Efficient separation method for sugar in sugar beet sugar production

A separation method and technology of sugar content, applied in the field of separation, can solve the problems of polluting the environment and failing to meet the discharge standards of wastewater, and achieve the effects of low water consumption and resin consumption, reasonable design, and environmentally friendly use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

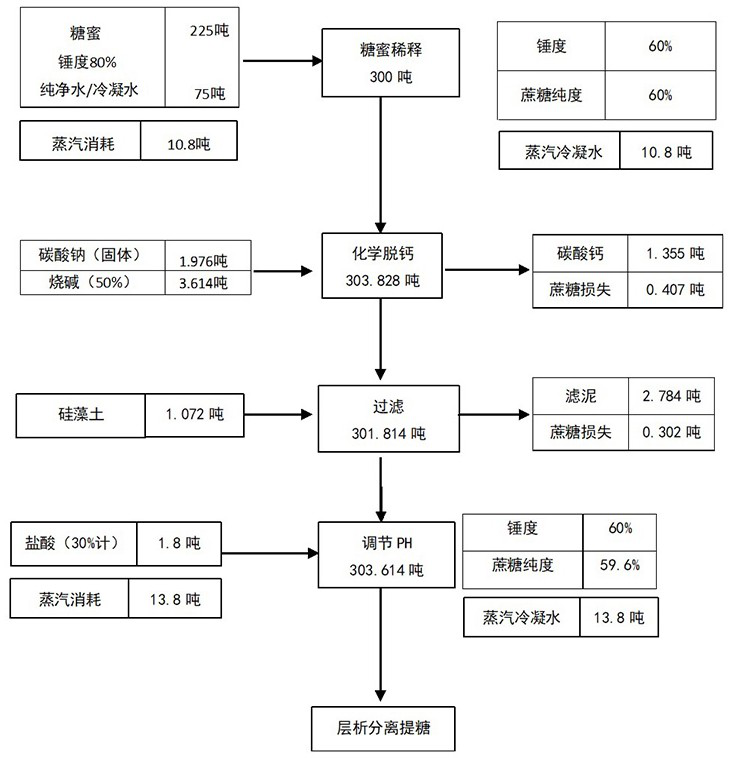

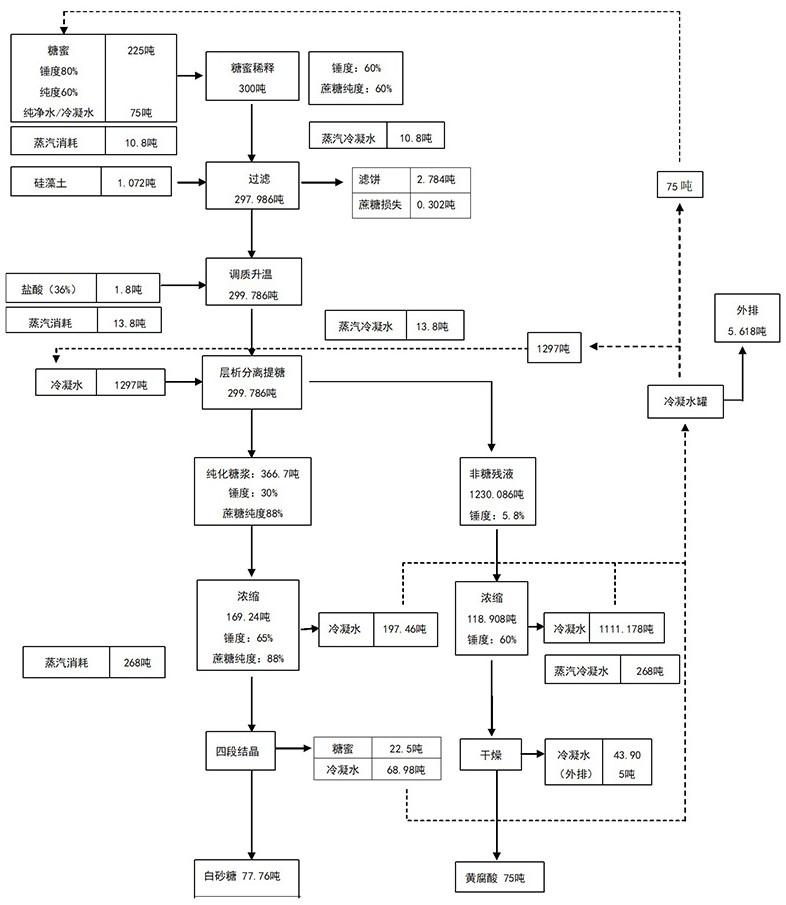

[0024] After the sugar beet production and squeezing period is stopped, the chromatographic desugaring equipment continues to be used to extract syrup to produce white sugar, but the calcium content in the molasses far exceeds the feed requirements of the chromatographic separation system. Therefore, when processing this part of the molasses, chemical softening must be used first. The method reduces the calcium ion concentration in molasses, and then the chromatographic separation system.

[0025] Chemical decalcification process

[0026] refer to figure 1 The material balance diagram of the beet molasses is stored in the molasses storage tank, and the molasses is pumped to the chemical decalcification unit. 0 Bx dropped to 50-70 0 Bx, add sodium carbonate for softening to form calcium carbonate precipitation, and then pass through the two-stage filtration of plate and frame filter and candle filter, in which impurities such as suspended solids and calcium carbonate precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com