Environment-friendly water-based double-component polyurethane floor coating

A two-component polyurethane and floor coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor weather resistance of epoxy resin, brittle and easy cracking of the coating film, unsatisfactory, and achieve good chemical resistance. Character, not easy to float and flower, the effect of overcoming inherent shortcomings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

[0022] Embodiment 1~2 prepares the second component of environment-friendly waterborne two-component polyurethane floor paint

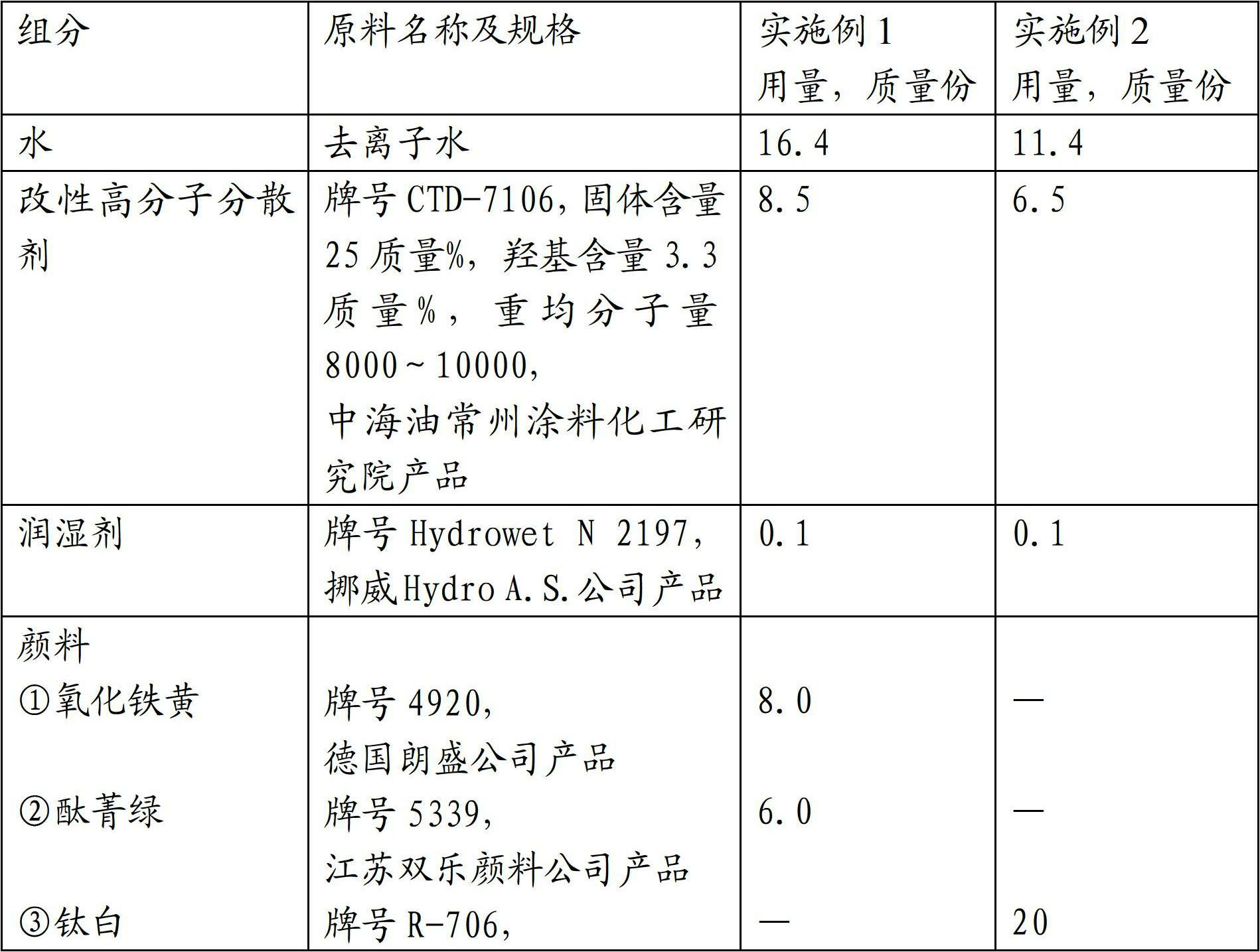

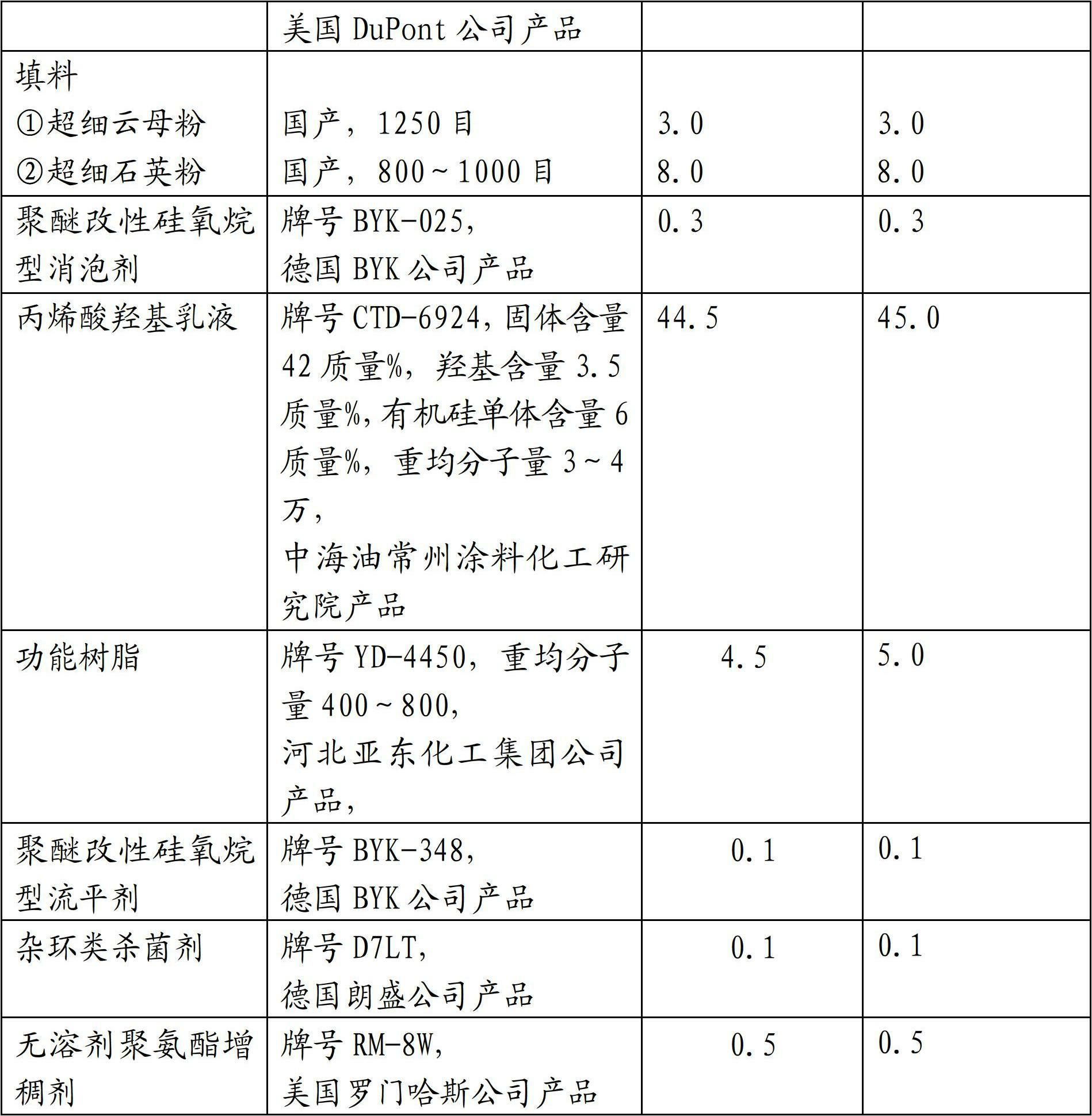

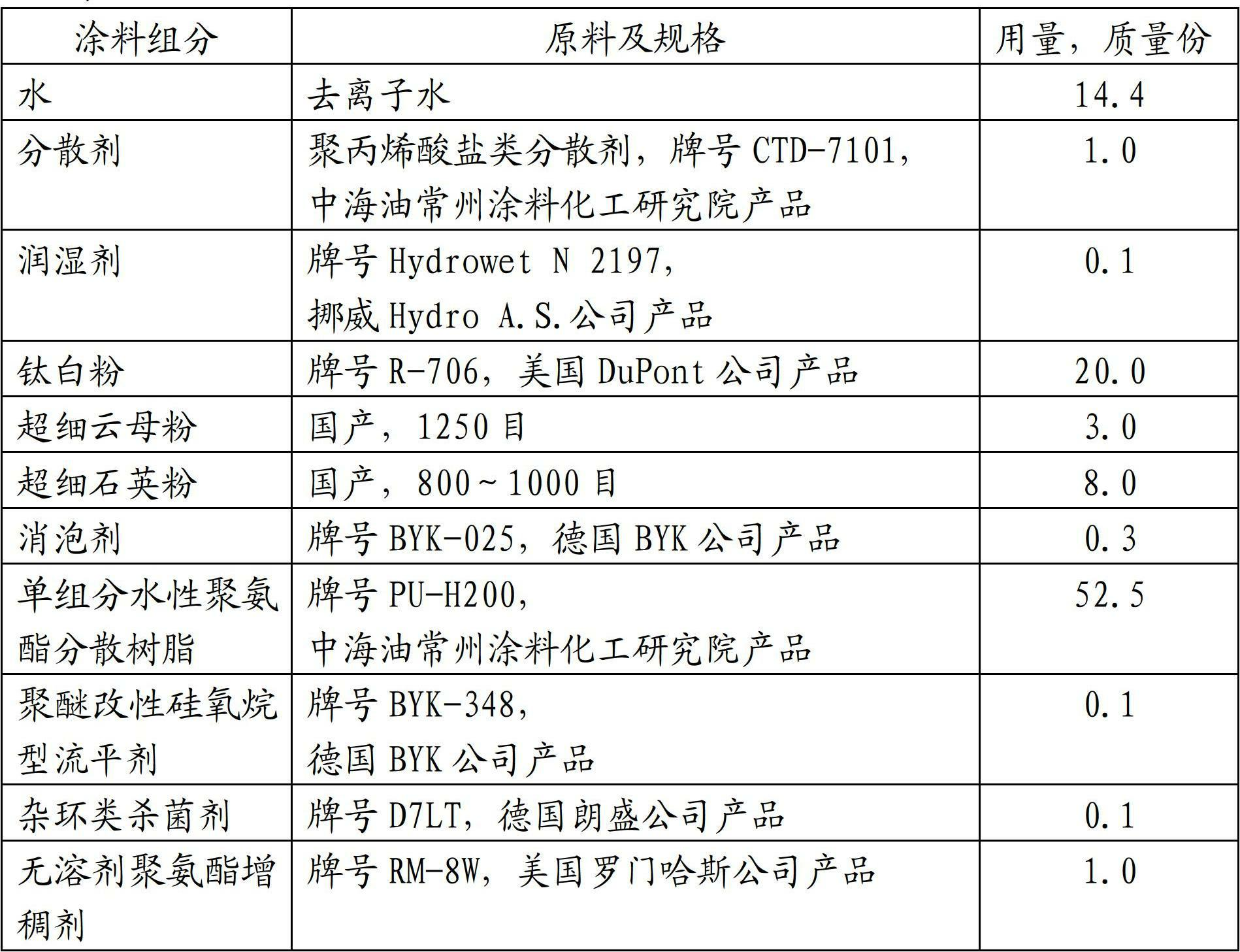

[0023] (1) Component B formula

[0024] Component B of the present invention is composed of the following components, and the mass parts of each component are: 10-18 water, 4-10 modified polymer dispersant, 0.1-0.3 nonionic and / or anionic wetting agent , Pigment 2~20, Filler 3~15, Acrylic hydroxyl emulsion 40~70, Functional resin 3~6, Polyether modified siloxane type defoamer 0.1~0.5, Polyether modified siloxane type leveling agent 0.1 to 0.3, heterocyclic bactericide 0.1 to 0.3, solvent-free polyurethane thickener 0.2 to 1.0, see Table 1 for the specific formulations of components B in Examples 1 and 2.

[0025] Table 1

[0026]

[0027]

[0028] (2) Preparation of component B

[0029] The specific operation is as follows:

[0030] ① Prepare raw materials according to the dosage of each component of component B in Table 1;

[0031]②In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com