Intensified cane juice clarification method

A technology for cane juice and mixed juice, which is applied in the directions of using oxidation/reduction purification and alkaline earth compound purification, etc., can solve the problems of large equipment, low investment, large consumption, etc., so as to reduce heat transfer efficiency, increase energy consumption, and reduce production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] An enhanced sugarcane juice clarification method, based on the sulfitic and carbonic 2 and Ca(OH) 2 Added to sugarcane juice and reacted in a vortex reaction device to produce nano-scale ultrafine calcium carbonate particles, these ultrafine calcium carbonate particles were used as sulfur fumigation and SO in the reaction 3 2- and Ca 2+ CaSO formed by the reaction 3 The crystal nuclei, so that the formation of CaSO at a lower degree of supersaturation 3 Process method for clarification of precipitated cane juice.

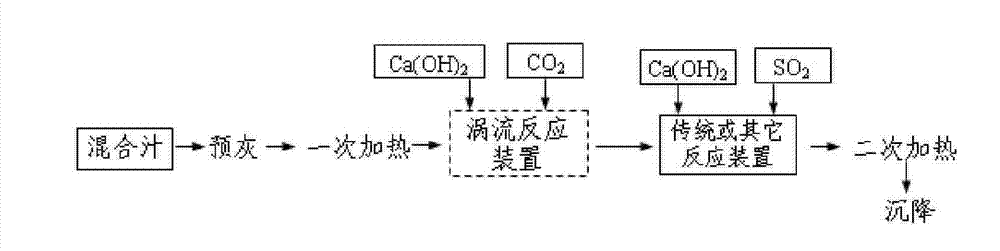

[0022] The specific process includes: pre-ash, primary heating, CO 2 Filling, sulfur fuming neutralization, secondary heating and settling processes (see figure 1 ), the CO 2 The filling process is to inject CO into the whole mixed juice after pre-ashing and heating once. 2 with Ca(OH) 2 , and pass the mixed juice to the vortex reaction device for CO 2 Saturation reaction, then carry out sulfur fumigation neutralization reaction with the sugarcane j...

Embodiment 2

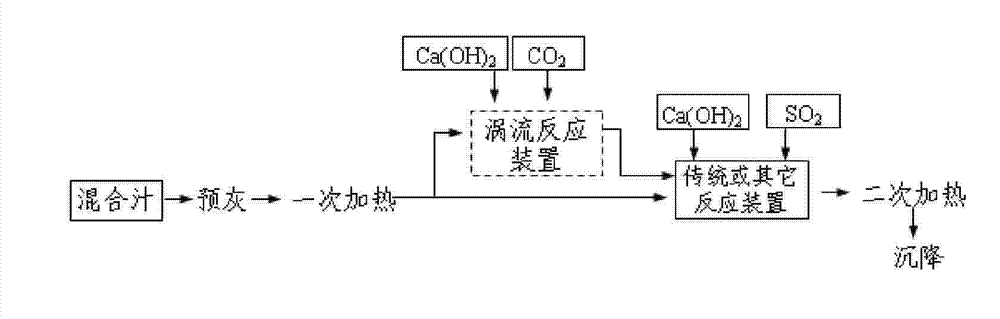

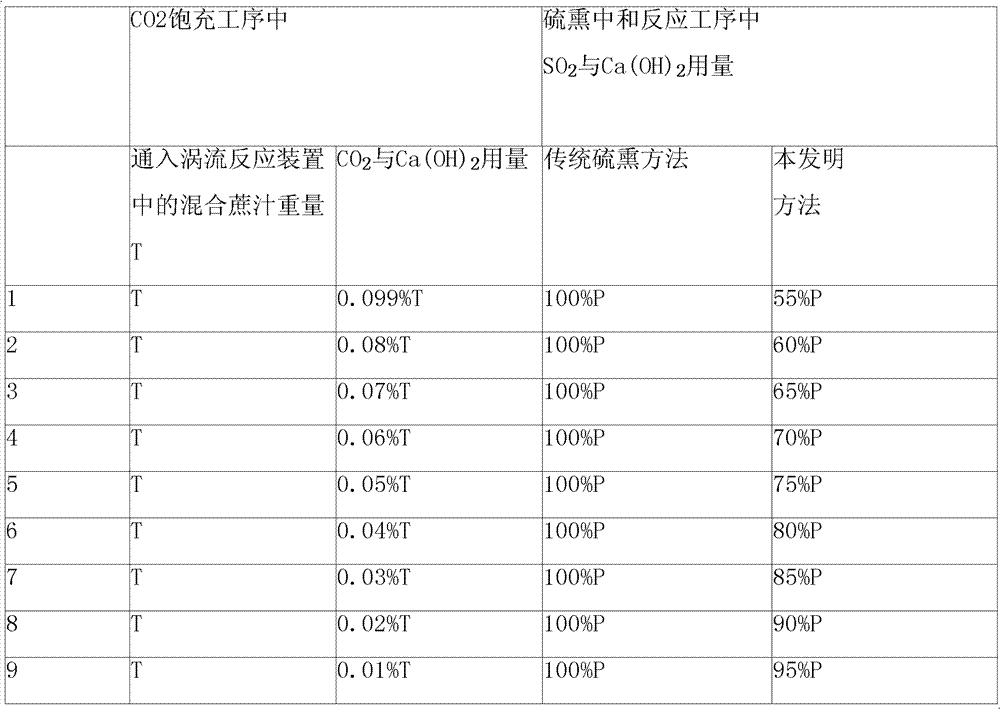

[0024] A kind of strengthened cane juice clarification method, its basic principle is the same as embodiment 1, the difference is: it is only part of the mixed cane juice after pre-ashing and heating 2 Filling process treatment, namely: CO 2 The filling process is to inject CO into a part of the mixed juice after pre-ashing and primary heating. 2 with Ca(OH) 2 , and lead the mixed juice to the vortex reaction device for CO 2 The reaction was saturated, and then the part was subjected to CO in a vortex reaction apparatus. 2 The sugarcane juice processed by the filling process and the other part are only pre-ashed, heated once without CO 2 The mixed juice processed in the filling process is mixed together for sulfur fumigation and neutralization reaction; for the specific process, see figure 2 ; In the sulfur fumigation neutralization process, after CO 2 The amount of the treated part in the full process and the amount without CO 2 The ratio of the amount of the treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com