Automobile buckle insertion and extraction force and stress-strain test fixture

A stress-strain testing, inserting and pulling force technology, applied in manufacturing tools, workpiece clamping devices, etc., can solve the problems of affecting the experimental results, inability to guarantee, fixed U-shaped slot opening size, etc., to increase flexibility, disassembly and assembly. Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

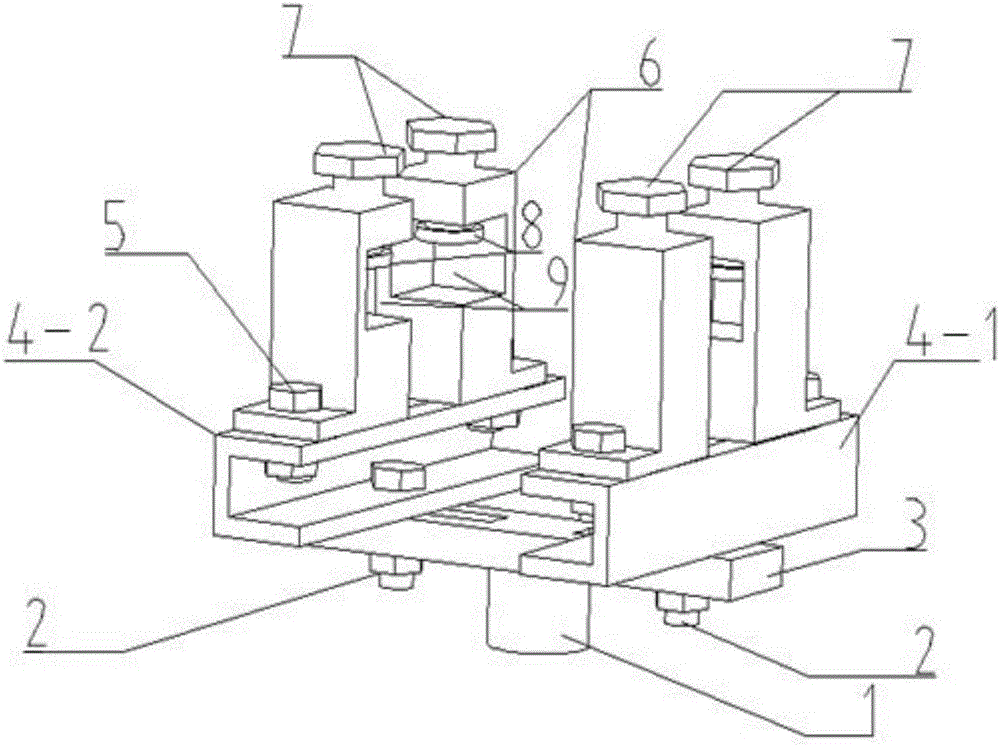

[0044] refer to figure 1 , an automobile buckle insertion force and stress-strain test fixture, the test fixture includes two parts: an insertion force fixture and a pull-out force fixture corresponding to the insertion force fixture; the test fixture includes an insertion force fixture and a corresponding to the insertion force fixture There are two parts of the pull-out force fixture; one end of the simulated buckle 23 is fixed on the simulated test pieces one and two 21, 22, and the other end is fixed on the pull-out force fixture; the simulated test pieces one and two 21 , 22 are fixed on the insertion force fixture.

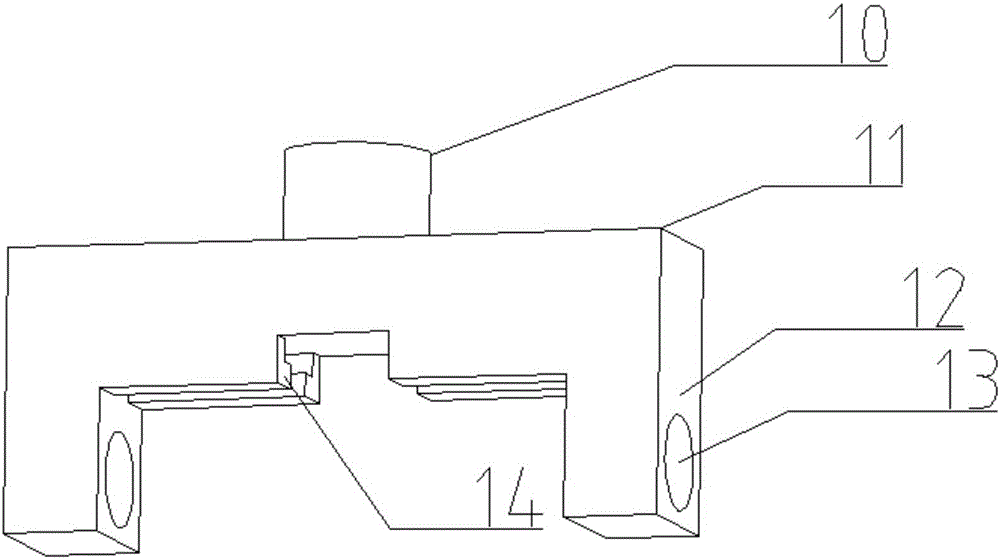

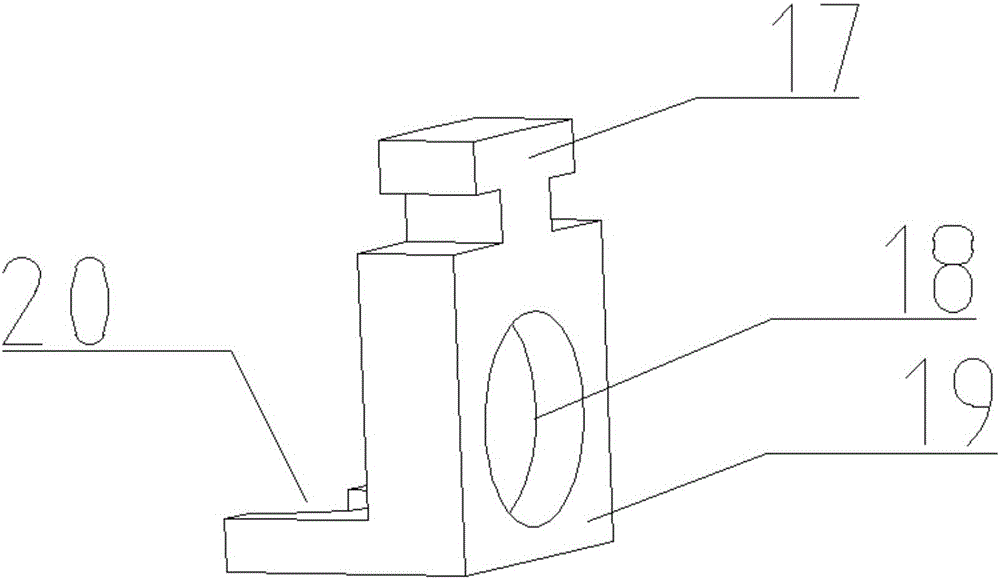

[0045] The insertion force fixture comprises an insertion force fixture clamping block 1 connected with a testing machine, a first body 3, a second body 4-1, a third body 4-2, 4 fixed sliders 6 and 4 pressing Tight circular plate 8; the first body 3 is a cuboid structure, on which a first track is provided, and a scale line is provided on one side of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com