A High Esterase Activity M. Maggi and its Application in Mead Fermentation

A technology of Metchi yeast and high esterase, applied in the field of winemaking, can solve problems such as no enzyme activity, and achieve the effect of increasing the fragrance of flowers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

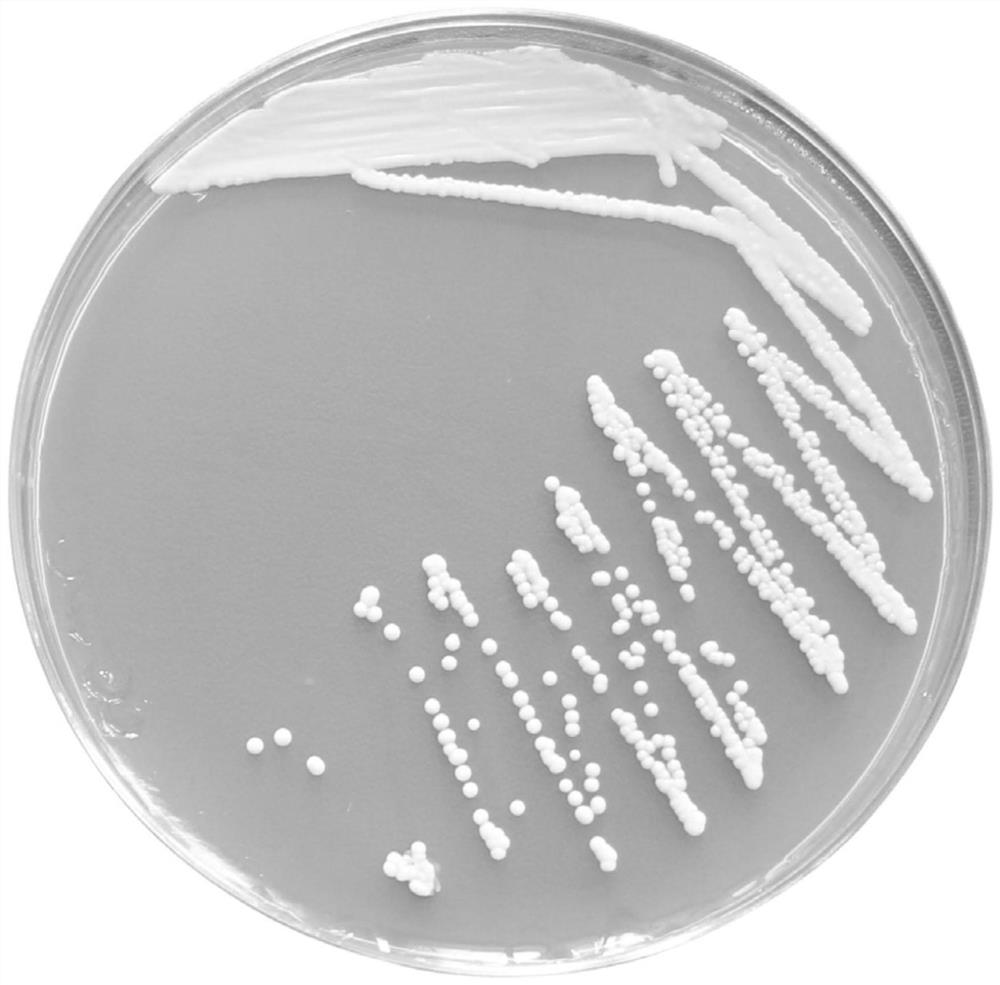

[0013] Example 1: Isolation and identification of strains

[0014] 1. The isolation process of strains

[0015] Aseptically weigh about 10g of ripe grapes, put them into a triangular flask containing 90ml of sterile water, shake and cultivate for 30 minutes to make a bacterial suspension, and dilute to 10 -2 , 10 -3 , 10 -4 , respectively draw 50 microliters into WL, LYS, ESA solid medium, spread evenly with a sterilized coating rod, put it upside down in a constant temperature incubator at 28°C, cultivate for 24-72h, and observe after the colonies grow. record form. According to different forms, single colony YPD plates were streaked, stored and identified.

[0016] 2. Strain screening

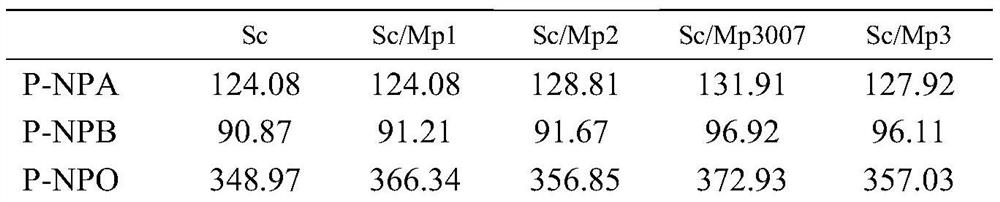

[0017] The isolated strains Mp1, Mp2, Mp3 and Mp3007 were inoculated with honey water (Hundred Flowers Honey, 18Brix) for fermentation, and the inoculum size was 10 6 cfu / mL, simultaneously inoculated with commercial Saccharomyces cerevisiae (the inoculation volume was 10 6 cfu / mL), an...

Embodiment 2

[0028] Example 2: Preparation of 12% v / v mead by fermentation

[0029] 1. Dilute the honey (Hundred Flowers Honey) with water to 20-20.5Brix, heat it to 65-70℃, keep it for 20 minutes, and then lower it to room temperature;

[0030] 2. Inoculate Maggi Maggi MP3007 and Saccharomyces cerevisiae DV10 in honey water for fermentation. The inoculation amount of Maggi Maggi is 10 6 10 cfu / mL and S. cerevisiae inoculum 6 cfu / mL; During the whole fermentation process, the temperature was kept at 18-20 °C, and the specific gravity was measured every 24 hours. When the specific gravity did not change within 72 hours, the fermentation was considered to be over. The production process does not need to add sulfur dioxide or take cooling, centrifugation and other methods to terminate the fermentation.

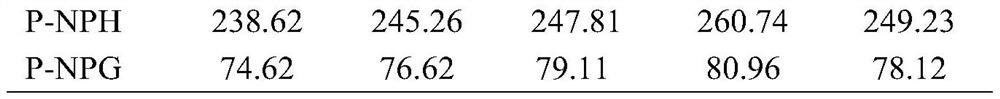

[0031] The following control group was set up, and the aroma components of fermented mead were detected by OAV method after adding Saccharomyces cerevisiae at different strains and at differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com