Surge type super-foam gas cap filtering device

A filtration device and gas cap technology, applied in filtration treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of insufficient ability to cultivate and treat ammonia nitrogen residues, no ability to cultivate beneficial bacteria, and bubble water retention Short time and other problems, to achieve the effect of strong ammonia nitrogen residue treatment ability, excellent odor and deodorization ability, and the applicability of various materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

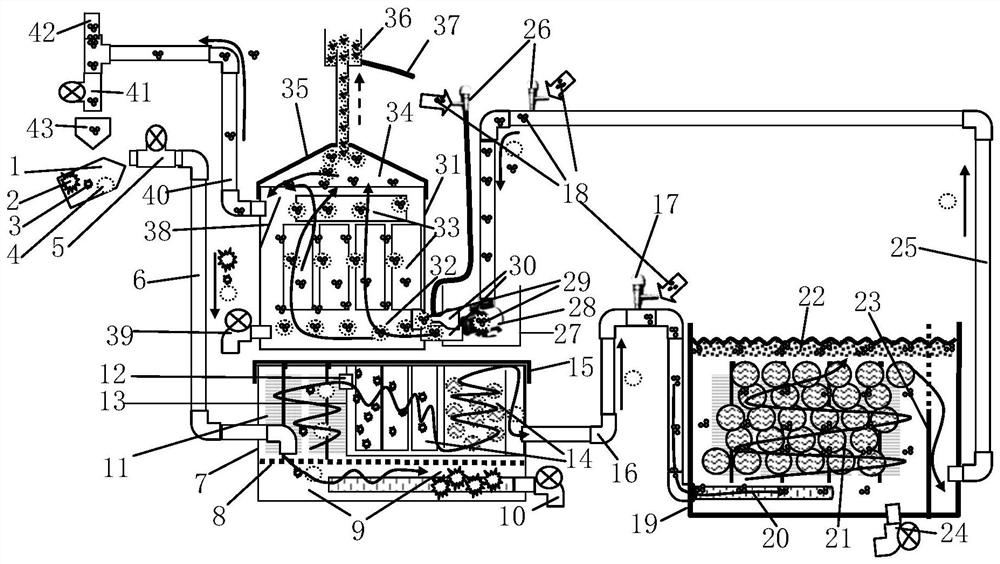

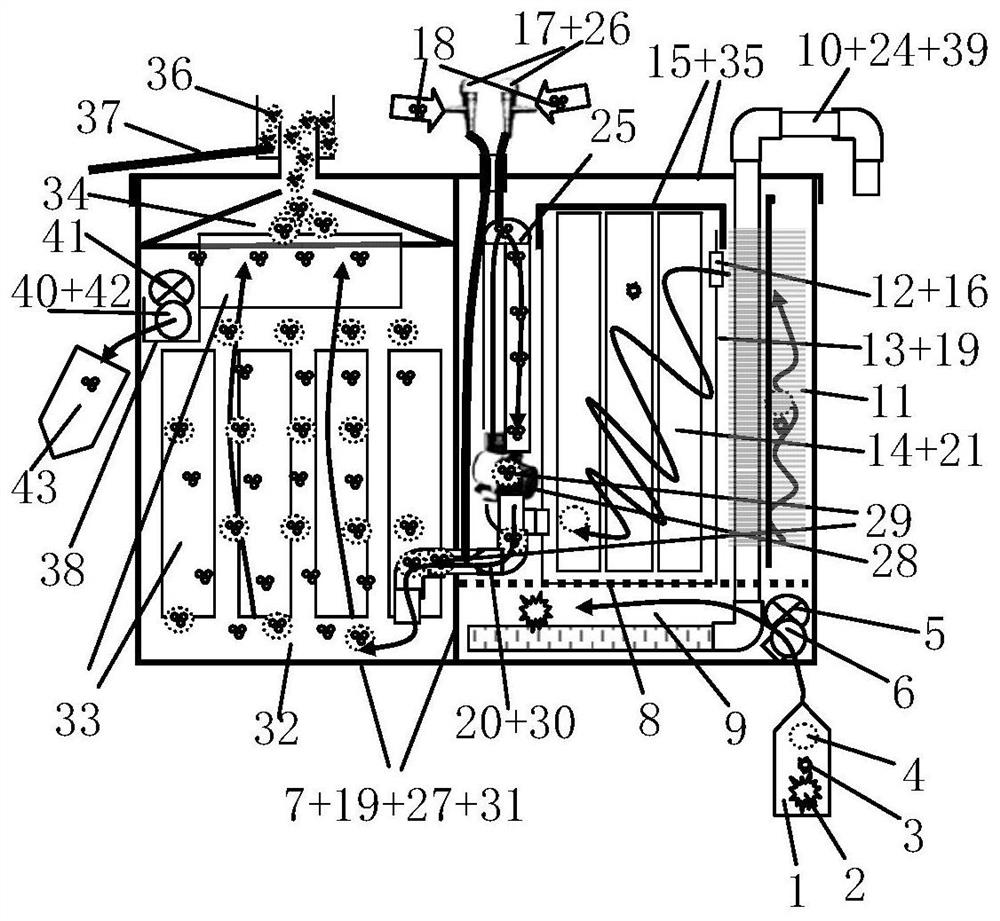

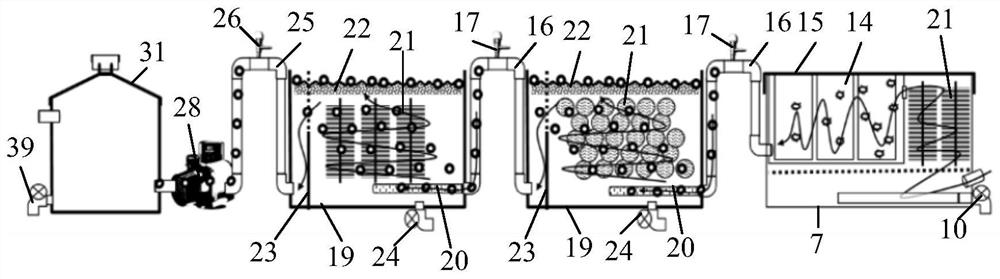

[0064] For specific embodiments, refer to the following description.

[0065] The working mode of the front section of the pump is divided into two types:

[0066] 1. The first is the semi-sealed front section working mode of the front biochemical chamber 19: the open front biochemical chamber 19 needs to inhale and discharge air, so it cannot be sealed; the suction of the water pump 28 causes the front biochemical chamber 19 to be closed. The water level will be lower than the front physical filter chamber 7, so the water flow at the high water level of the front physical filter chamber 7 will flow to the low water level of the front biochemical chamber 19, causing the negative pressure effect inside the front physical filter chamber 7. The filter chamber 7 uses negative pressure to suck the old water 1, the water treated by the front physical filter chamber 7 is sucked by the front biochemical chamber 19, and the water treated by the front biochemical chamber 19 is sucked aw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com