Blueberry distilled liquor and preparation method thereof

A technology of distilled wine and blueberry, which is applied in the field of blueberry distilled wine, can solve the problems of the loss of nutritional components of prepared wine, large product quality differences, and unfavorable large-scale production, and achieve the effects of enhancing immunity, stable product quality, and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of blueberry distilled wine, its raw material comprises by weight: 30 parts of blueberry, 5 parts of wheat koji, 2 parts of millet, 3 parts of chaff, 0.1 part of amylase, 0.09 part of glucoamylase, 0.004 part of pectinase, cellulose 0.003 part of enzyme, 1 part of yeast starter, 0.4 part of compound fermentation aid Fermaid K, 1 part of fructose, 2 parts of citric acid, 50 parts of water. A sourdough starter is a yeast starter comprising a floccin variant gene.

Embodiment 2

[0022] A kind of blueberry distilled wine, its raw material comprises by weight: 40 parts of blueberry, 1 part of wheat koji, 8 parts of millet, 2 parts of chaff, 0.2 part of amylase, 0.05 part of glucoamylase, 0.005 part of pectinase, cellulose 0.002 parts of enzyme, 2 parts of yeast starter, 0.2 parts of compound fermentation aid Fermaid K, 4 parts of fructose, 1 part of citric acid, and 80 parts of water. A sourdough starter is a yeast starter comprising a floccin variant gene.

Embodiment 3

[0024] A kind of blueberry distilled wine, its raw material comprises by weight: 32 parts of blueberries, 4 parts of wheat koji, 4 parts of millet, 2.8 parts of chaff, 0.15 parts of amylase, 0.08 part of glucoamylase, 0.0042 parts of pectinase, cellulose 0.0028 parts of enzyme, 1.6 parts of yeast starter, 0.33 parts of compound fermentation aid Fermaid K, 1 part of fructose, 1.6 parts of citric acid, and 60 parts of water.

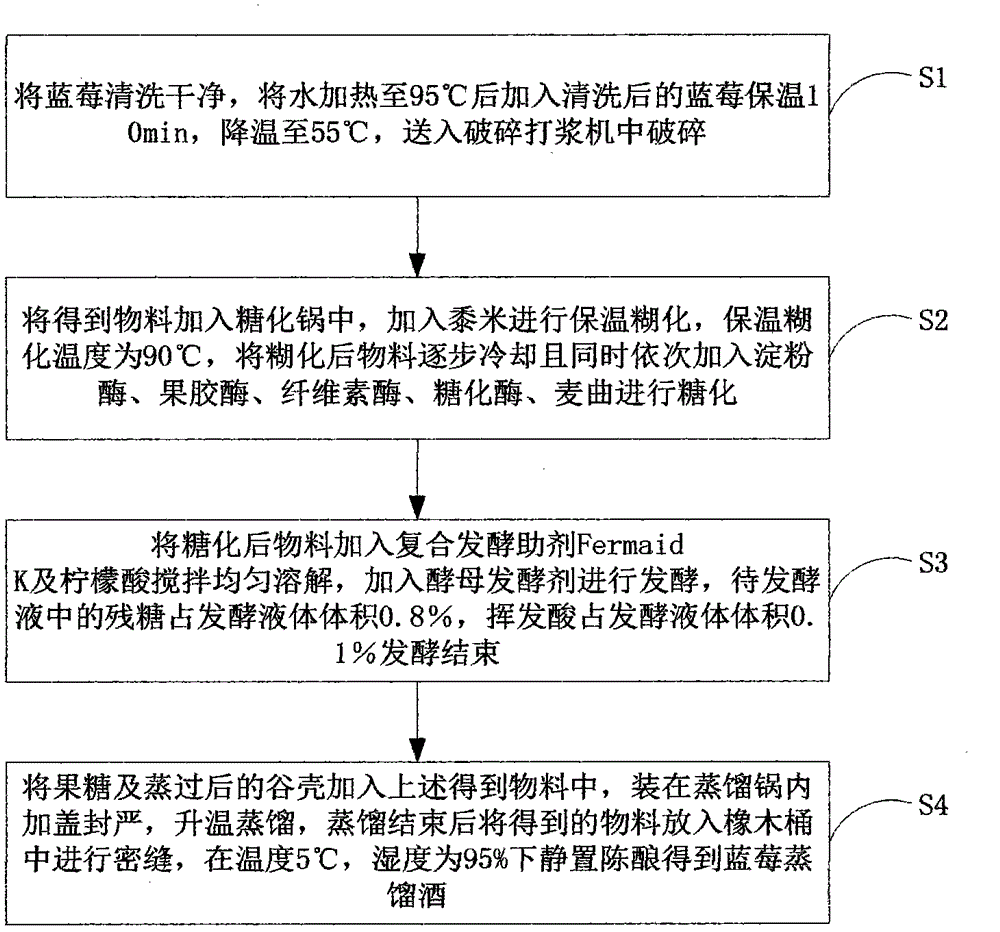

[0025] refer to figure 1 , the preparation method of above-mentioned blueberry distilled wine, comprises the steps:

[0026] S1. Clean the blueberries, heat the water to 95°C, add the cleaned blueberries to keep warm for 10 minutes, cool down to 55°C, and send them to a crushing and beating machine for crushing;

[0027] S2. Put the obtained material into the mash pot, add millet for heat preservation and gelatinization, the temperature of heat preservation and gelatinization is 90°C, gradually cool the material after gelatinization and simultaneously add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com