Multifunctional robot terminal execution apparatus

An end effector, robot technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of manual grasping, manual observation and manual welding, so as to reduce instability, improve production efficiency, and reduce safety. The effect of manipulating the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below according to the accompanying drawings and embodiments.

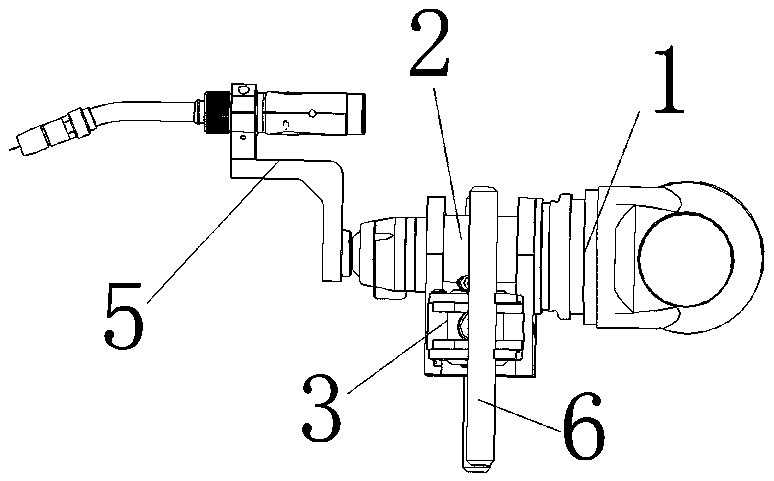

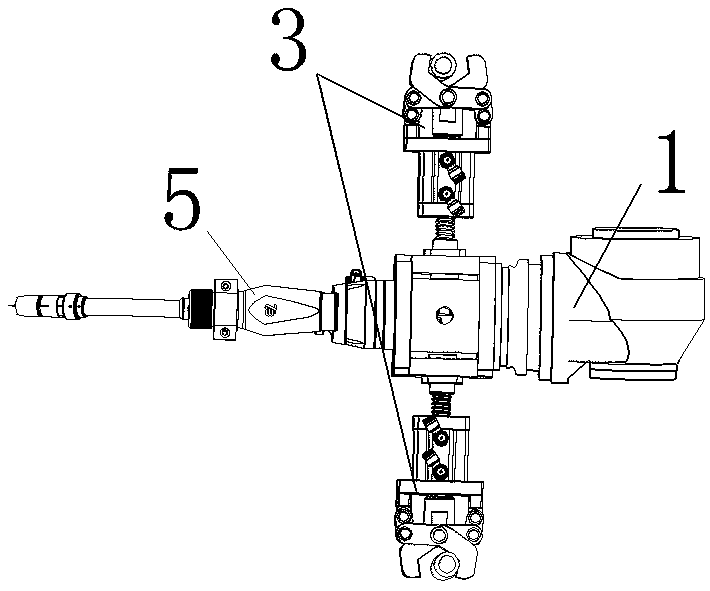

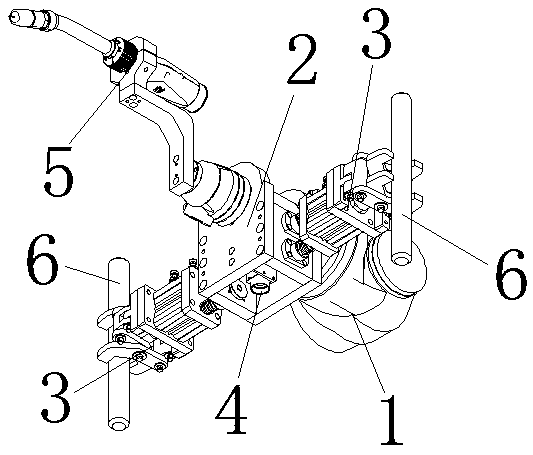

[0024] Such as Figure 1 to Figure 7 As shown, a multifunctional robot end effector includes a robot end 1, which is connected to a connection assembly 2, and both sides of the connection assembly 2 are connected with a gripper assembly 3, and the gripper assembly 3 uses a cylinder to drive a connecting rod The mechanism has more applicability to the diameter range of the bar stock 6. A welding torch device 5 is connected to the side of the connection assembly 2 away from the robot end 1 . As an improvement of this embodiment, a visual device 4 is installed on the bottom of the connection assembly 2, and the visual device 4 integrates a visual sensor, which improves the accuracy of grasping and discharging, reduces dimensional deviation, and meets higher dimensional requirements. Require. The robot end effector integrates grasping, vision and welding, reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com