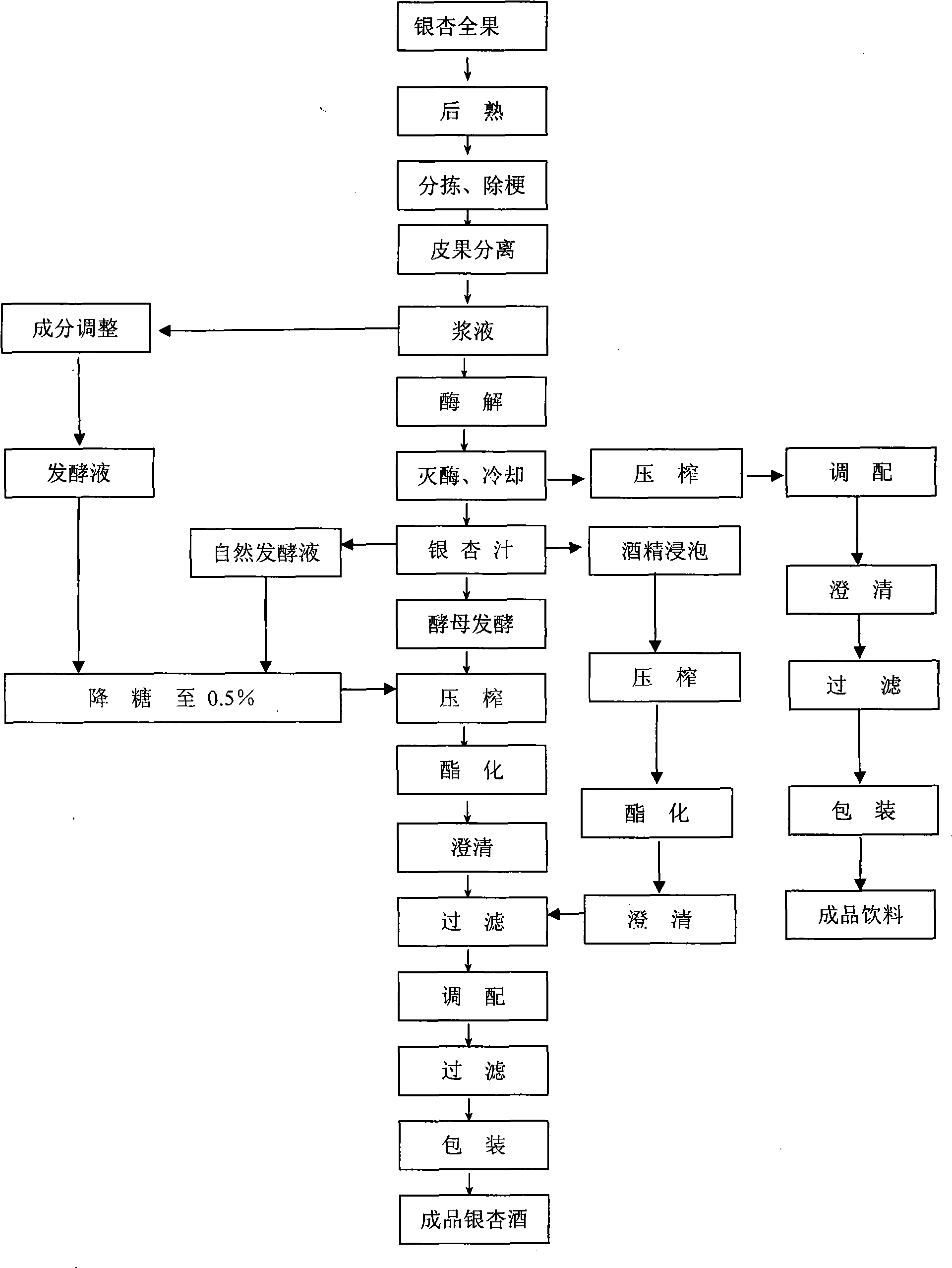

Gingko wine production process

A ginkgo wine and ginkgo technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of irritation, strong corrosion, waste of resources, pollution of the environment, etc., and achieve the effect of pure taste, short production cycle and golden color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Take 1000 kg of ginkgo whole fruit, after sorting, washing, destemming and crushing, pump the ginkgo pulp into the hot and cold tank and heat it to 55°C, add 100ml of combined biological enzyme preparation, keep it warm for 30 minutes, and then raise the temperature to 75°C ℃, heat preservation for 30 minutes, the temperature of the grape pulp is reduced to 25 ℃ with cooling water circulation, and pumped into a press for pressing to obtain 800 kg of ginkgo juice. Pump 100 ml of the prepared wine yeast liquid into the ginkgo pulp after enzymatic hydrolysis, add 40 kg of 70% deodorized alcohol, 80 kg of sugar, 80 g of partial sodium sulfite, and ferment at 20-25 °C for fermentation. When it reaches below 0.5g / 100ml, filter it with a diatomaceous earth filter to obtain 920 kg of fermented raw wine, pump the raw wine into the cold and hot tank, raise the temperature of the raw wine to 50°C, add 3 kg of Mingjiao, keep it warm for 35 days, and then Pump the original wine into...

Embodiment 2

[0041]Take 1000 kg of whole ginkgo fruit, after sorting, washing, destemming, and crushing, pump the ginkgo pulp into a hot and cold tank and heat it to 55°C, add 100ml of combined biological enzyme preparation, keep it warm for 40 minutes, and then raise the temperature to 70°C, Keep warm for 40 minutes, use cooling water to lower the temperature of ginkgo pulp to 25°C, pump it into a press to squeeze 850 kg of ginkgo juice, and then pump 250 kg of 70% deodorized alcohol to make original wine for soaking. Tons are heated to 50°C in a hot and cold cylinder, and kept for 40 days. After cooling down, they are pumped into a cold treatment tank at -7°C and kept for 35 days. After filtering, blending, and filling, the semi-dry ginkgo wine is obtained.

Embodiment 3

[0043] Take 1000 kg of whole ginkgo fruit, after sorting, washing, destemming and crushing, the ginkgo pulp is pumped into the hot and cold cylinders to adjust the temperature to about 25°C, and the white grapes (or peeled red grapes) are fermented naturally. Pump in 200 kilograms, add 40 kilograms of 65% deodorized alcohol, 80 kilograms of supplemented sugar, and 60 grams of partial sodium sulfite. When the residual sugar in the fermentation liquid drops below 0.5%, stop the fermentation, filter it with a diatomaceous earth filter, and then pump it into the cold water. Keep warm at 75°C for 30 days in a hot cylinder, pump it into a cold treatment tank at -7°C for 35 days after cooling down, filter, blend, and fill to get dry ginkgo wine. Sweet and semi-sweet ginkgo wine can be obtained by controlling the sugar content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com