Patents

Literature

32results about "Sucrose extraction by physical means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Separation of sugars, sugar alcohols, carbohydrates and mixtures thereof

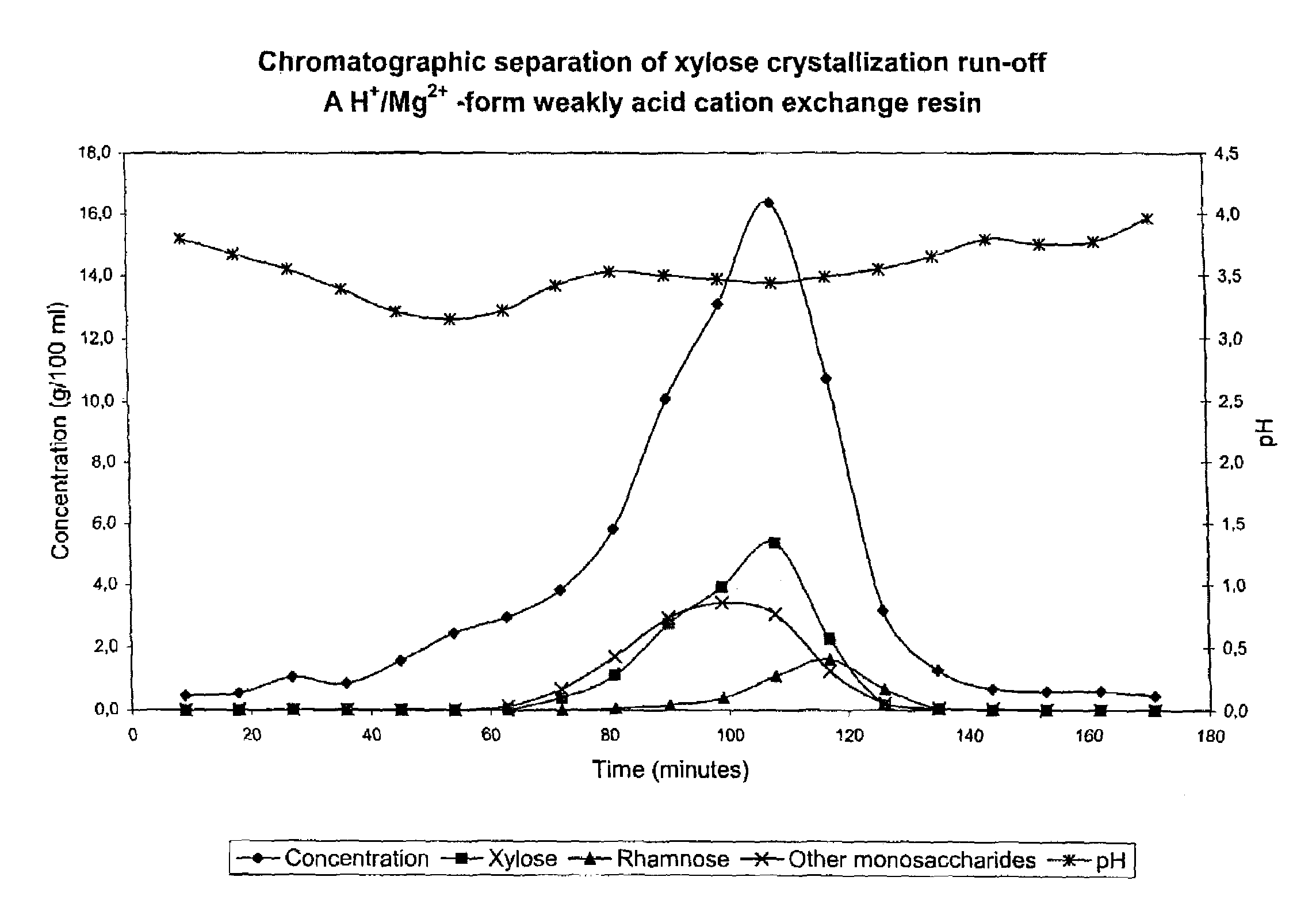

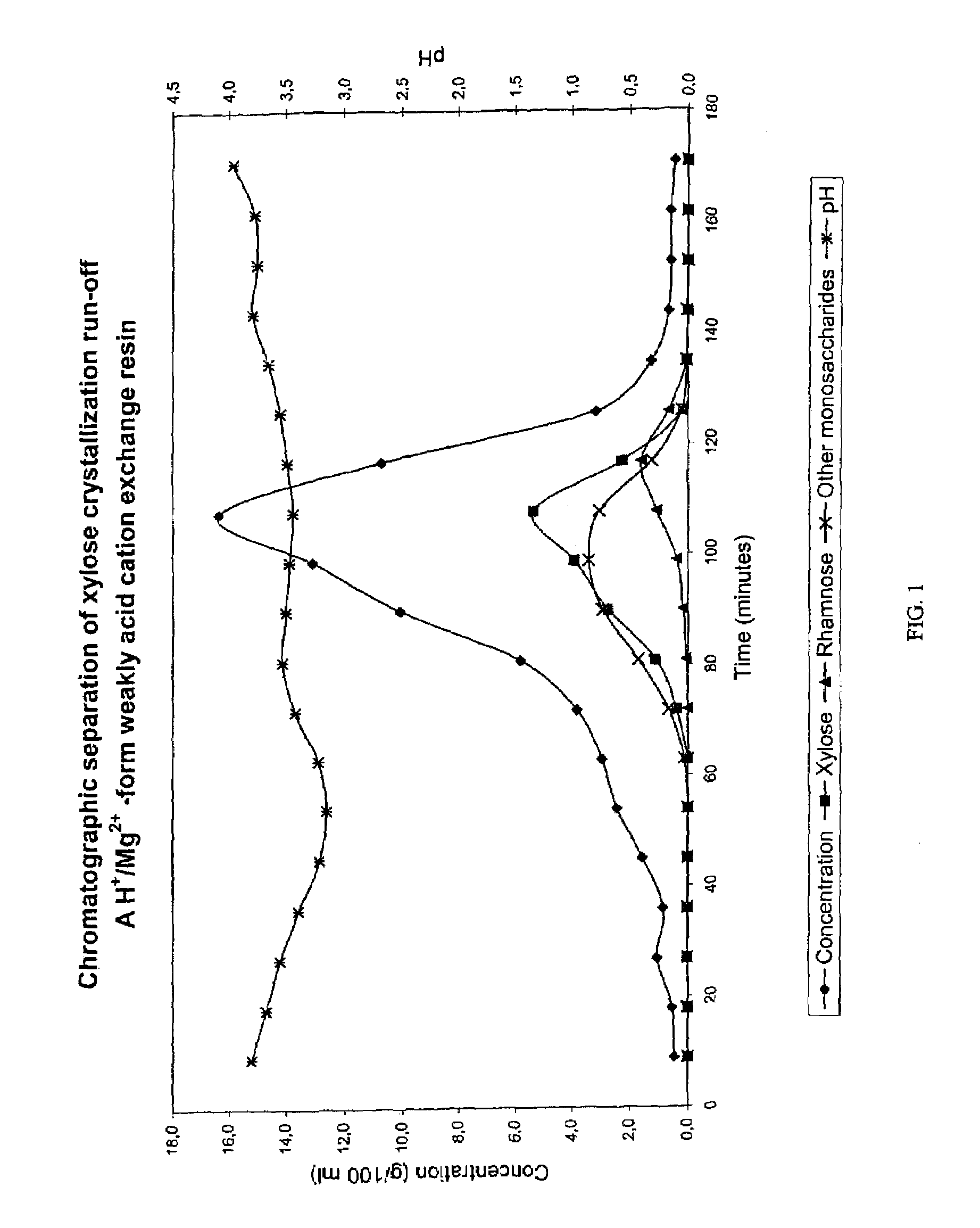

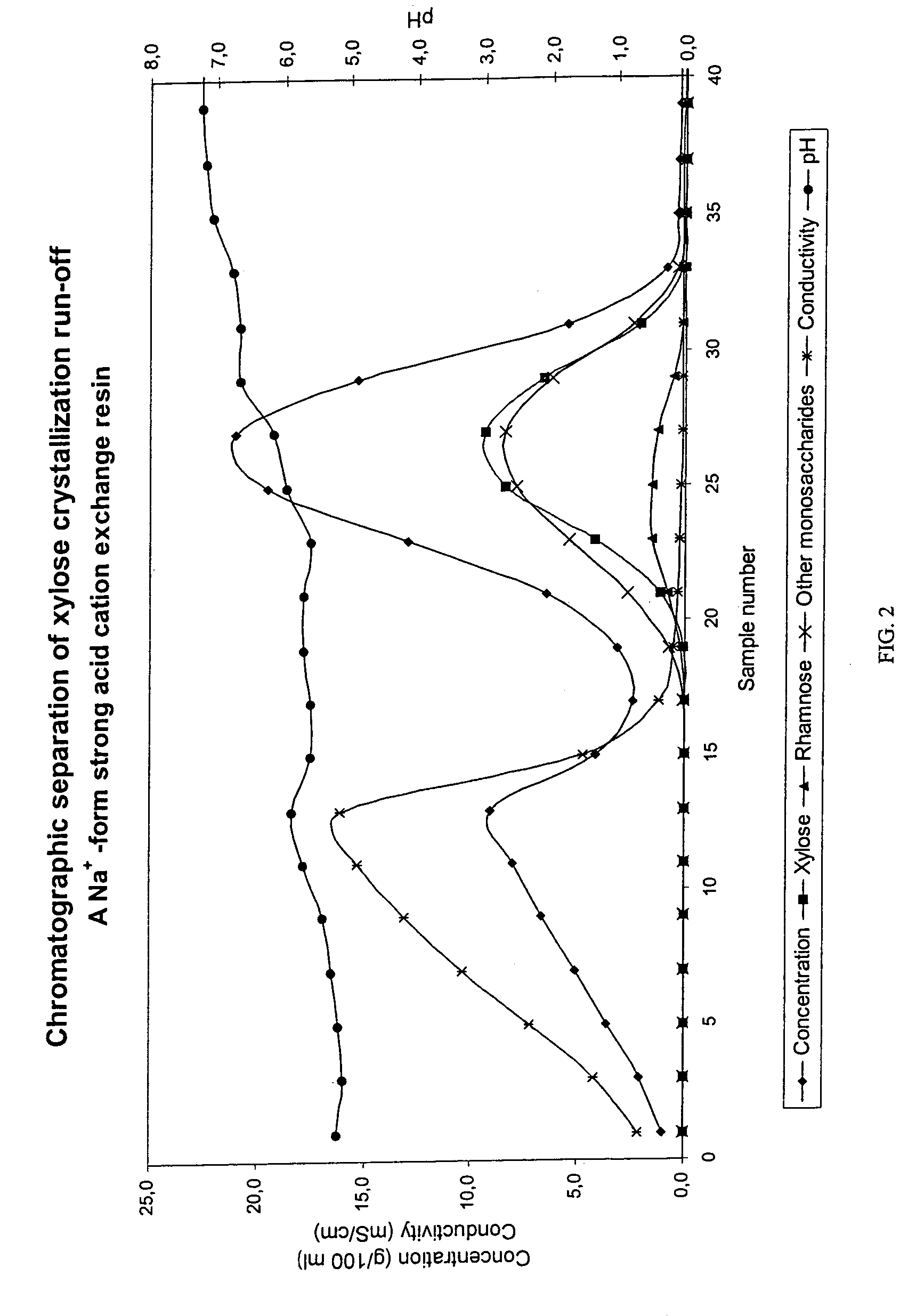

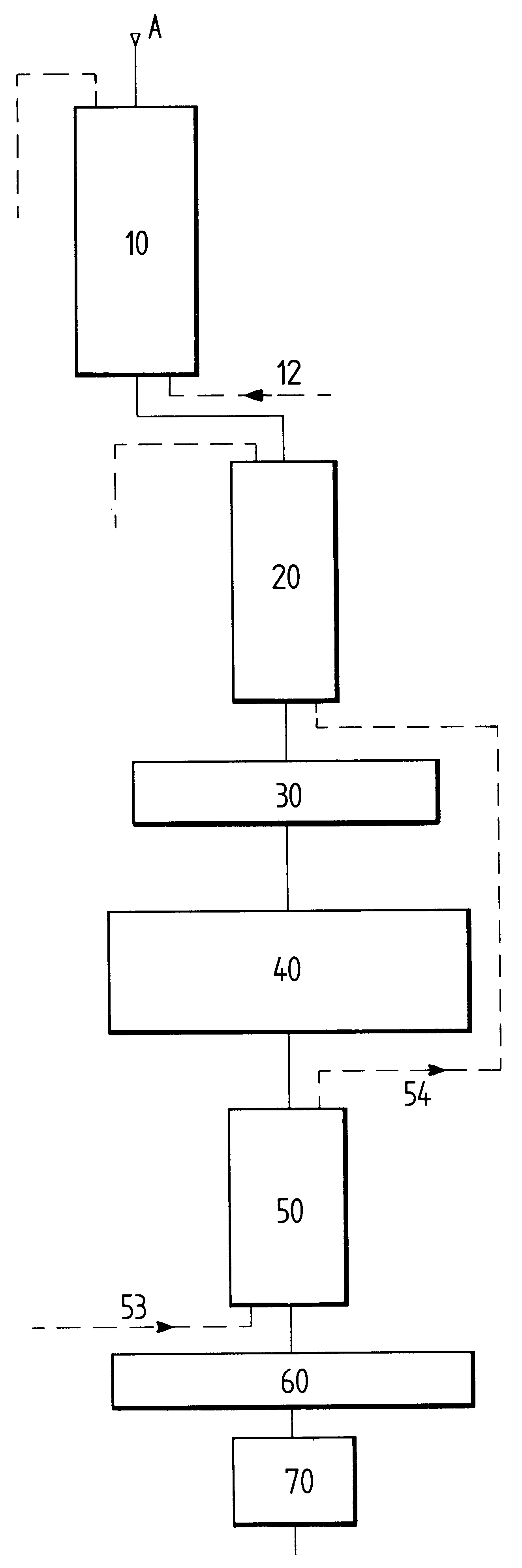

InactiveUS7361273B2Efficient separationCation exchanger materialsIon-exchanger regenerationChromatographic separationAlcohol sugars

The present invention relates to a method of separating sugars and sugar alcohols from each other. More particularly the present invention relates to the use of a weakly basic anion exchange resin in a chromatographic separation process. The advantage of the present invention compared with the prior art is that it is especially suitable for separating reducing sugars in acidic conditions as well as for example in weakly acidic conditions. The method using chromatographic separation comprises at least one step where a weakly basic anion exchange resin is used in a chromatographic column or in a part of a column.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Method of processing whey for demineralization purposes

InactiveUS6383540B1Reduce maintenanceLess upkeepIon-exchanger regenerationSolid sorbent liquid separationProtonChloride

A method of treating whey for demineralization purposes, the method comprising a stage of separating out salts by transfer through electrodialysis or nanofiltration membranes, wherein, upstream from this separation stage, the method comprises in succession at least one step of exchanging divalent cations for protons and at least one step of exchanging divalent anions for chloride ions.

Owner:EURODIA IND SA

Process for fractioning vinasse

InactiveUS6022394AIncrease PotassiumPromote crystallizationIon-exchange process apparatusBy-product recoveryOrganic fractionOrganic acid

PCT No. PCT / FI95 / 00329 Sec. 371 Date Mar. 10, 1997 Sec. 102(e) Date Mar. 10, 1997 PCT Filed Jun. 7, 1995 PCT Pub. No. WO96 / 00776 PCT Pub. Date Jan. 11, 1996The invention relates to a process for fractioning vinasse, in which process the pH value of the vinasse is lowered by adding acid, and the formed precipitate is separated in order to obtain an inorganic fraction, whereupon an organic fraction remains. The invention also relates to the products obtained. The inorganic fraction mainly contains potassium salt, and it is useful for example as a fertilizer. The organic fraction mainly contains organic acids, and it is useful for example as an additive in animal feed and in producing silage.

Owner:CULTOR LTD +1

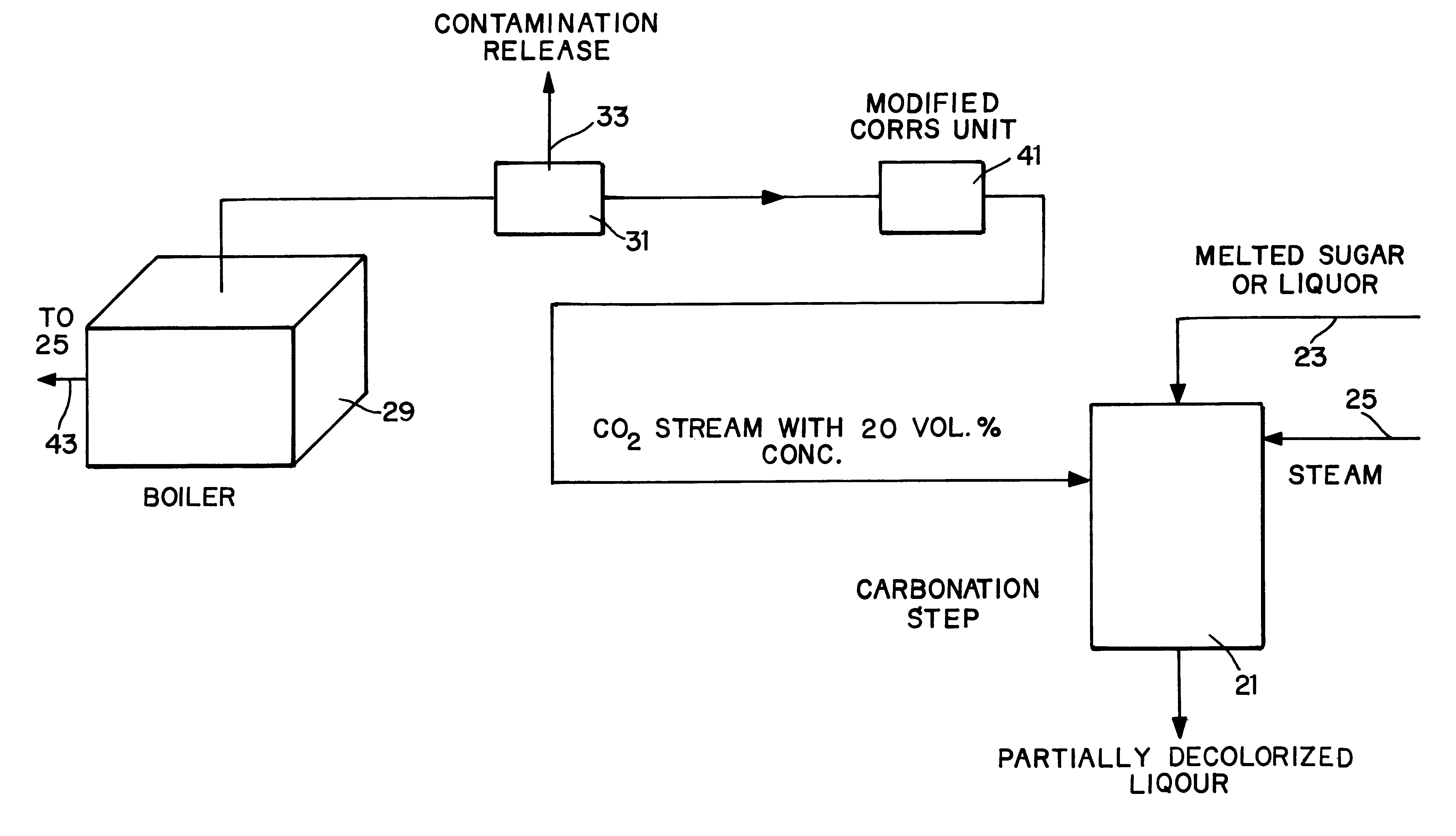

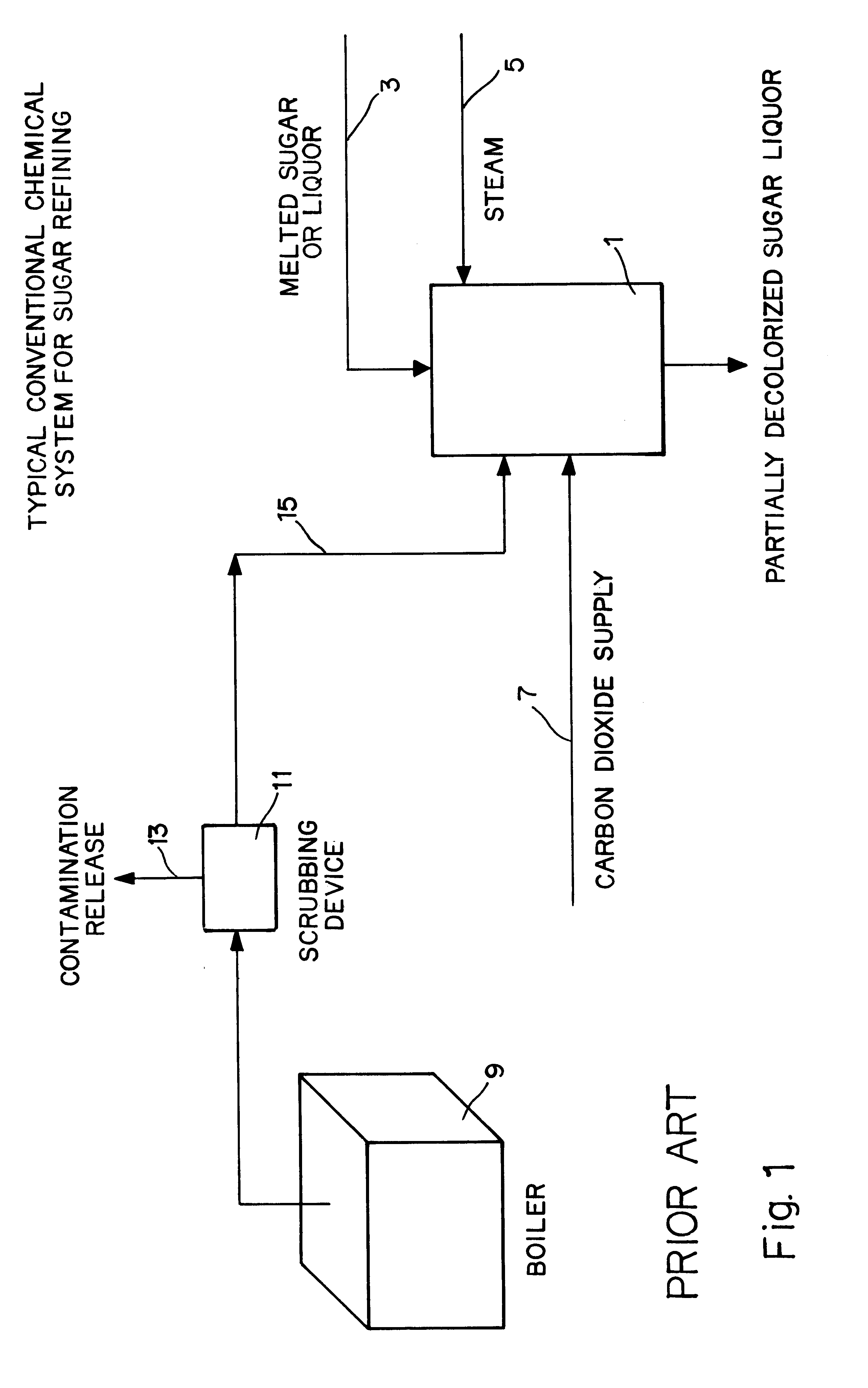

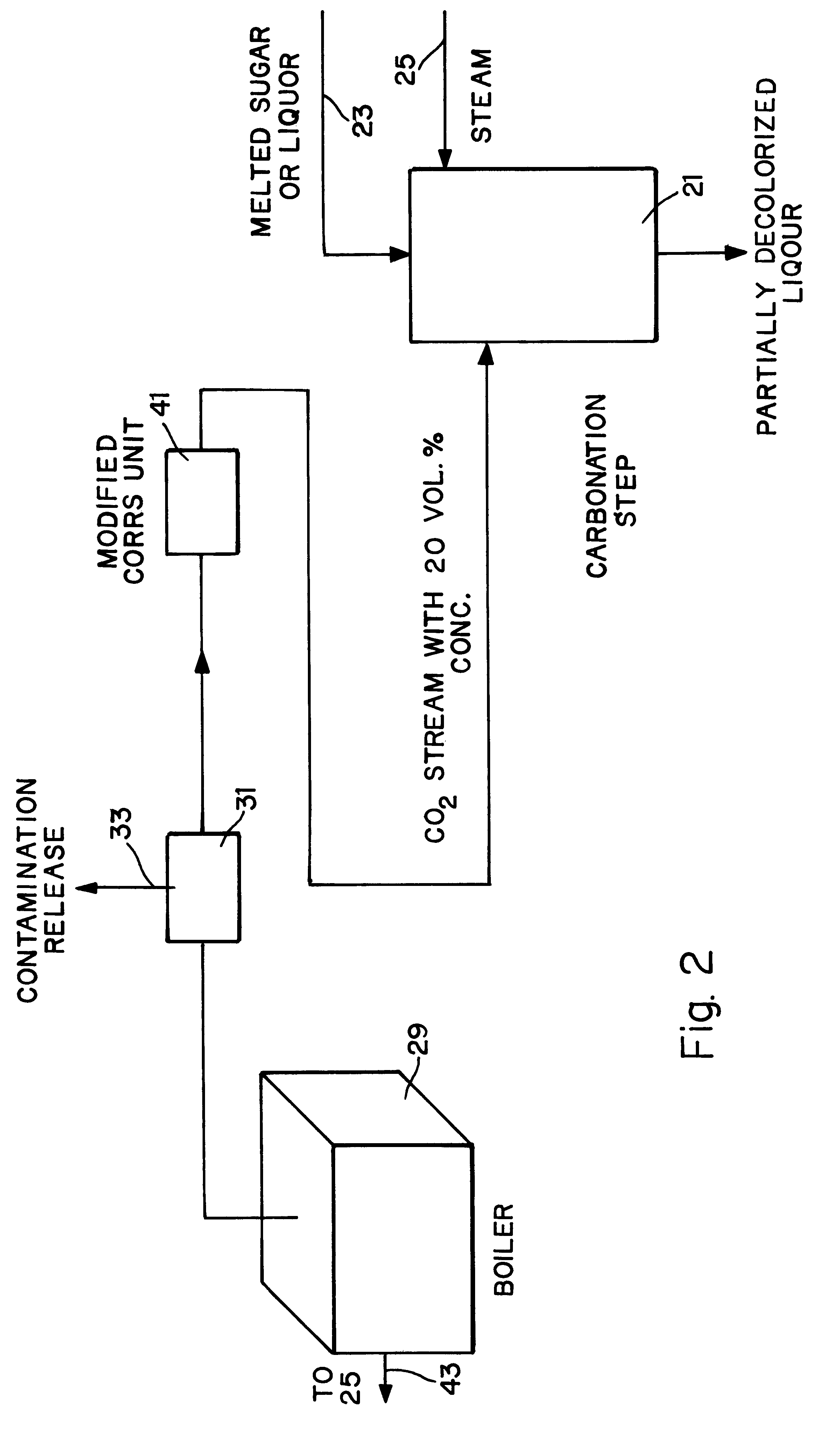

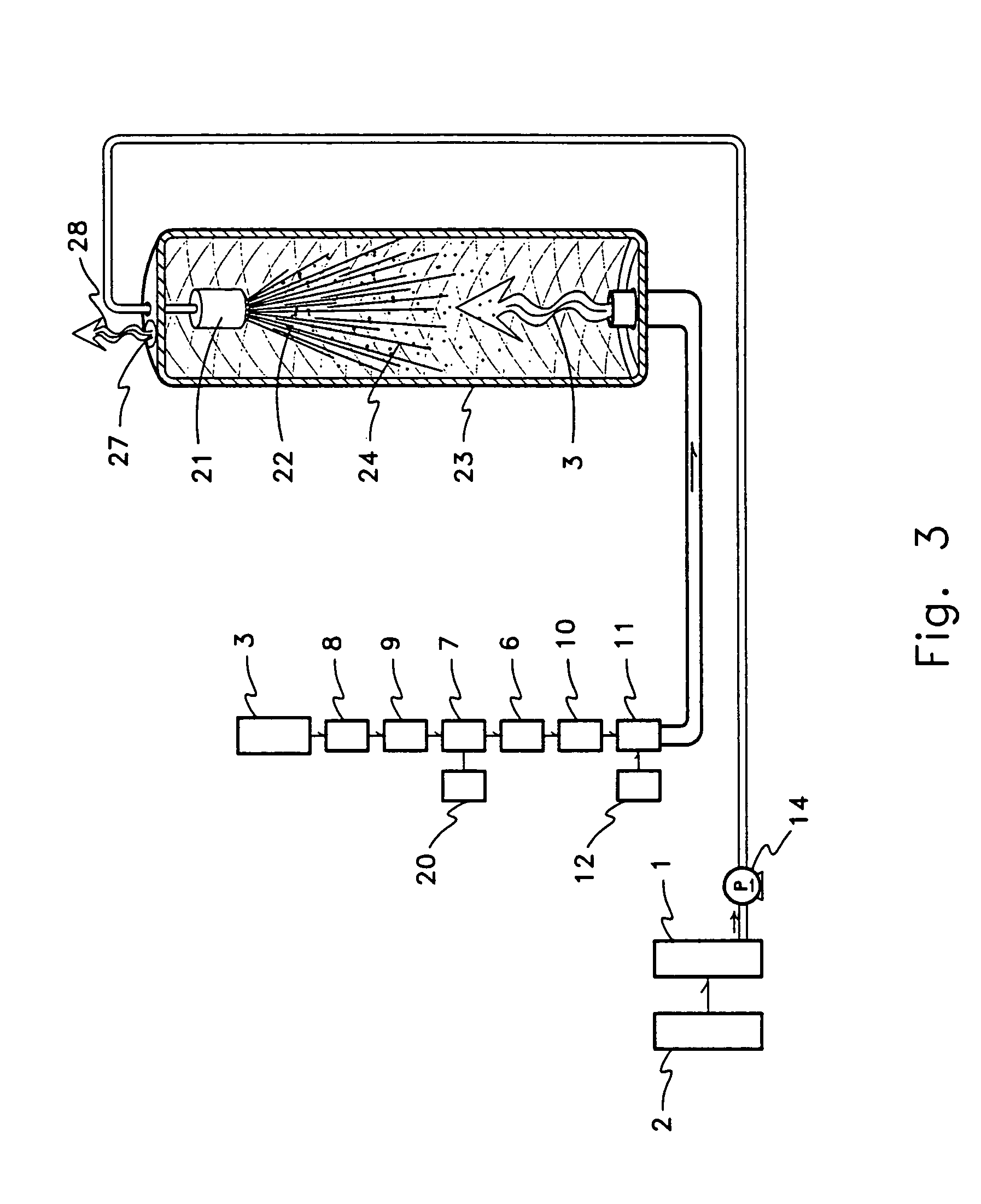

System and method for refining sugar

InactiveUS6176935B1Speed up the processEasily incorporated into existing refineryPurification using alkaline earth metal compoundsSugar crystal separationFlue gasSugar refining

A sugar refining process uses carbon dioxide obtained from a module containing a plurality of gas-permeable polymeric membranes. Flue gas from a boiler is scrubbed, and then passed through the gas-separation module. The output of the module contains an enhanced concentration of carbon dioxide, in the range of about 20% by volume. The carbon dioxide enhanced gas is then directed into a reactor in which raw sugar is exposed to carbon dioxide to cause carbonation, an essential step in the decolorization of the raw sugar. The same boiler used to produce the carbon dioxide is also used to produce steam which drives the reaction. The present invention provides carbon dioxide for carbonation in a highly efficient manner, as the gas separation membrane has no moving parts and requires little maintenance. The invention is especially suited for retrofitting existing sugar refining plants, to improve their efficiency, at a relatively small cost.

Owner:AIR LIQUIDE AMERICA INC +1

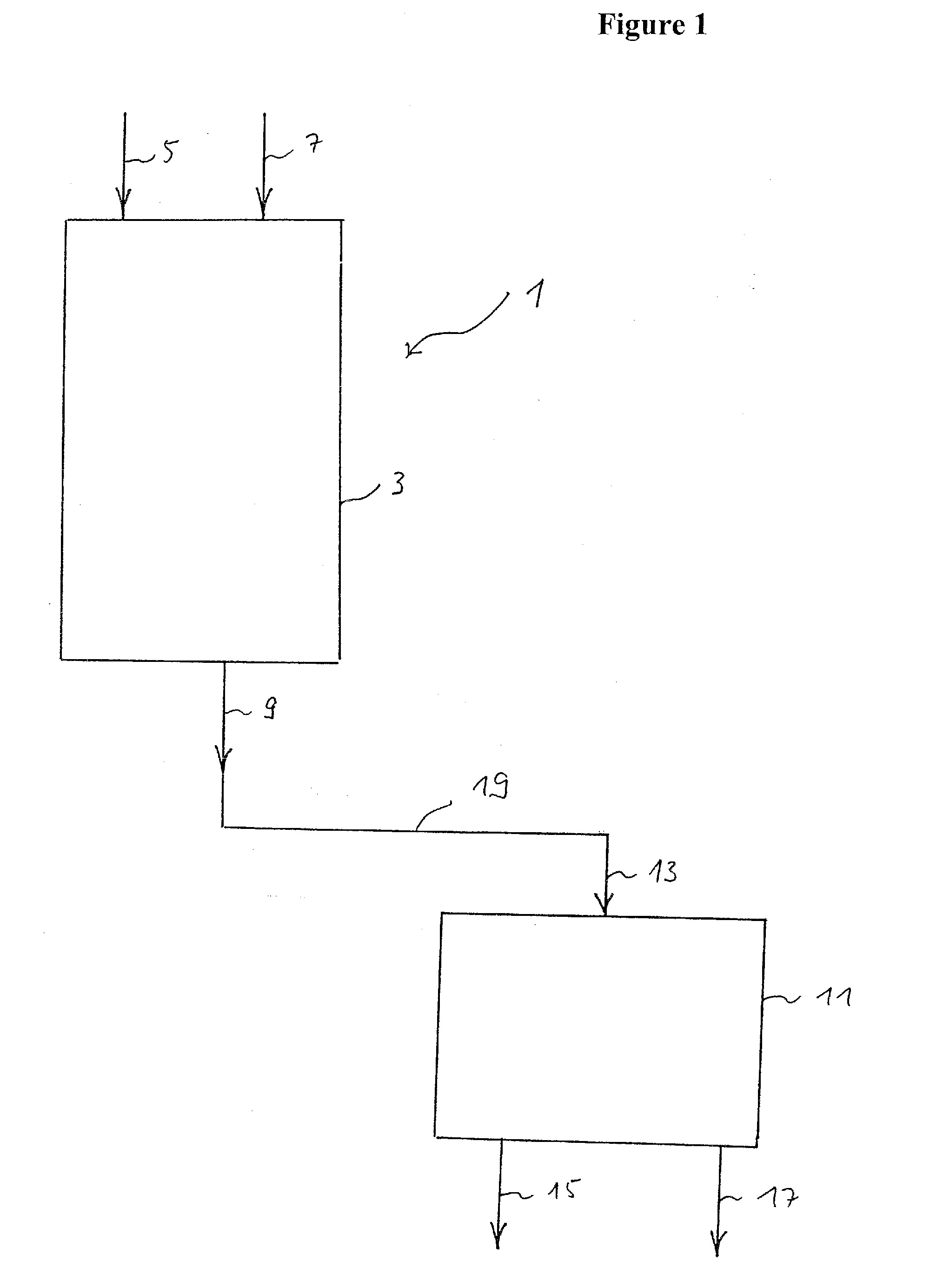

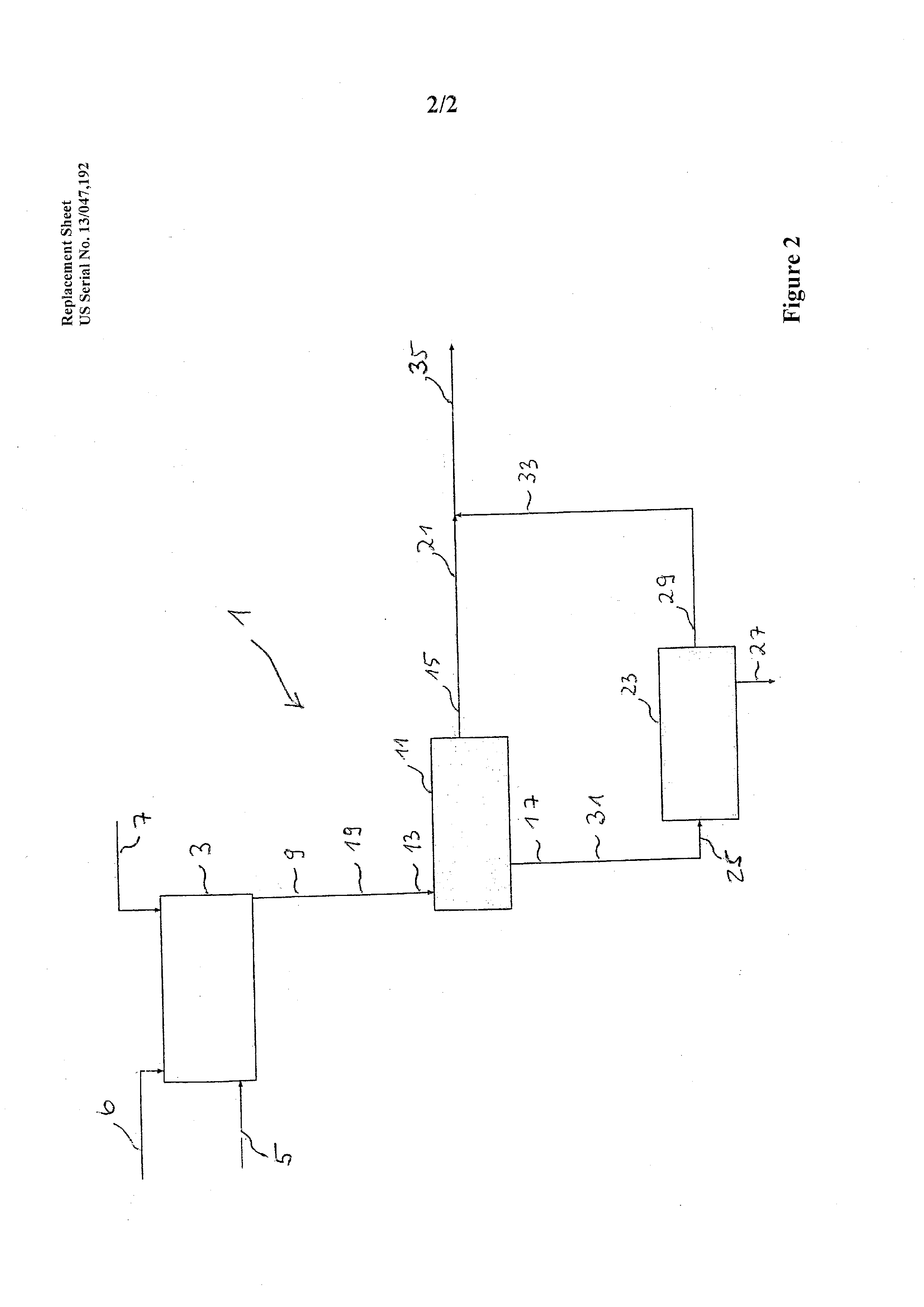

Separation process

The invention relates to an improved nanofiltration process for separating and recovering components, such as sugars and sugar alcohols from multicomponent mixtures. The process of the invention is characterized by collecting the nanofiltration retentate / permeate in several fractions with different purity, optional recycling of at least one of the collected nanofiltration retentate / permeate fractions to the nanofiltration and recovering the desired component from the nanofiltration permeate / retentate fractions by different methods. In one embodiment of the invention, the process comprises a combination of nanofiltration and chromatography.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Natural Sweetener

ActiveUS20080045464A1Improve gutLowering GIOrganic active ingredientsSugar food ingredientsPhytochemicalWaste product

Owner:POLY GAIN PTE LTD

Carbohybrate purification using ultrafiltration, reverse osmosis and nanofiltration

InactiveCN1242776APurification using adsorption agentsSugar derivativesEnzymatic synthesisUltrafiltration

The invention provides methods for purifying carbohydrates, including oligosaccharides, nucleotide sugars, and related compounds, by use of ultrafiltration, nanofiltration and / or reverse osmosis. The carbohydrates are purified away from undesired contaminants such as compounds present in reaction mixtures following enzymatic synthesis or degradation of oligosaccharides.

Owner:NEOSE TECH

Natural sweetener

Owner:POLY GAIN PTE LTD

Method and apparatus for producing a work product

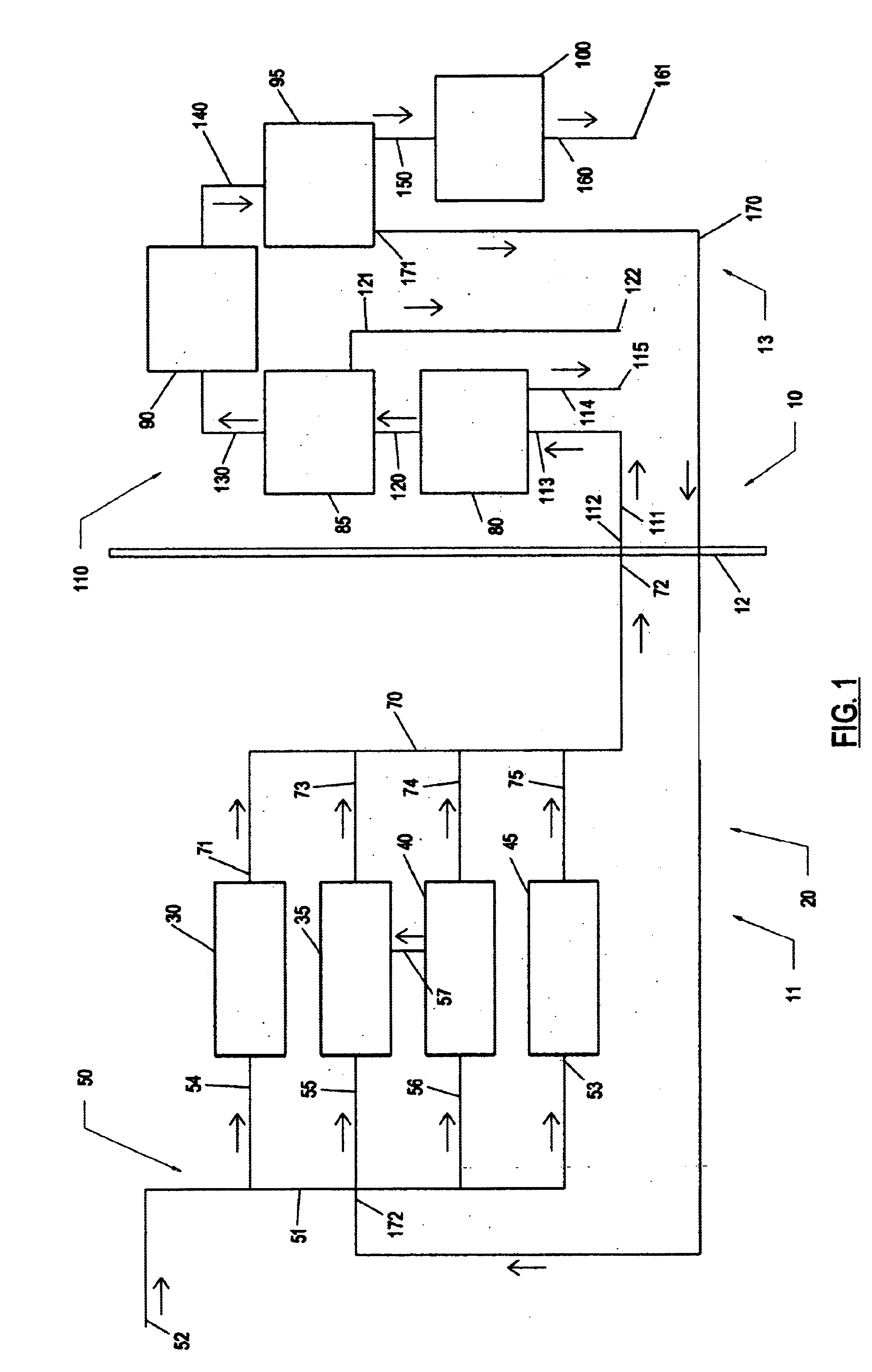

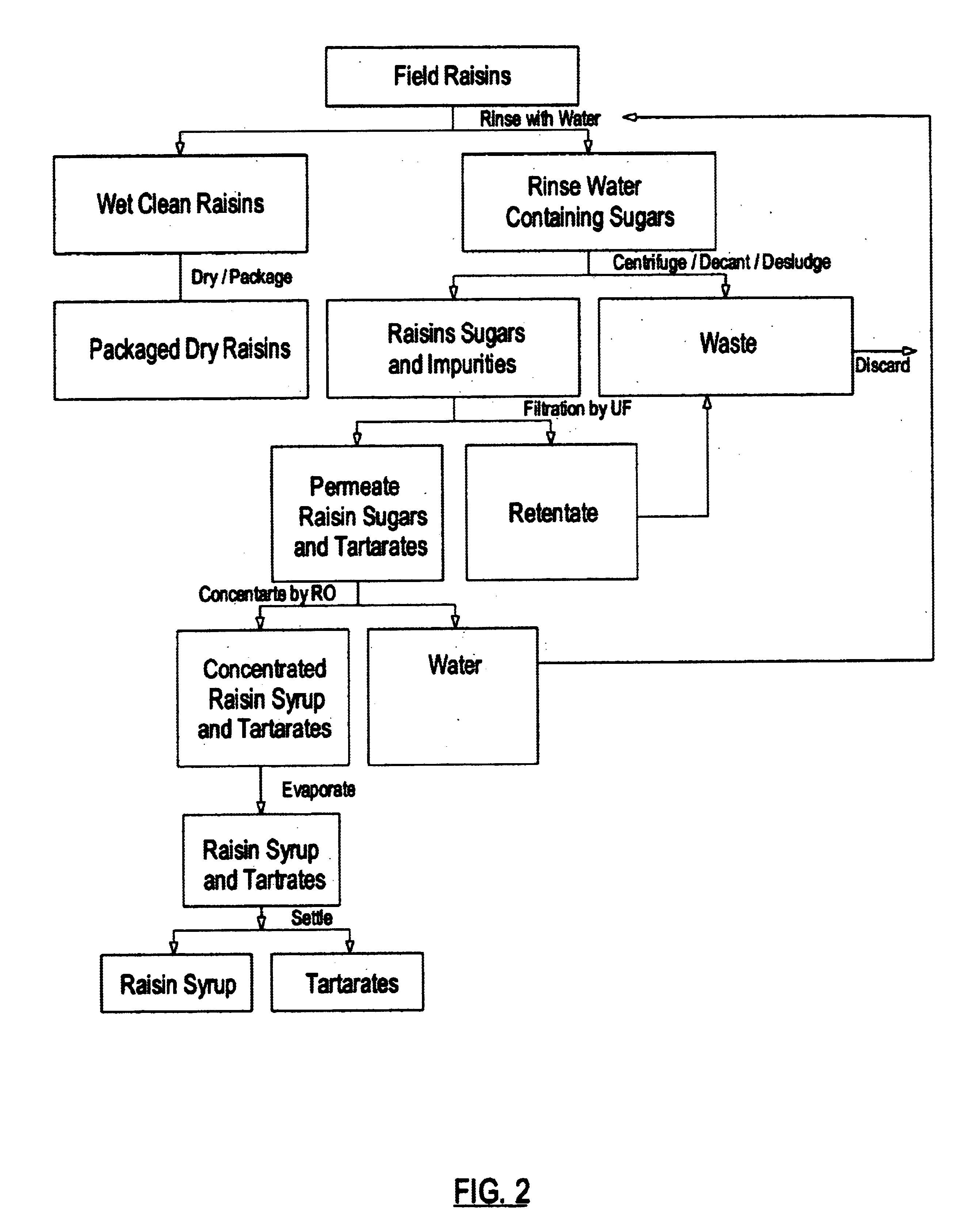

InactiveUS6736903B2Low costReduce the ratioPressurized chemical processSugar crystal separationReverse osmosisEngineering

A method for producing a work product including the steps of receiving a first fluid composed of a liquid, a target substance and at least one residual substance; passing the first fluid through a first work station for separating the residual substance from the first fluid to produce a secondary fluid substantially composed of the liquid and the target substance; and treating the secondary fluid to reduce the proportion of the liquid relative to the target substance in the secondary fluid to form the work product. An apparatus for producing a work product including an intake conduit adapted to receive a first fluid, composed substantially of water, a sugar substance and residual substances, from a rinsing system for raisins or the like; a first processing station adapted to remove the residual substances from the first fluid to form a second fluid, composed substantially of water and the sugar substance; and a second processing station adapted to treat the second fluid by reverse osmosis, nanofiltration, or the like to reduce the proportion of water relative to the sugar substance in the second fluid to form the work product.

Owner:SUNSHIE RAISIN CORP

System to produce sugar from plant materials

InactiveUS6656287B2Reduce the amount requiredReduce concentrationPurification by oxidation/reductionPurification using adsorption agentsProcess systemsFruit juice

A process system that uses a reduced amount of lime or other base to clarify or purify juice obtained from plant material such as sugar cane, sugar beets, or sweet sorghum. Specifically, apparatus and methods to reduce volatile materials in juice providing a product that has an increased pH requiring the use of less lime or other base to achieve the desired pH values for clarification or purification.

Owner:ECOLAB USA INC

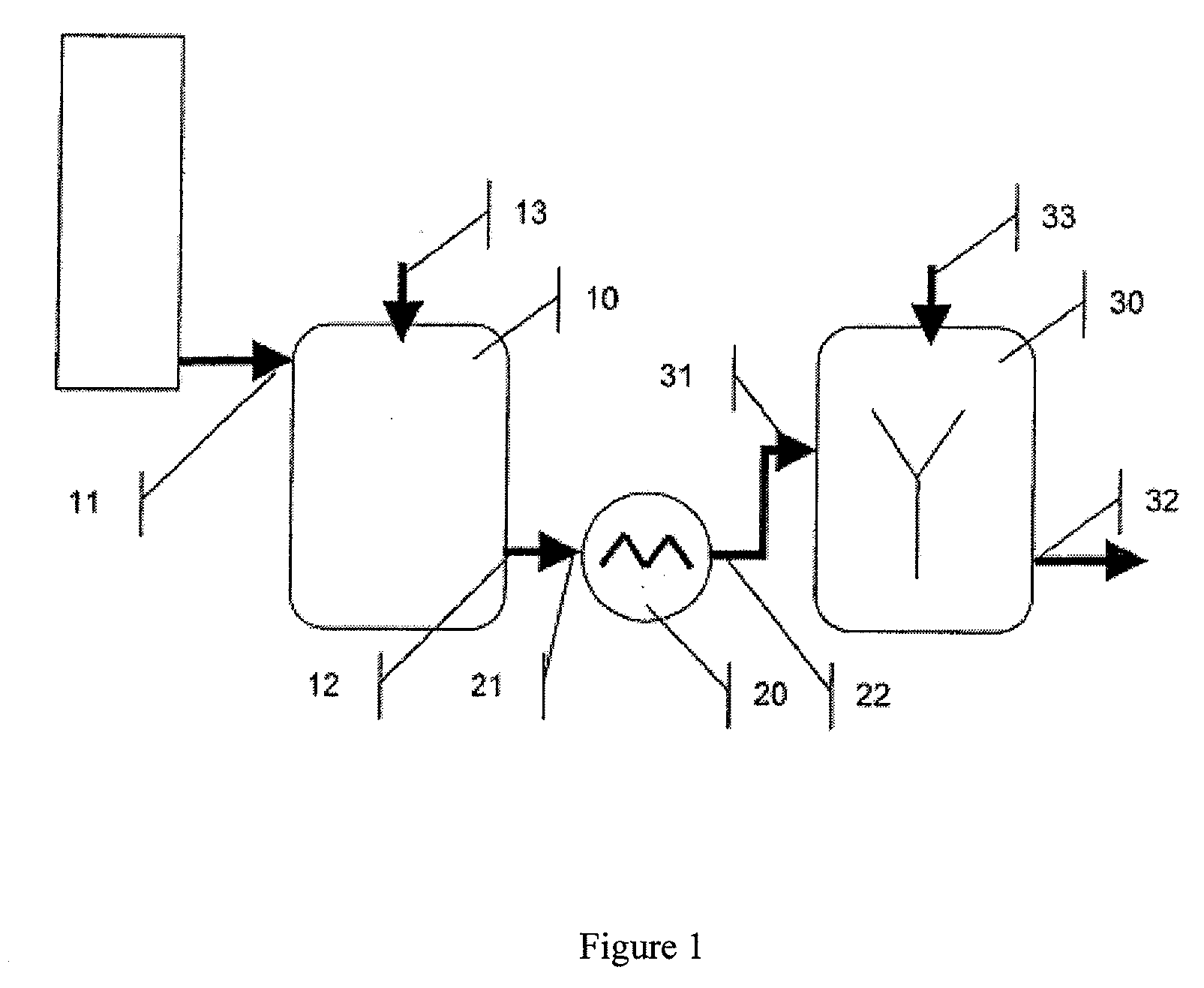

Raw juice alkalinization

ActiveUS20100043783A1Improve filtration efficiencyReduce the valuePurification using alkaline earth metal compoundsSedimentation separationSaccharumImproved method

The invention concerns an improved method for purification of raw sugar beet juice, which is obtained by extraction from sugar beets, and to devices for purification of raw sugar beet juice. The invention further concerns a method for producing sucrose syrup or sucrose from raw sugar beet raw.

Owner:SUDZUCKER AG MANNHEIM OCHSENFURT

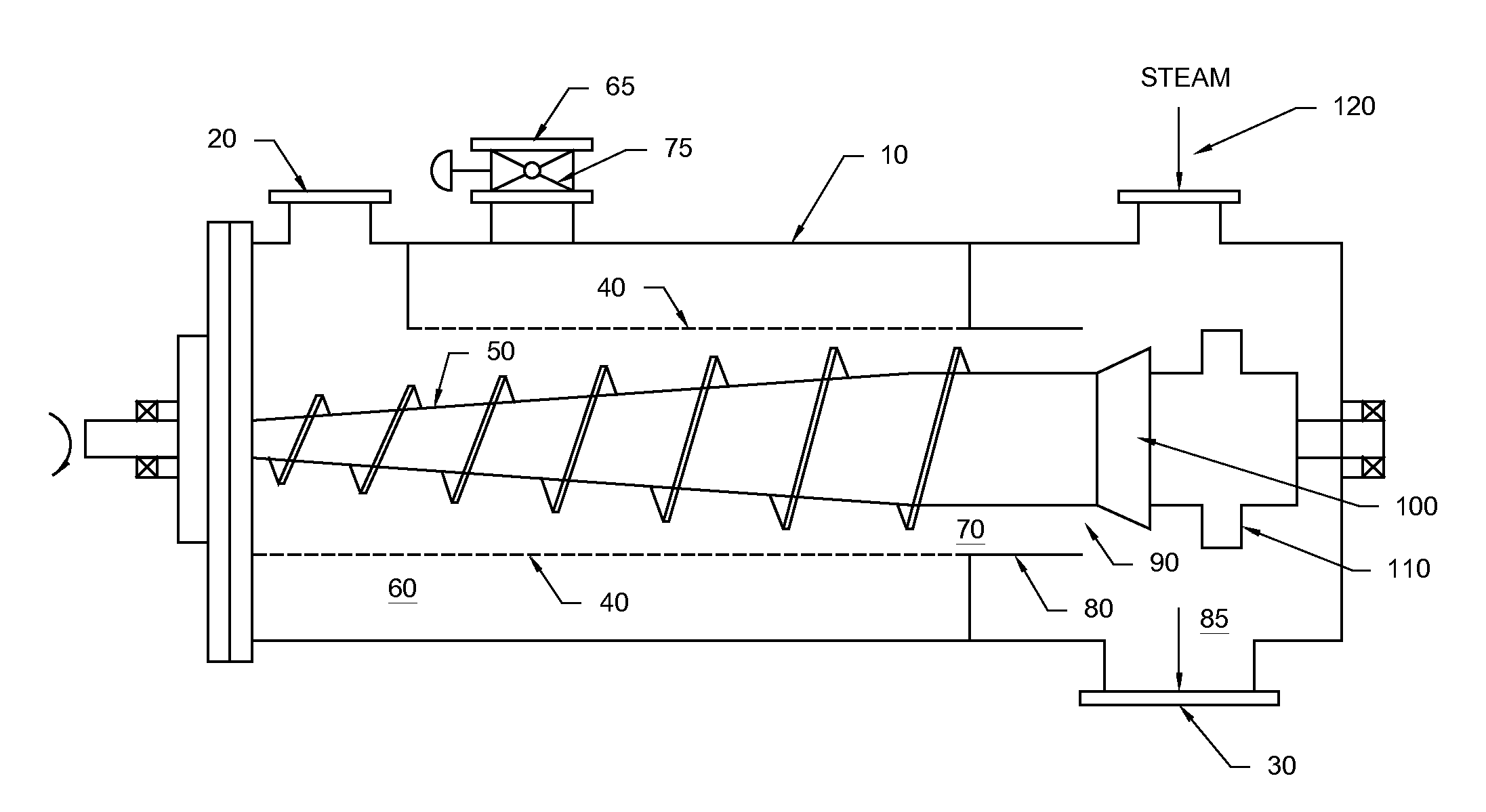

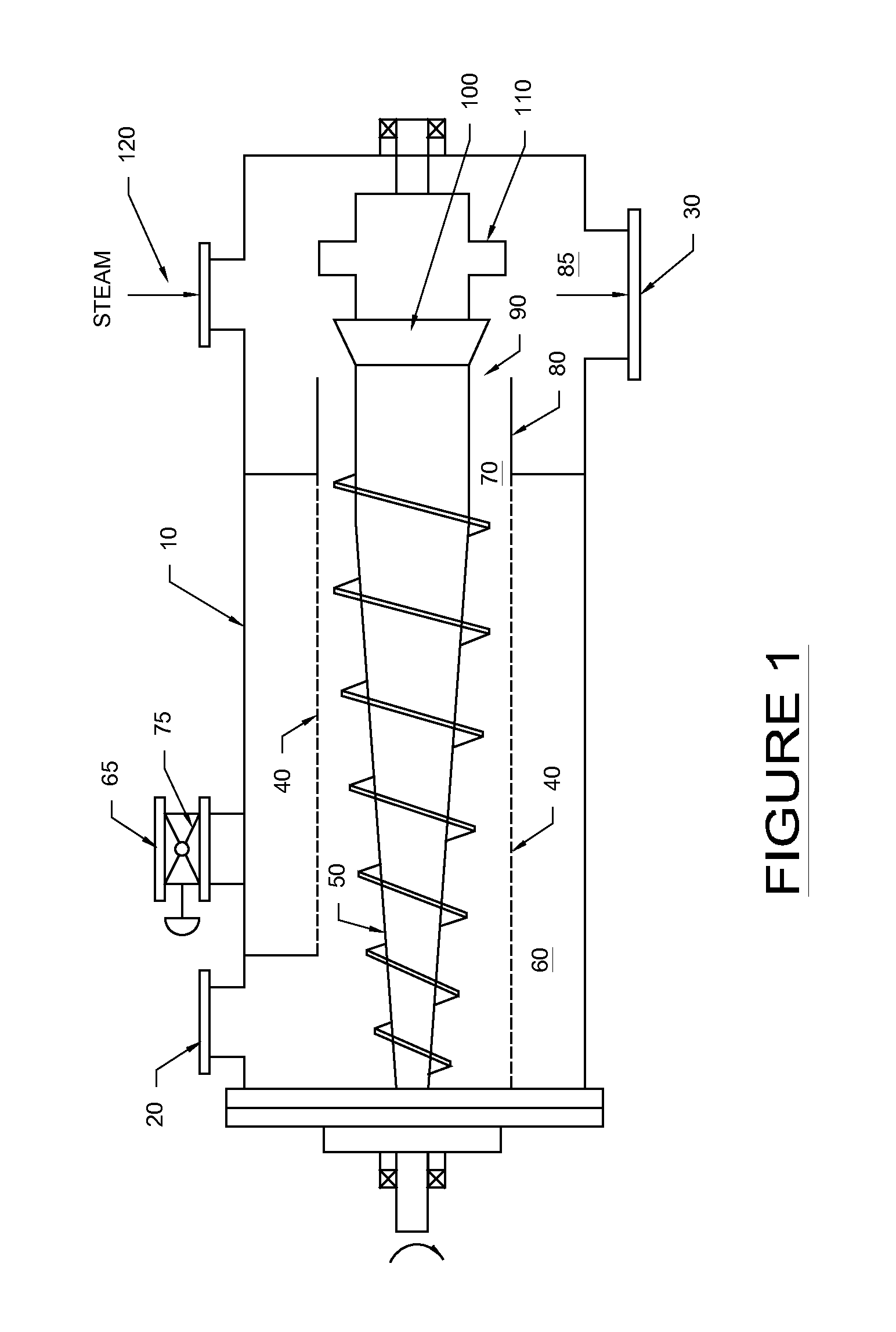

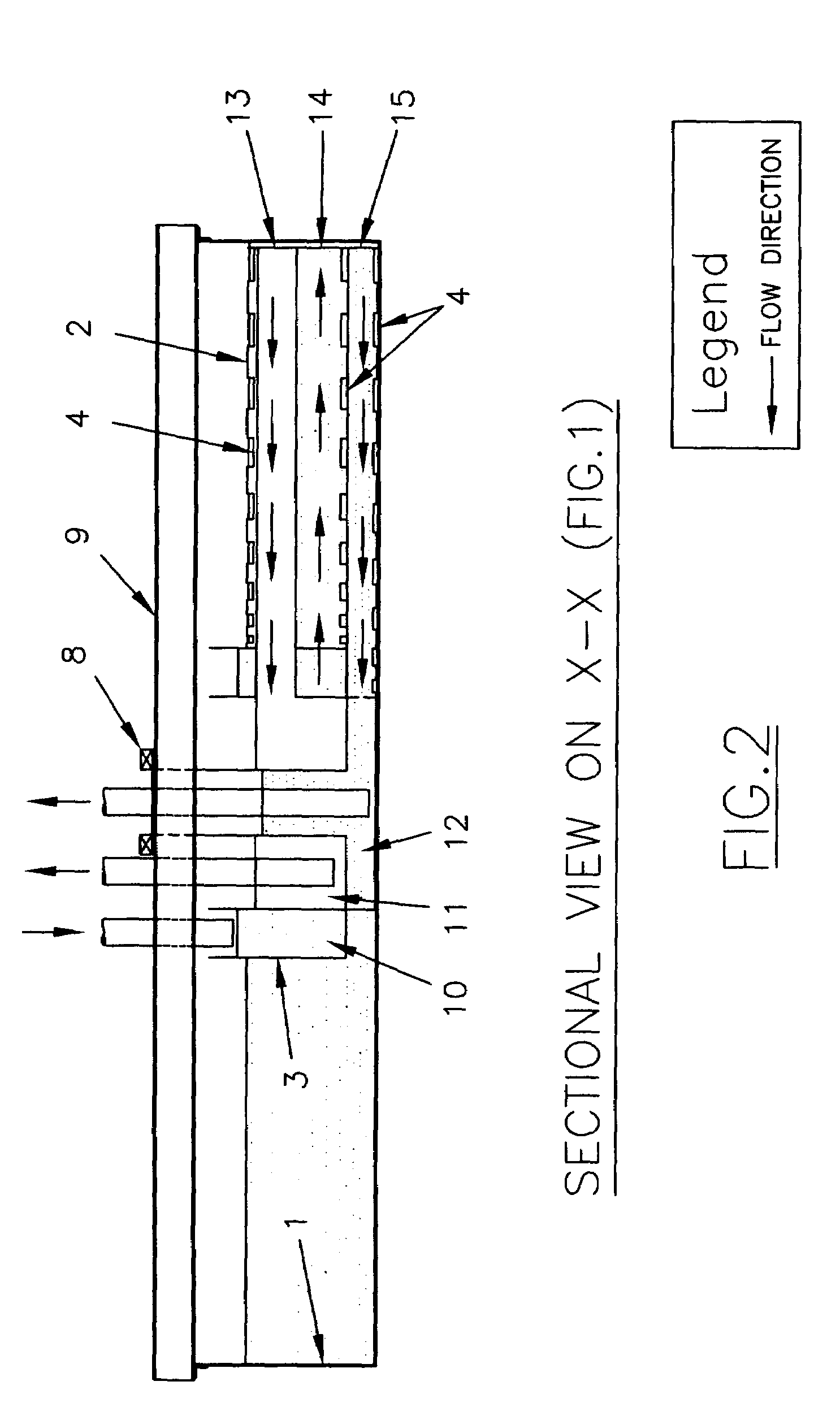

Method for removing liquid from a slurry

ActiveUS20150165709A1Reduce liquid contentPurification using adsorption agentsSludge treatmentDifferential pressureSlurry

The method includes the following steps: (i) feeding a slurry into the inlet of a press; (ii) removing liquid from the slurry as the slurry advances through a deliquefying section of the press, thereby producing a pressate stream; (iii) forming a plug of material as the slurry is advanced through a plug formation section of the press; (iv) advancing the plug of material to a discharge section of the press; and (v) removing additional liquid from the plug of material by operating the press so that the pressure in the discharge section of the press is greater than the pressure of the pressate stream by at least 2 psi. There is also described a method for controlling discharge consistency from a press, without provision of discharge restrictors, by varying a pressure differential between a discharge section of the press and a pressate stream.

Owner:IOGEN ENERGY CORP +1

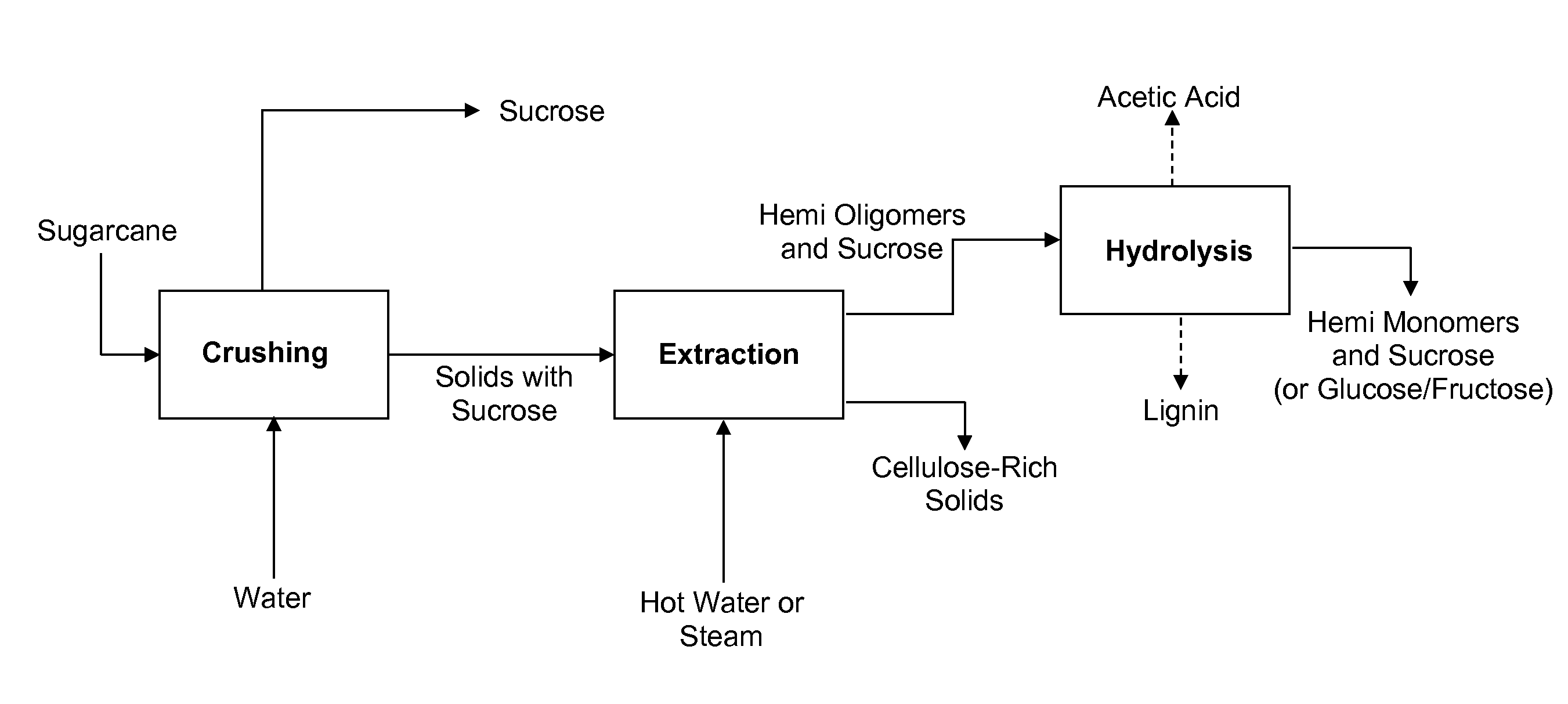

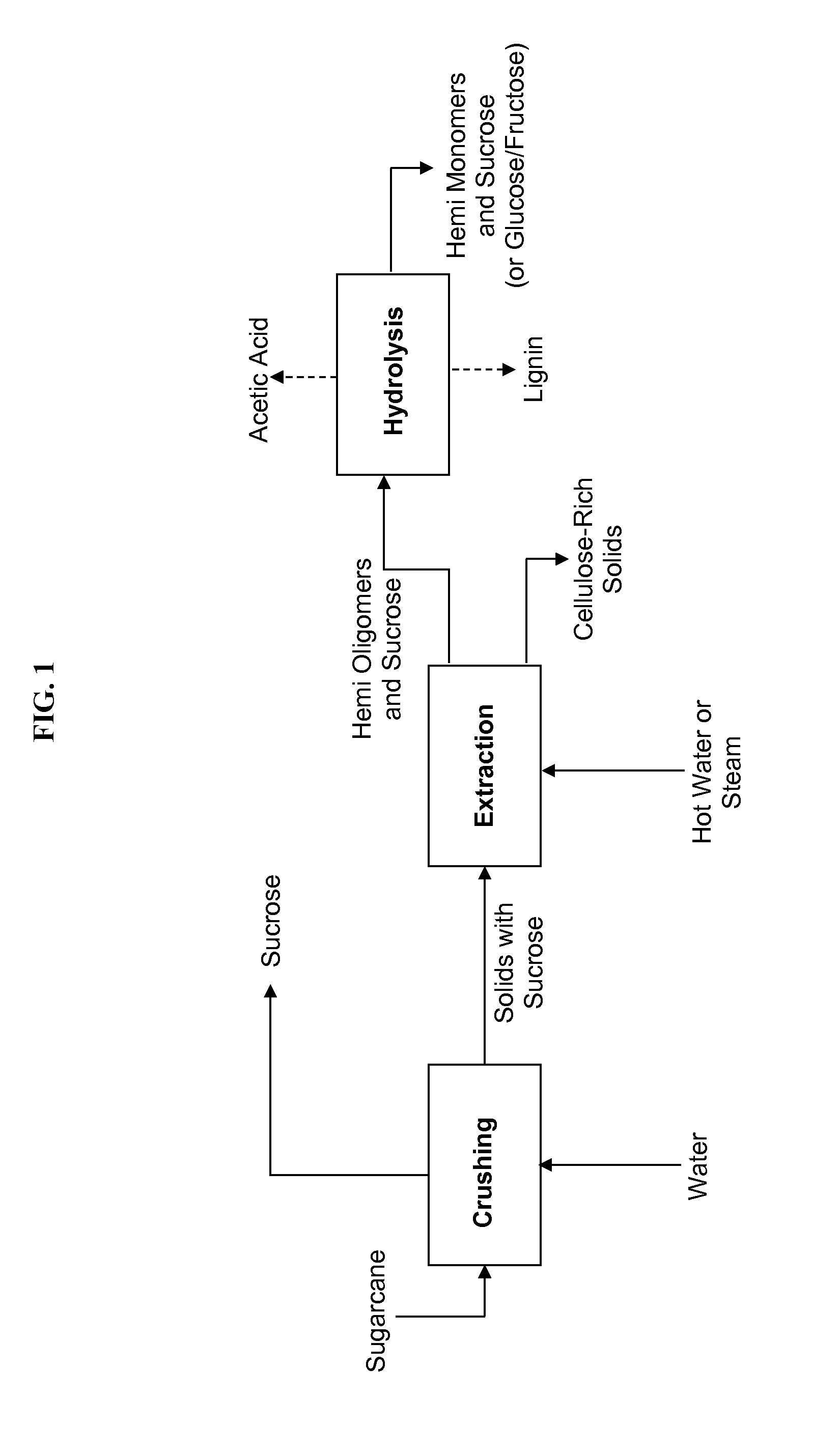

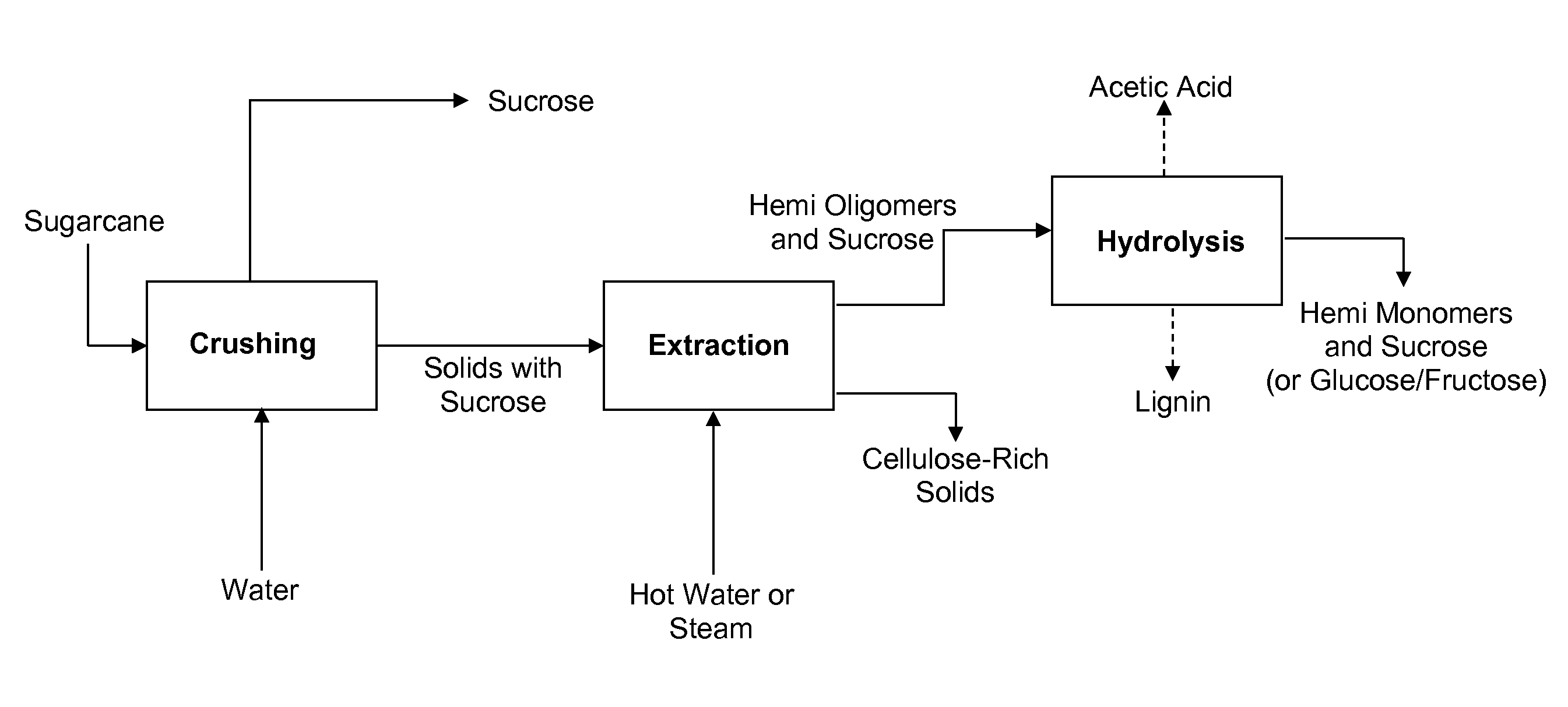

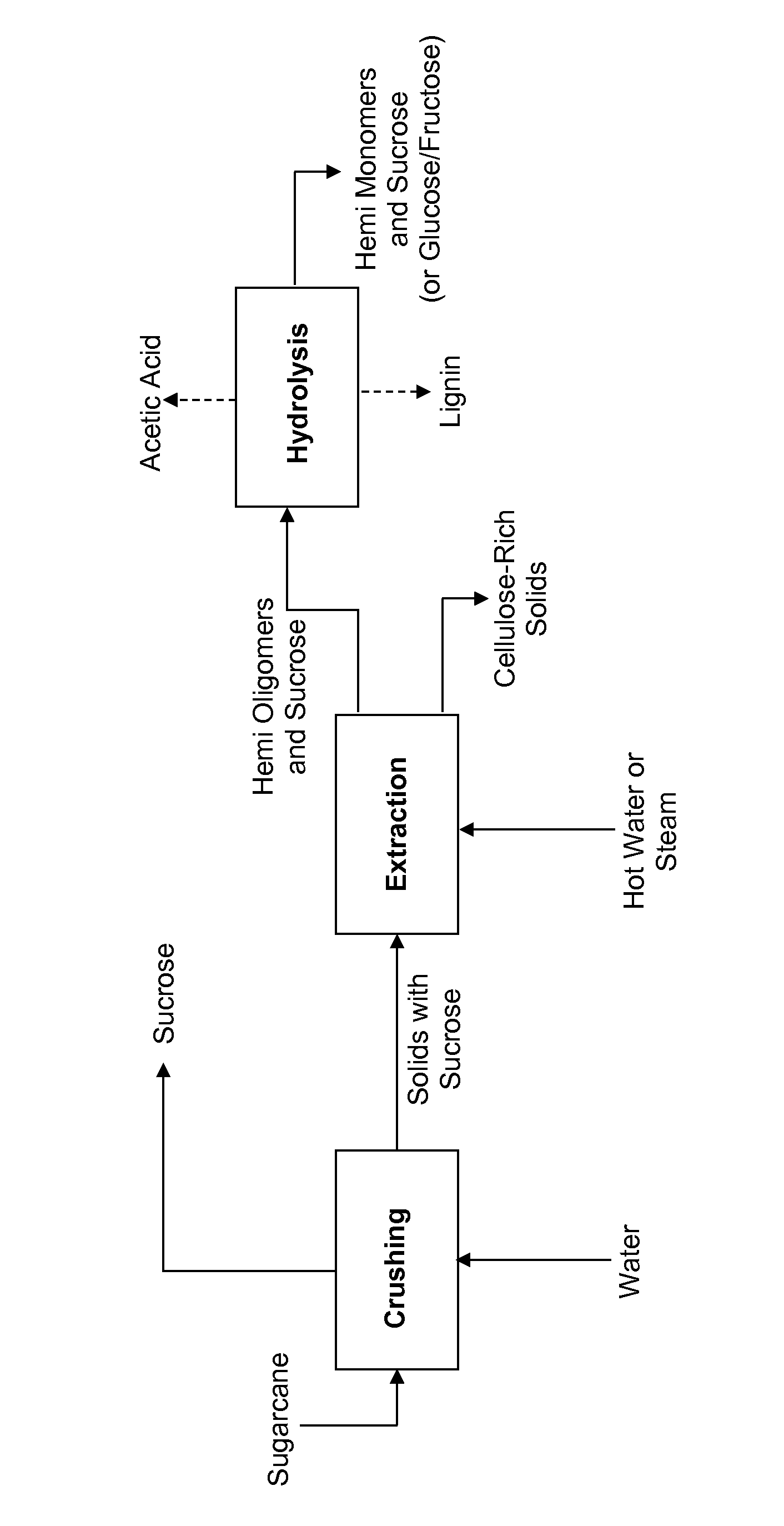

Processes and apparatus for refining sugarcane to produce sugars, biofuels, and/or biochemicals

Conventionally, sugarcane processing avoids leaving residual sucrose in the bagasse, since the bagasse will be burned and the value of the sucrose would be lost. However, when coupled with a Green Power+® process to extract hemicelluloses, sucrose may also be extracted and recovered from the bagasse. In some variations, a process includes mechanically treating a feedstock to generate a sucrose-rich stream and lignocellulosic material that intentionally retains a significant amount of the initial sucrose in the feedstock; extracting the lignocellulosic material with steam and / or hot water to produce cellulose-rich solids and an extract liquor containing hemicellulosic oligomers and sucrose; and then hydrolyzing the hemicellulosic oligomers into a hemicellulose sugar stream. Each of the sucrose-rich stream and the hemicellulose sugar stream (containing the starting residual sucrose) may be recovered or further processed (e.g., fermented to ethanol). Similar processes are possible with energy cane, sugar beets, and energy beets.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

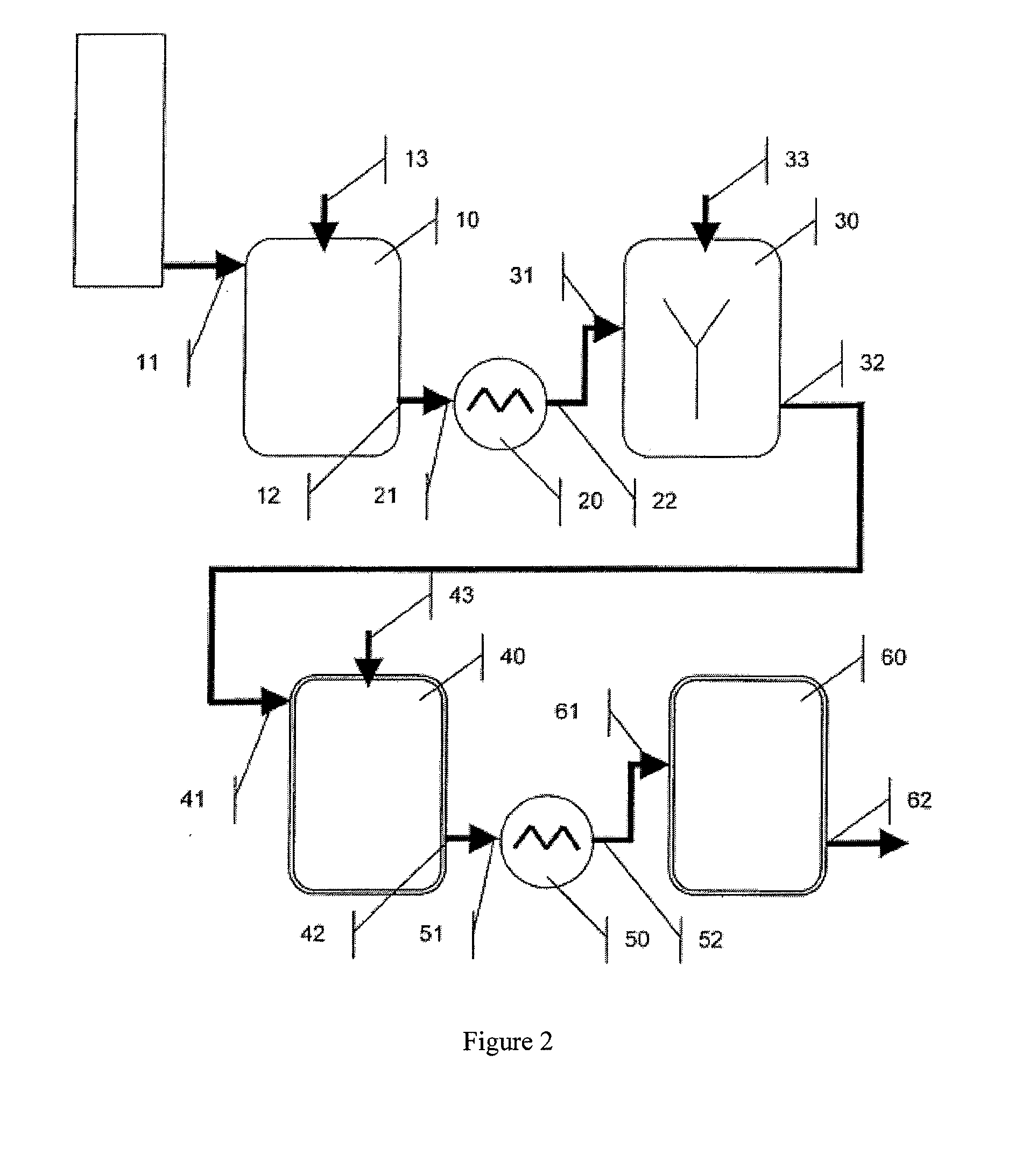

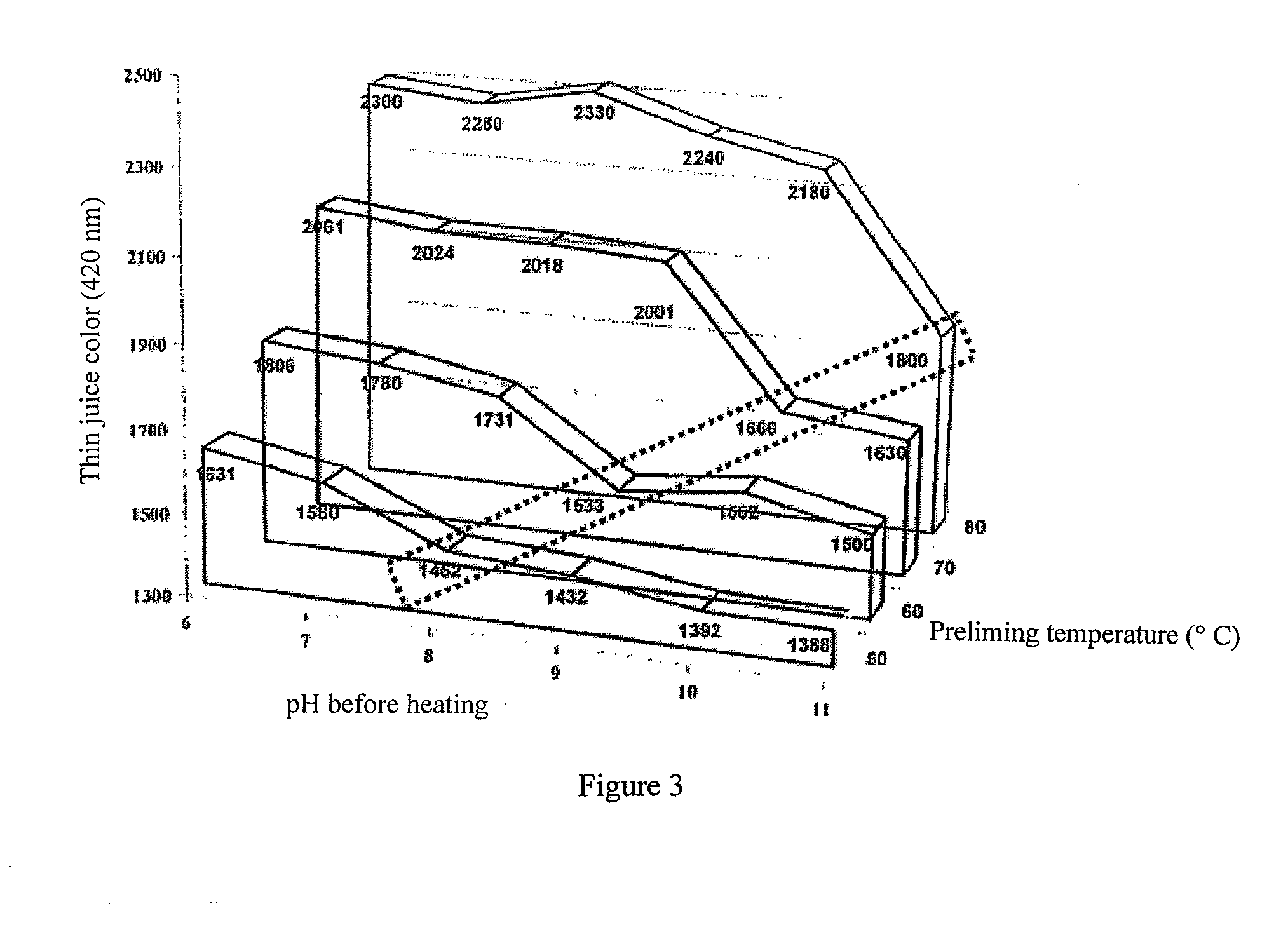

Process for reducing the lime consumption in sugar beet juice purification

ActiveUS20110214669A1Low costFurther processing processPurification using adsorption agentsPurification using alkaline earth metal compoundsSucroseSaccharum

The present invention relates to an improved process for extract purification of sugar beet raw juice, especially for reduction of lime consumption during the purification of sugar beet raw juice, to a process for producing a nutrient-rich non-sucrose concentrate from sugar beet raw juice, to the non-sucrose substance concentrate thus produced, to uses of the non-sucrose substance concentrate and to an apparatus for preliming sugar beet raw juice and / or for obtaining the non-sucrose substance concentrate.

Owner:SUDZUCKER AG MANNHEIM OCHSENFURT

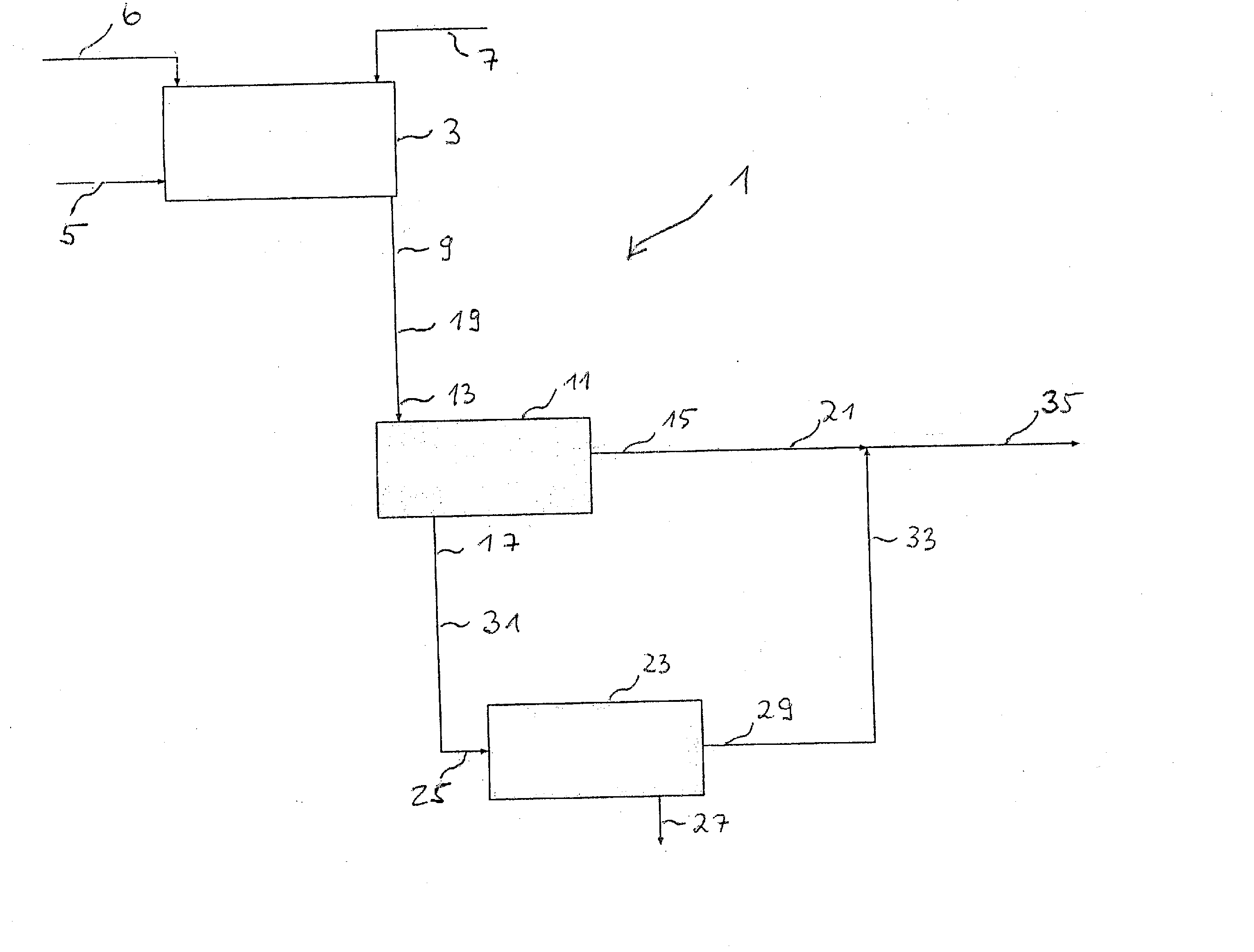

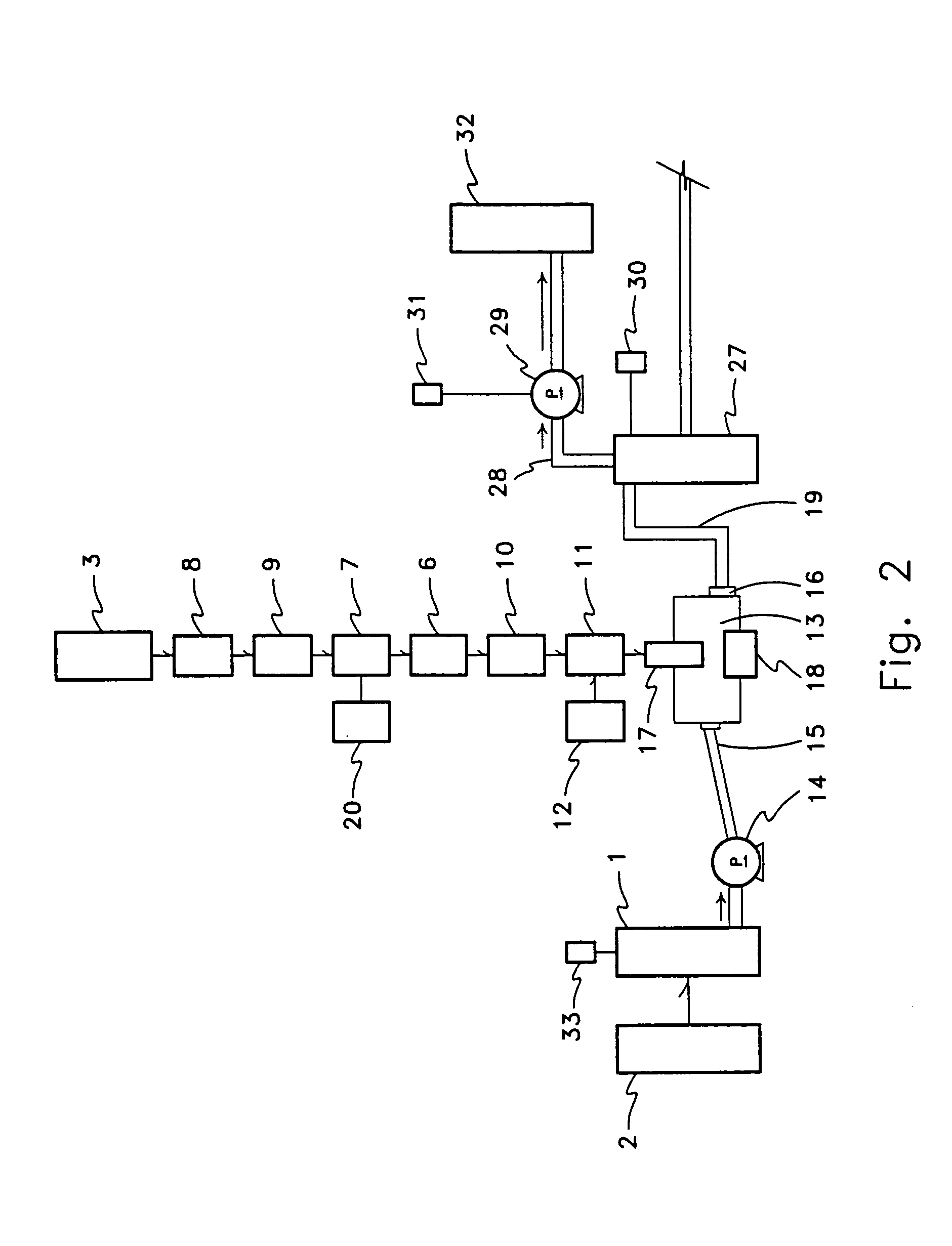

System to produce sugar from plant materials

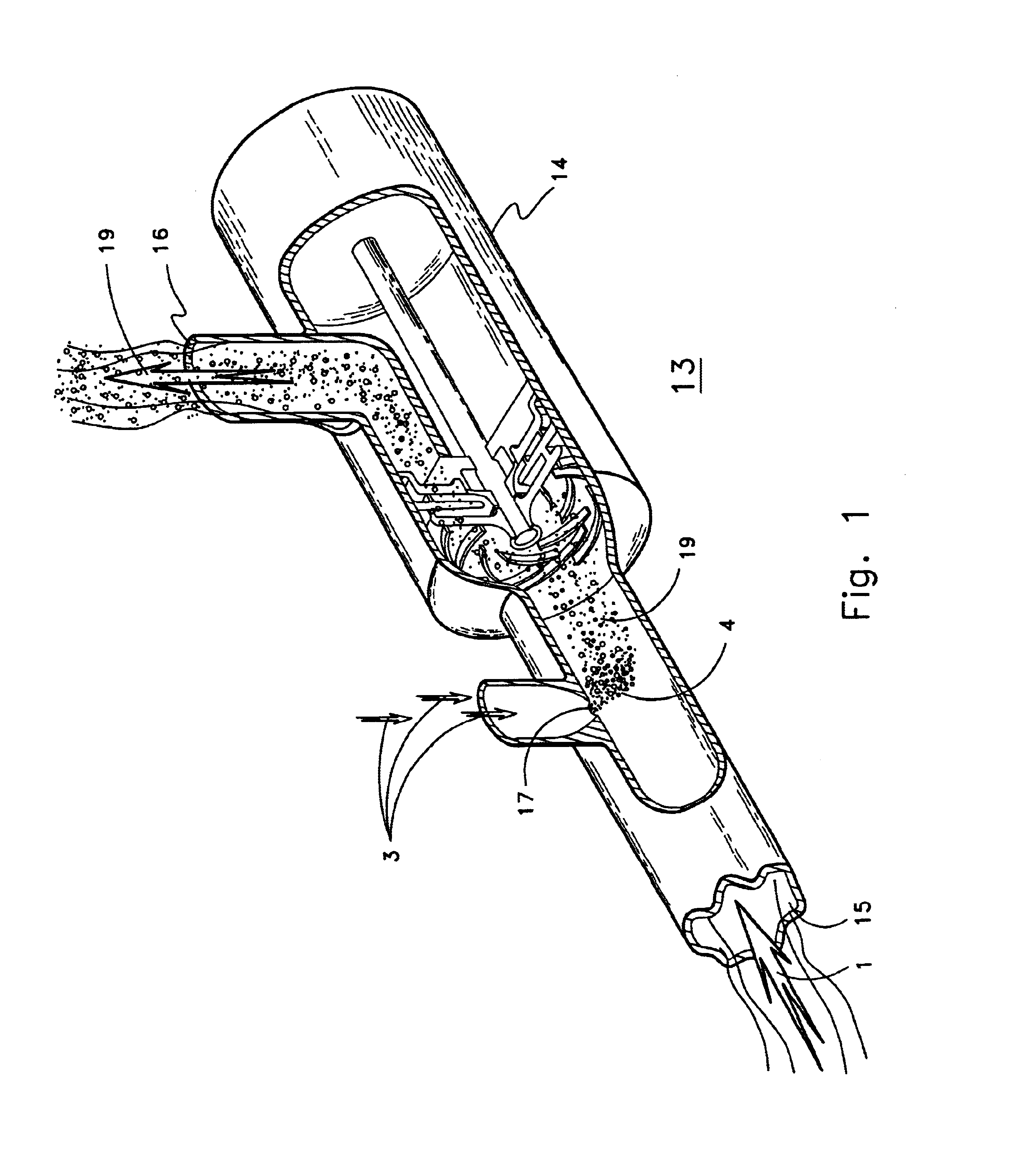

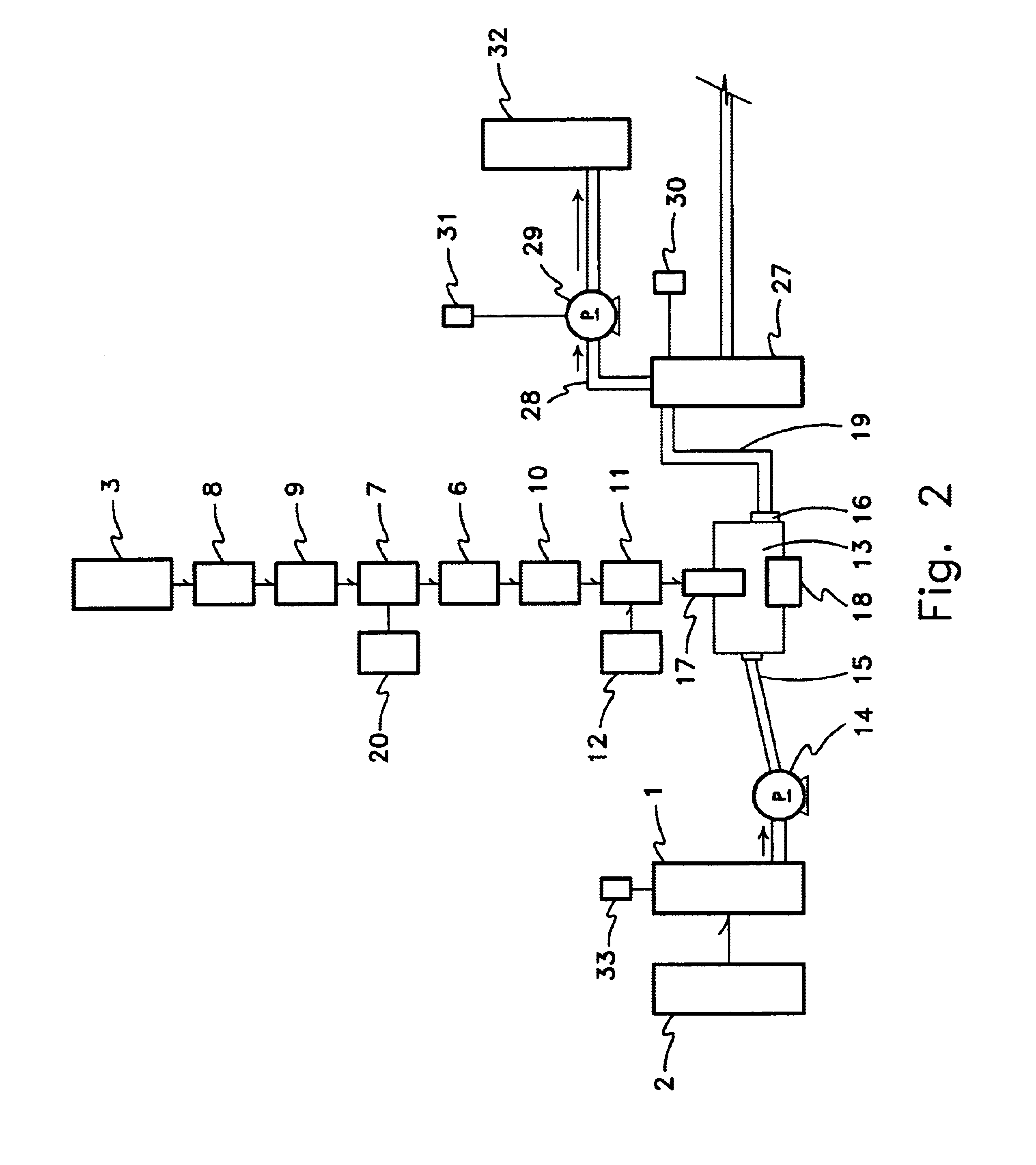

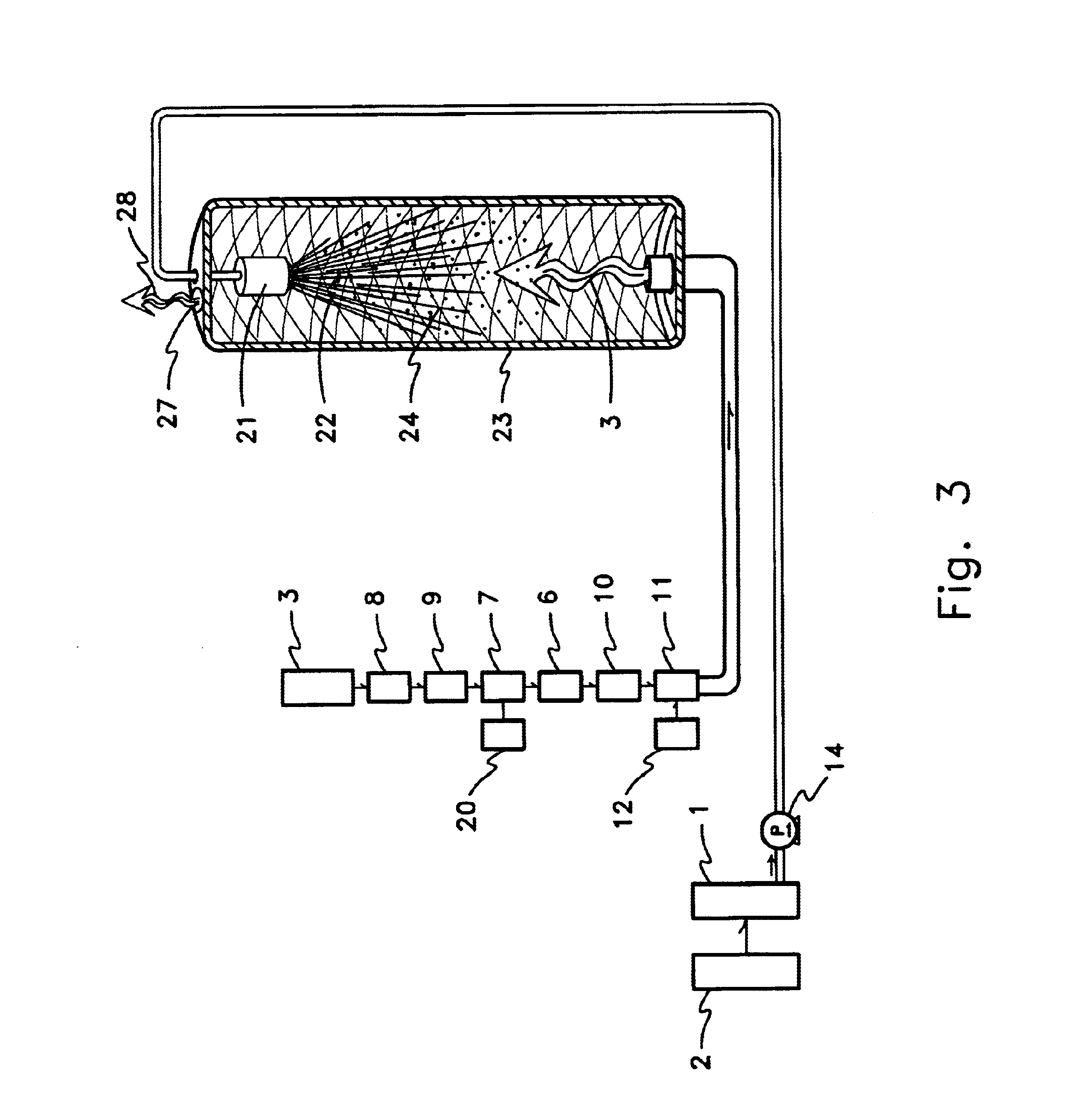

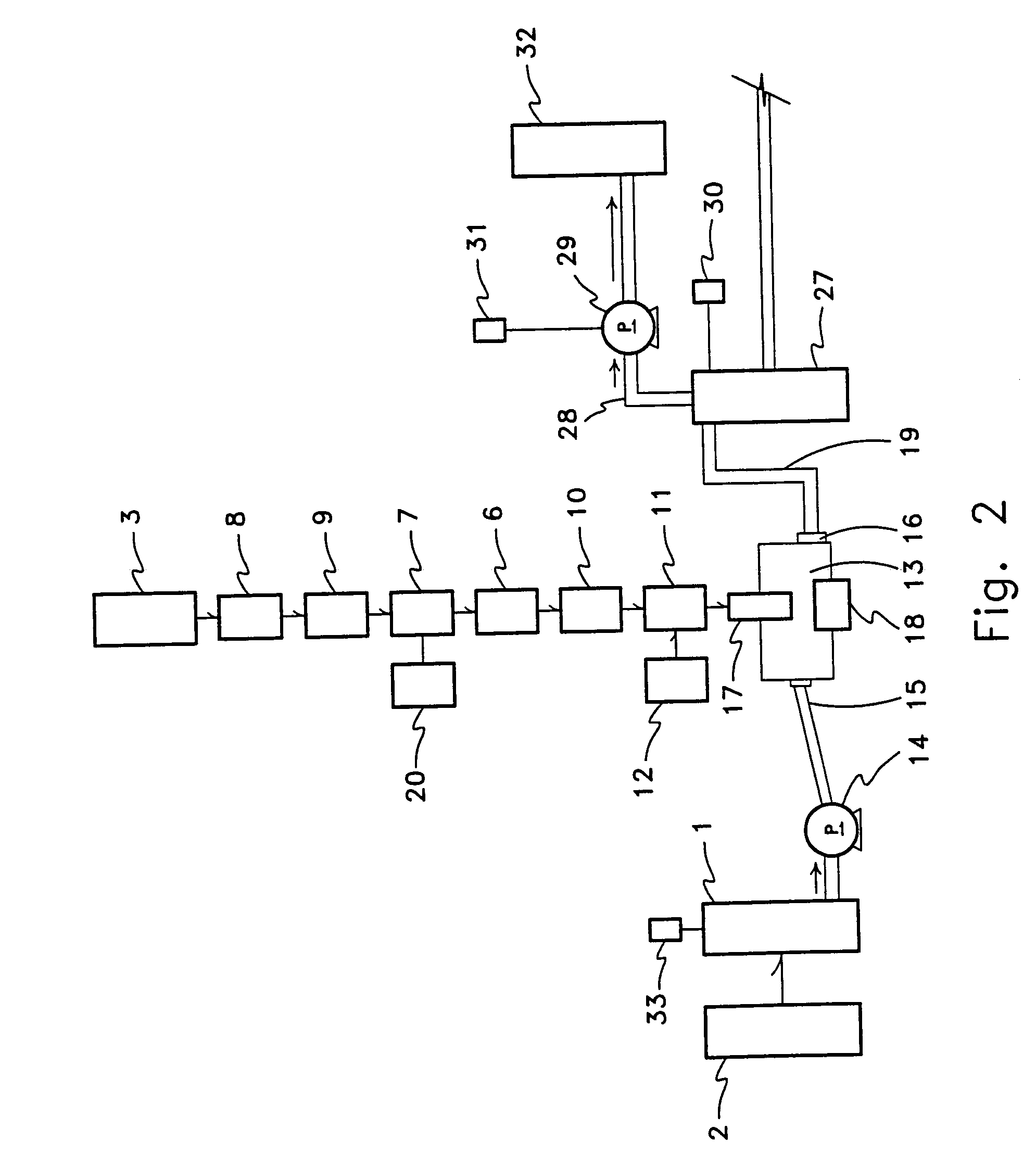

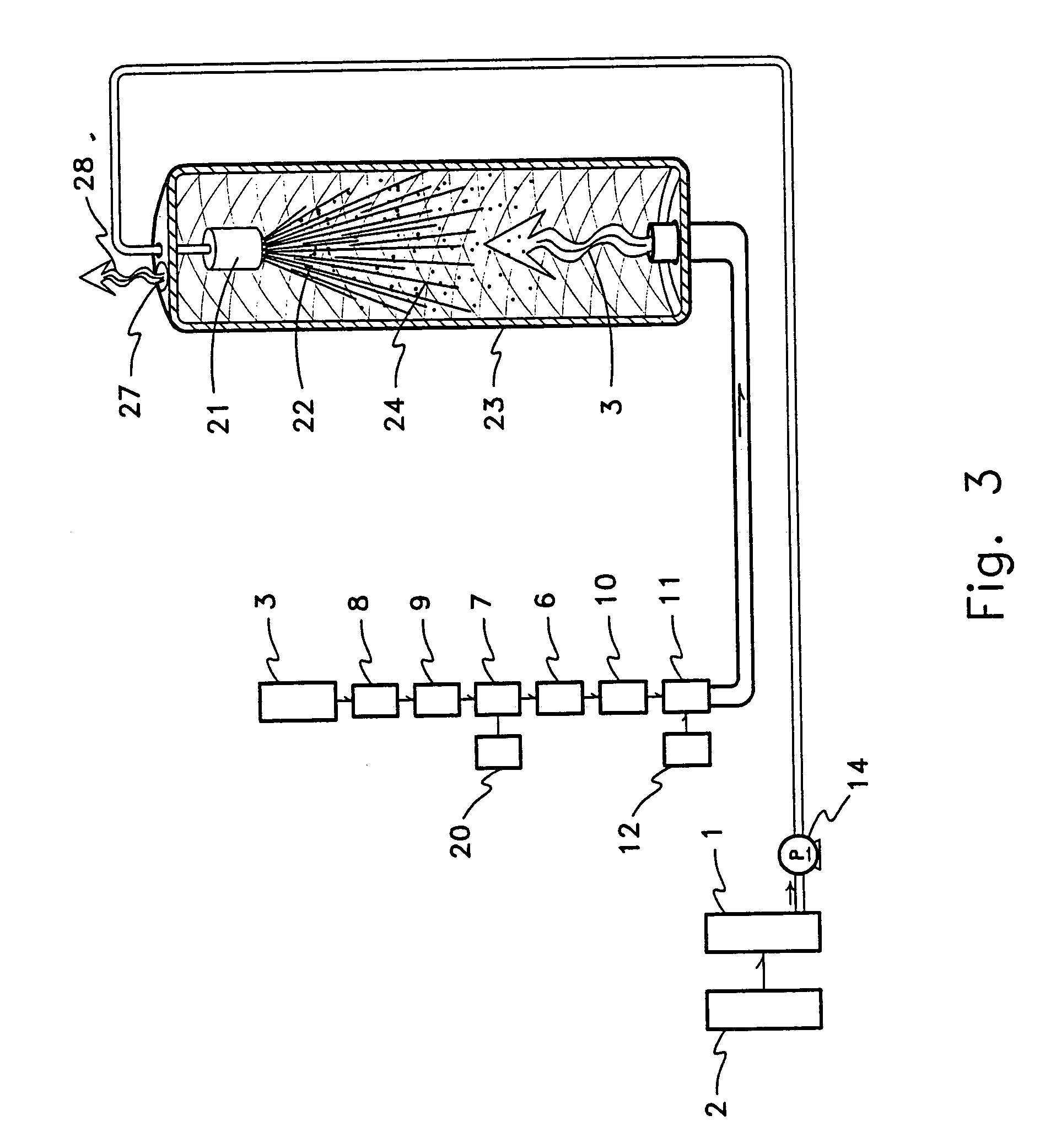

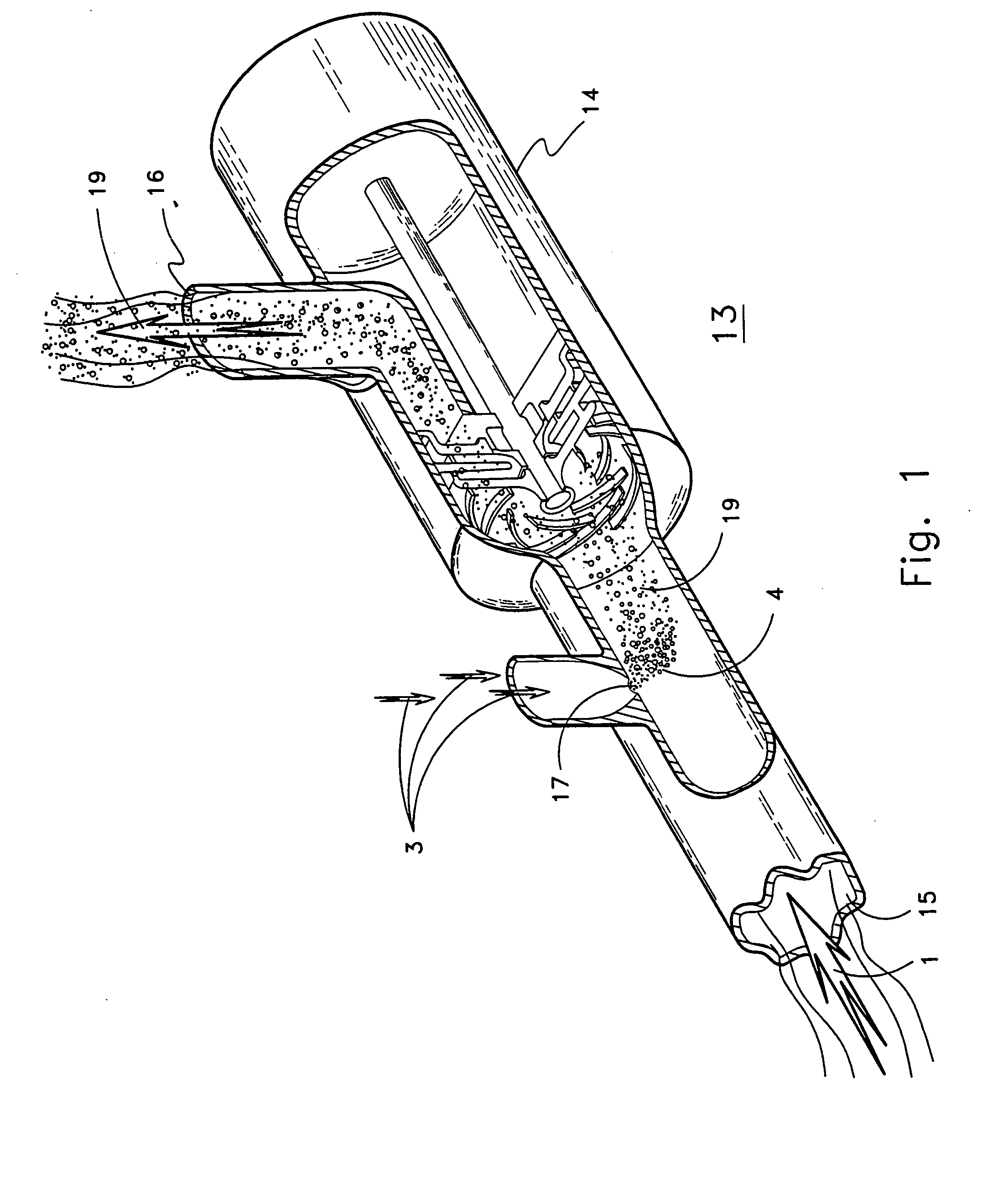

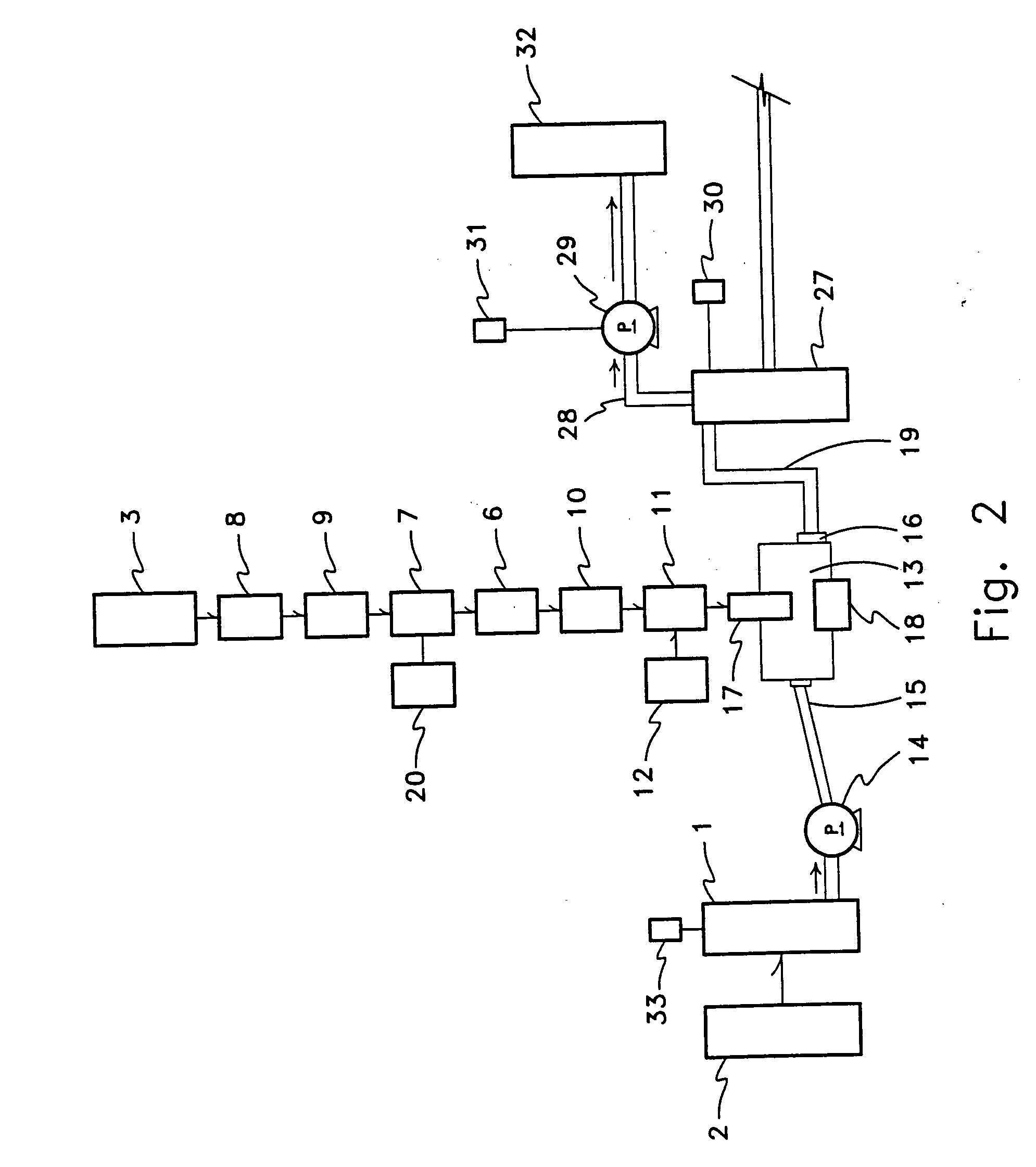

InactiveUS7182818B2Low costReduce the amount requiredPurification by oxidation/reductionPurification using adsorption agentsBiotechnologyFruit juice

A process system that uses a reduced amount of lime or other base to clarify or purify juice or other process liquid (1) obtained from plant material (2) such as sugar cane, sugar beets, or sweet sorghum. Specifically, apparatus and methods to reduce volatile materials in juice or other process liquid (1) to increase pH requiring the use of less lime or other base to achieve the desired pH values for clarification or purification in subsequent steps, such as preliming (33).

Owner:ECOLAB USA INC

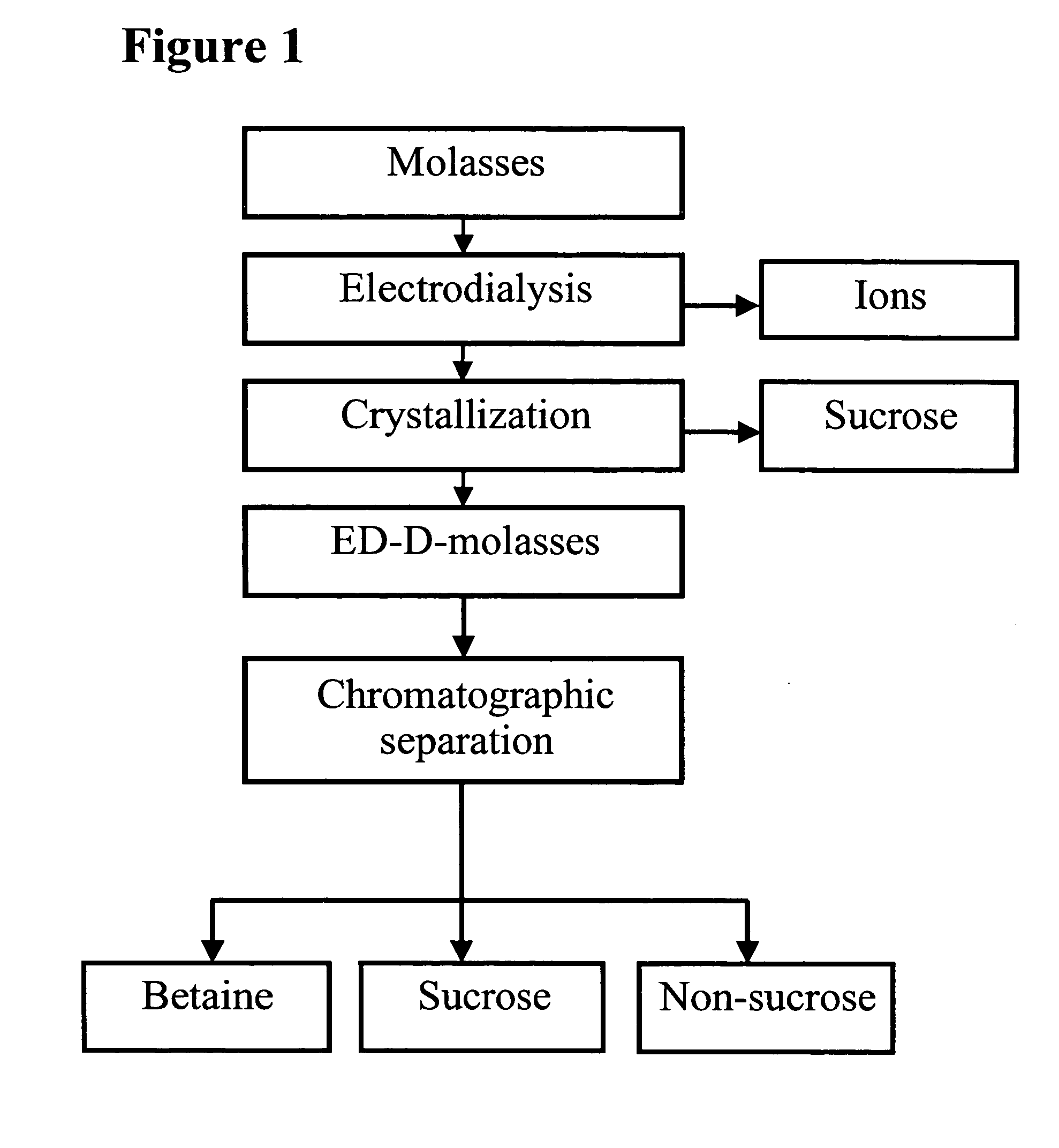

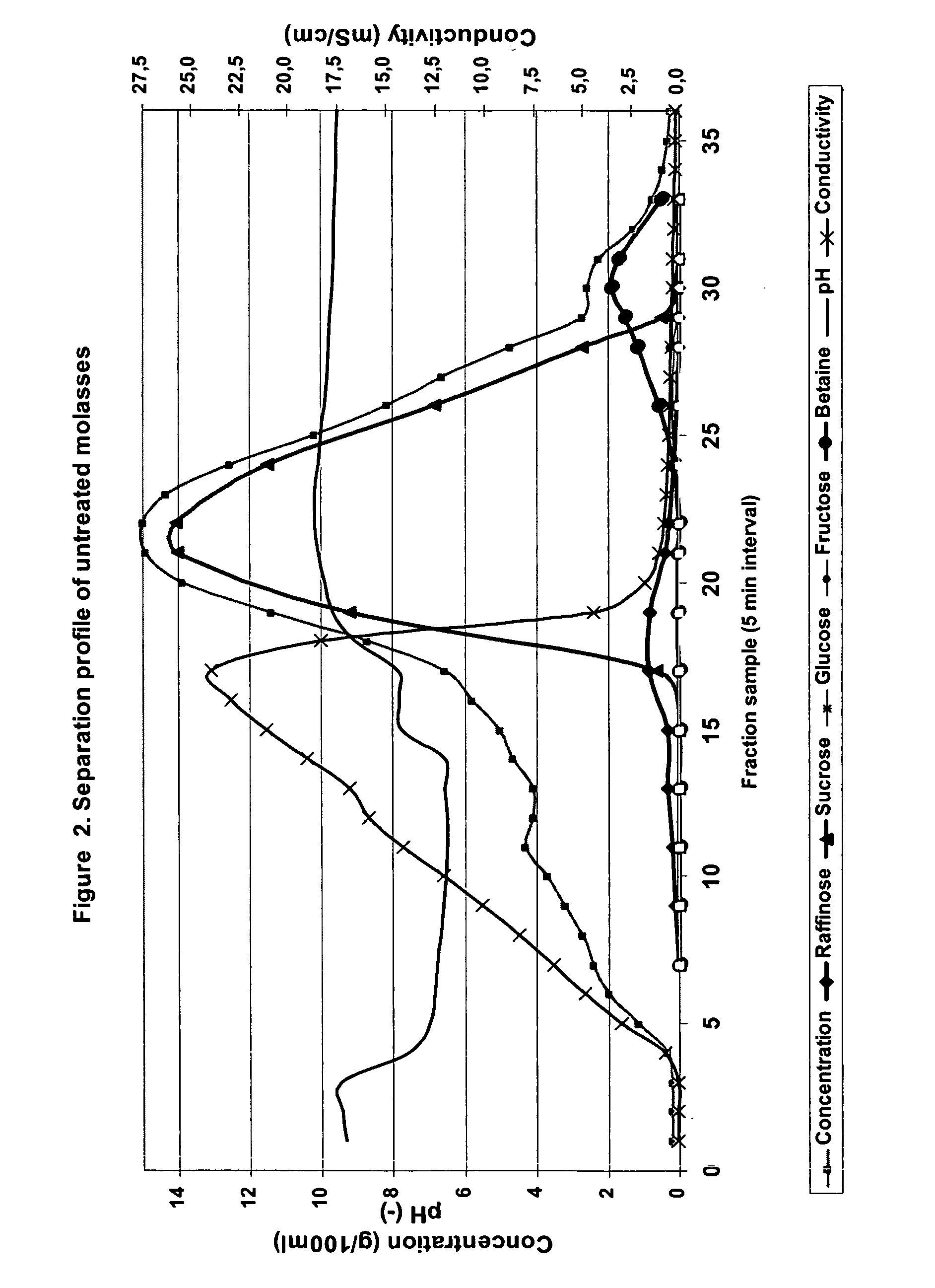

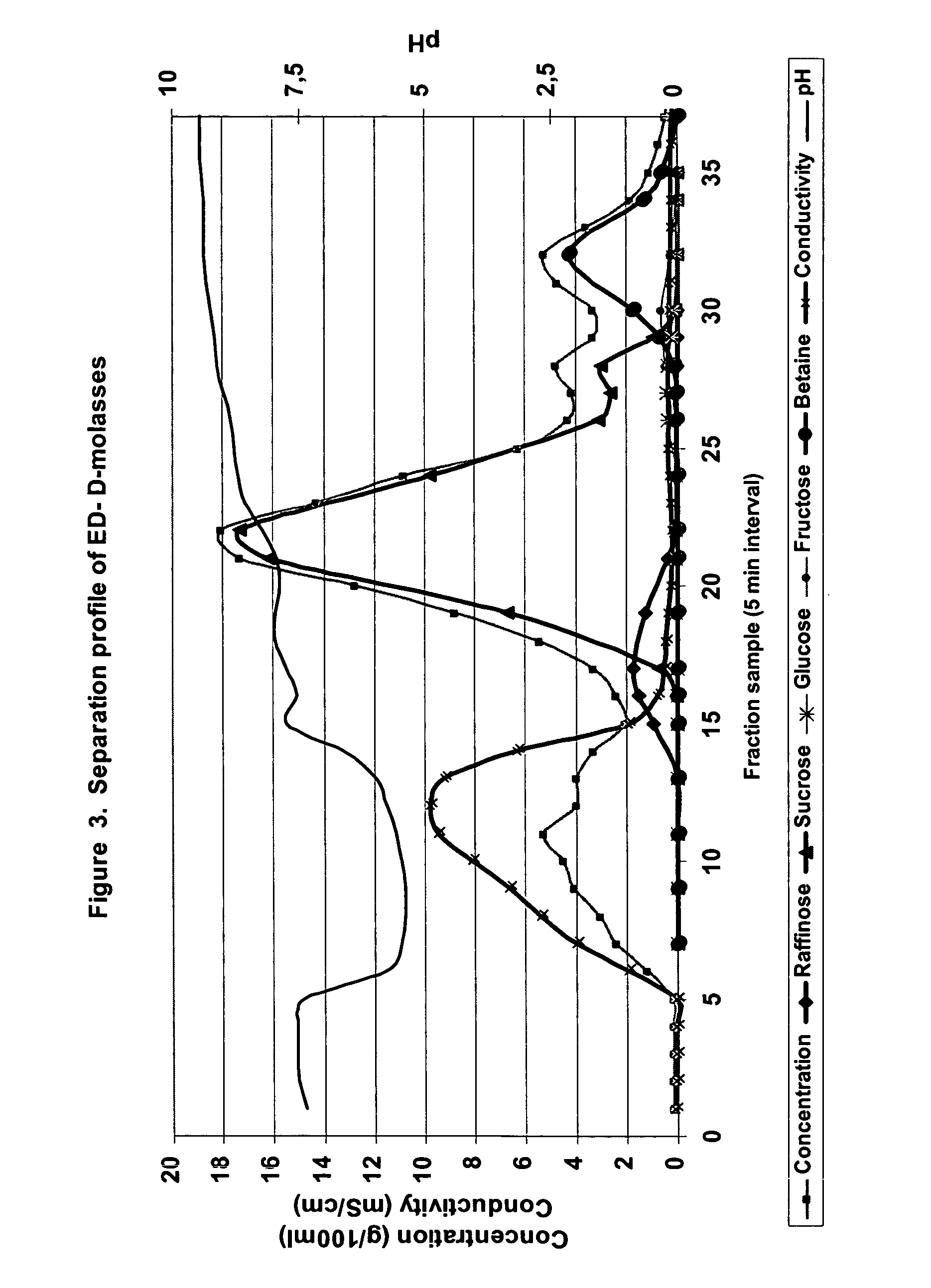

Process for the recovery of sucrose and/or non-sucrose components

InactiveUS20070169772A1Lower energy requirementsReduce needPurification using adsorption agentsSugar productsOrganic acidChromatographic separation

The invention relates to an industrially useful process for the recovery of sucrose and / or non-sucrose components. The process comprises (i) providing a solution of sugar beet and / or sugar cane origin selected from molasses, sugar juices and liquors, wherein said sugar juices are non-nanofiltered during the process; (ii) subjecting said solution to electrodialysis for removing therefrom inorganic and organic anions and cations and organic acids; (iii) subjecting the electrodialyzed solution to a chromatographic separation for obtaining sucrose and non-sucrose components in separate fractions; and (iv) recovering a product selected from sucrose and non-sucrose components from at least one of said fractions. The invention also relates to the use of electrodialysis for improving the efficiency of chromatographic separation in the industrial recovery of sucrose and / or non-sucrose components.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Water treatment

InactiveUS20080053899A1Low costLower water costsSolid sorbent liquid separationDialysisWater treatment systemSugar

This invention is directed to an integrated process and system for water treatment, in particular, an integrated process and system for water treatment in the beverage manufacture cycle. The water treatment process is directed to treating an influent water solution, a low sugar concentration solution, and a high sugar concentration solution. The water treatment system is directed to a system for treating an influent water solution, a system for treating a low sugar concentration solution, and system for treating a high sugar concentration solution.

Owner:ENVIRONMENTAL MANAGEMENT CORP

Method of reducing materials contained in juice

InactiveUS7150793B2Low costReduce the amount requiredSolid sorbent liquid separationSucrose extraction by chemical meansProcess systemsFruit juice

A process system that uses a reduced amount of lime or other base to clarify or purify juice obtained from plant material such as sugar cane, sugar beets, or sweet sorghum. Specifically, apparatus and methods to reduce volatile materials in juice providing a product that has an increased pH requiring the use of less lime or other base to achieve the desired pH values for clarification or purification.

Owner:ECOLAB USA INC

Method of reducing materials contained in juice

InactiveUS20040105924A1Low costReduce the amount requiredSolid sorbent liquid separationCocoaProcess systemsFruit juice

A process system that uses a reduced amount of lime or other base to clarify or purify juice obtained from plant material such as sugar cane, sugar beets, or sweet sorghum. Specifically, apparatus and methods to reduce volatile materials in juice providing a product that has an increased pH requiring the use of less lime or other base to achieve the desired pH values for clarification or purification.

Owner:ECOLAB USA INC

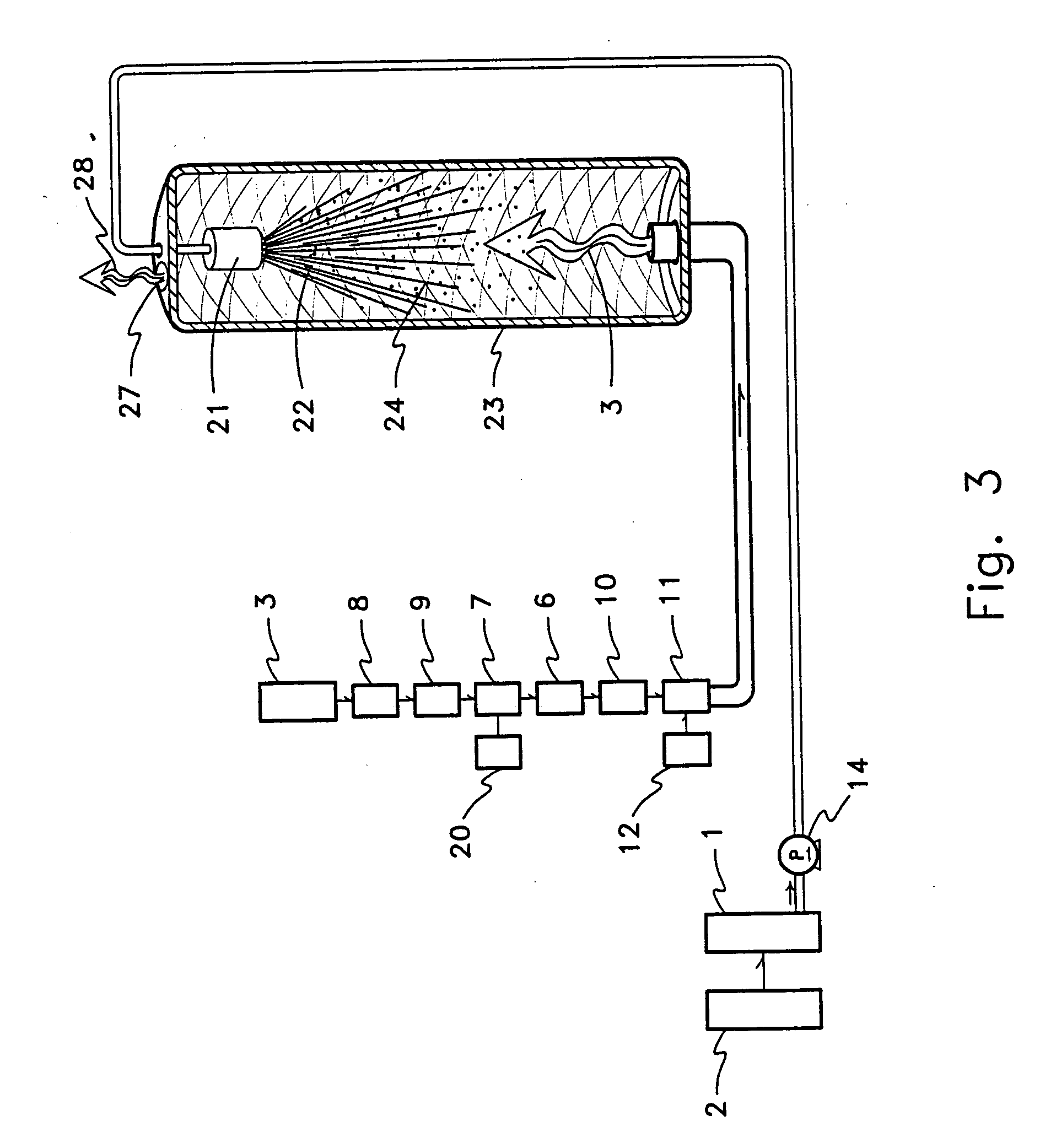

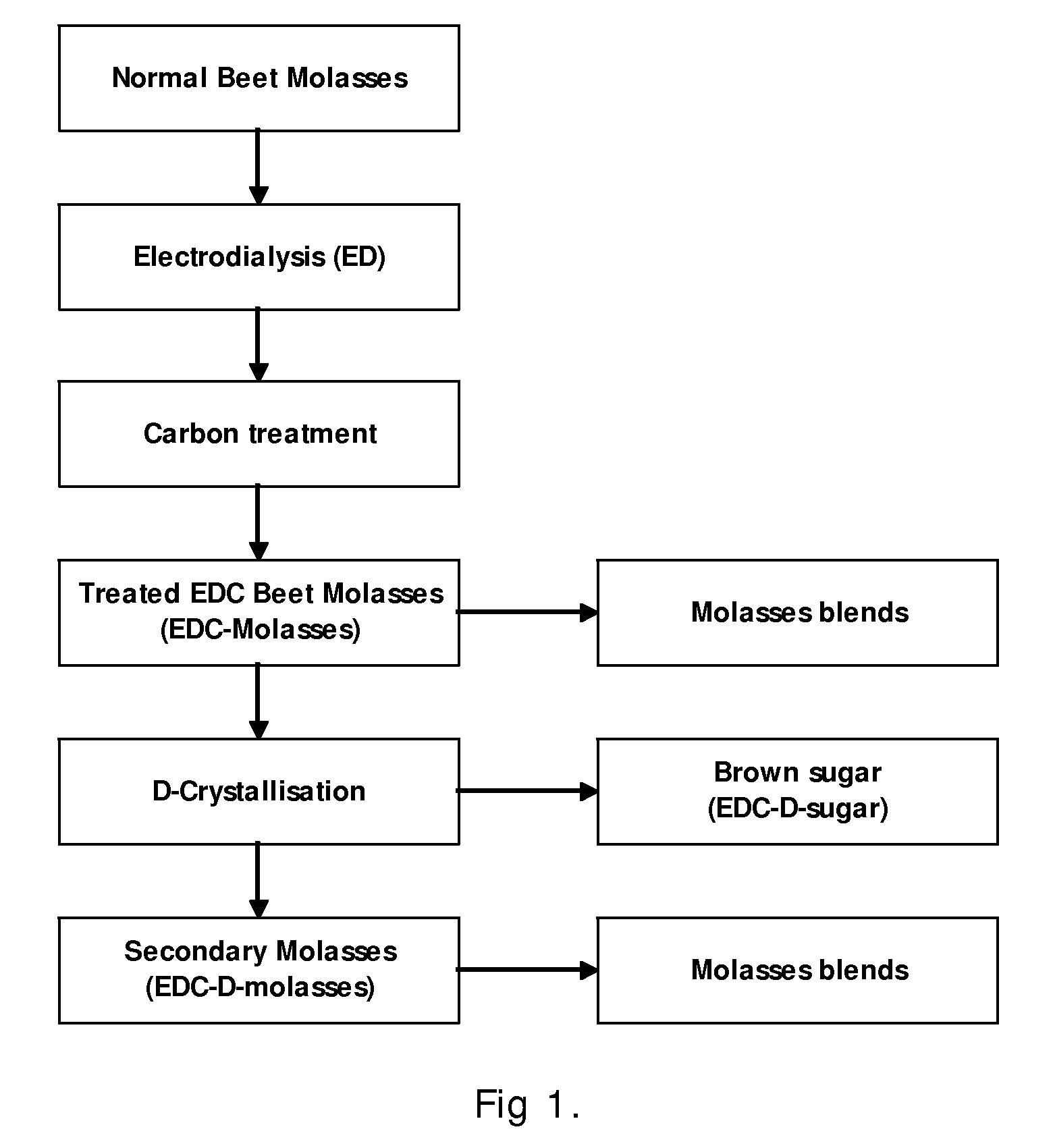

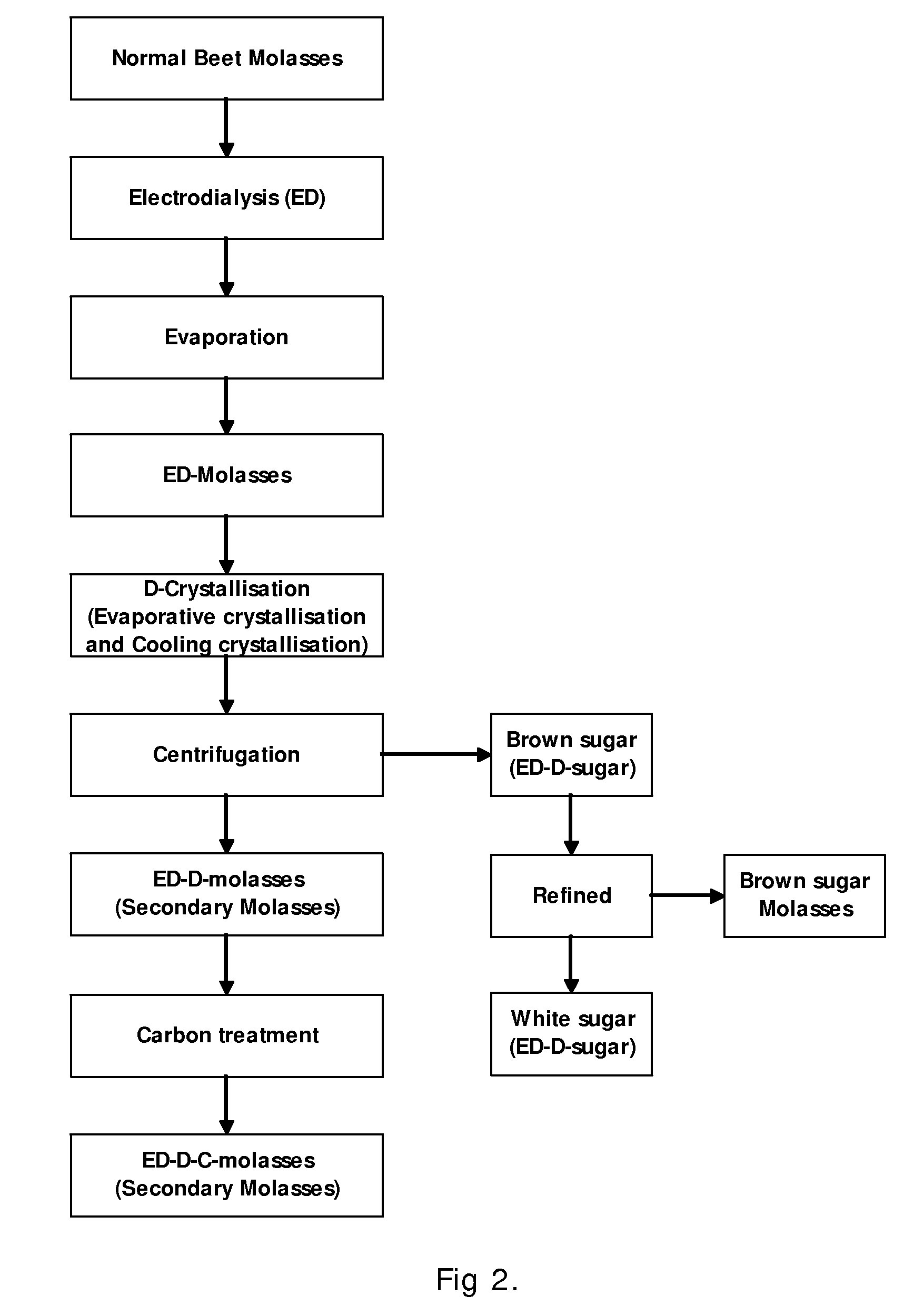

Process For The Recovery Of A Brown Food-Grade Sugar Product From A Sugar Beet Solution

InactiveUS20080299287A1High purityElectrolysis componentsSugar productsChromatographic separationOrganic acid

The invention relates to an industrially useful process for the recovery of sucrose and / or non-sucrose components. The process comprises (i) providing a solution of sugar beet and / or sugar cane origin selected from molasses, sugar juices and liquors, wherein said sugar juices are non-nanofiltered during the process; (ii) subjecting said solution to electrodialysis for removing therefrom inorganic and organic anions and cations and organic acids; (iii) subjecting the electrodialyzed solution to a chromatographic separation for obtaining sucrose and non-sucrose components in separate fractions; and (iv) recovering a product selected from sucrose and non-sucrose components from at least one of said fractions. The invention also relates to the use of electrodialysis for improving the efficiency of chromatographic separation in the industrial recovery of sucrose and / or non-sucrose components.

Owner:NORDIC SUGAR

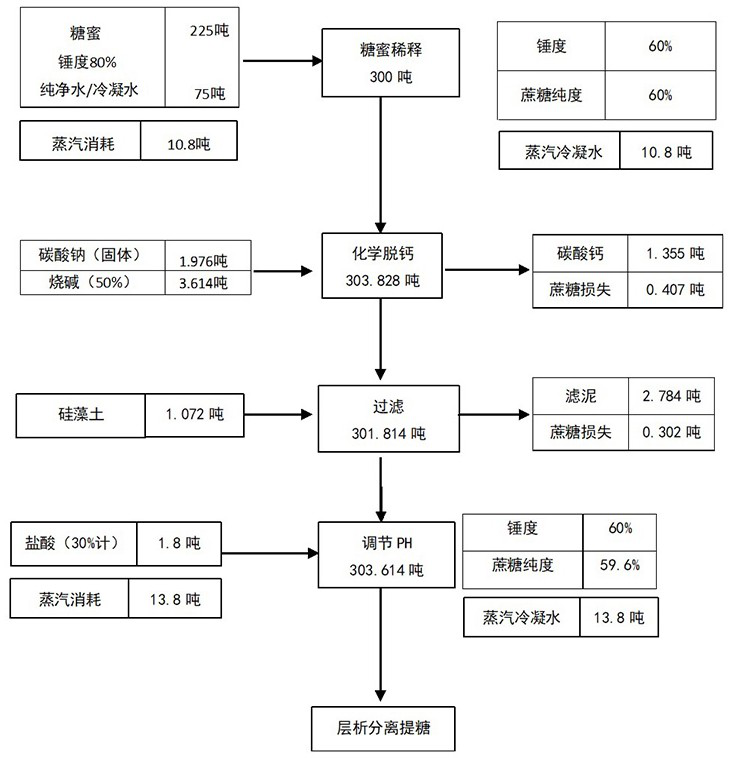

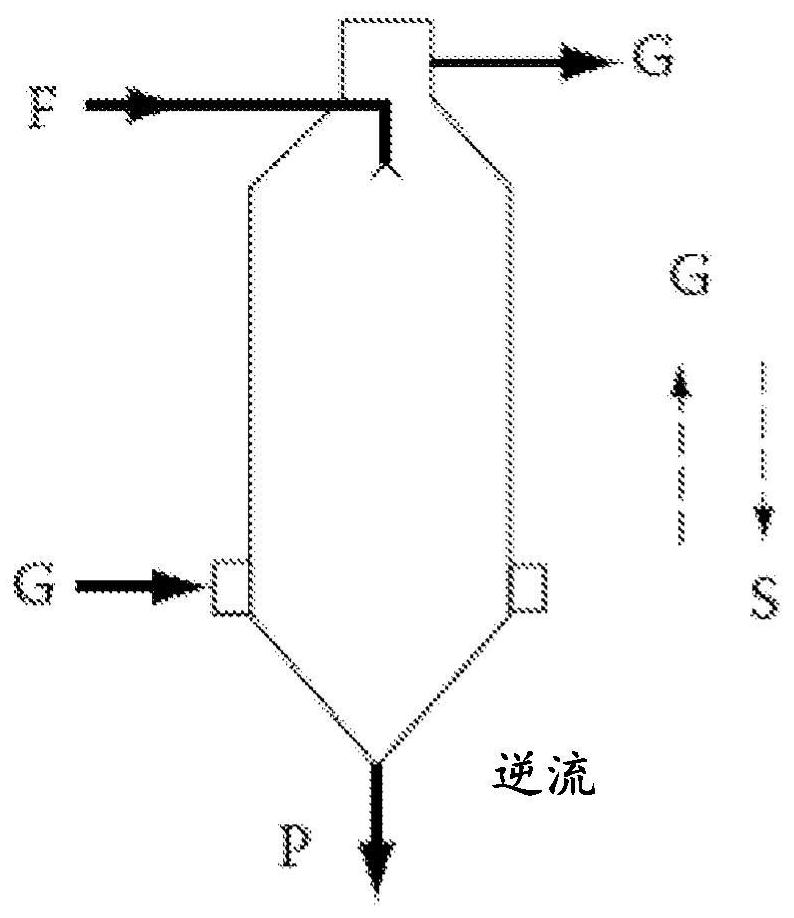

Efficient separation method for sugar in sugar beet sugar production

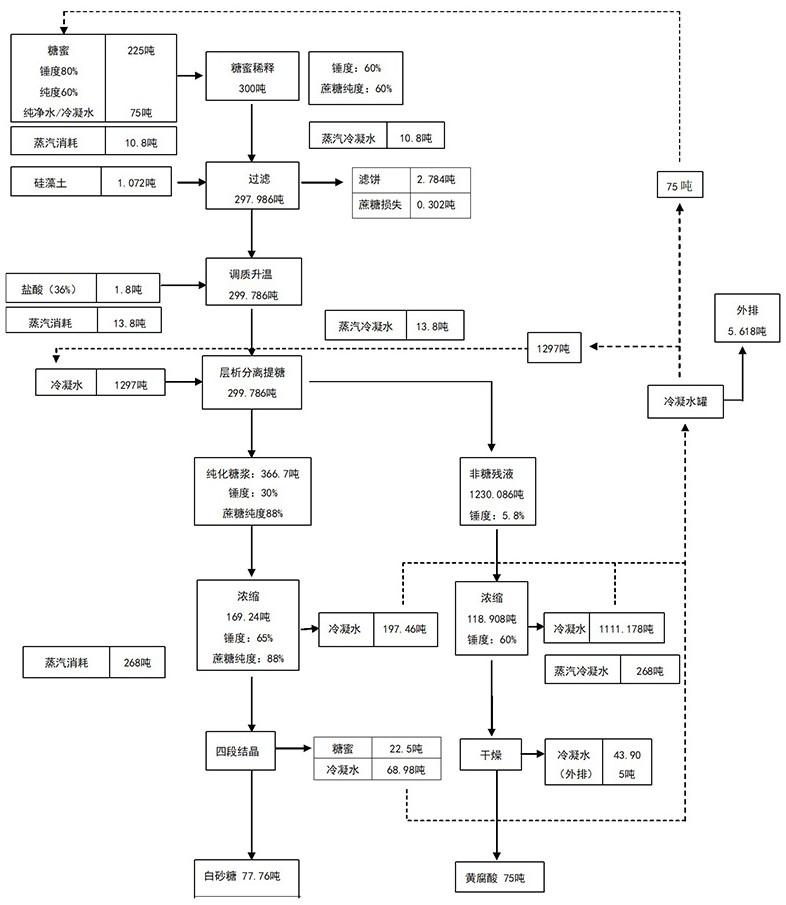

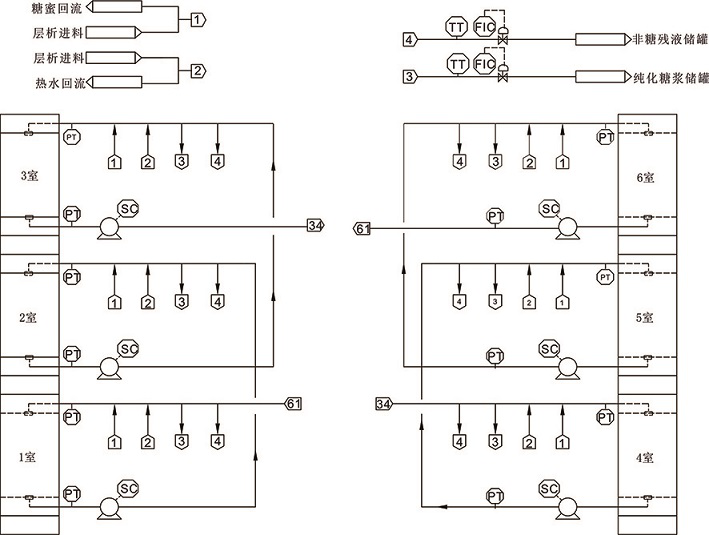

PendingCN112593017AReduce dosageReasonable designSucrose extraction by chemical meansSucrose extraction by physical meansBiotechnologyChromatographic separation

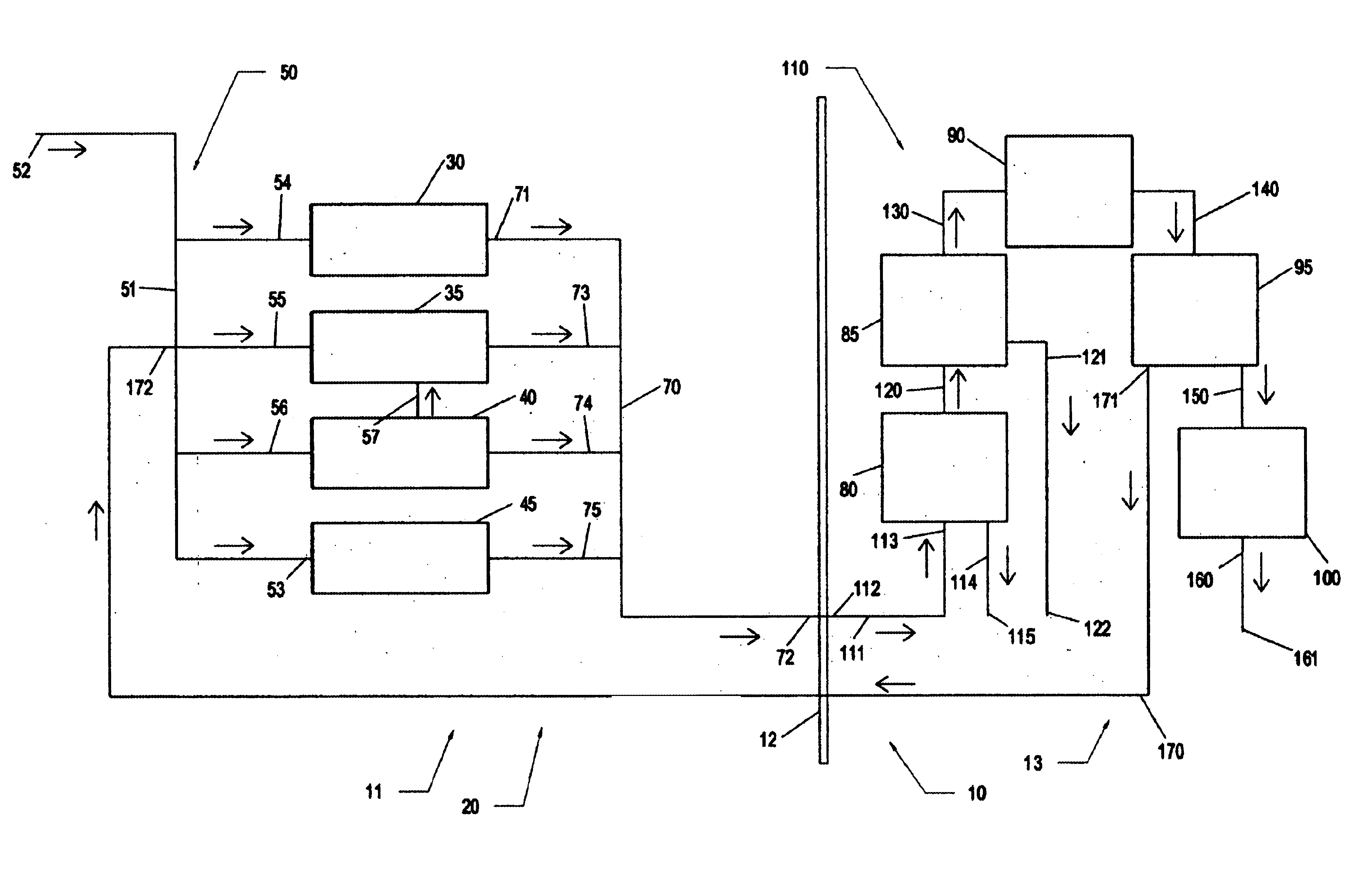

The invention discloses an efficient separation method for sugar in sugar beet sugar production. The method comprises the following specific steps: molasses pretreatment, chromatographic separation, concentration and crystallization, and sugar content detection. The method comprises the following steps: 1) molasses pretreatment: heating molasses to 70-90 DEG C, diluting the molasses to 50-70% withwashing water, removing suspended impurities from the diluted molasses aqueous solution, and filtering to obtain clean juice free of suspended impurities, calcium, magnesium and the like; 2) chromatographic separation: sequentially simulating a moving bed, and obtaining two items through separation, wherein an extraction phase contains sucrose with a high recovery rate, and a residual liquid phase contains non-sugar with a high recovery rate; 3) concentration and crystallization: evaporating and concentrating to 65-75% brix, storing, performing four-stage sugar boiling and crystallization toobtain qualified white granulated sugar (the color value is less than or equal to 35IU), and concentrating and crystallizing an extract phase to obtain purified syrup of which the sucrose purity can reach 89-95%, the brix is 30-350Bx and the sugar recovery rate is 88-95%; and 4) sugar content detection: detecting the purity of sucrose by using high performance liquid chromatography. The method isreasonable in design, environmentally friendly in use and high in economic benefit, and high-purity components can be obtained.

Owner:XINJIANG GUANNONG FRUIT & ANTLER GROUP +1

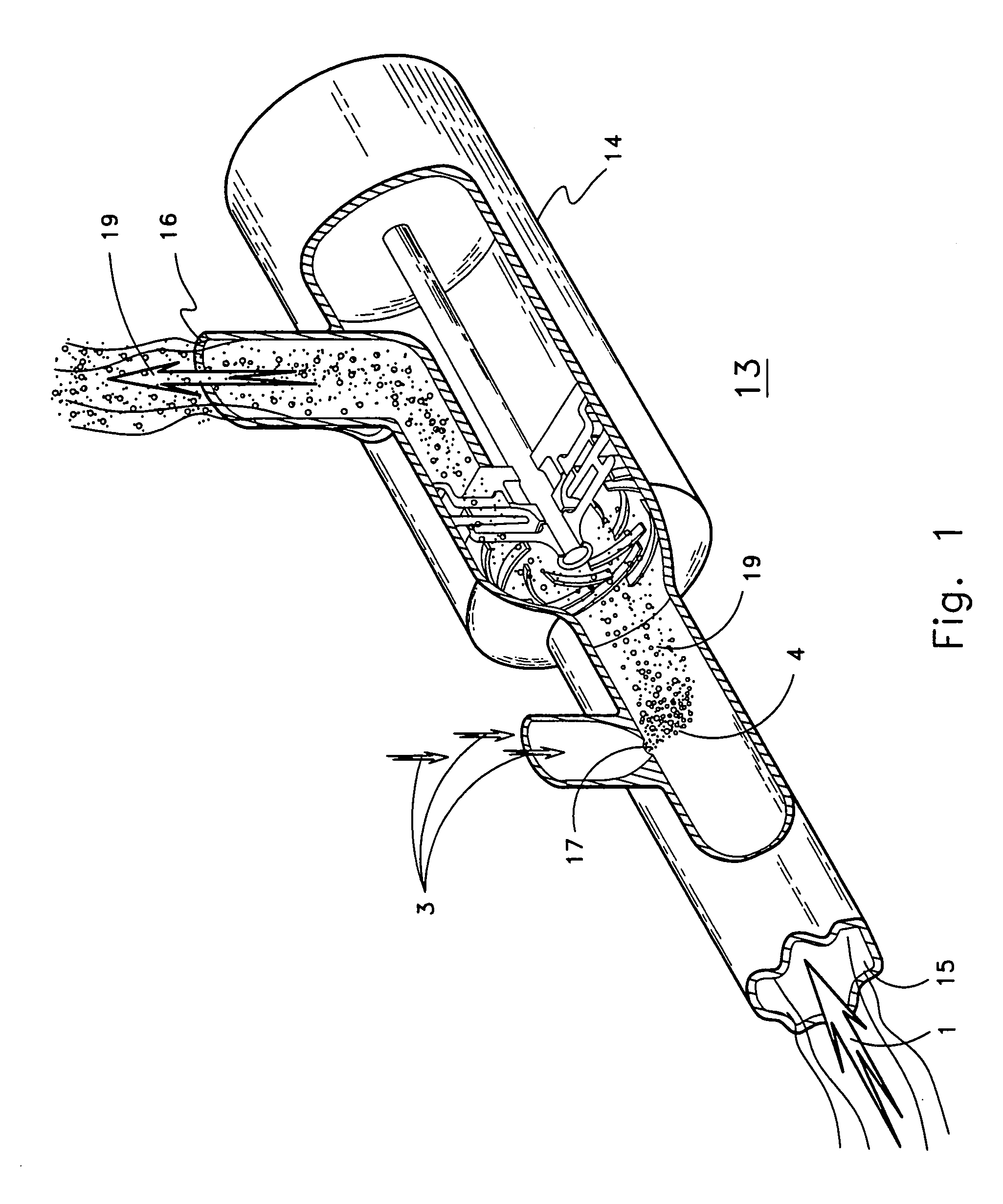

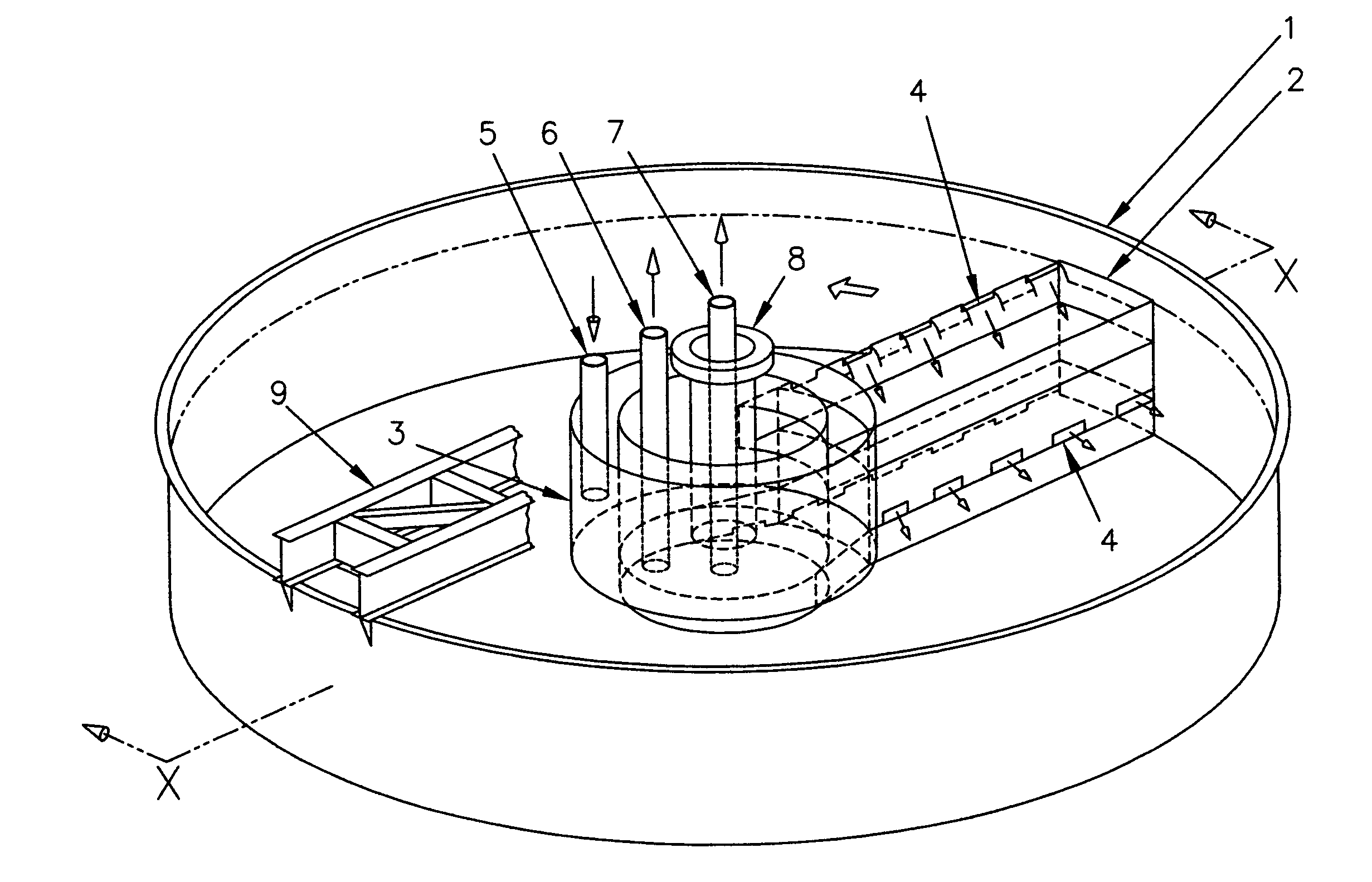

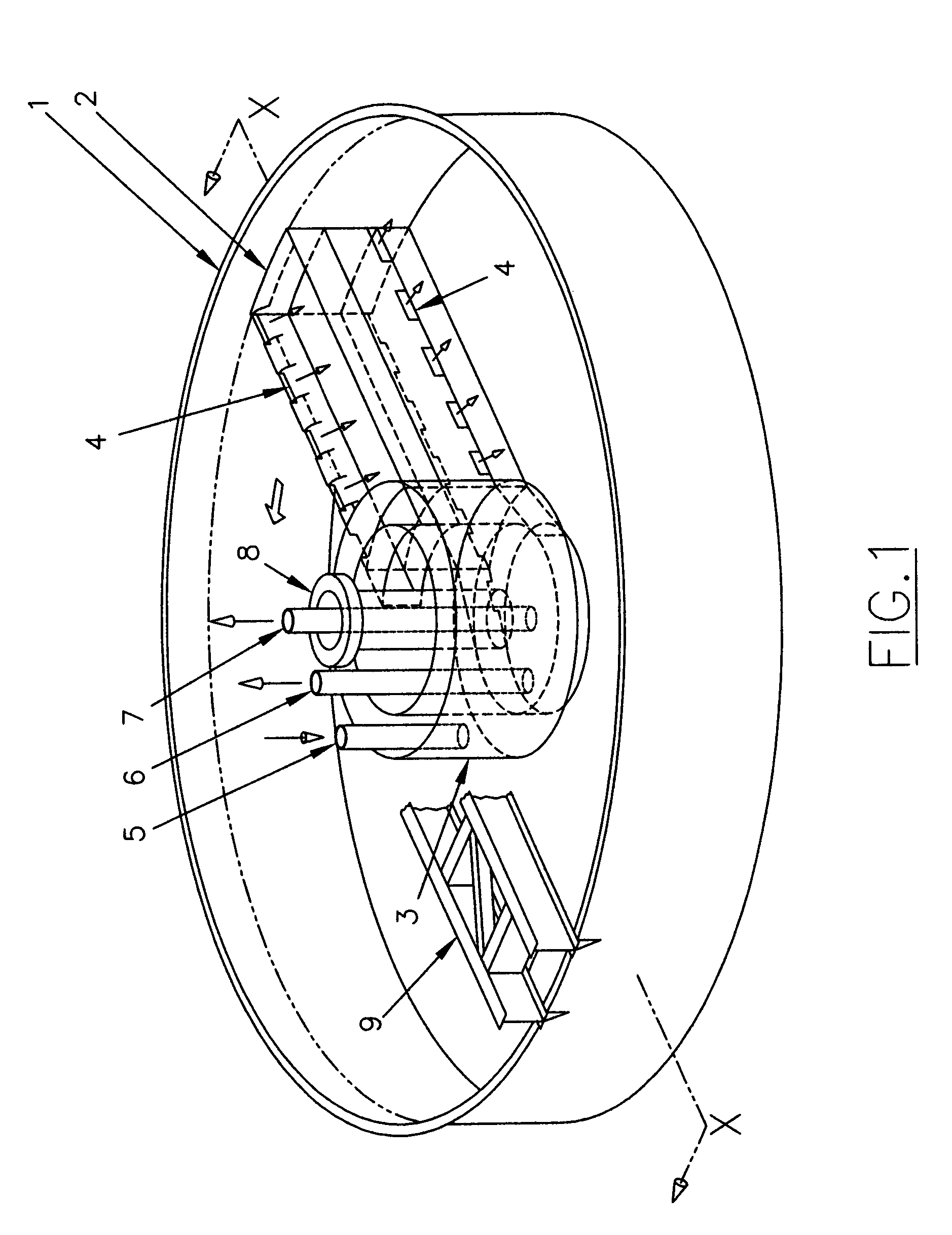

Sugar juice clarifier apparatus

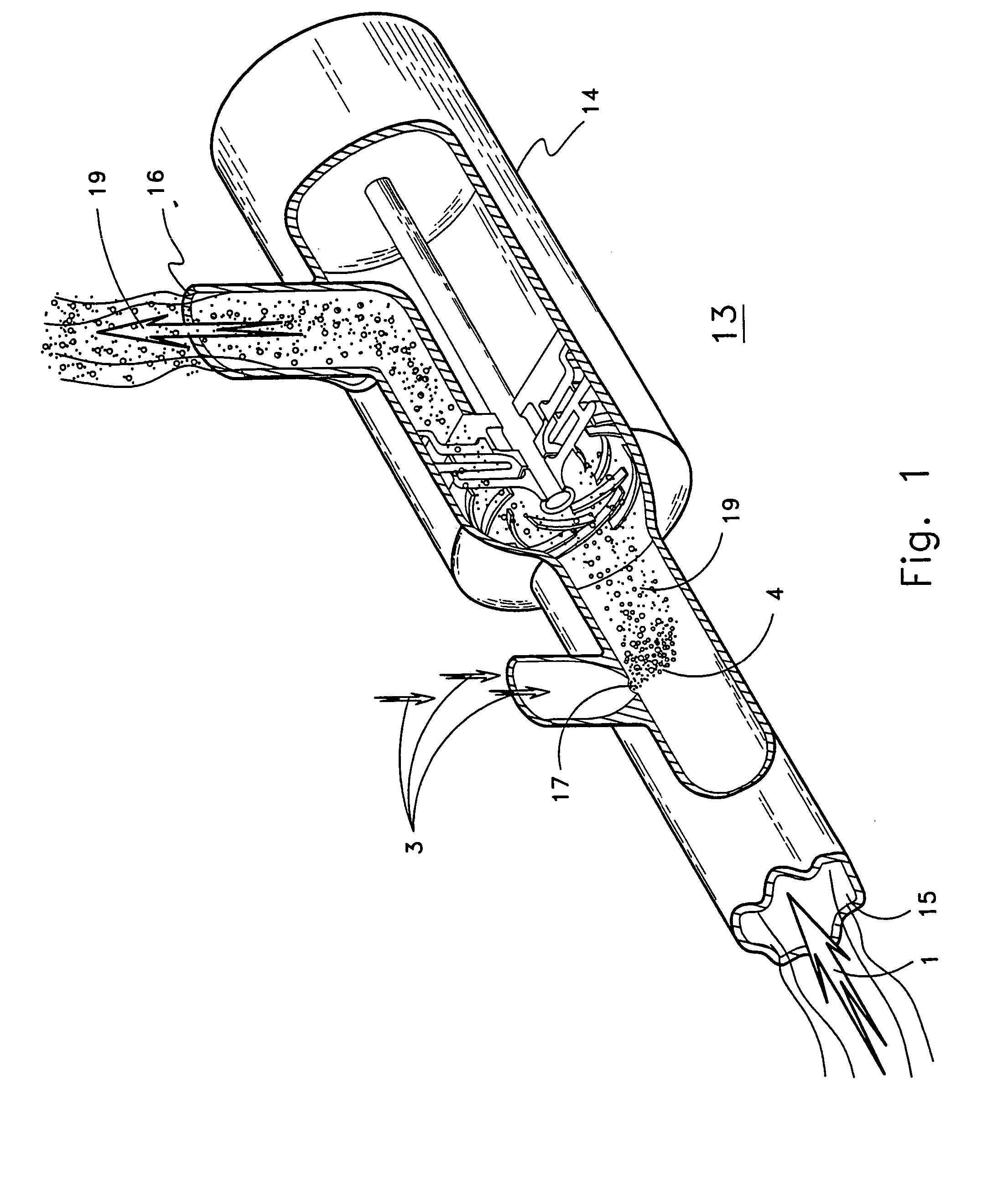

InactiveUS7160394B2Short retention timePressurized chemical processJuice extractionJuice clarificationRetention time

An apparatus for the continuous process of raw mixed sugar juice clarification by means of the settlement of insoluble particles and juice precipitate in a cylindrical clarifier tank that permits non-turbulent vertical subsidation and short retention time of the sugar juice in a relatively large, non-turbulent settling sector of the contents of the cylindrical clarifier tank which is maintained by the continuous rotary advancement of the raw mixed sugar juice entry and clear sugar juice and precipitate extraction station arm that rotates within and around the center of the annular shaped cylindrical clarifier tank. The rotating arm has three internal radial compartments which provide for the introduction of raw mixed sugar juice and the extraction of clear sugar juice and precipitate, in and out of the annular clarifier tank in the immediate vicinity of the respective leading and trailing faces of the rotating arm, through adjustable slots on the leading and trailing faces of the arm.

Owner:WRIGHT RICHARD WILFRED

Method for producing white granulated sugar by sugar boiling

The invention relates to the field of sugar production, in particular to a method for producing white granulated sugar by sugar boiling. The method comprises the following steps: repeatedly boiling refined syrup, separating white syrup, green molasses and sugar, and performing crystallization assistance on fine massecuite at the last time for 24 hours; then separating molasses from sugar by using a continuous separator, and mixing the sugar with the sugar obtained in the previous steps, thereby obtaining the white granulated sugar. The invention provides the method for producing white granulated sugar by sugar boiling, the sugar quality is improved, and the process is easy to operate and stable.

Owner:广西农垦糖业(集团)昌菱制糖有限公司

Process for commercial production of concentrated sugary syrup with low energy requirement

InactiveUS20140345603A1Efficient separationEnergy efficiencyPurification using adsorption agentsSolid sorbent liquid separationWater iceEnrichment methods

The invention provides a progressive freeze-concentration process for the commercial production of sugar, particularly maple, syrup including the steps of exposure of collected raw sugar solutions and maple sap on-site to a predominantly or relatively naturally occurring cold surface, gradually cooling the sap to a temperature sufficient to commence freezing of a water ice, continuing the cooling and freezing to form a solid body of water ice and a liquid component separate from the solid body containing first sugars, continuing the cooling and freezing until the first sugars containing liquid component reaches a substantially thickened or gel consistency, and thirdly, separation of the first sugars containing liquid component from the said solid body.

Owner:CHADBOURNE VALERIE GAY

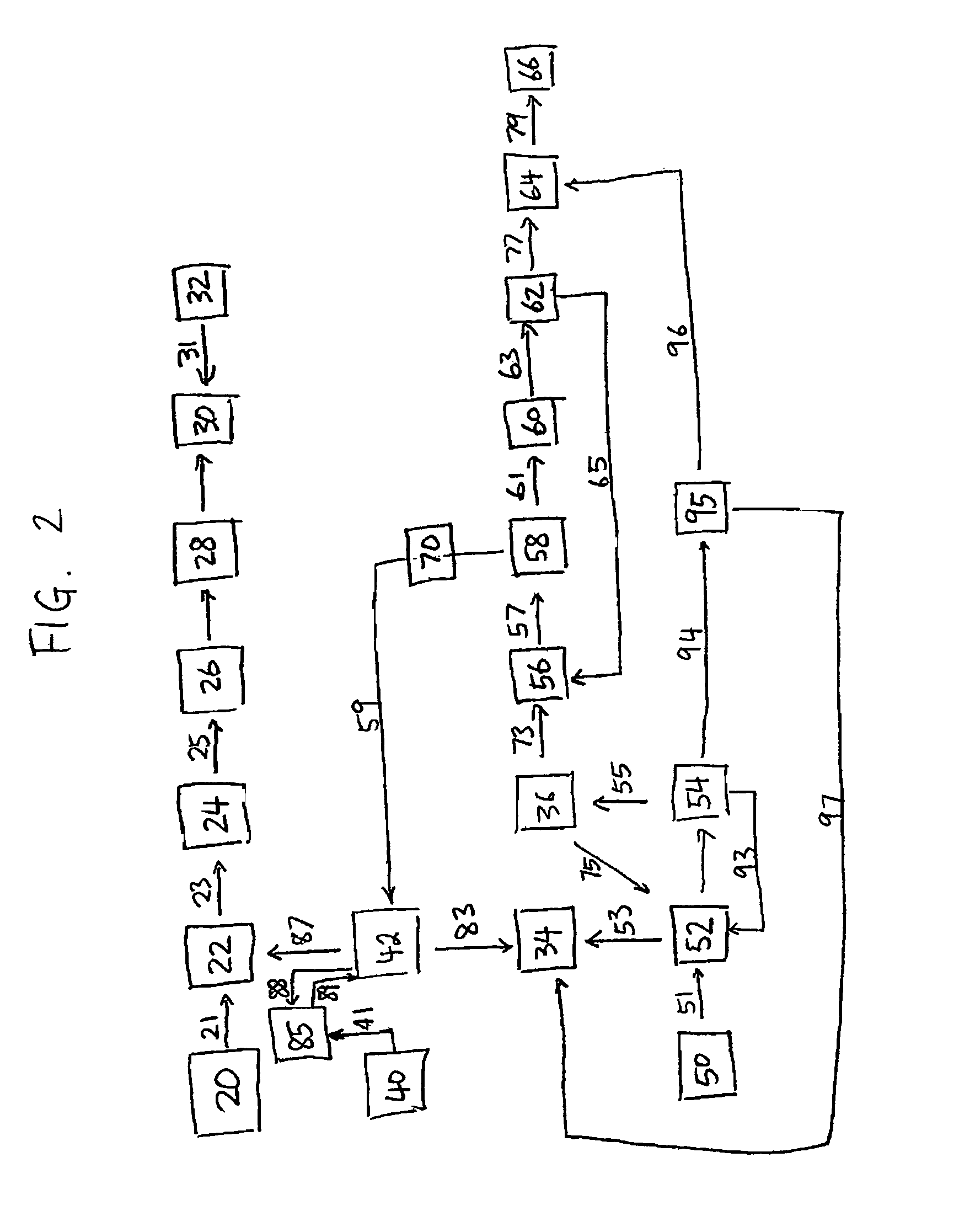

Separation process

The invention relates to an improved nanofiltration process for separating and recovering components, such as sugars and sugar alcohols from multicomponent mixtures. The process of the invention is characterized by collecting the nanofiltration retentate / permeate in several fractions with different purity, optional recycling of at least one of the collected nanofiltration retentate / permeate fractions to the nanofiltration and recovering the desired component from the nanofiltration permeate / retentate fractions by different methods. In one embodiment of the invention, the process comprises a combination of nanofiltration and chromatography.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Method for extracting soybean oligosaccharides from soybean molasses

ActiveCN107287362BReduce investmentReduce manufacturing costNatural extract food ingredientsFood ingredient functionsRotary evaporatorSoybean product

The invention discloses a method for extracting soybean oligosaccharides by using soybean molasses, belonging to the field of soybean product production. The problem of high reducing sugar content of soybean oligosaccharides produced in the prior art is solved, and the method comprises the following steps: dilute soybean molasses, heat and boil, add quicklime, then pass carbon dioxide gas to adjust the pH of the solution to neutral, and centrifuge to take the supernatant ; The supernatant is cooled to room temperature, and the colored substance is decolorized by using a macroporous adsorption decolorization resin to obtain a slightly yellow or colorless aqueous solution of soybean oligosaccharides; an acidic cationic resin and a basic anionic resin are used for adsorption and desalination treatment to obtain a colorless Color transparent soybean oligosaccharide aqueous solution; under the conditions of vacuum degree of 0.08-0.1MPa and temperature of 50-70°C, use a rotary evaporator or a thin film evaporator to carry out vacuum concentration until the product hangs on the wall to obtain the finished soybean oligosaccharide . The method of the invention is suitable for extracting soybean oligosaccharides from soybean molasses.

Owner:山东中阳生物科技有限公司

Processes and apparatus for refining sugarcane to produce sugars, biofuels, and/or biochemicals

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

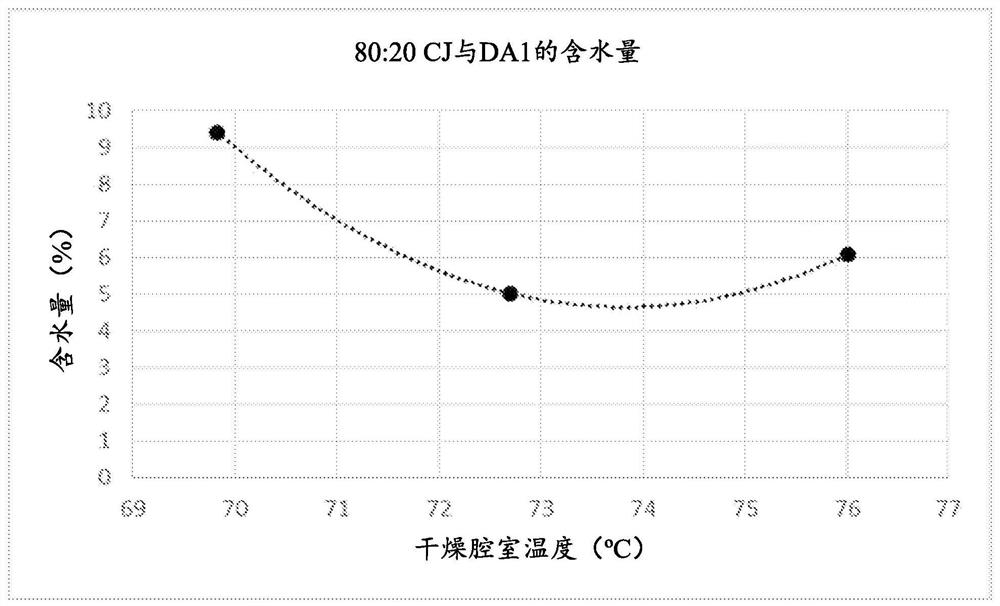

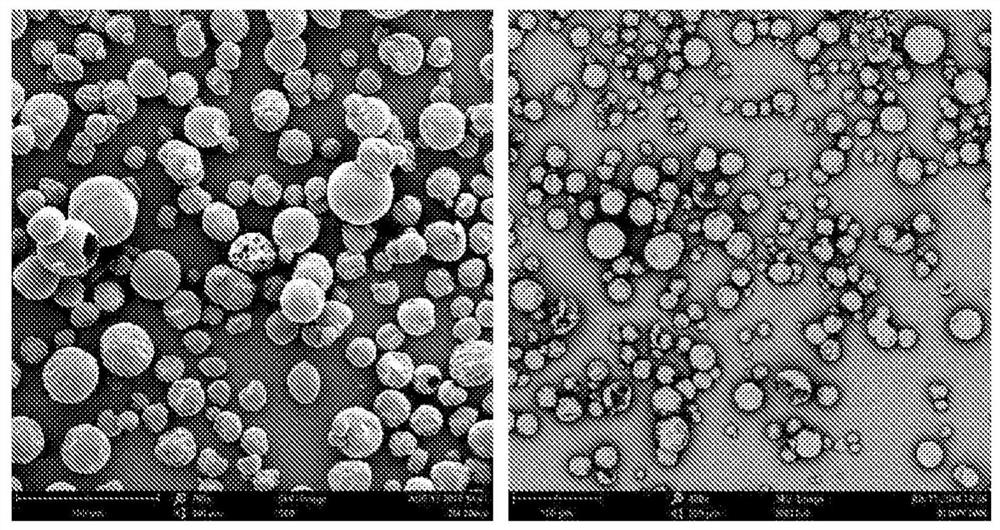

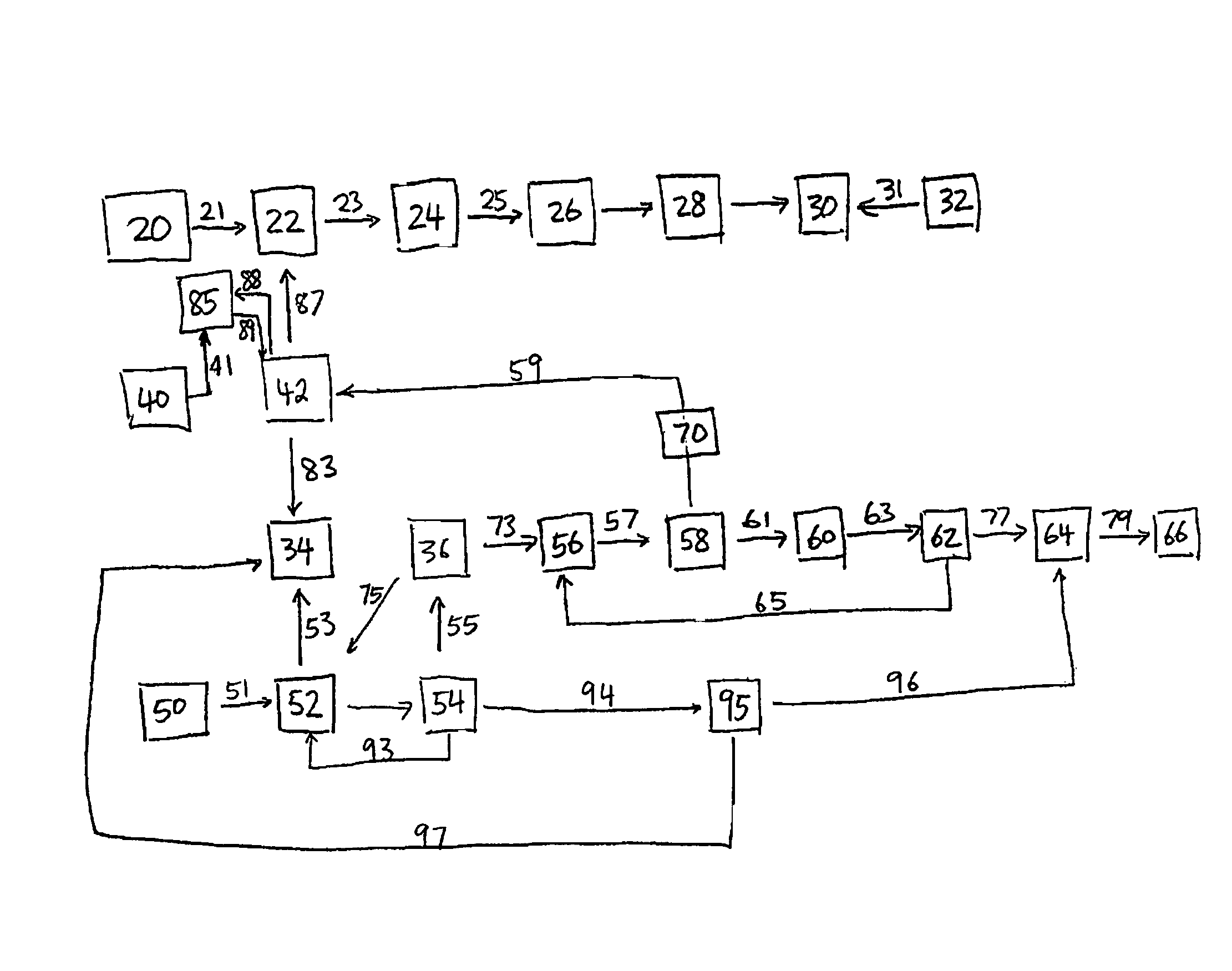

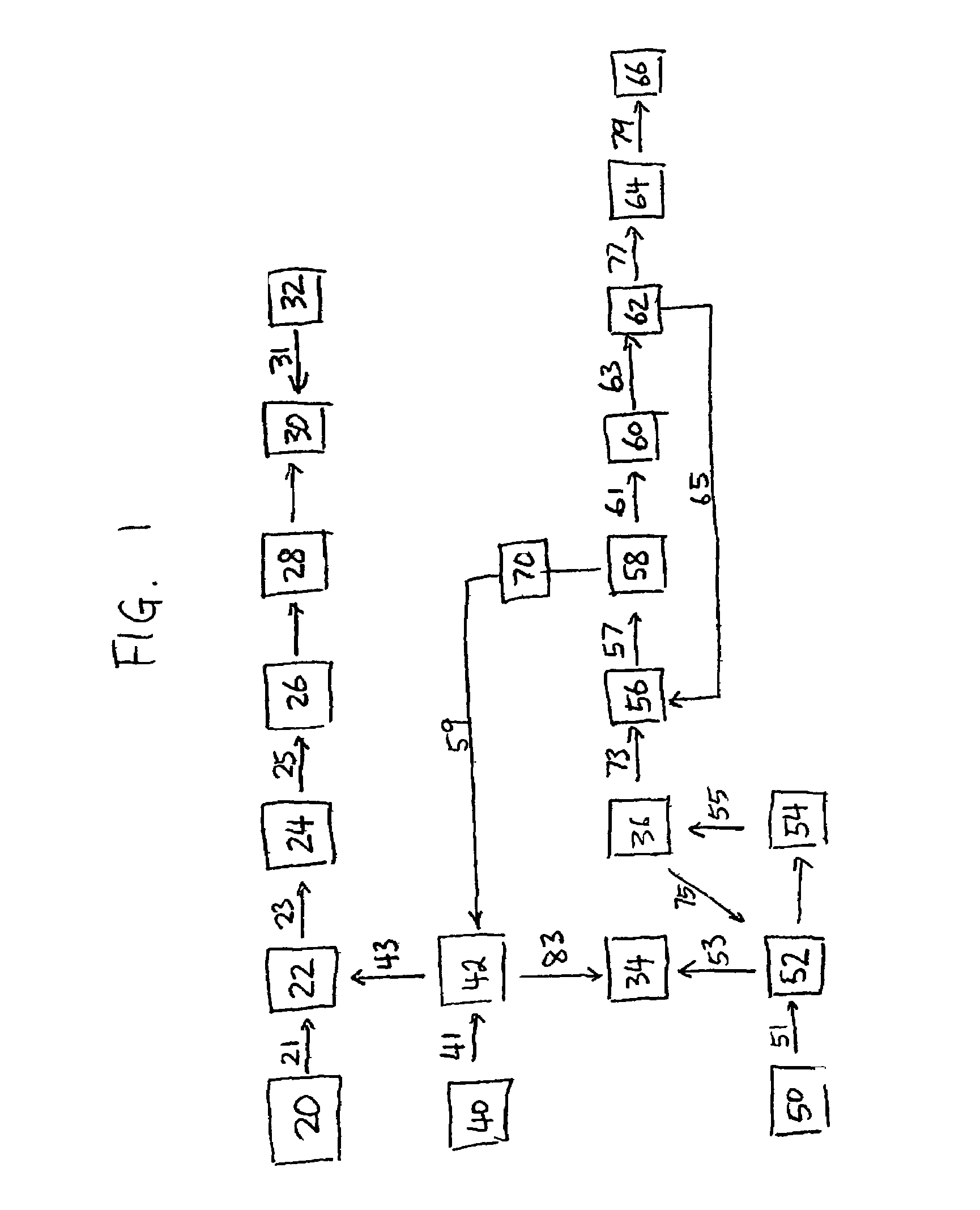

Amorphous sugar composition

PendingCN111670257AIncrease productionImprove efficiencySugar dryingDough treatmentBiotechnologyLow glucose

The present invention provides an amorphous sugar comprising sucrose, at least about 20mg CE polyphenols / 100g carbohydrate and a drying agent with a low glycaemic index. The invention further provides an amorphous sugar comprising one or more sugars and a drying agent with a low glycaemic index. The amorphous sugar of the invention may optionally further comprise prebiotics, alternative sweeteners, proteins and lipids. The amorphous sugar of the invention may optionally be aerated. The invention further provides methods of making the amorphous sugar including by rapidly drying, such as spraydrying. The invention further provides methods of preparing aerated amorphous sugar. The invention further provides methods of food and beverage preparation using the amorphous sugar.

Owner:NUTRITION SCI DESIGN PTE LTD

Water treatment

Owner:ENVIRONMENTAL MANAGEMENT CORP

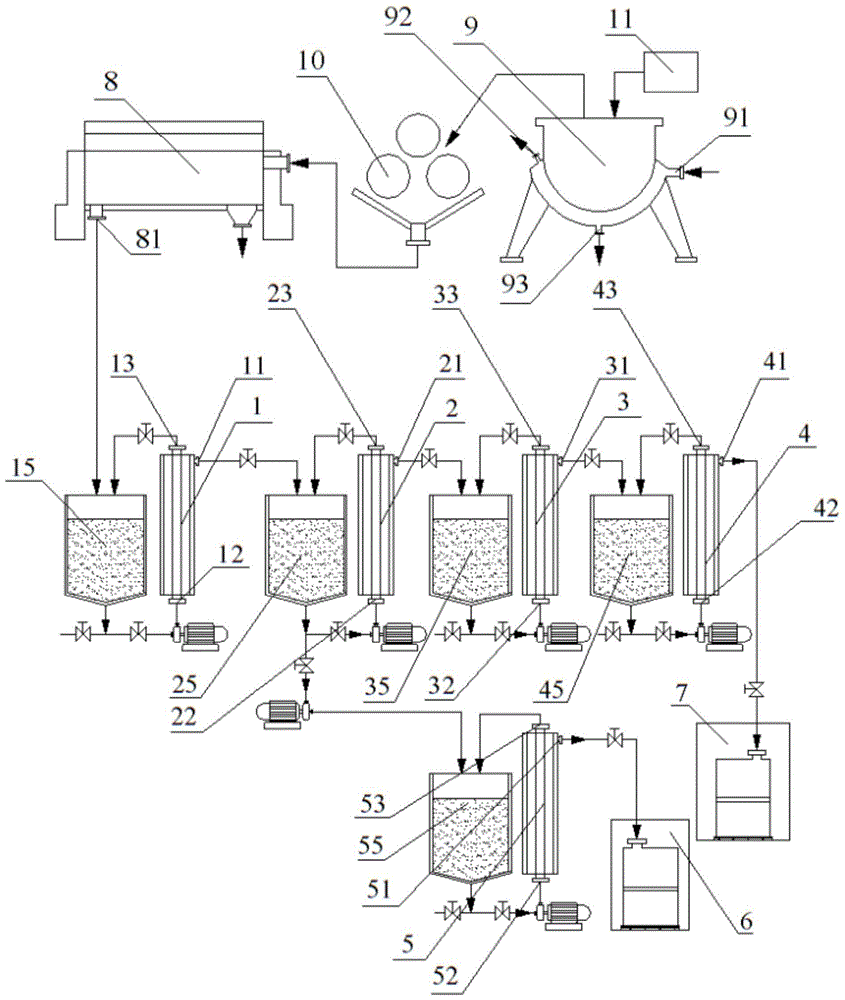

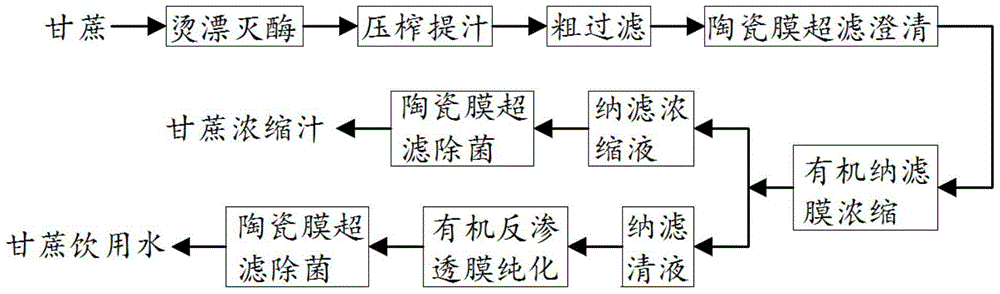

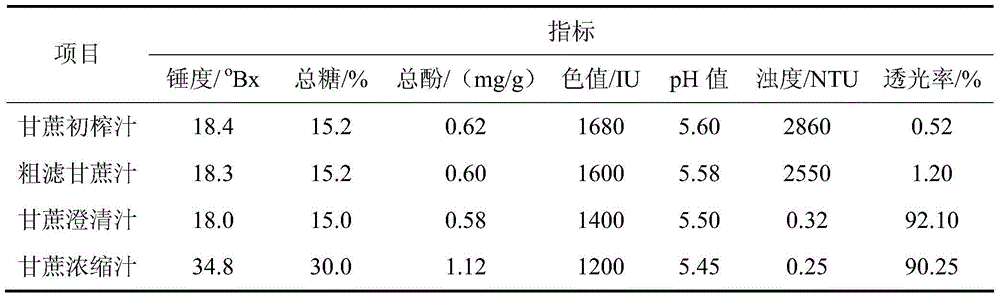

A device for parallel production of sugarcane concentrated juice and sugarcane drinking water with multi-stage membranes

ActiveCN104839827BGuarantee green safetyHigh permeation fluxSemi-permeable membranesJuice extractionFiltrationUltrafiltration

The invention provides a multistage-membrane apparatus for parallel production of concentrated sugarcane juice and sugarcane drinking water. A juice inlet of a first ceramic ultrafiltration membrane assembly of the apparatus is connected with a coarse filtration sugarcane juice vat, and a clear liquid outlet of the first ceramic ultrafiltration membrane assembly is connected with a clarified sugarcane juice vat; a juice inlet of an organic nanofiltration membrane assembly is connected with the clarified sugarcane juice vat, and a clear liquid outlet of the organic nanofiltration membrane assembly is connected with a nanofiltration clear liquid vat; a juice inlet of a second ceramic ultrafiltration membrane assembly is connected with a nanofiltration concentrated liquid vat, and a clear liquid outlet of the second ceramic ultrafiltration membrane assembly is connected with a concentrated sugarcane juice aseptic filling chamber; a juice inlet of an organic reverse osmosis membrane assembly is connected with the nanofiltration clear liquid vat, and a clear liquid outlet of the organic reverse osmosis membrane assembly is connected with a reverse osmosis clear liquid vat; and a juice inlet of a third ceramic ultrafiltration membrane assembly is connected with the reverse osmosis clear liquid vat, and a clear liquid outlet of the third ceramic ultrafiltration membrane assembly is connected with a sugarcane drinking water aseptic filling chamber. According to the invention, sugarcane is used as a raw material for parallel production of concentrated sugarcane juice and sugarcane drinking water, so the added value of sugarcane is increased.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com