Production method and product of fermented green plum wine

A production method and fermented technology, which is applied in the production of fermented plum wine and its products, can solve the problems of poor stability and insufficient leaching of aroma components, and achieve the effect of increasing stability, ideal effect and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

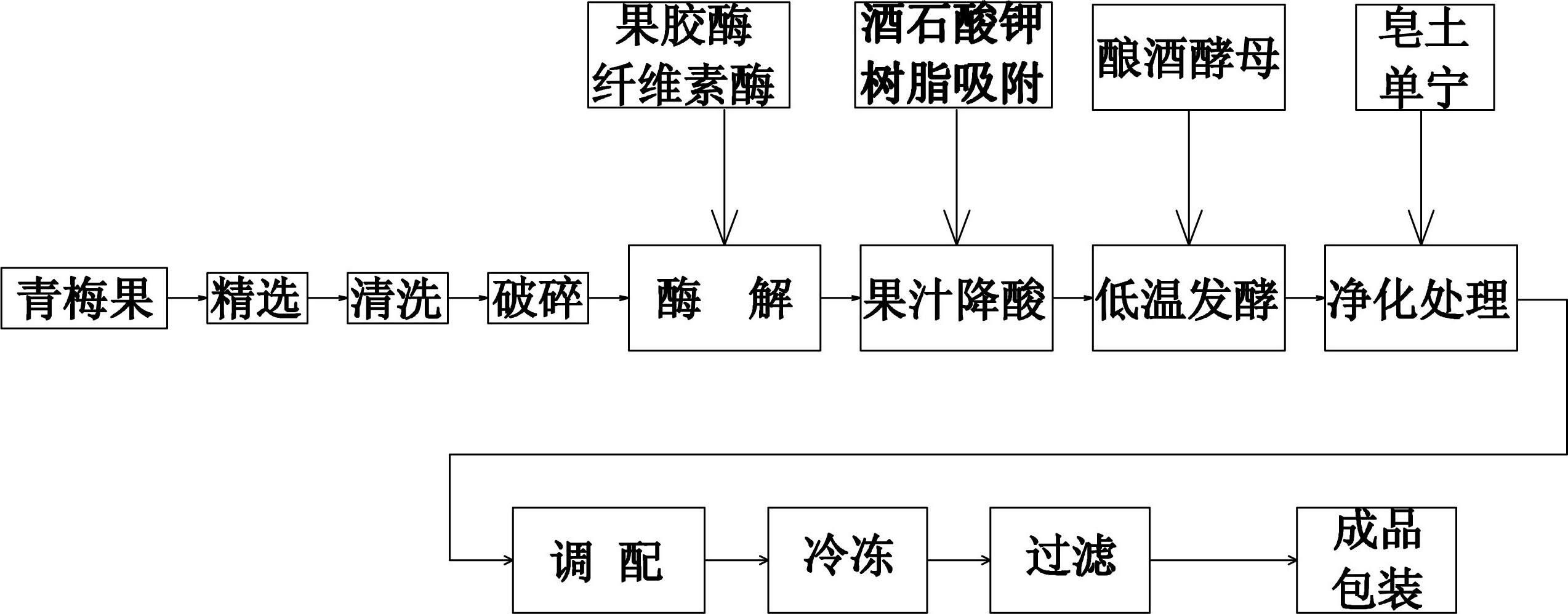

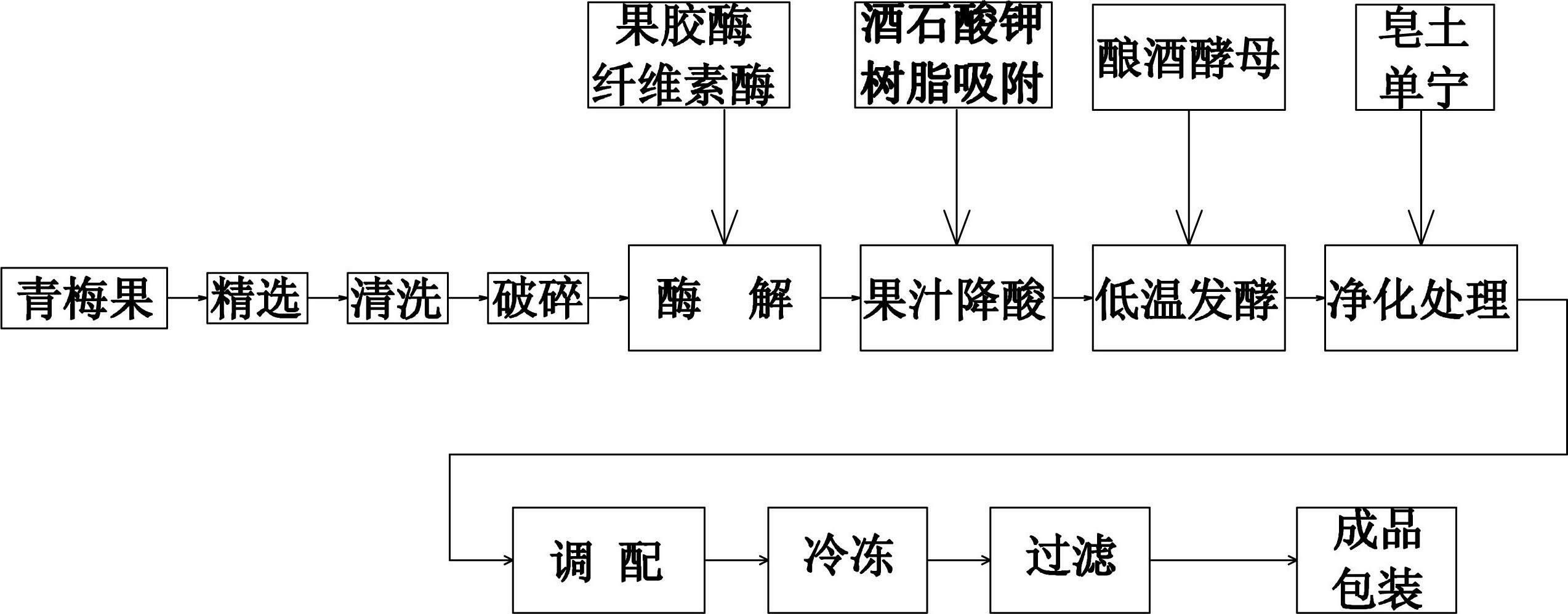

Image

Examples

Embodiment Construction

[0024] First of all, select the green plum fruit as raw material, select the fresh fruit that is more than seven or eight mature, remove the rotten fruit, the fallen fruit, and the fruit that is too small and not mature enough, thoroughly clean the qualified ones, and then crush them with a beater. And add SO at 30mg / L 2 , transfer the green plum pulp into a temperature-controllable dipping tank, add pectinase (30-40) mg / L, cellulase (100-150) mg / L, stir evenly, and control the dipping temperature at 15°C-18°C , maintained for 6 hours to 10 hours. The juice yield can reach more than 45%.

[0025] After the enzymatic hydrolysis is completed, add potassium tartrate to the juice to adjust the acidity to reduce the acidity. During the adjustment, the temperature is lowered to -6°C to -8°C, and the adjustment time is 48 hours to 72 hours, and then filtered at this temperature while it is cold Clarification; then use macroporous weakly basic anion exchange resin for cyclic adsorpt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com