Intensified cane juice clarification method

A technology of sugarcane juice and mixed juice, which is applied in the direction of using oxidation/reduction purification and alkaline earth compound purification, etc., can solve the problems of many equipment, large consumption, large investment, etc., achieve low SO32- content, reduce production efficiency, reduce transmission The effect of thermal efficiency

Inactive Publication Date: 2010-08-18

GUANGXI UNIVERSITY OF TECHNOLOGY

View PDF2 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the carbonic acid clarification process is complex and requires more equipment, and lime and CO 2 The consumption is large and the investment is large, so it has been gradually replaced by the sulfurous acid method

To develop a new clarification process that has both the advantages of the sulfite process and the carbonic acid process, and has low investment, is a more concerned issue in the field of sugar production; To clarify the process, there are successive publication numbers: CN1317577A, CN101280344A patent technology disclosures, but these methods are only a simple combination of the two methods, and cannot greatly improve the neutralization reaction speed and reaction degree, and improve the decolorization effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

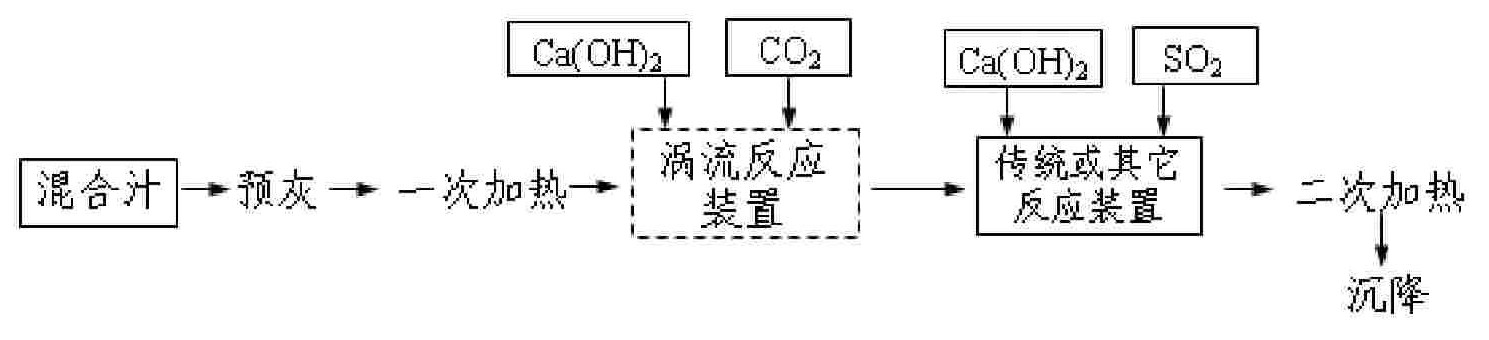

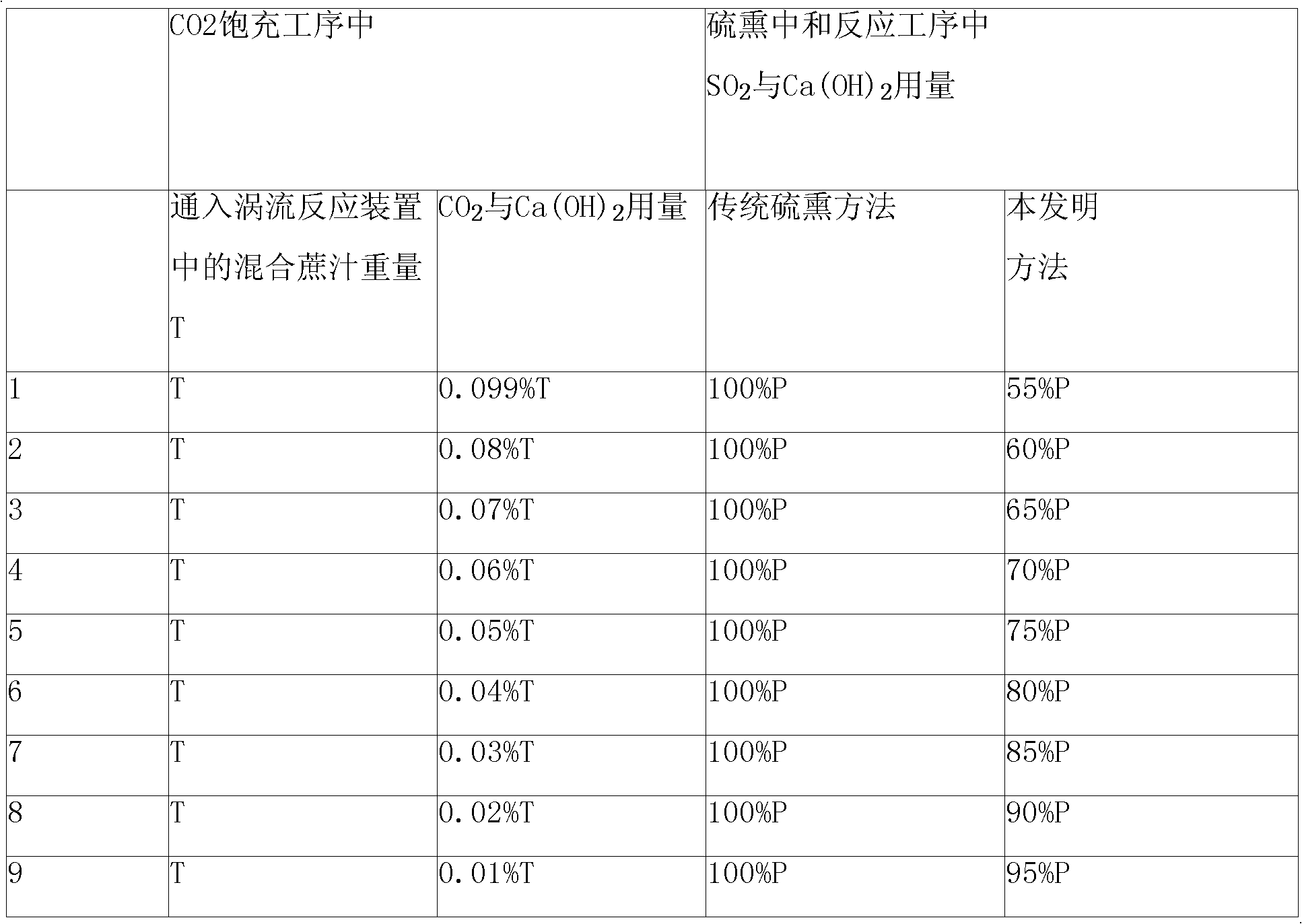

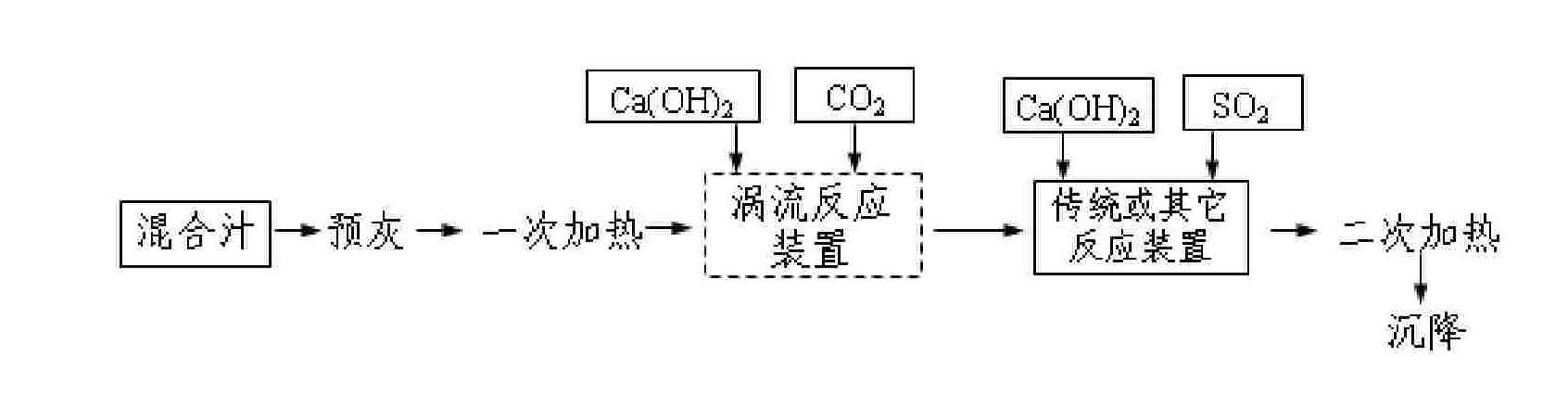

The invention relates to an intensified cane juice clarification method which comprises pre-liming, primary heating, CO2 full filling, sulphitation and neutralization, secondary heating and settlement; the CO2 full filling procedure is as follows: pre-limed and primarily heated mixed juice is fed with CO2 and Ca(OH)2, the mixed juice is fed into an eddy reactor to have CO2 full filling reaction, and then the cane juice from the eddy reactor has sulphitation and neutralization reactions or is added with some the mixed juice which does not have CO2 full filling reaction to carry out the sulphitation and neutralization reactions; the amount of the Ca(OH2) which is fed into the mixed juice in the CO2 full filling procedure is about 0.05 percent of the weight of the cane juice, and the molar ratio of the amount of CO2 to the amount of Ca(OH)2 is 1:1, and the amount of SO2 and the Ca(OH)2 added in the sulphitation and neutralization reactions is 55 to 95 percent of the amount required in the traditional sulphitation and neutralization reactions. The method can improve the cane juice neutralization reaction speed and the reaction degree as well as the decolorization effect, and reduce the residual sulfur.

Description

【Technical field】 The invention relates to a sugar making process, in particular to an improved sugarcane juice clarification process. 【Background technique】 The color value and sulfur content of white granulated sugar are the most important and most technically difficult quality indicators of white granulated sugar. Decolorization in sugar mills is done through clarification. At present, the most commonly used clarification processes in sugar factories are mainly sulfurous acid method and carbonic acid method. In the sulfite clarification process, by adding SO 2 , milk of lime and phosphoric acid to form calcium sulfite precipitation and calcium phosphate precipitation to adsorb and remove the colloids and pigments in the sugar juice. The advantages of the sulfurous acid method are short process flow, simple equipment and less investment, but the clarification effect is not as good as that of the carbonic acid method. In the carbonation clarification process, by adding ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C13D3/10C13D3/06C13B20/10C13B20/06

Inventor 黄永春李利军杨锋

Owner GUANGXI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com