Wine-making preparation method adopting litchi fermentation

A technology for fermenting wine and lychees, which is applied in the field of wine making technology to achieve the effects of promoting fermentation transformation, avoiding residual pollution, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

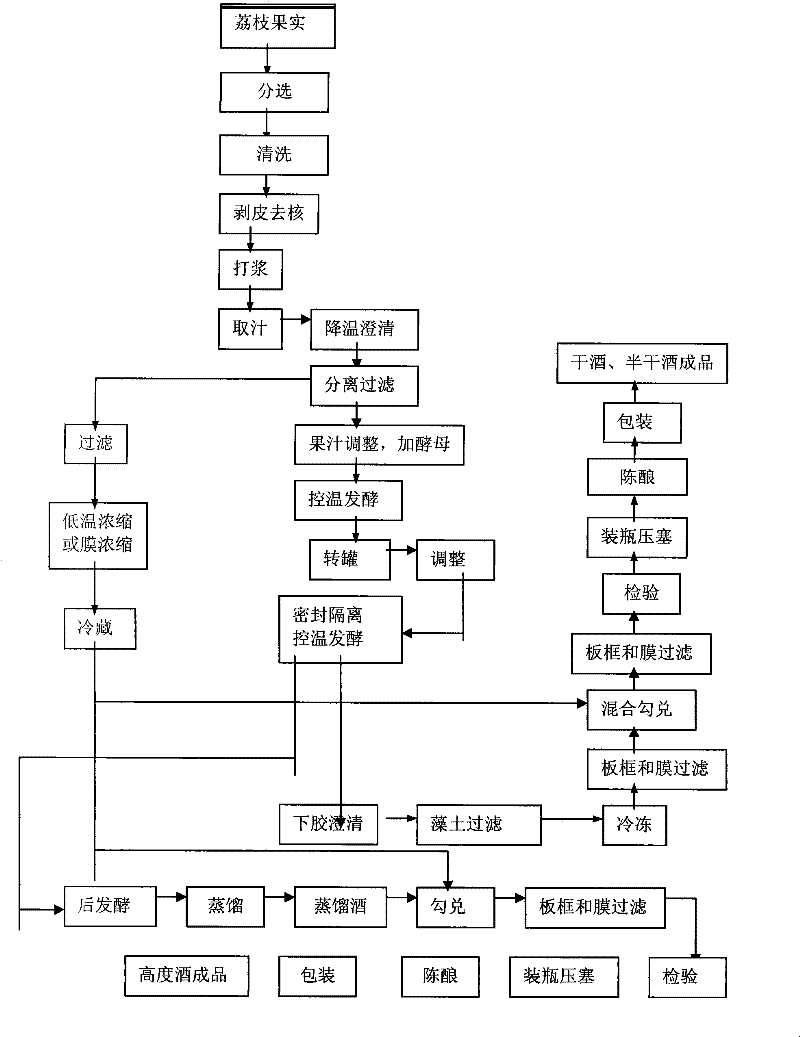

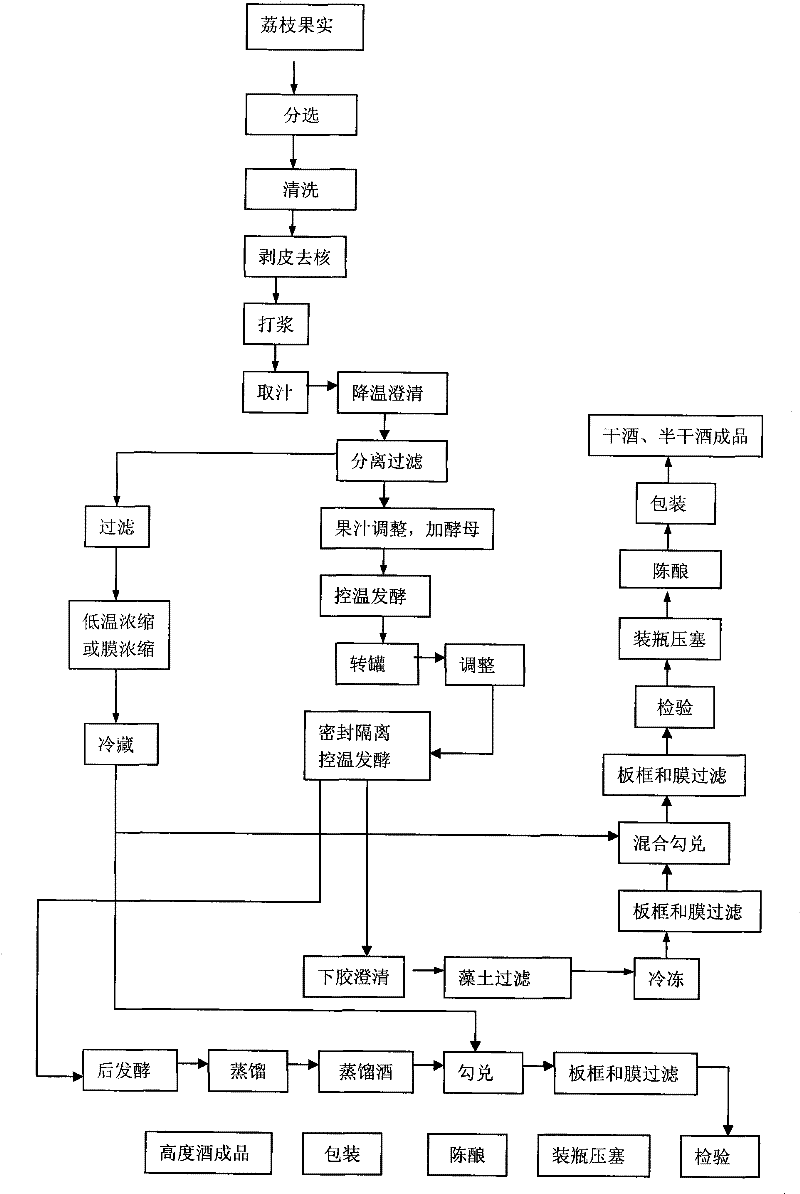

[0031] Litchi fermented wine preparation method as shown in Figure 1

[0032] Step (1): 1000kg of high-quality lychee pulp, beating for juice, and appropriate amount of sulfurous acid to adjust the SO in the juice 2 After the content reaches the best 75mg / L, add pectinase 30g / T, and carry out the clarification of the tank full of oxygen and cooling at 8-12°C; when the supernatant has no obvious suspended matter, the plate and frame filter is used to separate the filtrate and juice;

[0033]Step (2): The total soluble sugar of the fruit juice is adjusted to 15-25%; 0.12kg / T of active yeast for wine is added per ton of fruit juice, and lactic acid bacterial strains and acetic acid bacterial strains can also be added at the same time, and the addition amounts of the latter two are respectively 0.04kg / T, the weight ratio of active dry yeast, lactic acid strains, and acetic acid strains is 5:1:1, the strains cooperate to seal and oxygen-isolate fermentation for 8 days, the tempera...

Embodiment 2

[0041] Litchi fermented wine preparation method as shown in Figure 1

[0042] Step (1): 1000kg of lychee pulp is beaten to obtain juice, and sulfurous acid is used to adjust the SO in the juice 2 After the content is 75mg / L, add pectinase 50g / T, and carry out the clarification of the tank full of oxygen and cooling at 10°C; when the supernatant has no obvious suspended matter, separate the filtrate and juice;

[0043] Step (2): The total soluble sugar of the fruit juice is adjusted to 20%; 0.2 kg / T of active yeast for wine is added to each ton of fruit juice, and lactic acid bacterial strains and acetic acid bacterial strains are added at the same time, and the amount of the latter two is 0.4 kg / T respectively , the strains cooperate to seal and oxygen-proof fermentation for 10 days, the temperature-controlled fermentation temperature is 22°C, and ferment for 10 days; transfer the tank, then adjust the total sugar to 30%, adjust the citric acid to the acid content of 10g / L, se...

Embodiment 3

[0052] Litchi fermented wine preparation method as shown in Figure 1, comprises the following steps:

[0053] Step (1): Lychee pulp is beaten to extract juice, and sulfurous acid is used to adjust the SO in the juice 2 After the content is 110mg / L, add pectinase 40g / T, and carry out the clarification of the tank full of oxygen and cooling at 15°C; when the supernatant has no obvious suspended matter, the plate and frame filter is used to separate the filtrate and juice;

[0054] Step (2): The fruit juice is transferred to another temperature-controlled fermentation tank, and the total soluble sugar is adjusted to 10%; 0.05 kg / T of active yeast for wine is added to each ton of fruit juice, and lactic acid bacteria and acetic acid bacteria are added at the same time. The addition amount of each is 0.02kg / T, and the weight ratio of active dry yeast, lactic acid strains, and acetic acid strains is 6:0.5:0.5, and the strains cooperate to seal and oxygen-isolate fermentation for 7 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com