Method for producing alcohol through solid fermentation on mixed waste molasses containing cellulose substances

A cellulose material and solid-state fermentation technology, applied in fermentation, biofuels, etc., can solve the problems of difficult pollution control and high production costs, and achieve the effects of no distiller's grain pollution, reduced production costs, and increased alcohol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

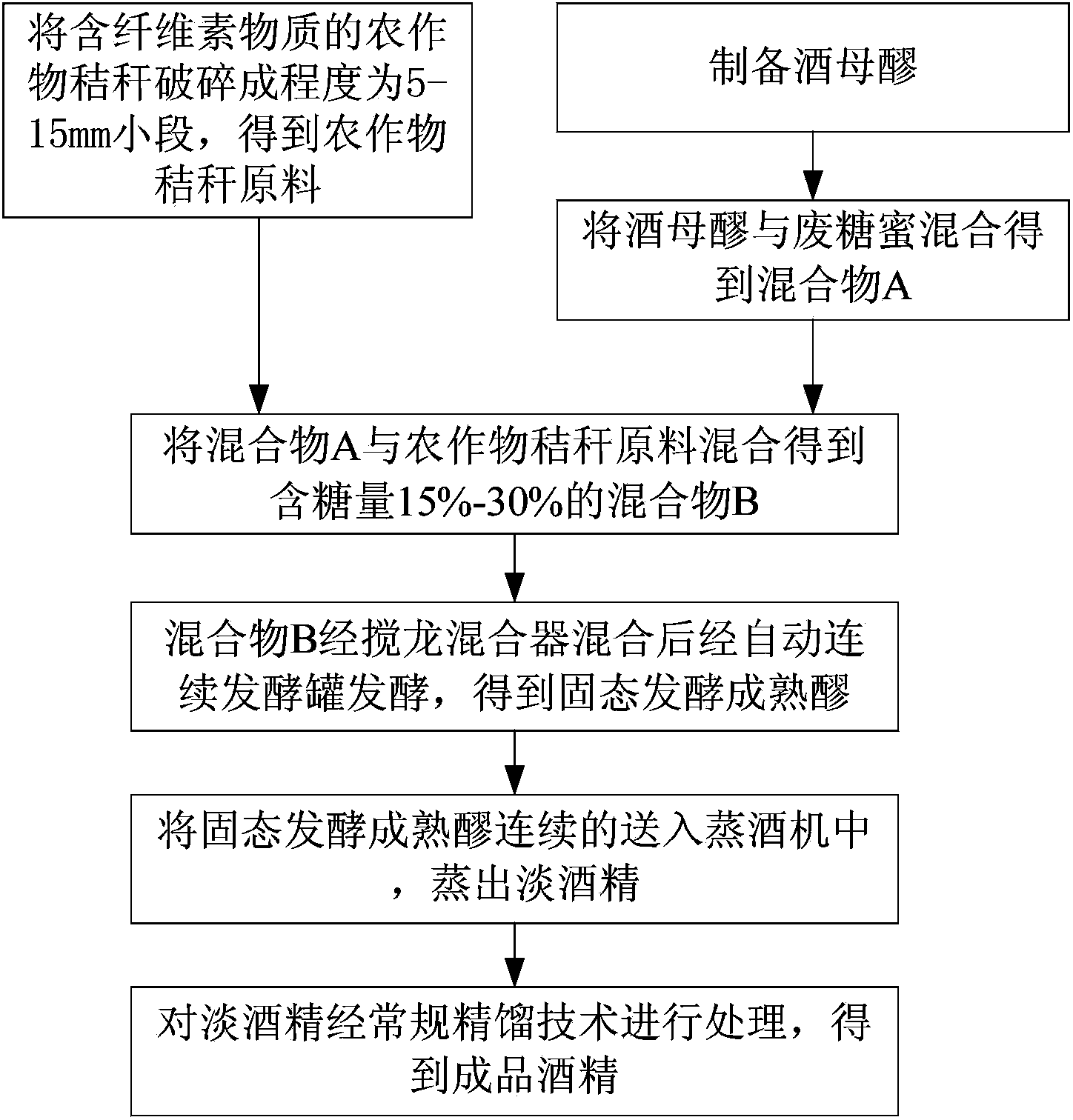

[0039] See attached figure 1 A method for producing alcohol by solid-state fermentation of cellulose-containing substances mixed with waste molasses of the present invention comprises the following steps:

[0040] Step 1: crushing one or several kinds of crop straws containing cellulose materials into small pieces with a length of 5-15 mm to obtain raw materials of crop straws;

[0041] Step 2: preparing distiller's mash;

[0042] Step 3: mixing the distiller's mash obtained in step 2 with waste molasses to obtain mixture A;

[0043] Step 4: Mix the mixture A obtained in step 3 with the crop straw raw material obtained in step 1 to obtain a mixture B with a sugar content of 15%-30%;

[0044] Step 5: the mixture B obtained in step 4 is mixed by an auger mixer and then fermented by an automatic continuous fermenter to obtain solid-state fermented mature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com