Clarification method for sugarcane juice

A technology for squeezing juice and cane juice, which is applied in the field of clarification of sugarcane squeezed juice, can solve the problems of increasing residual sulfur dioxide, increasing the amount of sulfur, increasing the cost of sugar production, etc., and achieves the reduction of residual sulfur dioxide, reduction of emission, and color value Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

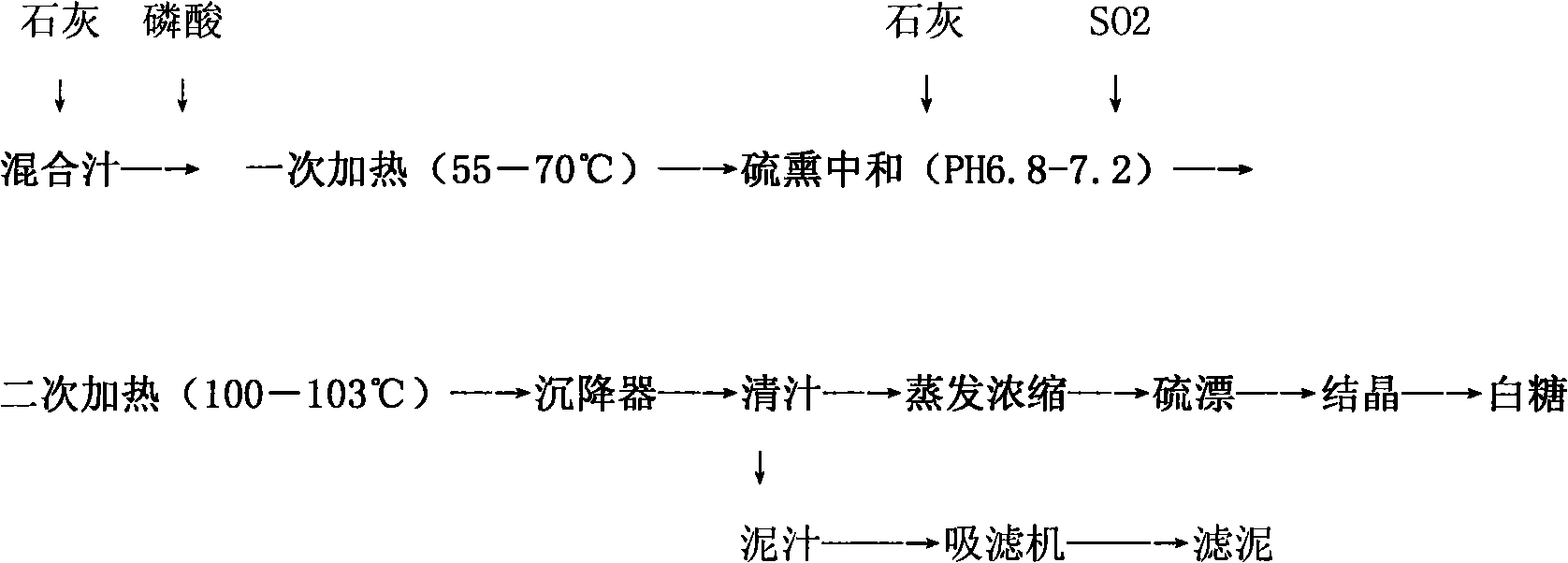

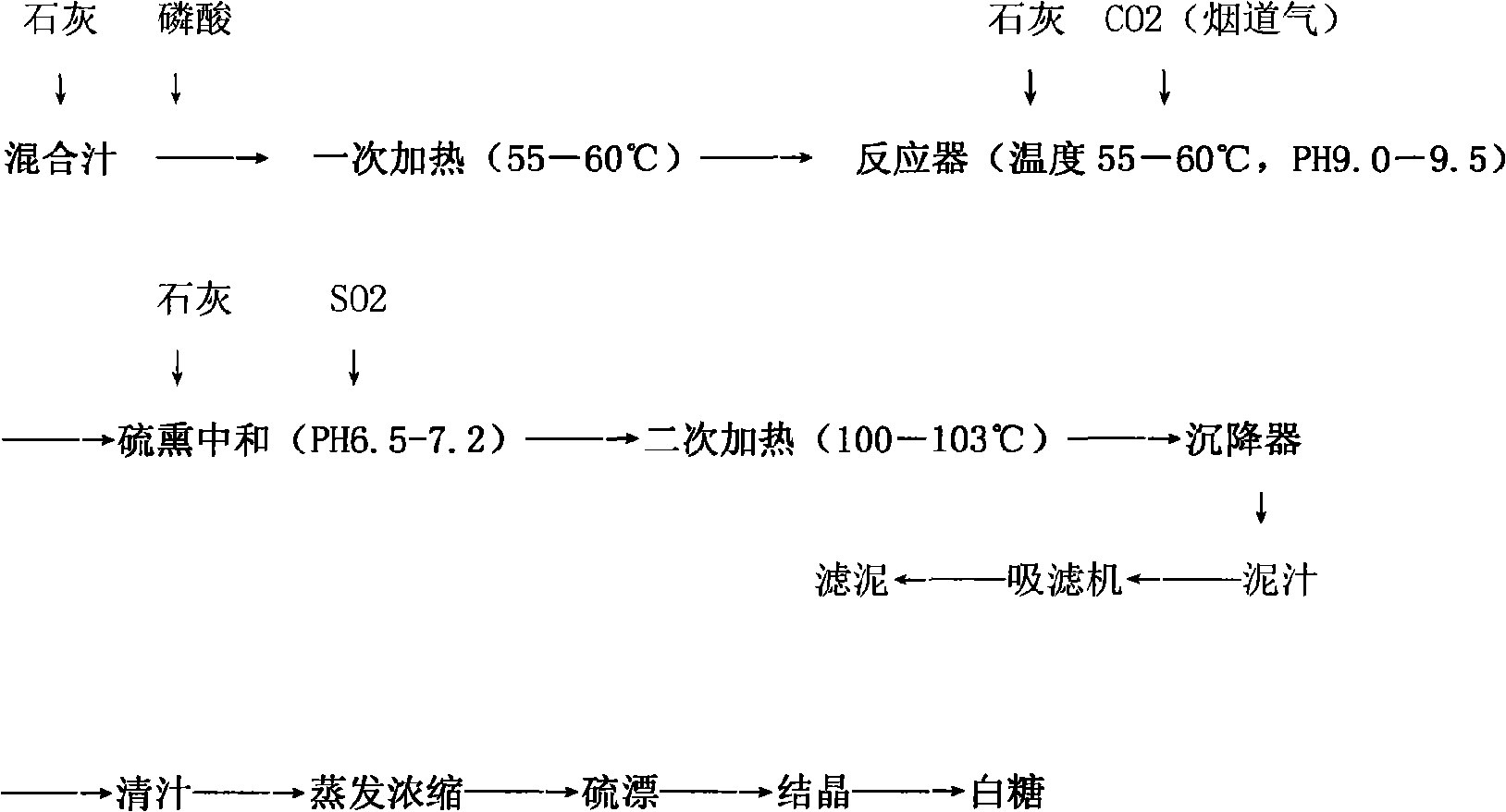

[0023] In the process flow of sulfite process, phosphoric acid and lime are added to the squeezed juice, and after one heating (heating temperature is 55-60°C), the cane juice is transported to the reactor to add lime and CO 2 Carry out carbonation, the amount of lime added is 0.1% of the amount of cane juice, CO 2 The effective absorption is 0.08% of the sugarcane juice, the pH value is controlled between 9.0 and 9.5, the filling temperature is controlled at 55-60°C, and then the sugarcane juice is sulfur fumigated and ashed with sulfur dioxide and lime as clarifiers. The sulfur fumigation intensity is 3, the pH value of the sulfur fumigation is 6.5-7.2, and after the second heating to 100-103°C, the calcium carbonate precipitate and the calcium sulfite precipitate are precipitated in the settler together, and the carbon dioxide comes from the exhaust gas of the boiler flue. The mud juice obtained from the settler enters the suction filter, and the filtered mud is used as fer...

Embodiment 2

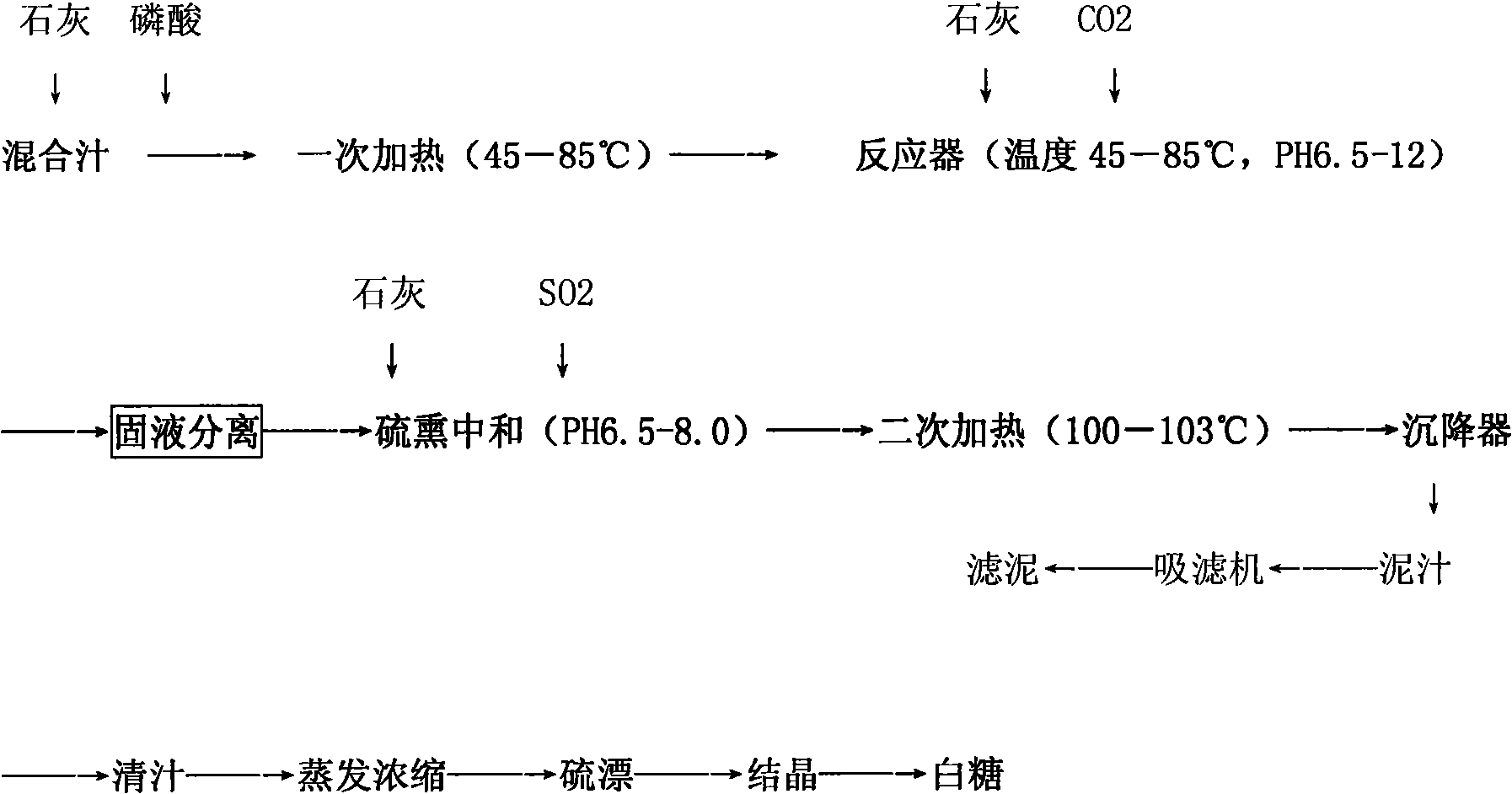

[0025] In the sulfite process process, phosphoric acid and lime are added to the squeezed juice, and after one heating (heating temperature is 45-55°C), the cane juice is transported to the reactor with flue gas (CO 2 ) is full, the amount of lime added is 0.9% of the amount of sugarcane juice, CO 2 The effective absorption is 0.8% of the sugarcane juice, the pH value is controlled between 10.5-11.0, the filling temperature is controlled at 45-55°C, the full-filled sugarcane juice is first heated to 65-70°C for the second time, and then Solid-liquid separation removes solid impurities, and the obtained clear juice is treated with sulfur dioxide and lime as clarifying agents for sulfur fumigation and ash neutralization. The sulfur fumigation intensity is 18, and the sulfur fumigation pH value is 7.2 to 7.8, and then heated for the third time to After 100-103°C, the cane juice enters the settler to separate the sediment from the clear juice. The mud juice obtained from the sett...

Embodiment 3

[0027] In the sulphite process flow, phosphoric acid and lime are added to the squeezed juice, and after heating (55-70°C) once, the cane juice is transported to the reactor with the waste gas produced by alcohol (CO 2 ) is full, the amount of lime added is 0.4% of the amount of sugarcane juice, CO 2 The effective absorption is 0.32% of the sugarcane juice, the pH value is controlled between 8.2 and 8.4, the filling temperature is controlled at 55-70°C, and calcium carbonate is formed to absorb impurities in the sugarcane juice and form solid impurities. The sugarcane juice containing solid impurities is then sulfur fumigated and ash neutralized with lime and sulfur dioxide (sulfur fumigation intensity: 10) as clarifiers. The pH value of sulfur fumigation is controlled at 6.8-7.2. The calcium precipitate is precipitated in the settler together with the calcium sulfite precipitate. The mud juice obtained from the settler enters the suction filter, and the filtered mud is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com