Industrial automatic three-dimensional detection system and method

An industrial automation and three-dimensional detection technology, which is applied in the field of product and parts manufacturing and processing, can solve the problems that cannot meet the requirements of production line batch detection, and the application of three-dimensional detection technology is slow, so as to meet the needs of production line batch intelligent detection , reduce the cumulative stitching error, avoid the effect of movement and angle conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

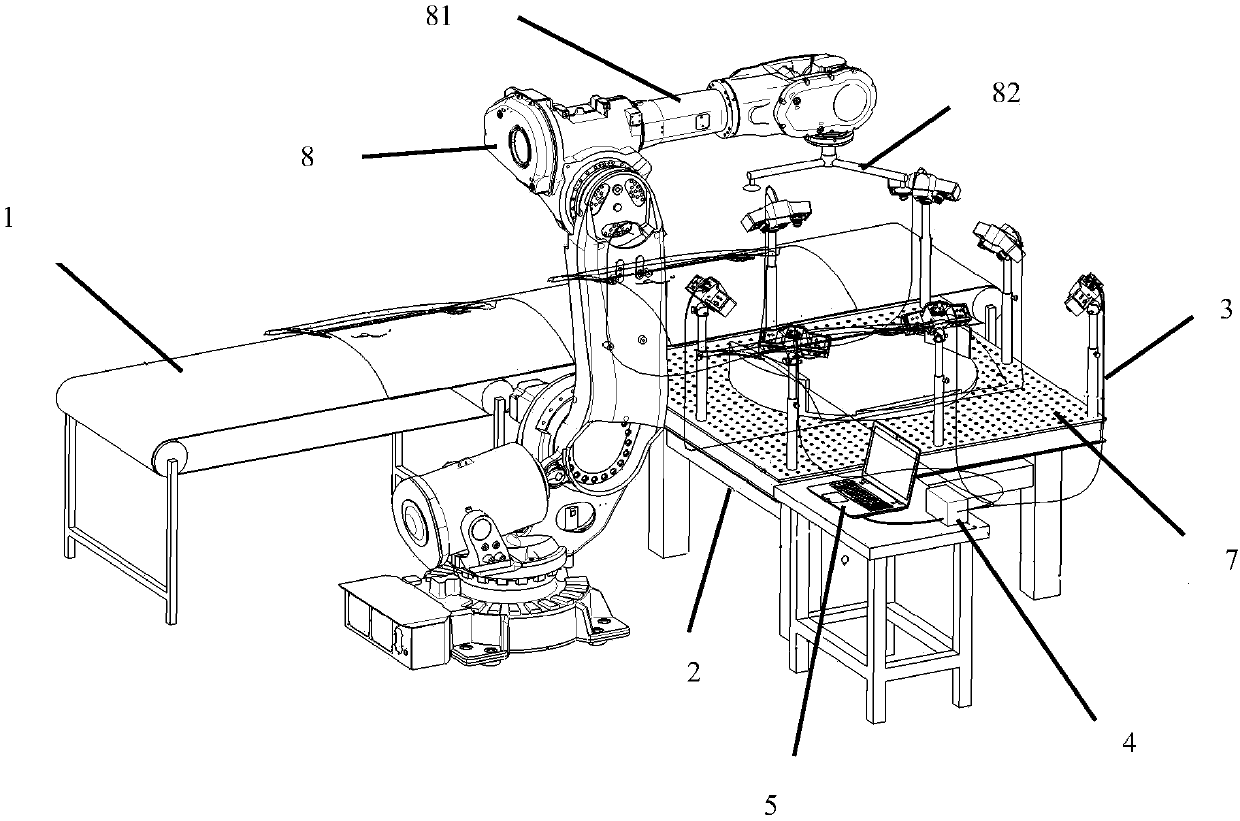

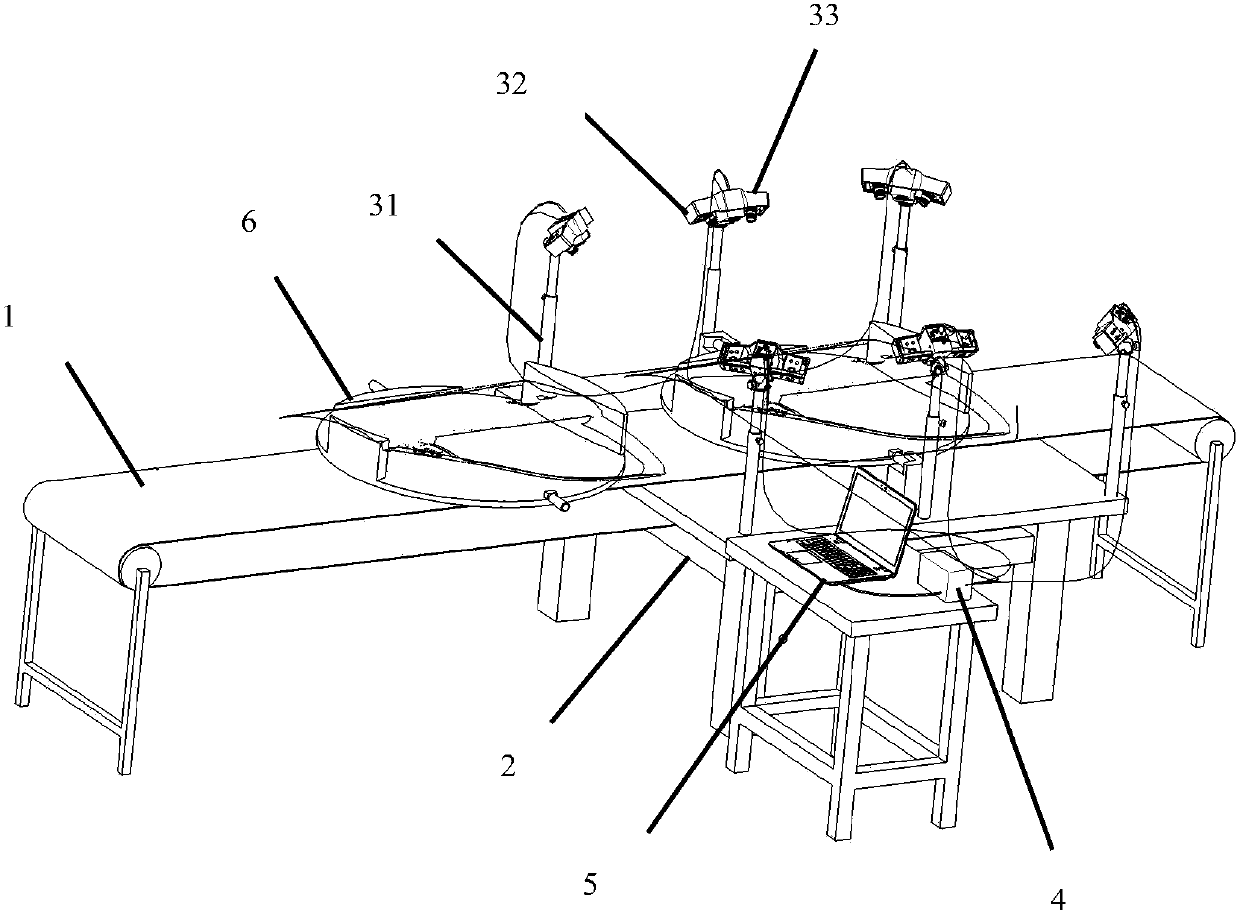

[0029] Such as figure 1 , figure 2 As shown, an industrial automatic three-dimensional detection system includes a workpiece transmission system 1, a working platform 2, a single or multiple three-dimensional optical scanning devices 3, a data transfer station 4, and a computer terminal 5. The middle section of the workpiece transmission system 1 is a A work platform 2 is provided on the side or in a closed space, and the work platform 2 is provided with a single or multiple three-dimensional optical scanning devices 3 according to the detection requirements in a multi-angle and omnidirectional space, and the single or multiple three-dimensional optical scanning devices 3 are connected to the The data transfer station 4 is signal connected, and the data transfer station 4 is connected with the computer terminal 5. The computer terminal 5 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com