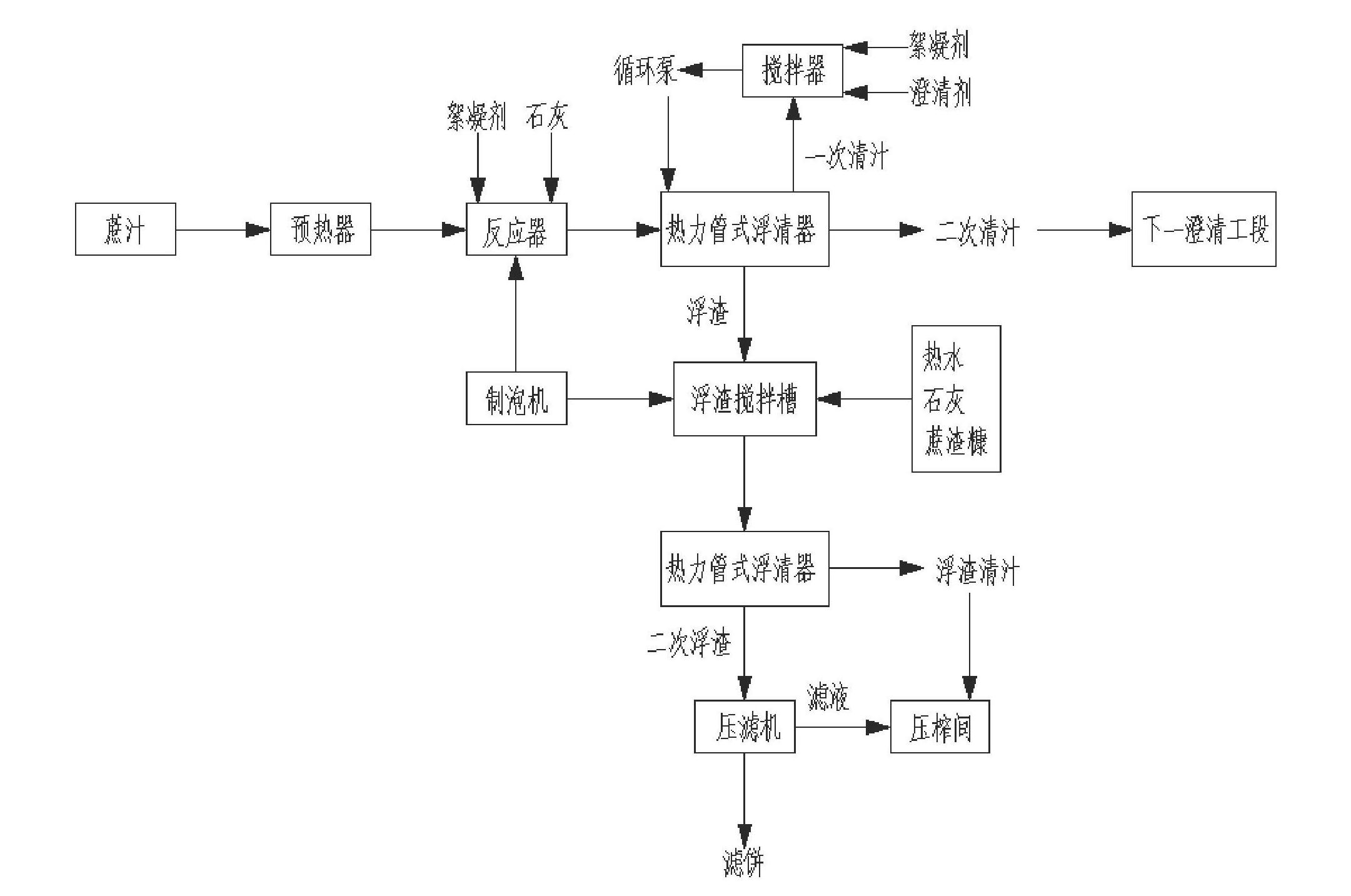

Method and equipment for clarifying cane juice by combining air floatation purification and thermal floatation purification

A combined and clean technology, applied in the direction of purification using physical methods, sucrose production, sugar production, etc., can solve the problems of single application of float cleaner, cleaning of rare mixed juice, single cleaning process, etc., and achieve good treatment effect , pH value drop is small, the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

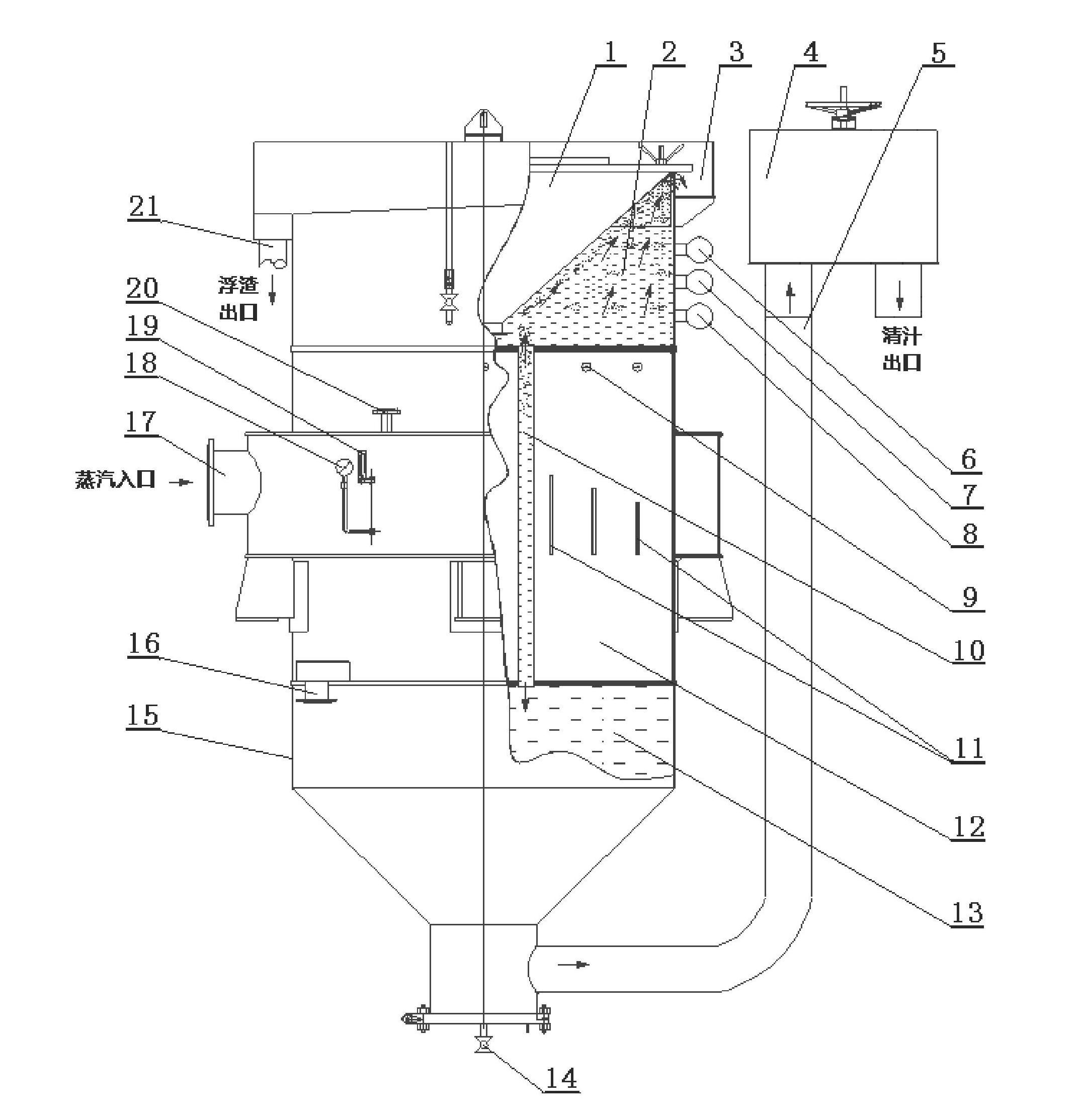

[0054] A method for clarification of sugarcane juice that combines air flotation cleaning and hot flotation cleaning. First, the mixed juice is preheated to 45°C, and then transported to the reactor, and lime is added to adjust the pH value to 5.6. The amount of lime added is 0.02% of the weight; if the pH is low, the amount of lime can be appropriately increased; then use the bubble maker to fill in fine and uniform bubbles, then add 1ppm polyacrylamide in the weight of the mixed juice and mix well, then enter the thermal tube type float cleaner, Carry out air flotation cleaning at 50°C to separate solids with light specific gravity and condensed matter with low melting temperature, such as sugarcane wax, sugarcane fat, sugarcane bran and starch, etc. After air flotation cleaning, a clear juice is obtained, and the primary clear juice is extracted Add 0.02% lime and 1ppm polyacrylamide to the blender at the same time, and then send it to the thermal tube type floater through t...

Embodiment 2

[0056] A method for clarification of sugarcane juice that combines air flotation cleaning and hot flotation cleaning. First, the mixed juice is preheated to 50°C, then transported to the reactor, and lime is added to adjust the pH value to 6.0. The amount of lime added is the mixed juice 0.03% by weight; if the pH is low, the amount of lime can be appropriately increased; then use a bubble maker to fill in fine and uniform bubbles, then add 1ppm polyacrylamide and mix well, then enter the thermal tube type float cleaner, and carry out at 60°C Air flotation cleans, separates solids with lighter specific gravity and condensed matter with low melting temperature, such as cane wax, sugar cane fat, sugarcane bran and starch, etc. After air flotation and cleansing, a clear juice is obtained, and the clear juice is pumped out to the mixer. Add 0.05% lime and 1ppm polyacrylamide to the mixed juice at the same time, and then send it to the thermal tube type float cleaner through the cir...

Embodiment 3

[0058] A method for clarification of sugarcane juice that combines air flotation cleaning and hot flotation cleaning. First, the mixed juice is preheated to 55°C, then transported to the reactor, and lime is added to adjust the pH value to 6.6. The amount of lime added is the mixed juice 0.05% of the weight; then use a bubble maker to fill in fine and uniform bubbles, then add 2ppm polyacrylamide and mix well, then enter the thermal tube type float cleaner, carry out air flotation cleaning at 70°C, and separate solids with lighter specific gravity Condensate and low melting temperature condensate, such as cane wax, sugarcane fat, cane bran and starch, etc., after air flotation and cleaning, a clear juice is obtained, and the clear juice is pumped out to the agitator, and 50ppm phosphoric acid and 2ppm polyacrylamide are passed through at the same time. The circulation pump is then sent to the thermal tube type float cleaner for hot float cleaning at 90°C to separate the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com