Air ejection mechanism of super-bubble biochemical air ejection separator and application thereof

A separation device and gas cap technology, which is applied in the application, fish farming, animal husbandry and other directions, can solve the problem of insufficient ability to cultivate and process ammonia nitrogen residues, low ability of beneficial bacteria to cultivate and process ammonia nitrogen residues, and no cultivation is beneficial. bacteria capacity and other issues, to achieve the effects of strong ammonia nitrogen residue treatment capacity, strong beneficial bacteria cultivation capacity, and excellent odor and deodorization capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

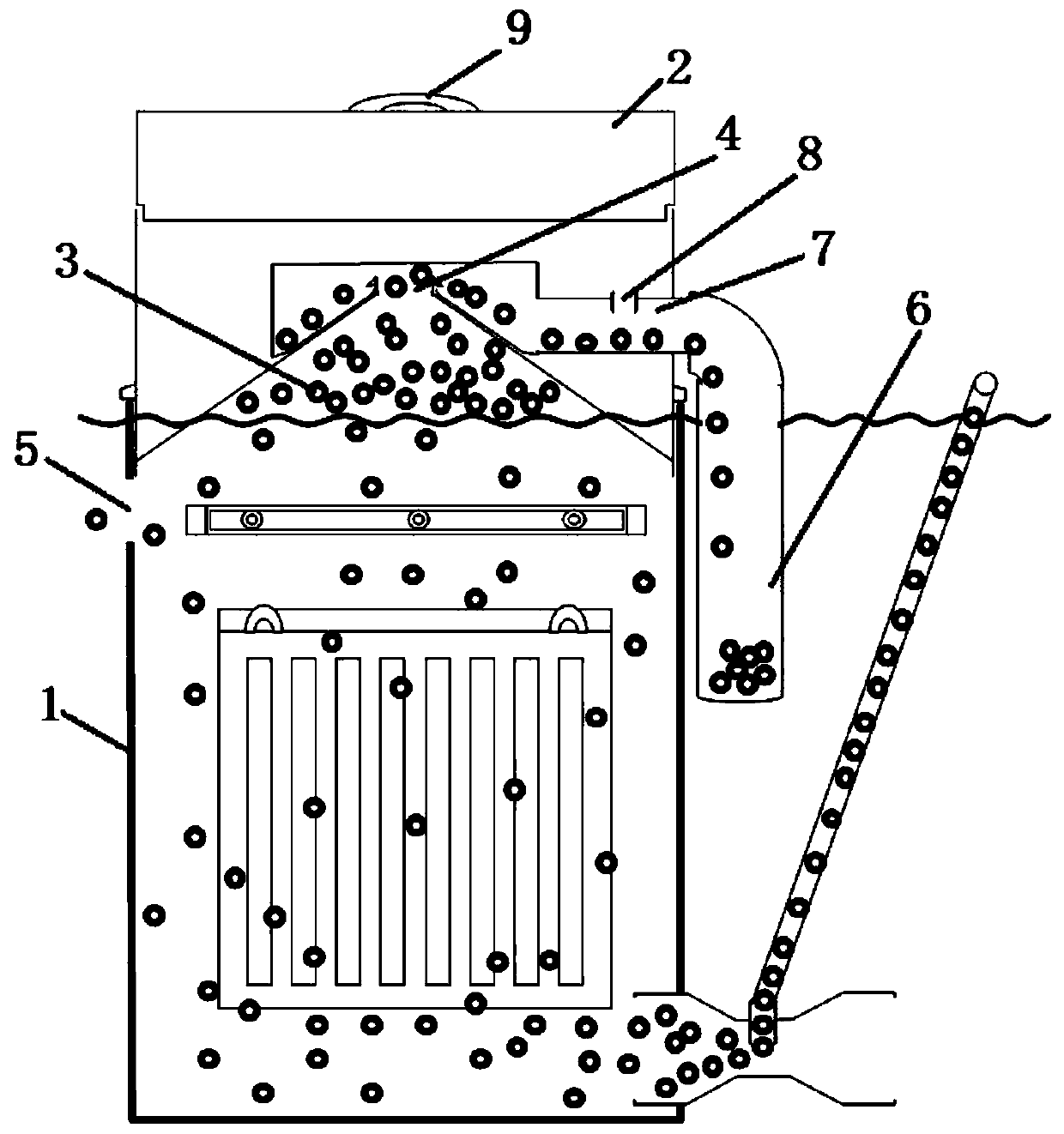

[0031] This embodiment provides a gas cap mechanism of a superbubble biochemical gas cap separation device, the gas cap mechanism is arranged above the container 1, and the gas cap mechanism includes a gas cap 2 arranged above the container 1, and the gas cap mechanism is arranged above the container 1. An air cap chamber 3 is formed between the top cover 2 and the top of the container 1 , the top of the air cap chamber 3 is provided with an air cap overflow port 4 , and the bottom of the air cap chamber 3 is provided with a water outlet 5 .

[0032] Preferably, the gas cap overflow port 4 is provided with a collector 6 , and the collector 6 communicates with the gas cap overflow port 4 . A connecting pipe 7 is provided between the gas cap overflow port 4 and the collector 6 , and an exhaust port 8 is provided on the connecting pipe 7 . The gas cap overflow port 4 is provided with an extension pipe. The extension tube is externally connected to the collection bucket. The gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com