Method for producing high-quality white granulated sugar by clarifying syrup

A high-quality technology for white granulated sugar, which is applied in the production of sucrose, sugar production, and juice purification, etc. It can solve the problems of declining market competitiveness, high residual sulfur content, and the product is easy to return to moisture and turn yellow, and achieve a slightly yellow color. , the effect of high purity and low color value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

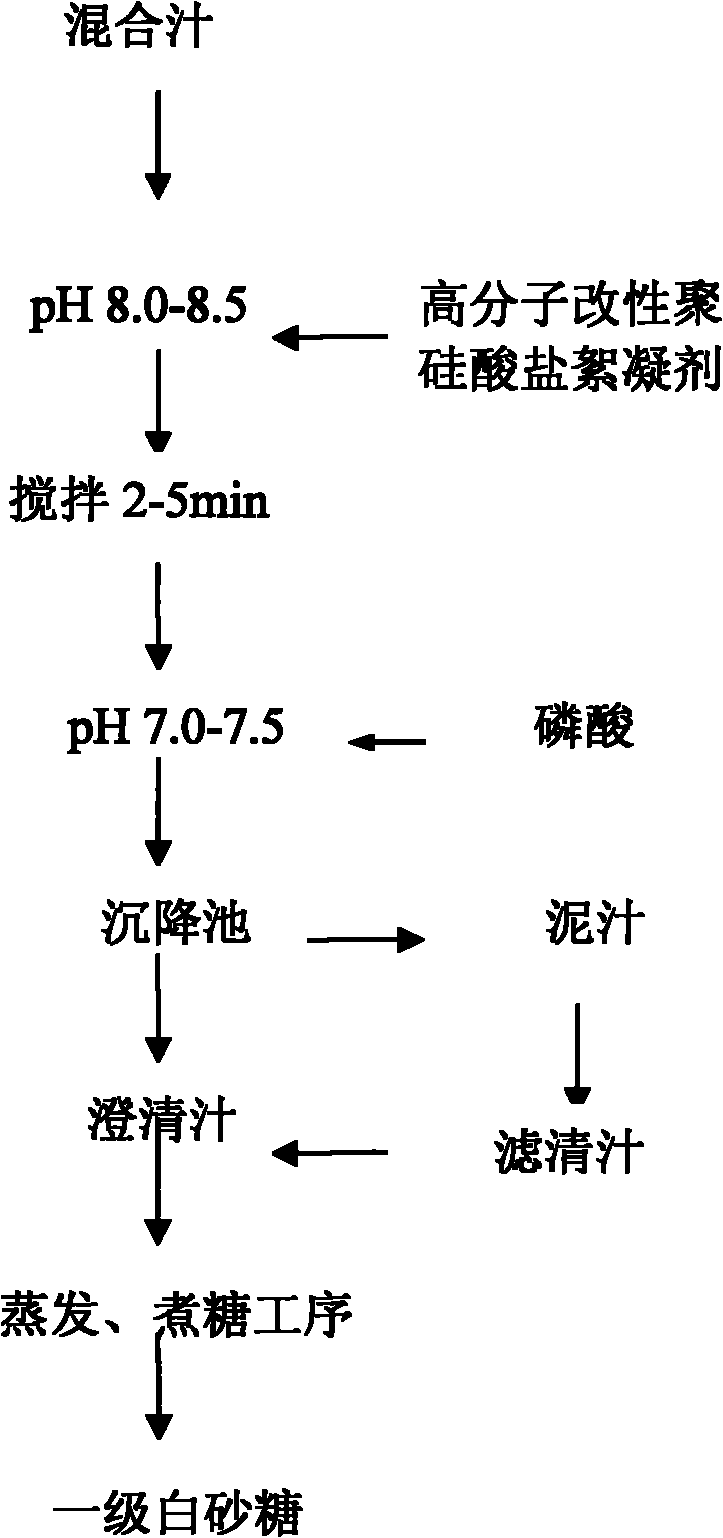

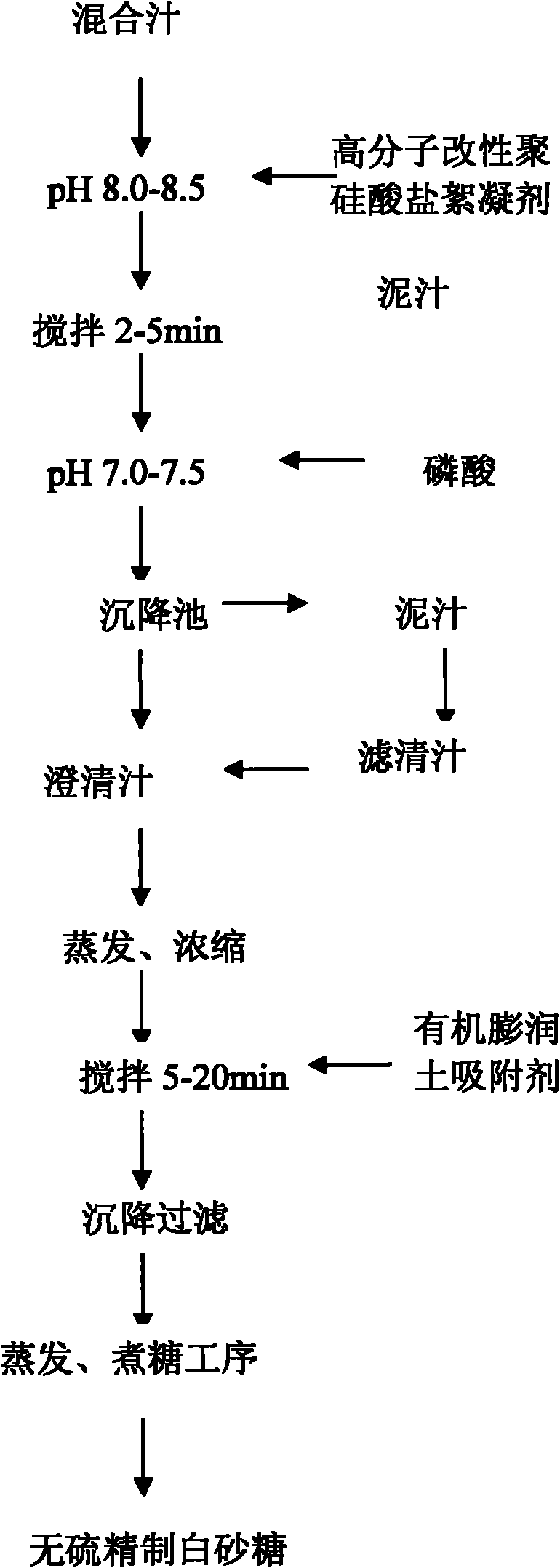

Method used

Image

Examples

Embodiment 1

[0018] The modified polysilicate microgel flocculant is prepared by the following method:

[0019] Under high-speed stirring conditions, 400 g of water glass with a modulus of 3.2 and a silica concentration of 5% was acidified with dilute sulfuric acid at a concentration of 10% by weight to a pH of 9 to prepare a polysilicate microgel. Dissolve chitosan with a deacetylation degree of 85% with 1% concentration of acetic acid to prepare a chitosan-acetic acid solution with a concentration of 1% by weight, and add polysilicic acid to the solution according to the mass ratio of chitosan to 0.2% of silicon dioxide In the microgel, after fully stirring for 2 minutes, dilute the solution with water to a silicon dioxide concentration of 0.5%, then fully stir for 10 minutes, vacuum dry or dry naturally, and the obtained solid powder is the prepared chitosan-modified polysilicic acid microgel flocculant.

[0020] Modified organic bentonite is prepared by the following method:

[0021]...

Embodiment 2

[0027] The modified polysilicate microgel flocculant is prepared by the following method:

[0028] Under high-speed stirring conditions, 400 g of water glass with a modulus of 3.2 and a silica concentration of 15% was acidified with dilute sulfuric acid at a concentration of 30% by weight to a pH of 10 to prepare a polysilicate microgel. Dissolving chitosan with a deacetylation degree of 95% with 3% concentration of acetic acid is prepared into a chitosan-acetic acid solution with a concentration of 3% by weight, and the solution is added to polysilicic acid according to the mass ratio of chitosan to 1% of silicon dioxide. In the microgel, after fully stirring for 10 minutes, dilute the solution with water to a silicon dioxide concentration of 2%, then fully stir for 30 minutes, vacuum-dry or air-dry, and the obtained solid powder is the prepared chitosan-modified polysilicic acid microgel flocculant.

[0029] Modified organic bentonite is prepared by the following method:

...

Embodiment 3

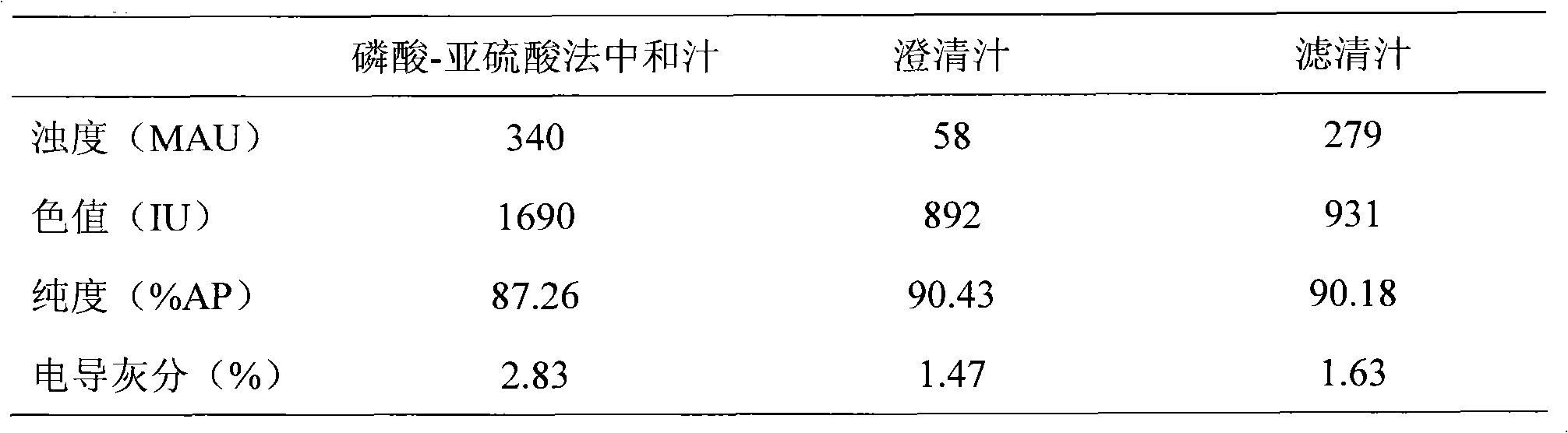

[0036] In the production process of the raw sugar refinery, take the 60°Bx syrup prepared with raw sugar, heat it to 85°C, add 1% organic bentonite adsorbent, stir for 5 minutes, filter with a filter cloth, and boil the sugar, crystallize and separate the nectar , to obtain sulfur-free white granulated sugar, which meets the national GB317-2006 refined sugar standard after testing. The relevant indicators of the filtered syrup were measured, and the results are shown in Table 3.

[0037] Table.3 Decolorization and purification index of organic bentonite adsorbent to syrup in raw sugar refinery

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com