Construction method for roadbed filling and device thereof

A technology for construction equipment and roadbed, applied in the directions of roads, roads, buildings, etc., can solve the problems of reducing the efficiency of roadbed filling, wasting mechanical resources, and limited leveling range, and achieves the effect of improving leveling efficiency, saving costs, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings.

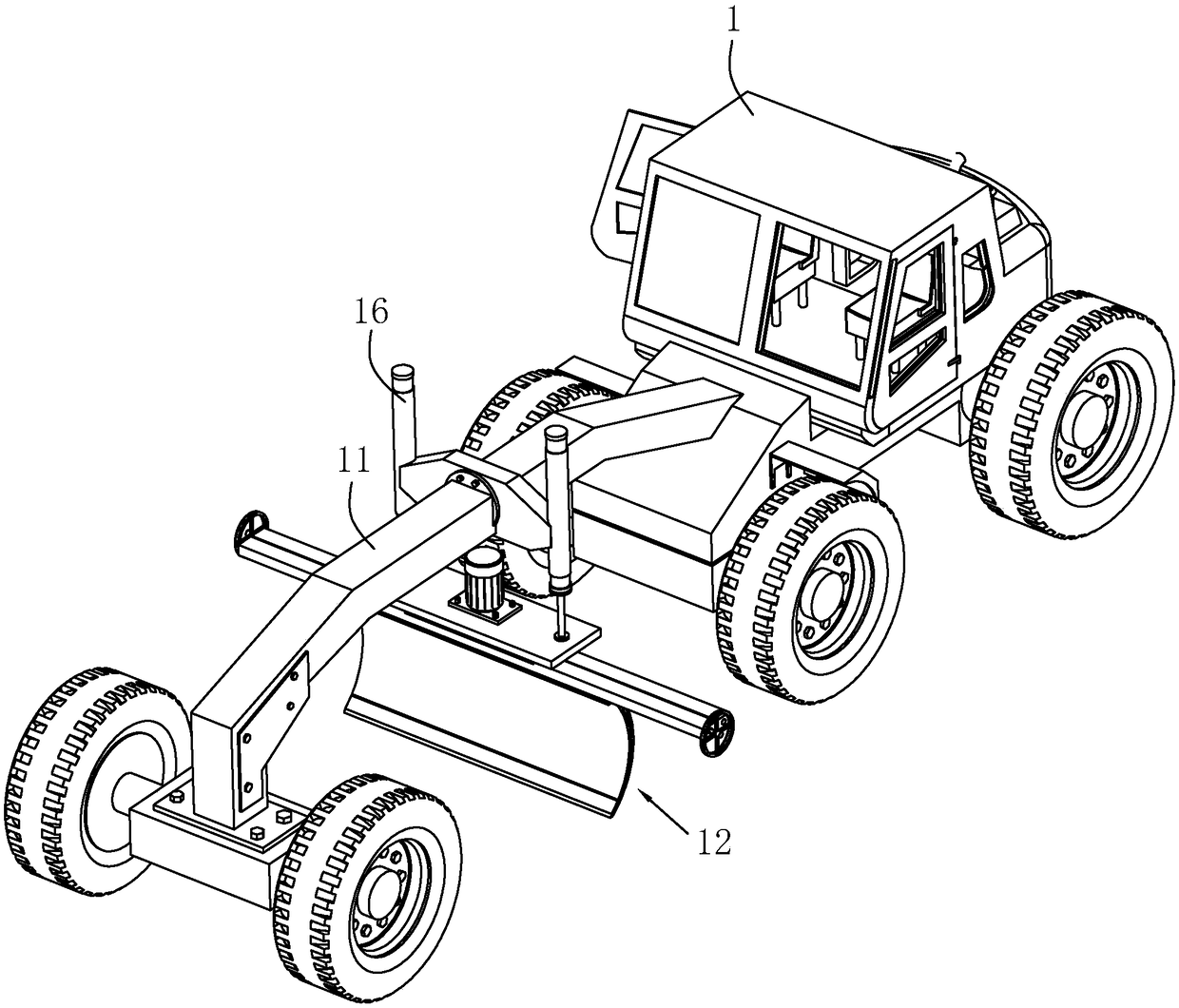

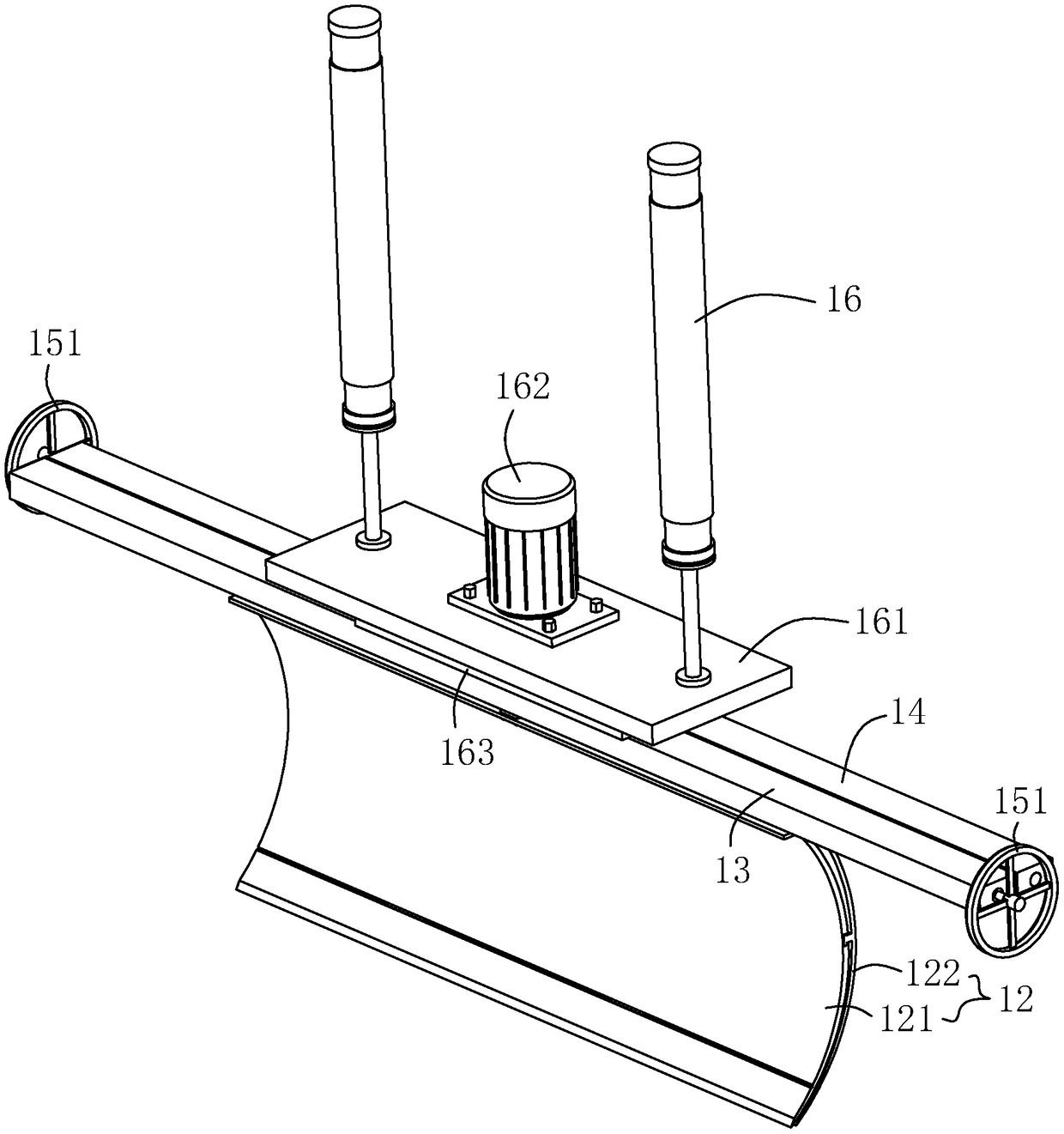

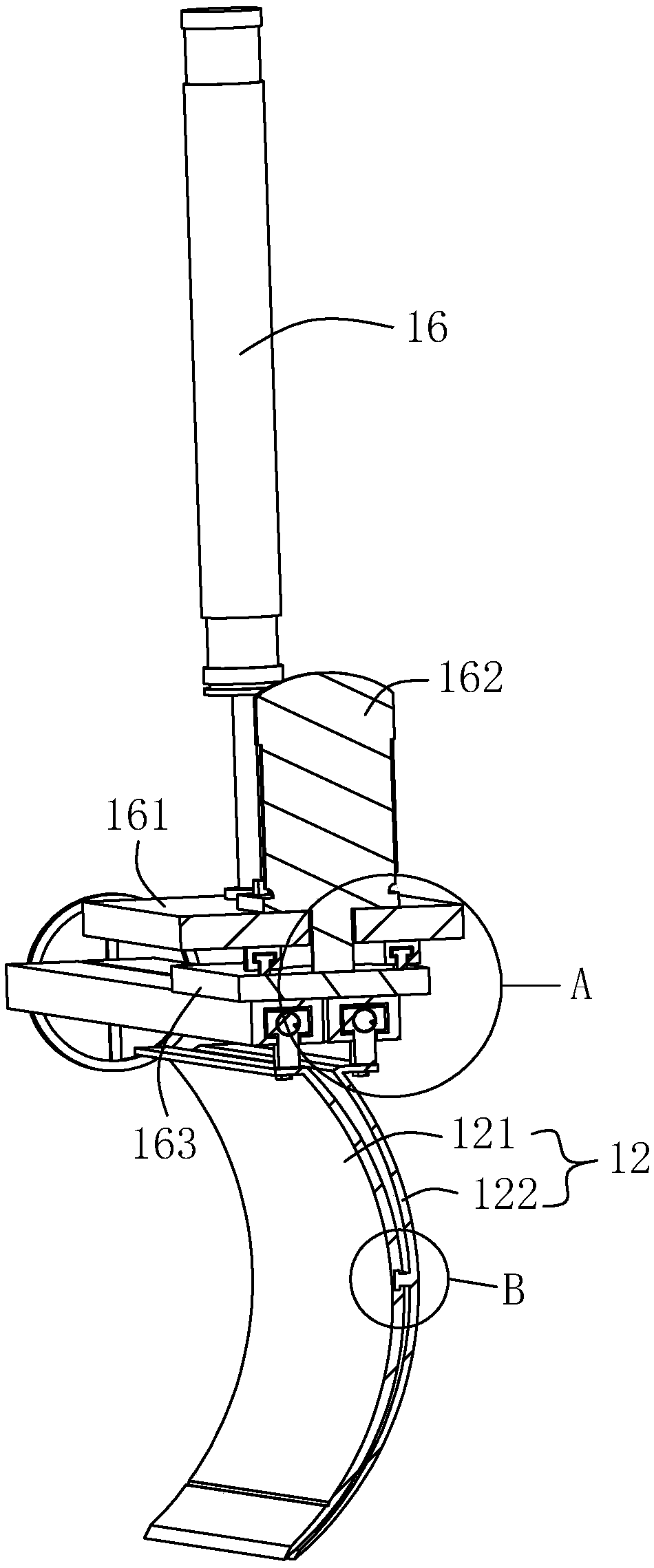

[0051] combine figure 1 and figure 2 , is a roadbed filling construction equipment disclosed in the present invention, comprising a body 1, a beam 11 is arranged on the body 1, a spatula 12 is arranged under the beam 11, and the spatula 12 includes a first scraper 121 and is parallel to the first scraper 121. And the second scraper 122 is attached to it.

[0052] combine figure 1 and figure 2 On the crossbeam 11 and on both sides of the crossbeam 11, a cylinder 16 is fixedly arranged, and a plate body 161 is arranged on the driving end of the cylinder 16 on both sides, and a motor 162 is fixedly arranged on the surface of the board body 161 facing the crossbeam 11. The end is vertical and set through the plate body 161. The drive end of the motor 162 is provided with a drive plate 163 parallel to the plate body 161. The drive plate 163 is fixedly provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com