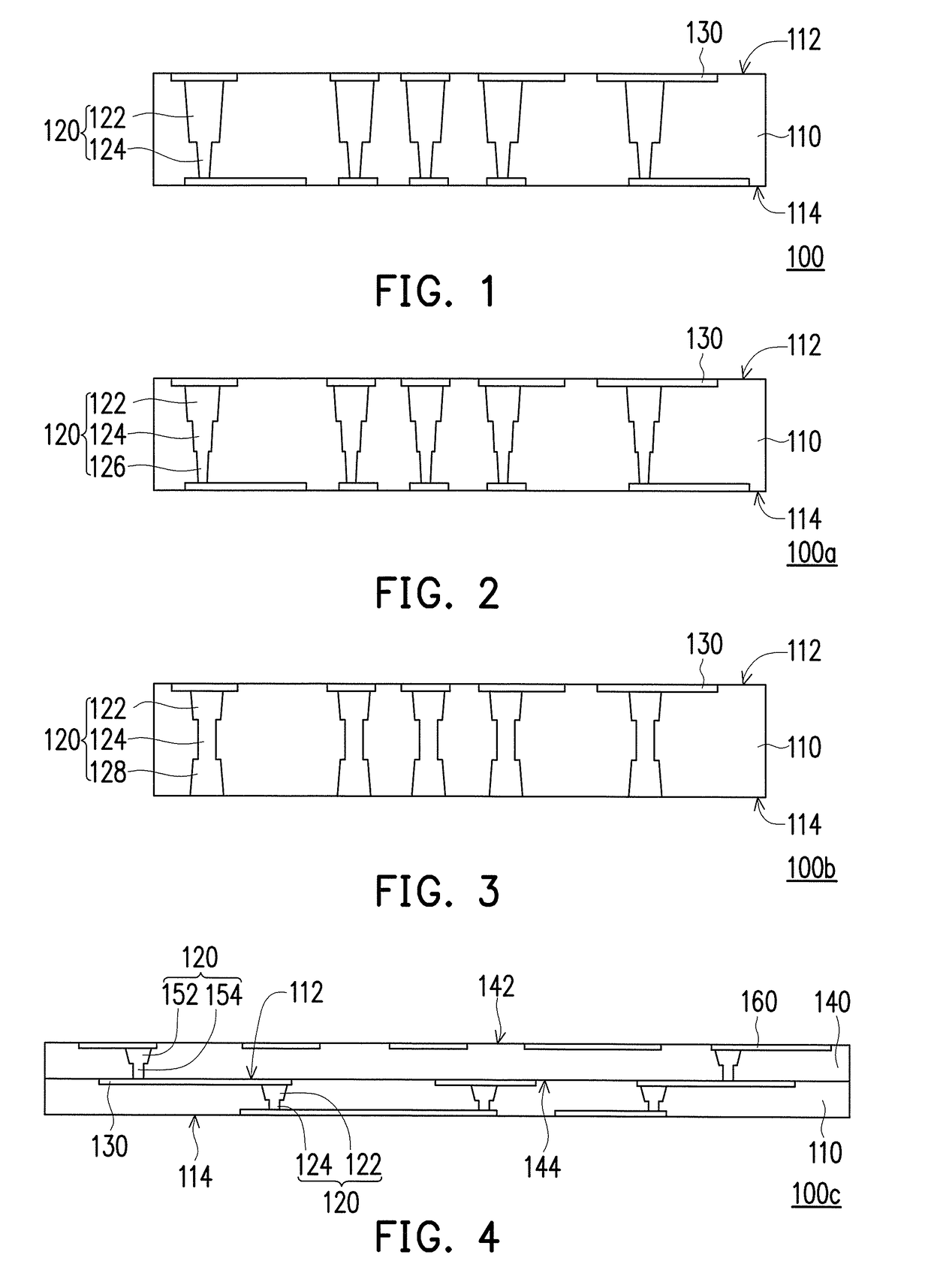

Modular organ microphysiological system with integrated pumping, leveling, and sensing

ActiveUS10876088B2Improve reliabilityLow costBioreactor/fermenter combinationsBiological substance pretreatmentsMulti organDaisy chain

Fluidic multiwell bioreactors are provided as a microphysiological platform for in vitro investigation of multi-organ crosstalks for an extended period of time of at least weeks and months. The disclosed platform is featured with one or more improvements over existing bioreactors, including on-board pumping for pneumatically driven fluid flow, a redesigned spillway for self-leveling from source to sink, a non-contact built-in fluid level sensing device, precise control on fluid flow profile and partitioning, and facile reconfigurations such as daisy chaining and multilayer stacking. The platform supports the culture of multiple organs in a microphysiological, interacted systems, suitable for a wide range of biomedical applications including systemic toxicity studies and physiology-based pharmacokinetic and pharmacodynamic predictions. A process to fabricate the disclosed bioreactors is also provided.

Owner:MASSACHUSETTS INST OF TECH

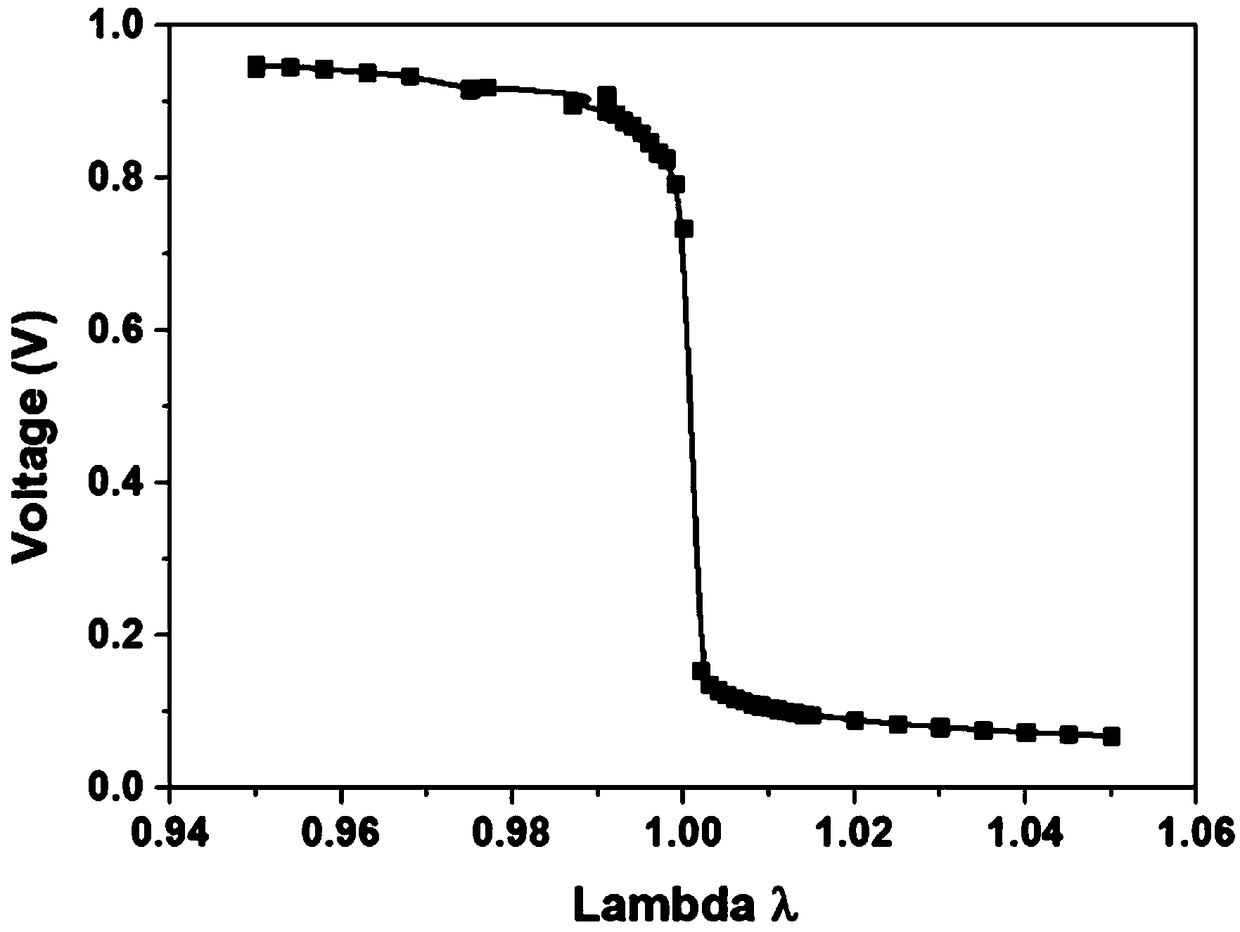

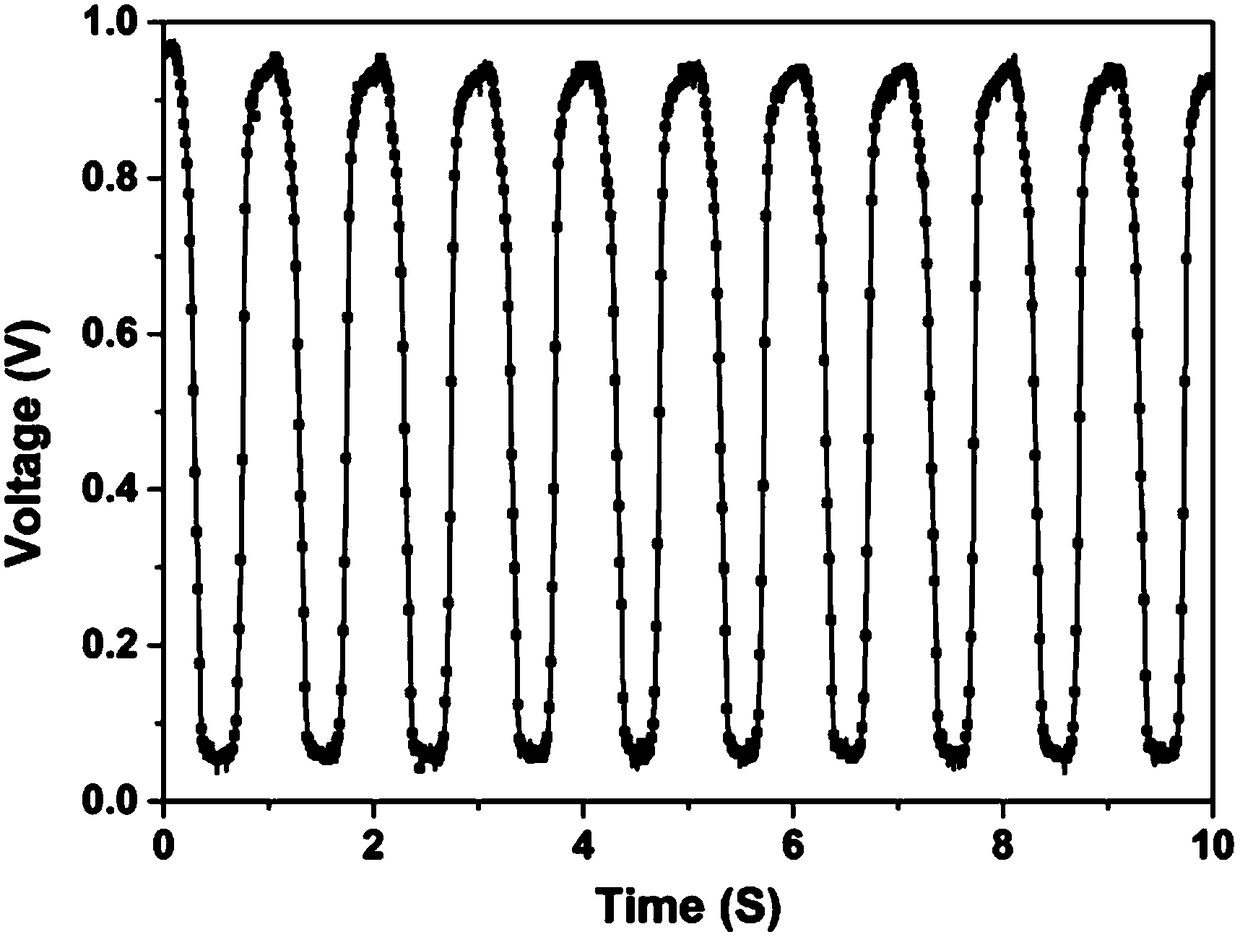

Disk type oxygen sensor for motorcycle and preparation method thereof

ActiveCN108760823AAvoid changes in reference gas oxygen concentrationHigh sensitivityMaterial analysis by electric/magnetic meansCeramicwarePower flowOxygen sensor

The invention discloses a disk type oxygen sensor for a motorcycle. The disk-type oxygen sensor comprises a porous protection layer, a functional layer, a diffusion layer and a heating layer which aresequentially overlapped and sintered from top to bottom, wherein a porous aluminum oxide substrate is arranged at one end of the porous protection layer, and a first aluminum oxide substrate is arranged at the other end of the porous protection layer; the functional layer comprises a first zirconium oxide substrate, an internal electrode and an external electrode, and the internal electrode and the external electrode are arranged on the two sides of the first zirconium oxide substrate; the diffusion layer comprises a second zirconium oxide substrate and a diffusion channel arranged above thesecond zirconium oxide substrate; the heating layer comprises a second aluminum oxide substrate and a third aluminum oxide substrate which are sequentially overlapped from top to bottom, and a heateris arranged on the third aluminum oxide substrate. In work of the disk type oxygen sensor for the motorcycle, pump current serving as testing reference is exerted on the internal electrode and the external electrode. The invention further discloses a preparation method of the disk type oxygen sensor for the motorcycle. The disk type oxygen sensor disclosed by the invention is compact in structureand is suitable for a motorcycle tail gas exhausting system.

Owner:成都科锐传感技术有限公司

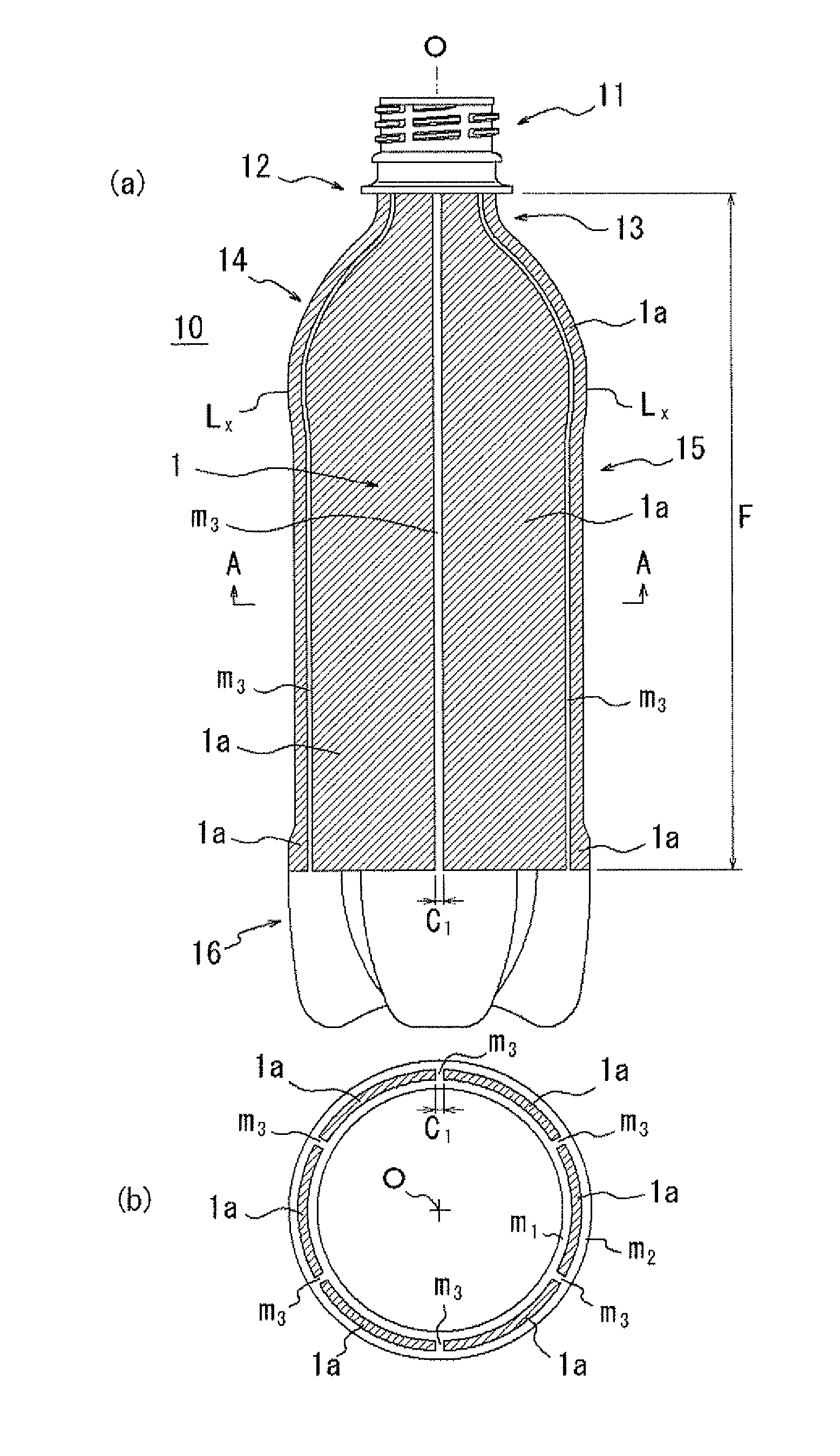

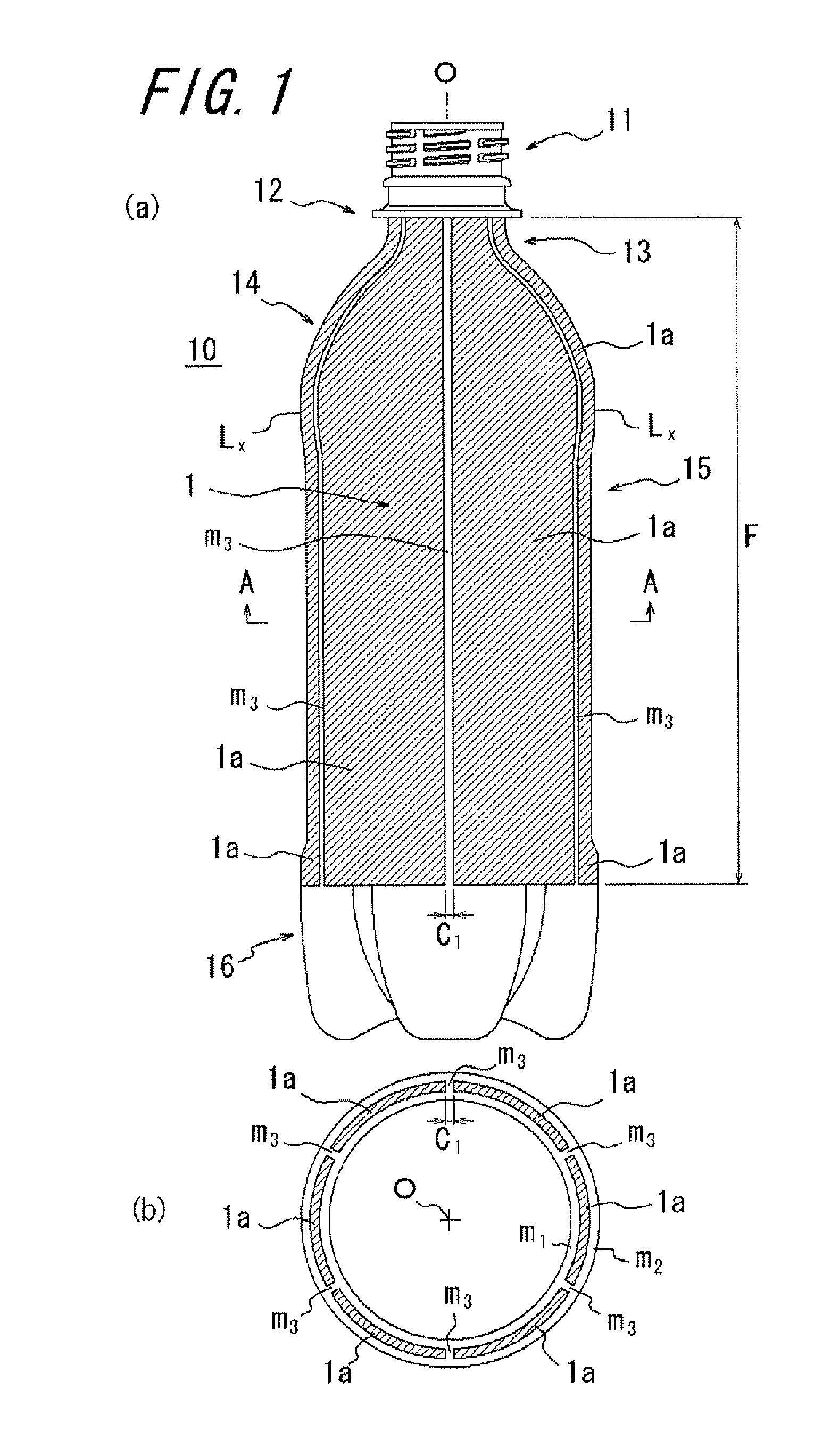

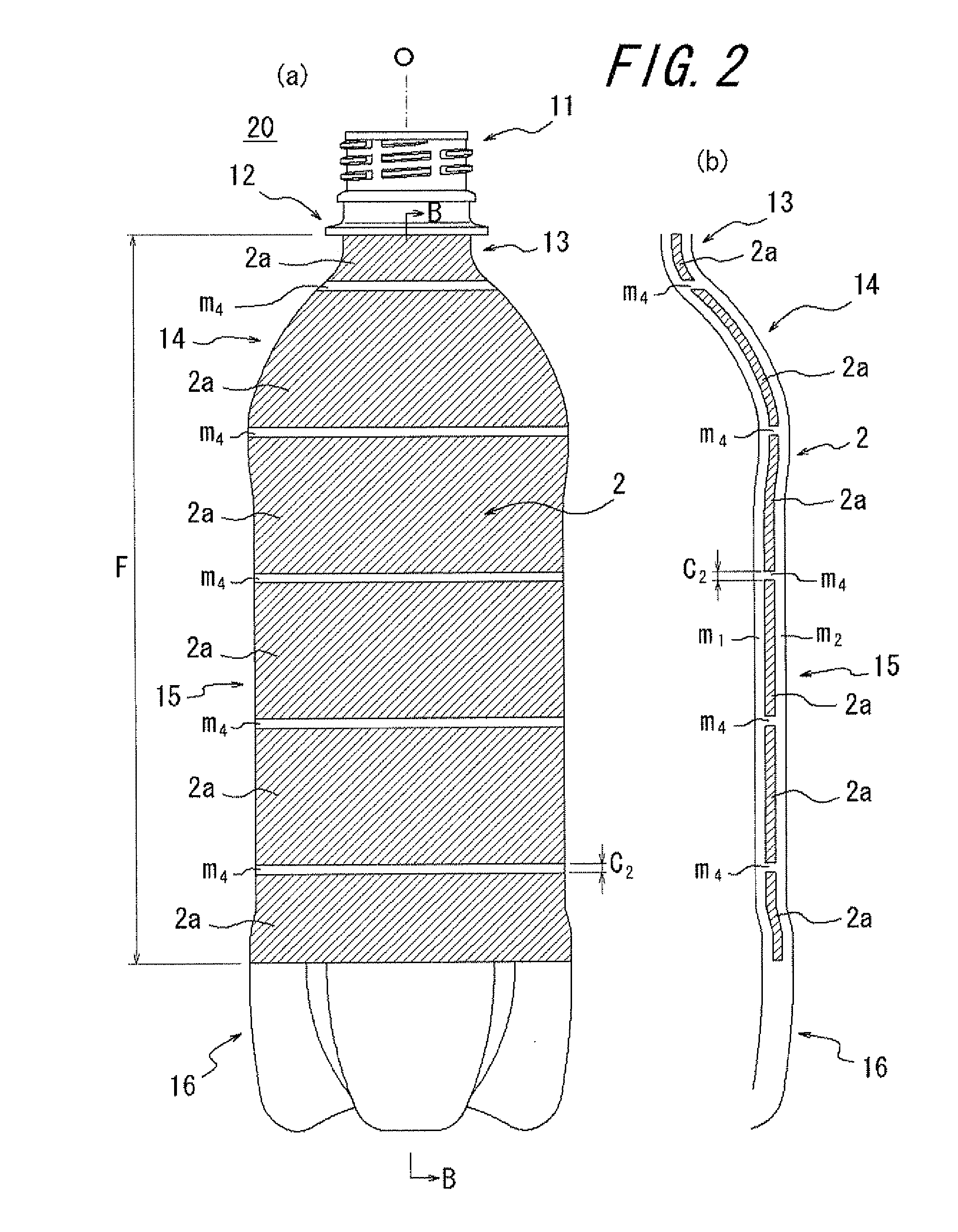

Laminated bottle

ActiveUS20100314281A1DelaminationBetter overall contouringPackage recyclingWrappersPolyester resinEngineering

A laminated bottle with a gas barrier resin layer arranged between polyester resins layers is provided. The gas barrier resin layer includes a plurality of quadrangular segments with two sides extending along the bottle axis and two sides extending around the bottle axis, wherein the segments are arranged at a distance to each other via connecting layers which connect the inner layer and the outer layer.

Owner:YOSHINO KOGYOSHO CO LTD

Apparatus and method for removing epithelium from the cornea

ActiveUS8834916B2Facilitating de-epithelializationSoftens a corneal epitheliumBiocideOrganic active ingredientsMedicineCornea surface

An apparatus and a method for removing epithelium from the cornea include a fluid agent for facilitating de-epithelialization of the cornea. A disc includes a biocompatible material operable for covering a predetermined zone of a cornea. The disc is hydrated by the fluid agent, wherein the hydrated disc is pliable for conforming to a surface of the cornea. An application of the hydrated disc to the cornea substantially constrains the fluid agent to the determined zone and softens a corneal epithelium enabling delamination of the epithelium from an underlying stroma.

Owner:NEWMAN LEONARD A

Semiconductor structure

InactiveUS20170077045A1Improve reliabilityEffectively reduces diameterSemiconductor/solid-state device detailsPrinted circuit aspectsSemiconductor structureMaximum diameter

A semiconductor structure includes an insulating layer, a plurality of stepped conductive vias and a patterned circuit layer. The insulating layer includes a top surface and a bottom surface opposite to the top surface. The stepped conductive vias are disposed at the insulating layer to electrically connect the top surface and the bottom surface. Each of the stepped conductive vias includes a head portion and a neck portion connected to the head portion. The head portion is disposed on the top surface, and an upper surface of the head portion is coplanar with the top surface. A minimum diameter of the head portion is greater than a maximum diameter of the neck portion. The patterned circuit layer is disposed on the top surface and electrically connected to the stepped conductive vias.

Owner:IBIS INNOTECH

Method of production of a conductive particle, conductive paste, and method of production of electronic device

InactiveUS8075949B2Superior in wettability and bondabilityAvoid disconnectionLiquid surface applicatorsTransportation and packagingConductive pasteAdditive ingredient

A method of production of conductive particles able to suppress growth of the conductive particles at the firing stage, able to effectively prevent spheroidization and electrode disconnection, able to effectively suppress a drop in electrostatic capacity, and able to efficiently produce core particles covered by thin coating layers without abnormal segregation of the coating layer metal particularly even when the internal electrode layers are reduced in thickness. A method of producing conductive particles comprising cores 51 having nickel as their main ingredients and coating layers 52 covering their surroundings. A core powder, a water-soluble metal salt containing a metal or alloy forming the coating layers 52, and a surfactant (or water-soluble polymer compound) are mixed to deposite by reduction a metal or alloy for forming the coating layers 52 on the outer surfaces of the core powder. The metal or alloy forming the coating layers 52 has at least one type of elements selected from Ru, Rh, Re, and Pt as a main ingredient.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com