Refining post-treatment method for non-woven cellulose fibers and non-woven cellulose fibers

A technology of cellulose fiber and treatment method, which is applied in the field of viscose fiber, and can solve problems such as poor whiteness uniformity and reduced strength index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

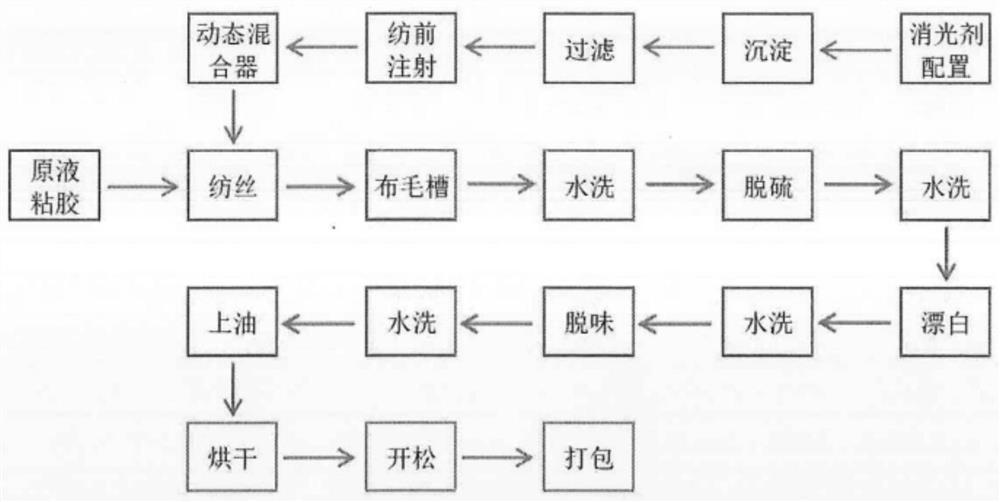

[0081] Example 1 A post-refining treatment method for non-woven cellulose fibers

[0082] Use pre-spinning injection equipment to evenly inject the matting agent dispersion liquid into the spinning tube according to the volume ratio of 0.008:1 to the raw liquid viscose and mix it with the raw liquid viscose. After being mixed evenly by a dynamic mixer, it is sent to the spinning machine, and passed through the nozzle of the spinning machine. Produces non-woven cellulose fibers.

[0083] The non-woven cellulose fibers produced by spinning are sent to refiners for processing. It goes through one water washing, desulfurization, two water washing, three water washing, one bleaching, four water washing, deodorization, five water washing, final water washing, and oiling process (including secondary bleaching).

[0084] The non-woven cellulose fiber processed above is sent to the drying equipment for drying, and the finished product of non-woven cellulose fiber is obtained after dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com