Manufacturing method of primitive blueberry distilled liquor

A production method and technology of distilled wine, which is applied in the field of production of original ecological blueberry distilled wine, can solve the problems of no unified purchase market, large fluctuations in sales prices, and difficulties in sales by farmers, and achieve the effect of easy storage, easy acceptance, and long storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

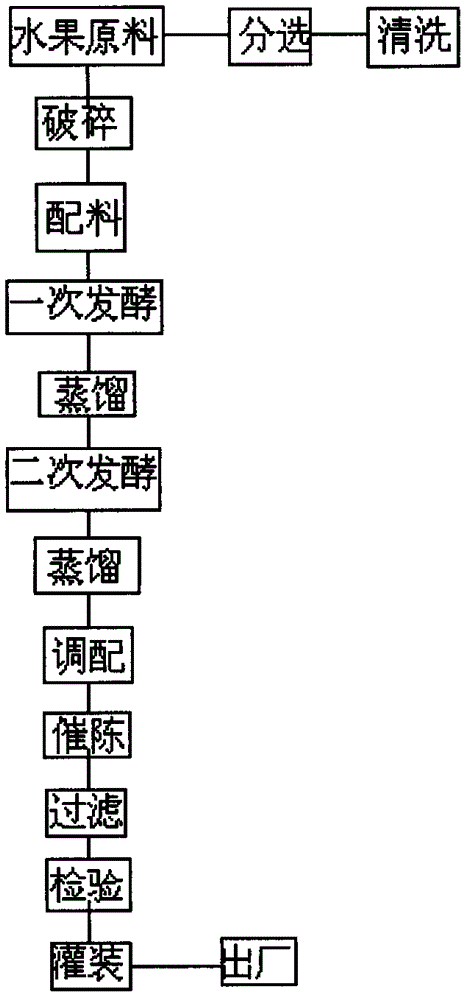

[0024] The present invention uses fresh fruit blueberries as the wine-making raw material, and is prepared through the steps of raw material sorting, cleaning, crushing, batching, primary fermentation, distillation, secondary fermentation, distillation, aging, deployment, filtration, inspection, filling, delivery and the like. . In the present embodiment, select 50 parts of blueberries, and its concrete steps are as follows:

[0025] The first step, selection of raw materials: choose 50 blueberries without pests and diseases, without fruit, wash them, remove impurities, and drain;

[0026] The second step, the pretreatment of the original ingredients: after the drained blueberries are crushed by the machine to form the required raw materials, the raw materials are stirred by the machine and the homemade Baiyao, liquor high-activity dry yeast and high temperature-resistant yeast are added during the stirring process. , adjust the sugar content of the raw material to 10%, and t...

Embodiment 2

[0043] The present invention uses fresh fruit blueberries as the wine-making raw material, and is prepared through the steps of raw material sorting, cleaning, crushing, batching, primary fermentation, distillation, secondary fermentation, distillation, aging, deployment, filtration, inspection, filling, delivery and the like. . In the present embodiment, 100 parts of blueberries are selected, and the specific steps are as follows:

[0044] The first step, selection of raw materials: choose 100 blueberries without pests and diseases, without fruit, wash them, remove impurities, and drain;

[0045] The second step, the pretreatment of the original ingredients: after the drained blueberries are crushed by the machine to form the required raw materials, the raw materials are stirred by the machine and the homemade Baiyao, liquor high-activity dry yeast and high temperature-resistant yeast are added during the stirring process. , adjust the sugar content of the raw material to 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com