Patents

Literature

37results about How to "Guarantee green safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

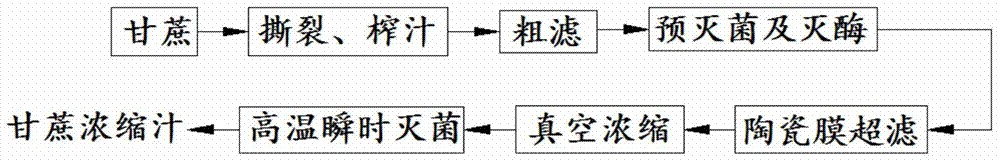

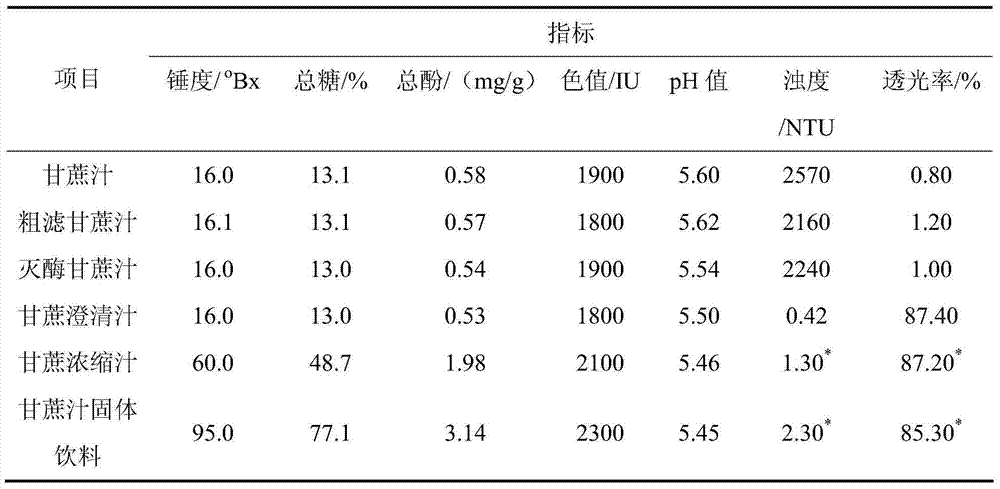

Processing technology of sugarcane concentrated juice

InactiveCN104489827AGuarantee green safetyExtended cleaning cycleFood preparationCause blockageFlavor

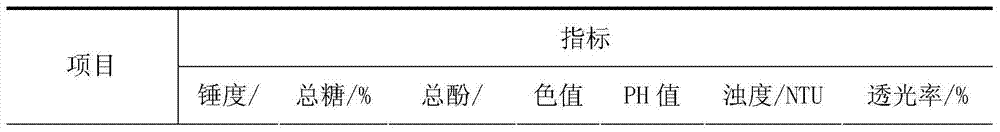

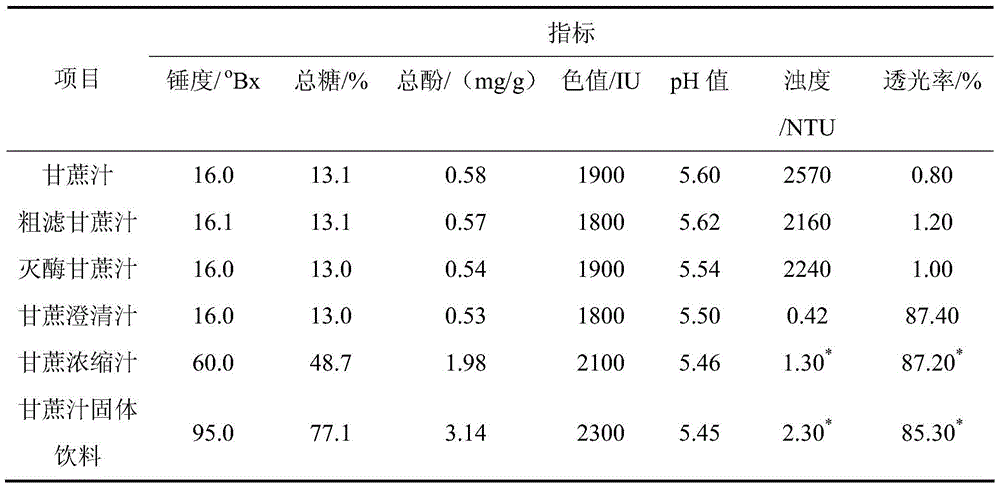

The invention relates to a processing technology of sugarcane concentrated juice. The sugarcane concentrated juice is processed by taking sugarcanes as raw materials and performing six steps, namely juicing, coarse filtration, pre-sterilization, enzyme inactivation, ultrafiltration by a ceramic membrane, vacuum concentration and high-temperature instant sterilization. The sugarcane concentrated juice prepared by the processing technology provided by the invention has clear and transparent color and luster, rich aroma, and sweet and delicious taste, and can keep the original flavor and nutritional components of the sugarcanes; and furthermore, the precipitation of a precipitate and the production of turbidity are avoided in the storage period. By adopting the processing technology provided by the invention, the technical problems of relatively high loss of flavor substances and the nutritional components in the production process of the sugarcane concentrated juice, browning in the processing and storage processes, deterioration of the sugarcane juice in the enzymolysis process, easiness in formation of membrane scales to cause blockage of membrane pores when the organic membrane is used for ultrafiltration and clarification and the like are solved.

Owner:GUANGXI UNIV

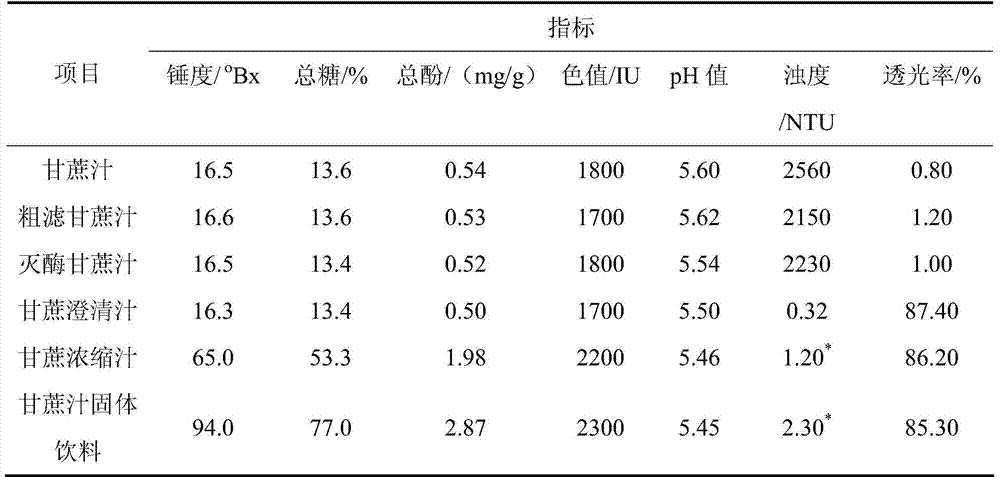

Processing method of sugarcane juice solid beverage

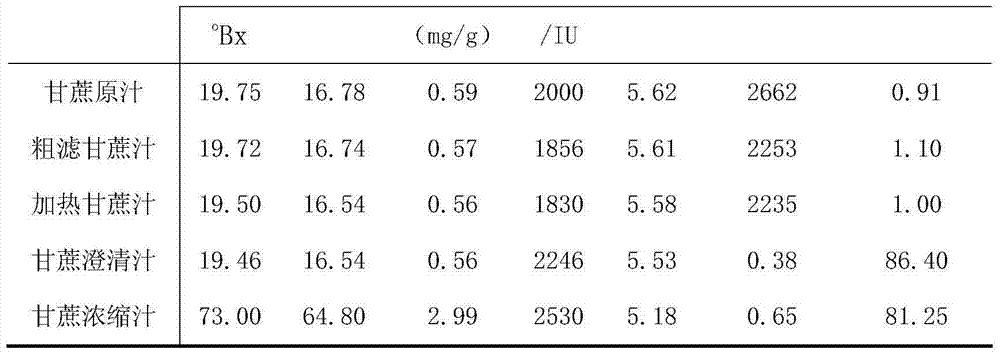

A processing method of a sugarcane juice solid beverage comprises the following steps: filtering a sugarcane juice by allowing the sugarcane juice to sequentially go through a drum sieve and a curved sieve in order to obtain a coarse filtration sugarcane juice; heating the coarse filtration sugarcane juice to 90-100DEG C, maintaining the temperature for 1-2min, and rapidly cooling to obtain an enzyme killed sugarcane juice; carrying out ultrafiltration clarification on the enzyme killed sugarcane juice by adopting a multistage ceramic membrane ultrafiltration system with the membrane aperture of 0.02-0.10[mu]m; carrying out evaporative concentration on the clarified sugarcane juice to obtain a sugarcane juice concentrate; sending the sugarcane juice concentrate to a vacuum sugar boiling pan, and carrying out further evaporative concentration to obtain a massecuite; and stirring the massecuite until caster sugar appears, pouring the massecuite into a die, cooling to room temperature, cutting to form blocks, drying, and packaging to obtain a finished product. The sugarcane juice solid beverage prepared in the invention can be instantly drunk after dissolution in hot water, and the dissolved solid beverage has cleared and transparent color, rich fragrance and sweet and tasty taste, and well maintains the original nutritional components and flavor substances of sugarcane.

Owner:广西百桂堂食品科技有限公司

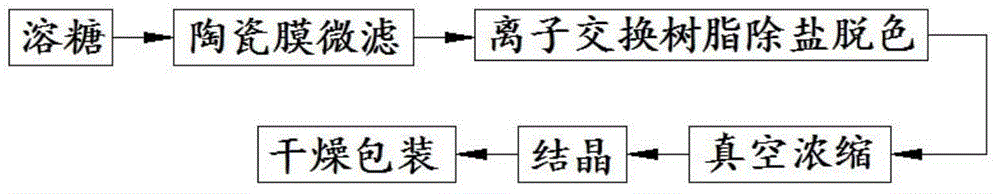

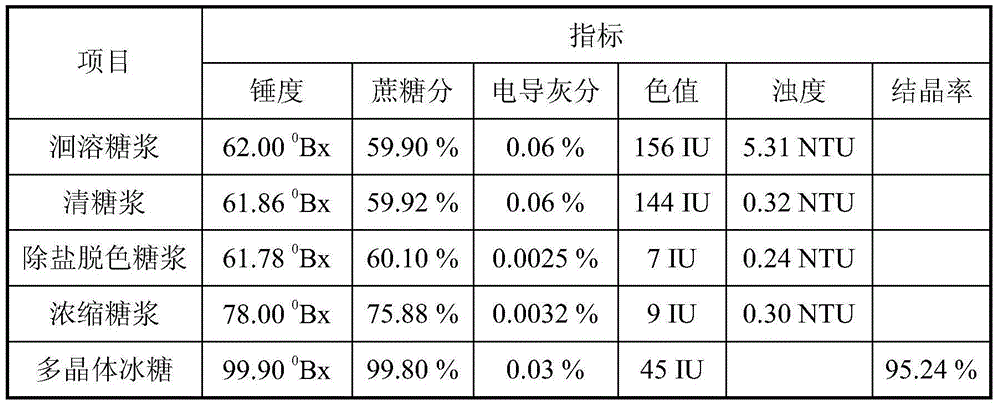

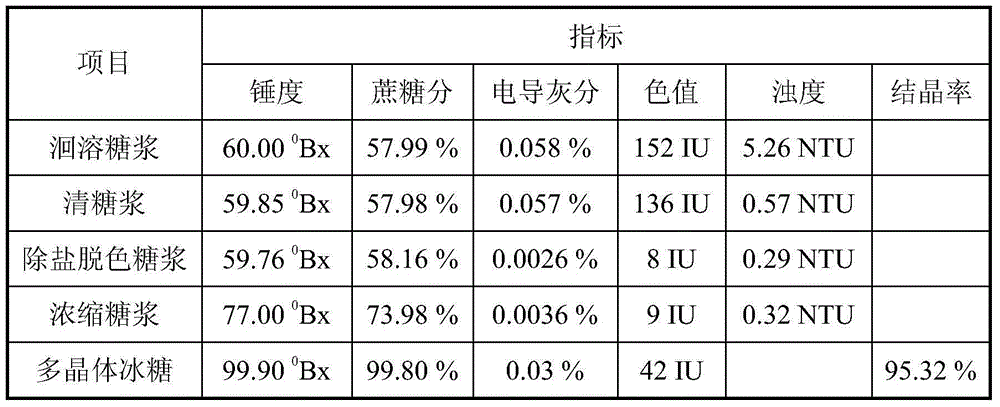

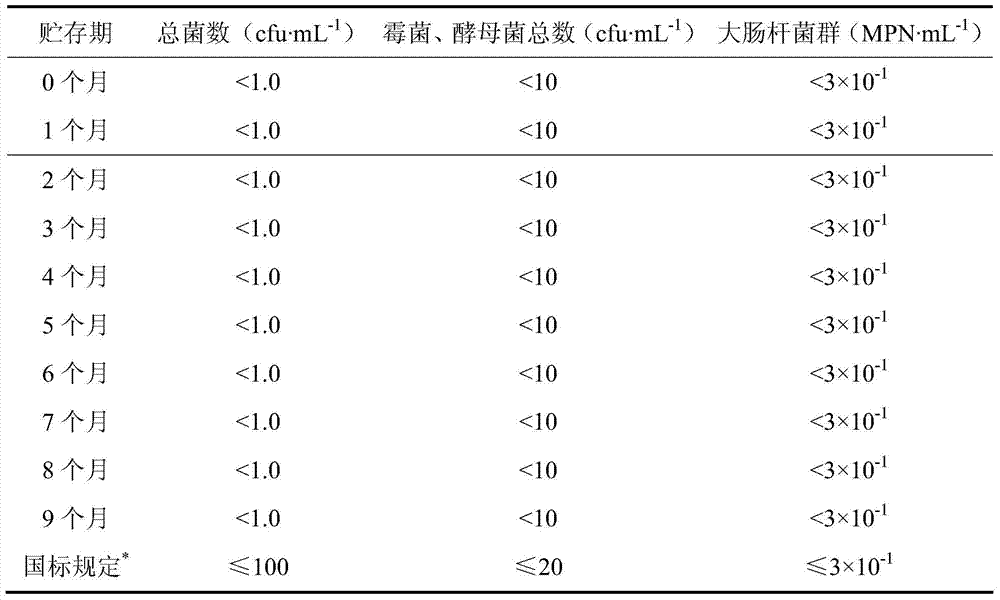

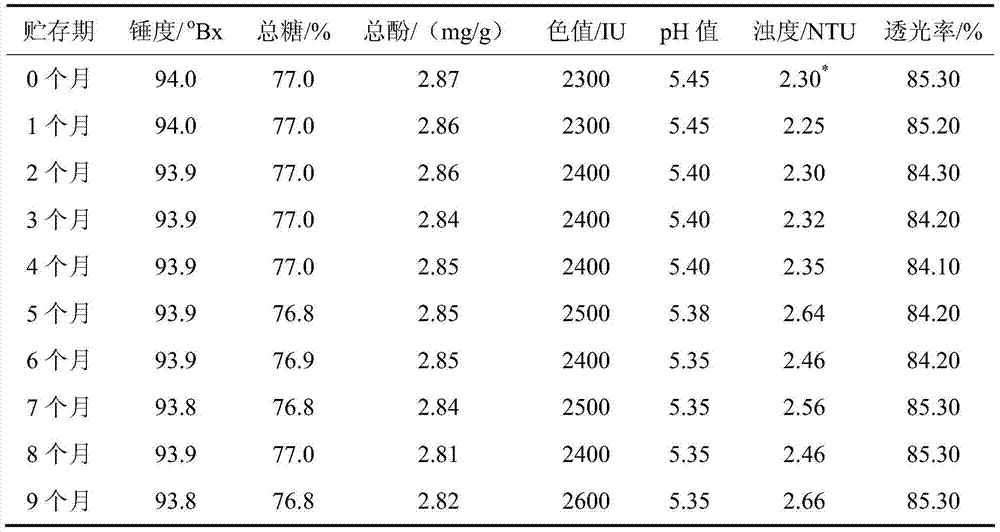

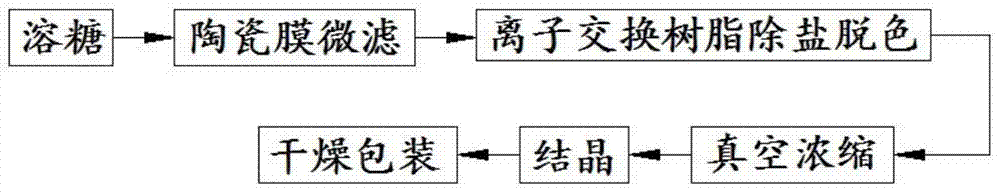

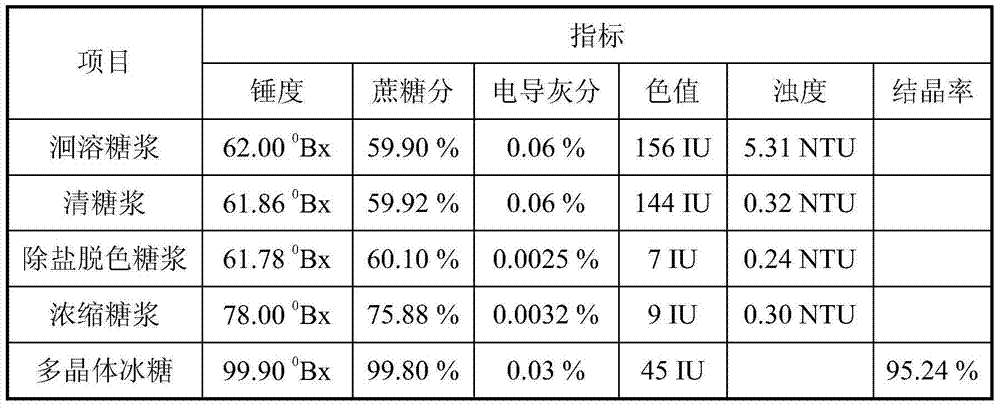

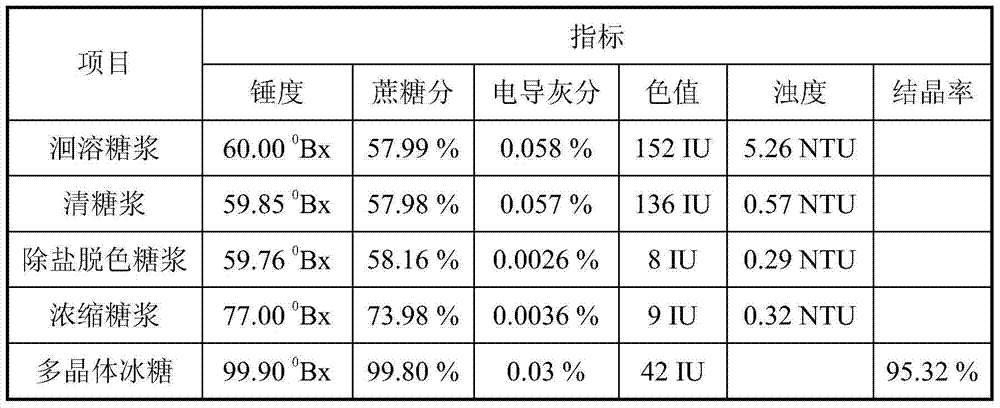

Production process of poly-crystal rocky candy

The invention discloses a production process of poly-crystal rocky candy. The production process comprises the following six steps: by taking first-grade white sugar as a raw material, dissolving the sugar, micro-filtering and clarifying, desalting and decolorizing by using ion exchange resin, concentrating in vacuum, charging seeds for crystallization, drying and packaging to produce the poly-crystal rocky candy. The poly-crystal rocky candy produced by the method disclosed by the invention is sweet and delicious in taste and white and transparent in color and luster; no sodium hydrosulfite is added for color protection during the overall production, so the product is environmental friendly and safe; the crystallization rate of the rocky candy is above 95%; the problem of low crystallization rate during production of the poly-crystal rocky candy for a long time is solved.

Owner:GUANGXI UNIV

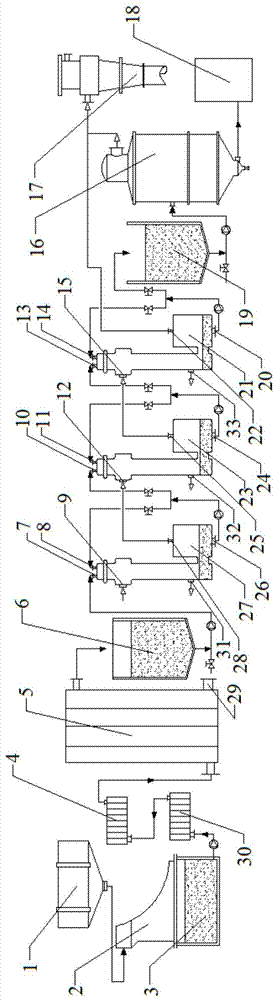

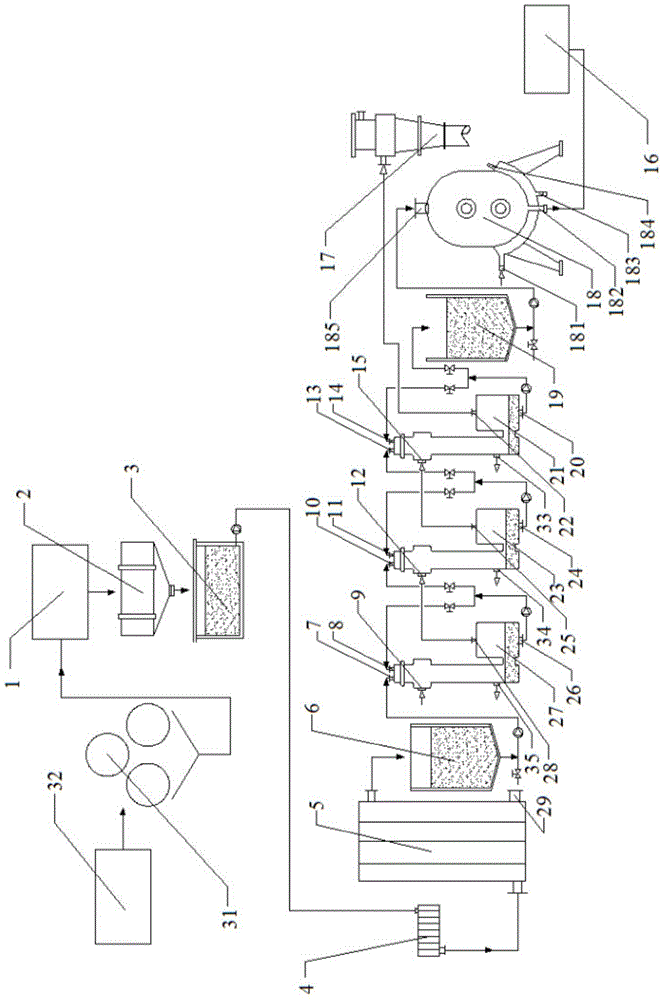

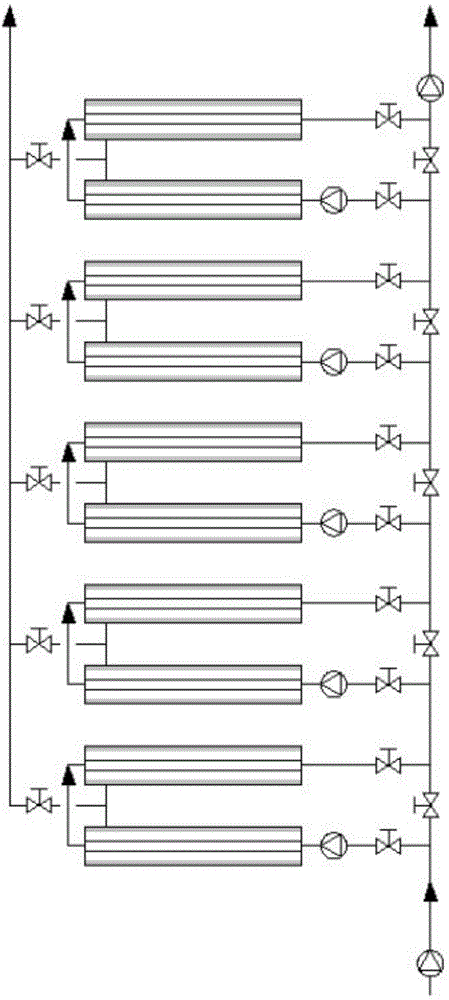

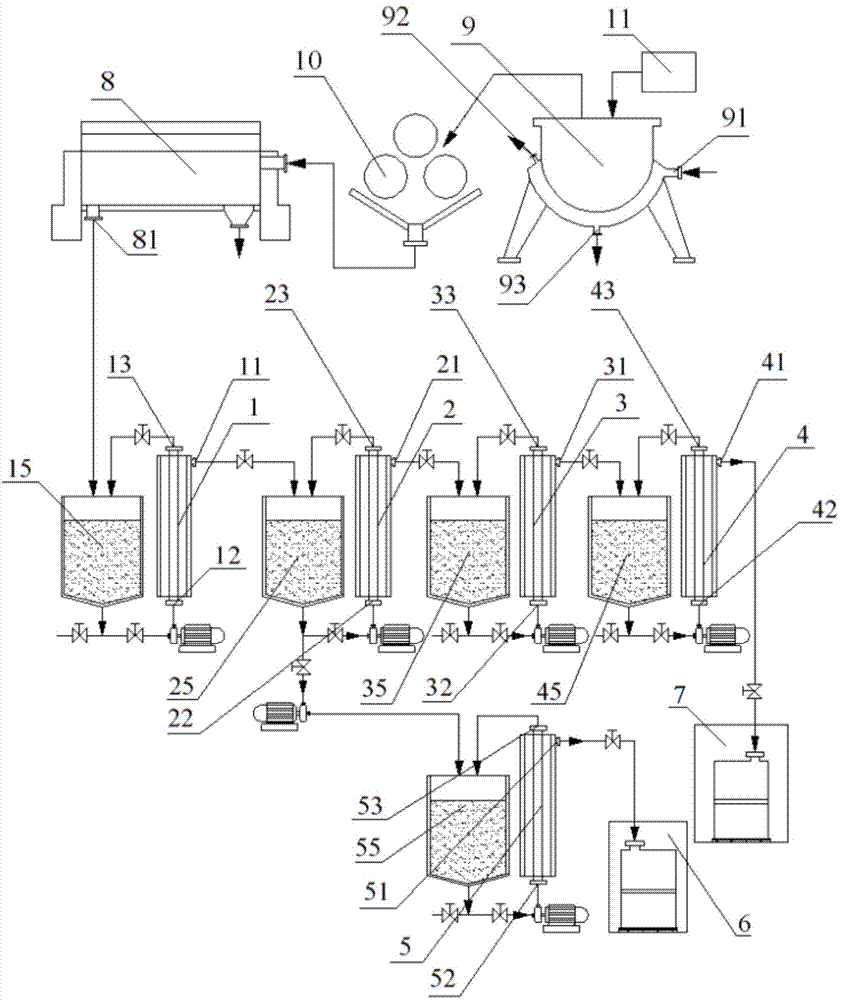

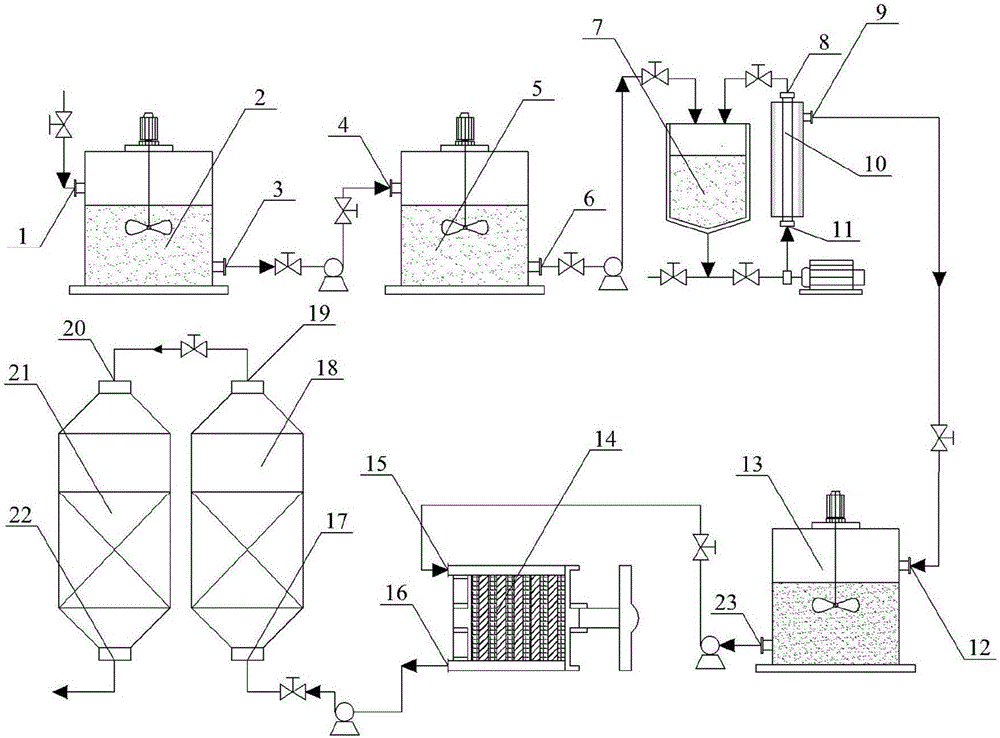

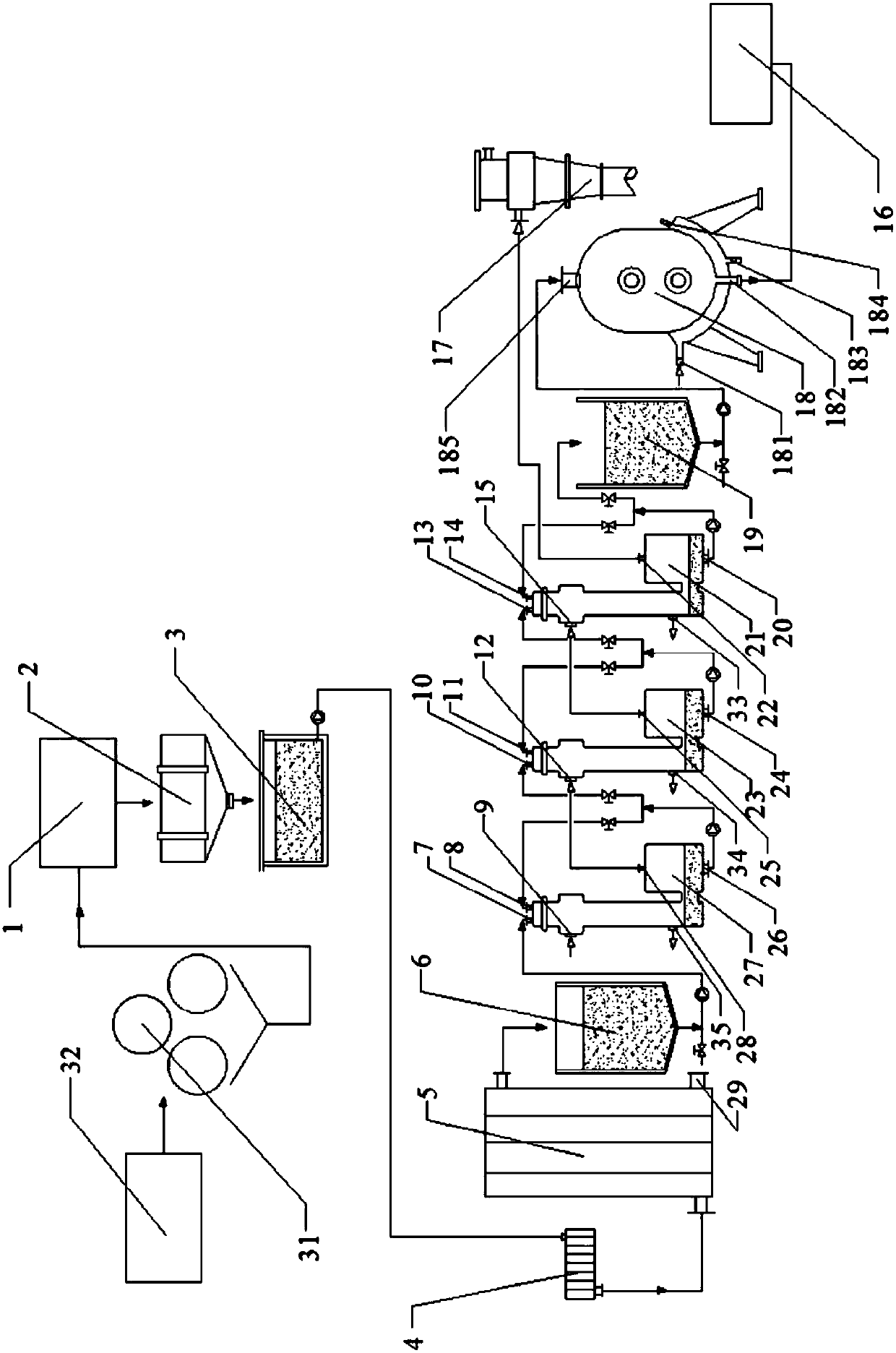

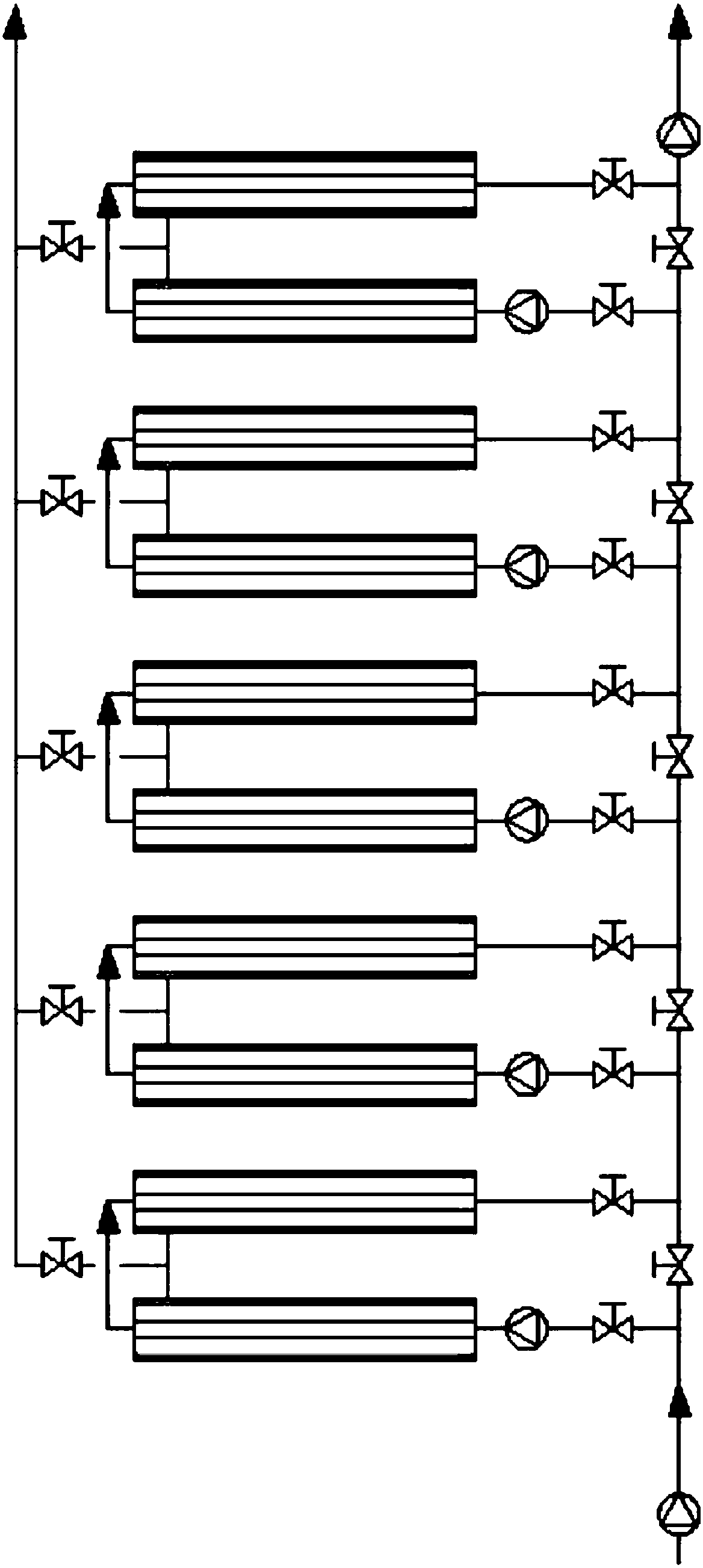

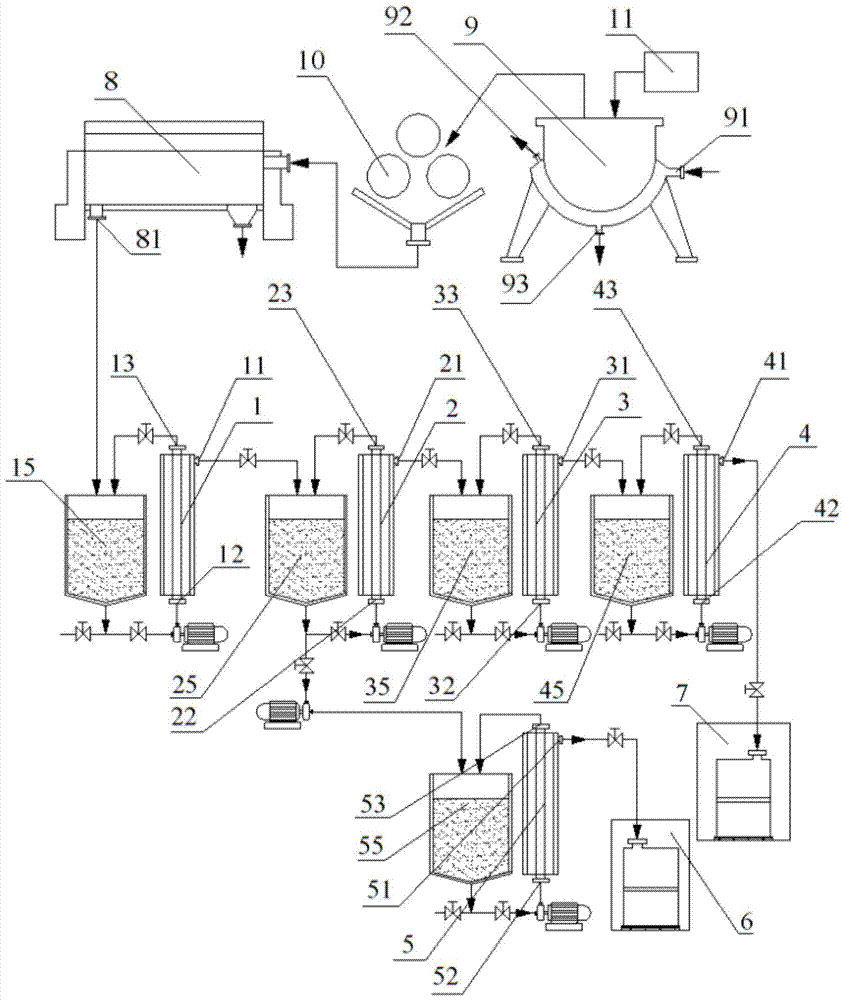

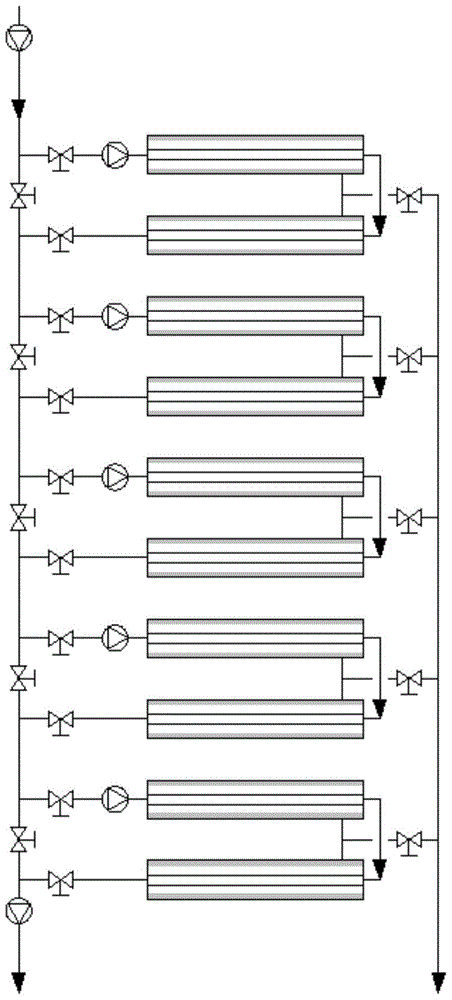

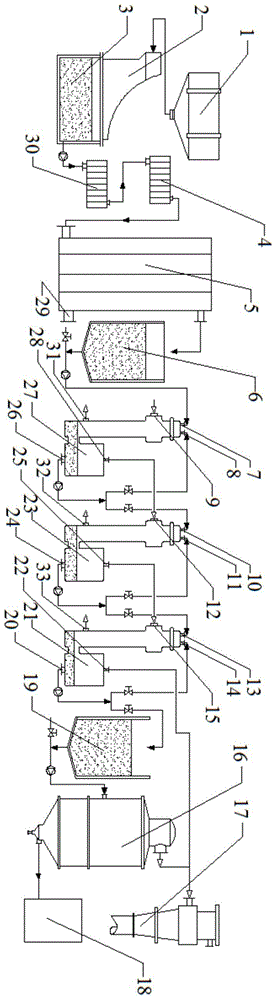

Processing device for sugarcane juice solid drink

ActiveCN104720071AGuarantee green safetyExtended cleaning cycleFood scienceAdditive ingredientSlurry

The invention discloses a processing device for a sugarcane juice solid drink. The processing device comprises sugarcane juice rough filtration equipment, a first heat exchanger, a second heat exchanger, multistage ceramic membrane ultrafiltration equipment, falling-film three-effect vacuum evaporation equipment, vacuum concentration equipment and drying-forming equipment, wherein the sugarcane juice rough filtration equipment comprises a drum sieve, a curved sieve and a roughly filtrated sugarcane juice storage box; a clarified sugarcane juice box is connected between the multistage ceramic membrane ultrafiltration equipment and the falling-film three-effect vacuum evaporation equipment; the falling-film three-effect vacuum evaporation equipment comprises a falling-film first-effect vacuum evaporation tank, a falling-film second-effect vacuum evaporation tank and a falling-film third-effect vacuum evaporation tank; a sugarcane slurry box is connected between the falling-film three-effect vacuum evaporation equipment and the vacuum concentration equipment; the vacuum concentration equipment comprises a sugarcane boiling tank and a water jet condenser. The sugarcane juice solid drink prepared by the processing device disclosed by the invention can be drunk after being dissolved with hot water, is clear and transparent in colour, strong in fragrance, and fresh, sweet and delicious in taste, as well as keeps the original nutritional ingredients and flavour substances of the sugarcane well.

Owner:广西百桂堂食品科技有限公司

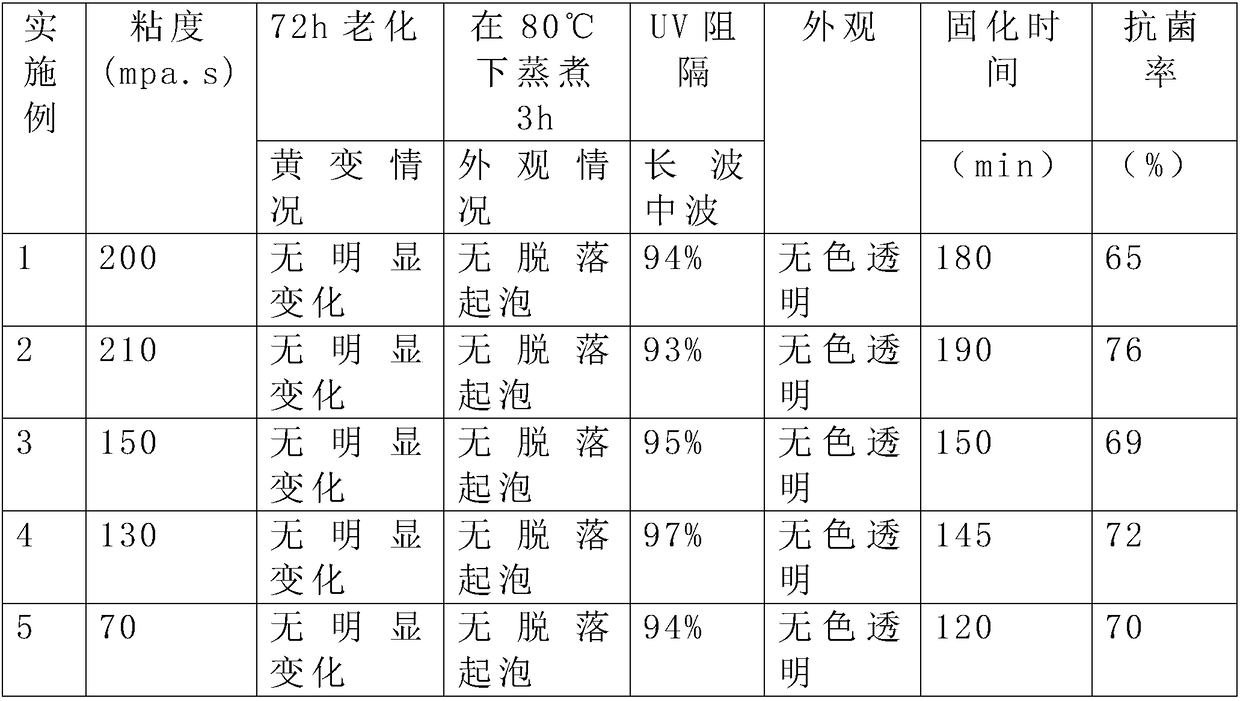

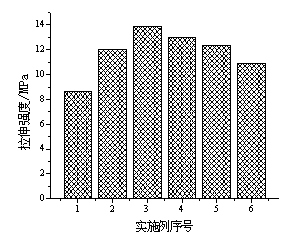

Nano-modified two-component solventless flexible packaging adhesive and preparation method thereof

InactiveCN108084949AImprove the degree of internal crosslinkingReduce volatile and free matterNon-macromolecular adhesive additivesFilm/foil adhesivesOxideAdhesive

The invention provides a nano-modified two-component solventless flexible packaging adhesive and a preparation method thereof. A component A of the adhesive comprises castor oil or palm oil vegetableoil-based polyol, hexylene glycol, polyether polyol, additives and graphene oxide-pretreated nanoscale titanium dioxide. A component B comprises MDI, TPU, polypropylene glycol, polyether polyol and lignin amine-modified diphenylmethane diisocyanate. The components A and B are obtained through reactions in a reactor. The castor oil replaces a part of polyether polyol or polyester polyol, the adhesive contains few volatile and free materials and is eco-friendly and safe, through use of pretreated nano-titanium dioxide and additives, the reaction is mild and effective, the adhesive has UV resistance, and according to the reaction product chain length of the active NCO group of the MDI and the OH group of the polyol in the reaction process, the reaction temperature is timely adjusted. The solventless flexible packaging adhesive has excellent adhesive performances.

Owner:新纳奇材料科技江苏有限公司

Method for preparing eucommia seed oil micro-emulsion

ActiveCN108272661AGuarantee green safetyCosmetic preparationsToilet preparationsEmulsionFreeze-drying

The invention discloses a method for preparing eucommia seed oil micro-emulsion. The eucommia seed oil micro-emulsion prepared with the method is prepared by the steps: taking eucommia seed oil prepared by a bio-surfactant with an aqueous enzymatic method as a main raw material, taking a cosurfactant, emulsion and water as auxiliary materials, and preparing the micro-emulsion through phase inversion emulsification. The micro-emulsion prepared with the method solves the problem that the eucommia seed oil is difficult to store due to high content of unsaturated fattyacids, reduces application ofa chemical surfactant, and has the characteristics of being green and safe. Meanwhile, freeze-dried powder obtained by drying the eucommia seed oil micro-emulsion is stable in product property, highin encapsulation efficiency and wide in application range.

Owner:JISHOU UNIVERSITY +1

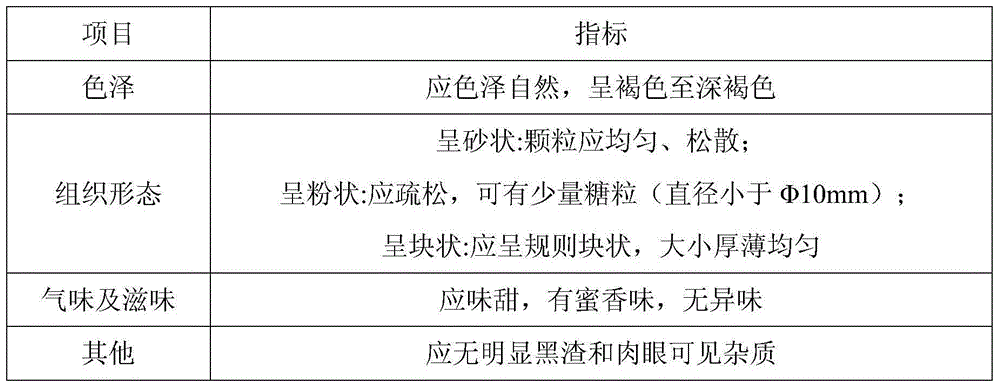

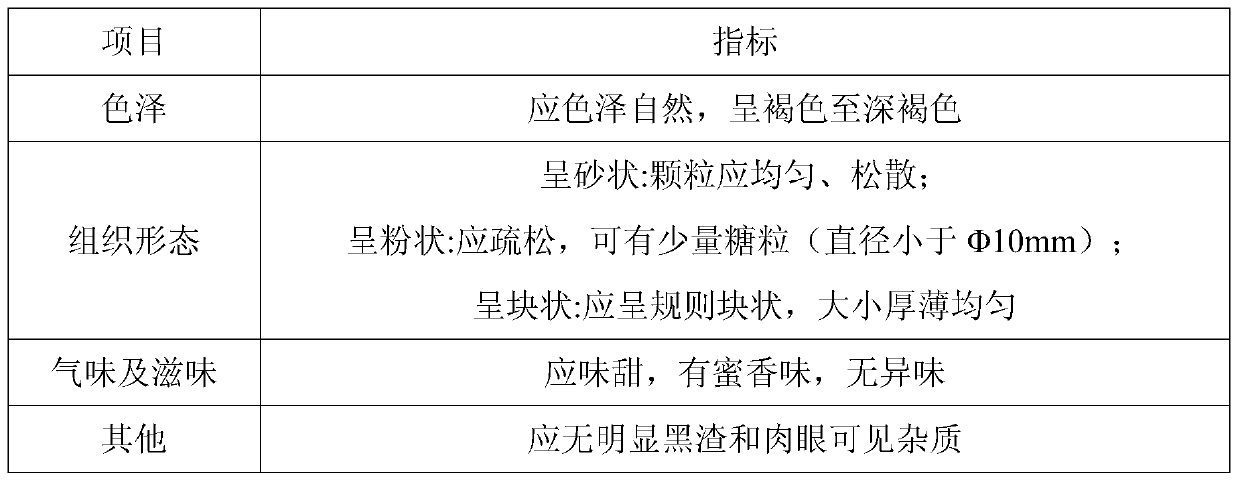

Originally ecological black sugar processing device

ActiveCN104805224ATroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsAdditive ingredientUltrafiltration

An originally ecological black sugar processing device comprises a squeezing rough-filtration device, a heat exchanger, a multistage ceramic membrane ultrafiltration device, a falling-film type three-effect vacuum evaporation system, a water jet condenser, a jacketed iron pot and a graining drying forming device, which are sequentially connected, wherein a clarified sugarcane juice box is connected between the multistage ceramic membrane ultrafiltration device and the three-effect vacuum evaporation device; a syrup box is connected between the falling-film type three-effect vacuum evaporation system and the jacketed iron pot. The black sugar prepared through the device provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, sweet, delicious, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that black residues exist after the black sugar is dissolved is solved and the quality of the black sugar is improved.

Owner:广西百桂堂食品科技有限公司

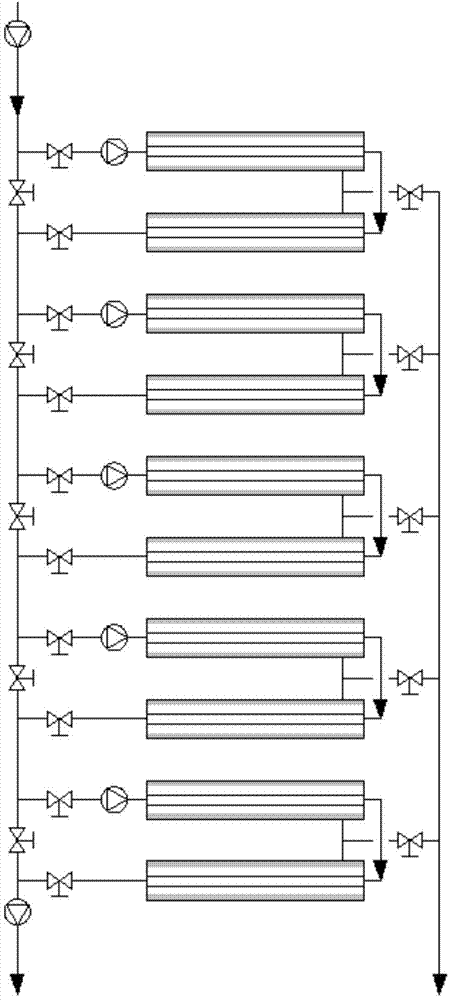

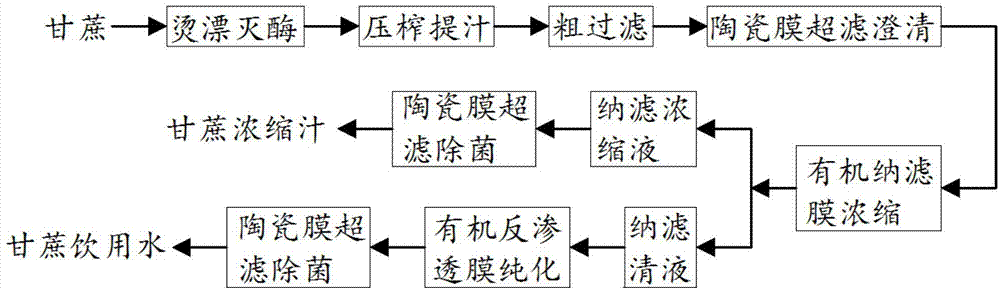

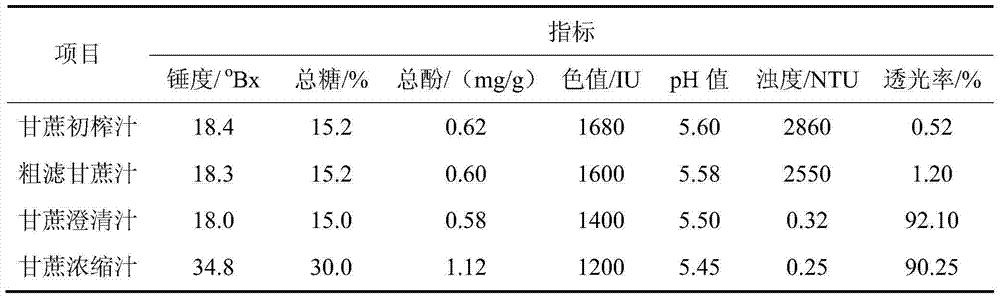

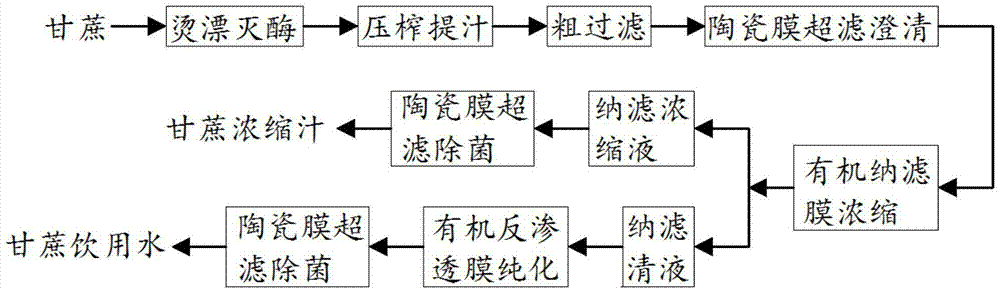

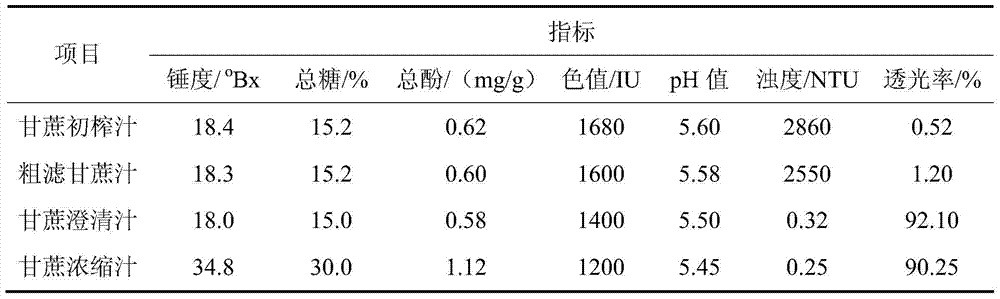

Method for parallel production of sugarcane concentrated juice and sugarcane drinking water by multi-stage films

The invention provides a method for parallel production of sugarcane concentrated juice and sugarcane drinking water by multi-stage films. The method comprises the steps as follows: enabling sugarcanes to be subject to blanching enzyme deactivation, pressing and juice extracting and crude filtering sequentially, to obtain crudely filtered sugarcane juice; ultra-filtering and cleaning the crudely filtered sugarcane juice by a first ceramic film to obtain clear sugarcane juice; concentrating the clear sugarcane juice by an organic nano-filtration film to obtain a nano-filter clear solution and a nano-filter concentrated solution; ultra-filtering the nano-filter concentrated solution by a second ceramic film, sterilizing and filling sterilely to obtain the sugarcane concentrated juice; purifying the nano-filter clear solution by an organic reverse osmosis film to obtain a reverse osmosis clear solution; ultra-filtering and sterilizing the reverse osmosis clear solution by a third ceramic film, and filling sterilely to obtain the sugarcane drinking water. Based on the integration of film process separation, concentration, cold sterilizing and other functions, the high-quality sugarcane concentrated juice and sugarcane drinking water are produced in parallel with sugarcanes as a raw material, and the optimization of products and comprehensive utilization of sugarcane resource are prompted.

Owner:GUANGXI UNIV

Process for producing shellfish premix feed

InactiveCN102018140AReduce lossesProne to explosionFood processingClimate change adaptationFish oilMixed materials

The invention discloses a process for producing a shellfish premix feed, which is characterized in that the shellfish premix feed is prepared by using attapulgite, flours, corn husks and the like as carrier raw materials through the steps of adding bioactive peptides into the carrier raw materials by a liquid adding device through using a high-pressure atomized spraying method; drying the obtained evenly-mixed materials by air flows, then carrying out ultra-micro pulverization on the materials, and adding fish oil into the materials in the process of pulverization; then adding feed decavitamin and composite trace elements into the materials, after evenly mixing the materials, adding bioactive peptides and immune polysaccharides into the mixed materials; drying the mixed materials by air flows until the moisture content of the mixed materials is 10 to 15 percent, sieving the obtained materials so as to ensure the materials can completely pass through a 90-mesh sieve to obtain the finished product of the premix feed. The process for producing the shellfish premix feed has the advantages that the process is more reasonable, and the premix feed is ensured to be environmental friendly and safe; the losses of vitamins, microelements and other active materials can be reduced; and oil-phase, solid-phase and aqueous-phase materials in the product are added simultaneously, after the materials are mixed and dried, an envelope can be formed on the surface of the product, thereby improving the product stability.

Owner:JIANGSU TIANFULAI GROUP

Sustained-release antioxidant packaging film for food and preparation method thereof

ActiveCN103435894AGuarantee green safetyControl Oxidative DeteriorationFlat articlesMasterbatchPolymer science

The invention relates to a sustained-release antioxidant packaging film for food and a preparation method thereof. A film substrate of the packaging film is formed by blending 50-80 parts by weight of HDPE (High-Density Polyethylene) and 20-50 parts by weight of EVA (Ethylene-Vinyl Acetate Copolymer) while adding 5-12.5 parts by weight of diatomite and 0.75-1.25 parts by weight of quercetin. The preparation method comprises the steps: (1) uniformly mixing an HDPE master batch and an EVA master batch, and plasticating; (2) sprinkling diatomite on a roller-wrapped blending thin sheet, plasticating for 6-8 minutes, sprinkling quercetin, and plasticating for 6-8 minutes; (3) carrying out roller release, tiling on a flat plate in single layer, cooling, and then cutting; (4) carrying out hot pressing; (5) carrying out pressure forming, thereby obtaining the packaging film. The packaging film disclosed by the invention has sustained release antioxidant performance, so that the effective utilization ratio of an antioxidant can be increased obviously; meanwhile, the packaging film has good mechanical properties and dampness and oxygen barrier performance; the condition that the packaging film prepared by the method disclosed by the invention has a higher antioxidant retention ratio can be guaranteed.

Owner:JIANGNAN UNIV

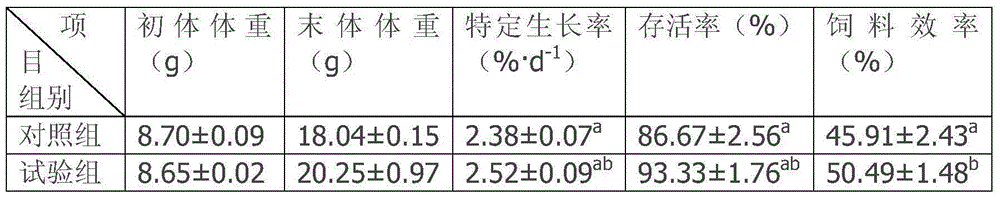

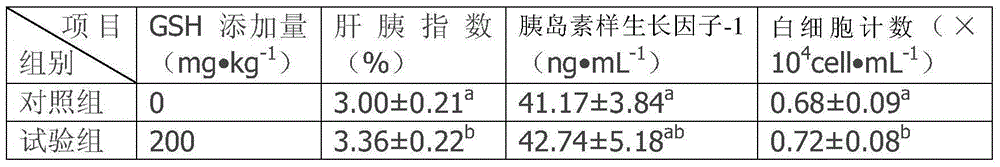

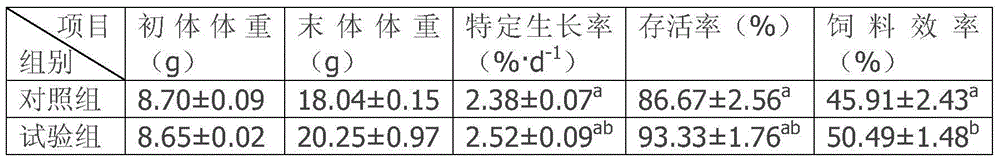

Preparation method for wet and soft feed capable of improving survival rate of ctenopharyngoden idella

InactiveCN104938776APromote growth and developmentImprove survival rateAnimal feeding stuffImproved survivalObserved Survival

The invention discloses a preparation method for a wet and soft feed capable of improving the survival rate of ctenopharyngoden idella. The wet and soft feed can promote the growth of ctenopharyngoden idella, increase the survival rate of ctenopharyngoden idella, reduce the death and elimination rate, improve the feed efficiency, reduce the input cost, and realize the high-yield and efficient culture of ctenopharyngoden idella accordingly; according to the preparation method, reasonable use of fish products and fish product leftovers can be realized, environmental pollution is reduced, the use of antibiotics in the feed is reduced, and the environment protection property and safety of fish products can be ensured.

Owner:武义明

Technical process of snow pear condensed juice

The invention relates to a technical process of snow pear condensed juice. The snow pear condensed juice is processed by the following six steps: deactivating an enzyme; juicing; coarsely filtering; carrying out ultrafiltration by a ceramic membrane; concentrating in vacuum; and carrying high-temperature instantaneous sterilization by taking snow pears as a raw material. The snow pear condensed juice obtained by the invention is clear and transparent in color, strong in fragrance and sweet and tasty in flavor, the original flavor and nutritional components of the snow pears are maintained, and no precipitates are separated out and the turbidity is not generated in the storage period.

Owner:GUANGXI UNIV

Clearing device for producing crystalline fructose with raw sugar as raw material

PendingCN105886671AGuarantee green safetyReduce resistanceFructose productionProduct optimizationCrystalline fructose

A clearing device for producing crystalline fructose with raw sugar as the raw material comprises a raw sugar dissolving box, an acid hydrolysis box, a first fructose corn syrup storage box, a ceramic film assembly, an activated carbon pre-decoloring box, a frame filter press, a first ion exchange resin tower and a second ion exchange resin tower. The clearing device solves the technical problems that when raw sugar serves as the raw material to produce crystalline fructose, a large amount of suspended solids, colloid, protein and non-sugar impurities in the raw sugar block or plug an activated carbon adsorption channel, accordingly activated carbon adsorption capacity is reduced, filter cloth of the frame filter press is blocked, filtering is difficult, and subsequent ion exchange resin is easy to pollute. The clearing device reduces cost of raw materials, improves production efficiency, and facilitates product optimization and upgrading and comprehensive utilization of raw sugar resources.

Owner:GUANGXI UNIV +1

Processing method of dark brown sugar

InactiveCN112779363ASolve the phenomenon of black slagFine grainSugar productsPurification by physical meansFood additiveSucrose

The invention provides a processing method of dark brown sugar, and the method comprises the following steps of: S1, peeling sugarcane, cutting sugarcane into sections, performing juicing, filtering juice, adding sucrase and maltase, adjusting conditions for enzymolysis, deactivating enzyme, and conducting filtering and concentrating to obtain concentrated sugarcane juice; S2, boiling the concentrated sugarcane juice at 150-190DEG C for 30-50min, adding brown granulated sugar, performing stirring and dissolving, conducting boiling at 190-220DEG C for 60-100min, adding stevioside, performing stirring and dissolving, and conducting boiling at 220-270DEG C for 30-60min; and S3, spreading the boiled liquid on a cold bed, neatly scribing the liquid by using a scribing tool, and packaging and selling the liquid after the liquid is completely cooled and formed. According to the method, industrial continuous production can be achieved, the problem that traditional dark brown sugar production is complex in manual operation is solved, no chemical reagent or food additive is added in the processing process, and the green safety of food is guaranteed.

Owner:湖南山界红糖有限公司

Feed for preventing and treating colibacillosis in broiler chicken

InactiveCN106666182AIncrease appetiteImprove gastrointestinal environmentFood processingAnimal feeding stuffAdditive ingredientPeanut meal

The invention discloses a feed for preventing and treating colibacillosis in broiler chicken. The feed is prepared from the following ingredients in parts by weight: rice bran, peanut meal, pig bone meal, wheat bran, corn flour, katsuragi powder, calcium hydrophosphate, camellia-seed oil, plant leavening, multi-vitamins, compound amino acid and table salt. According to the feed for preventing and treating colibacillosis in the broiler chicken, through mixed use of the ingredients, the taste and the flavor of the feed can be improved, the appetite of the chicken is promoted, meanwhile, the gastrointestinal environment of the chicken can be improved, the digestive absorption of the broiler chicken on nutrient elements in the feed is promoted, the fast fattening of the broiler chicken can be achieved, and the prevention and treatment effect on the colibacillosis in the broiler chicken is very good.

Owner:蚌埠市宗洼草鸡养殖农民专业合作社

Preparation method lactic acid bacteria fermented wet-soft feed for grass carp

InactiveCN105981995ALow costReduce consumptionFood processingClimate change adaptationLactobacillusCulling

The invention discloses a preparation method lactic acid bacteria fermented wet-soft feed for grass carp. The preparation method is simple and easy to perform and easy to popularize, requires low manpower and material sources, is low in energy consumption, uses a wide range of materials, is low in production investment and low in cost and is widely applicable, growth and development of grass carp can be promoted, survival rate of grass carp can be increased, death and culling rate can be decreased, feed efficiency is improved, input cost is reduced, high-yield and high-efficiency cultivation of grass crap can be achieved, fish products and their leftovers can be utilized reasonably, environmental pollution is reduced, the usage of antibiotics in the feed is reduced, and fish products are kept green and secure.

Owner:凤阳县兴科农业生态发展有限公司

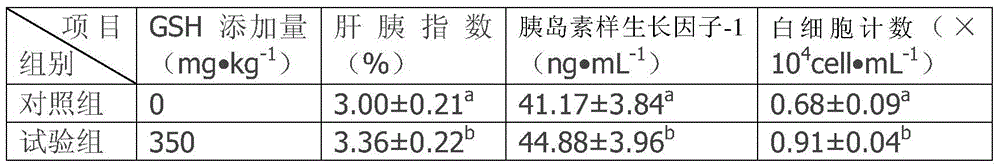

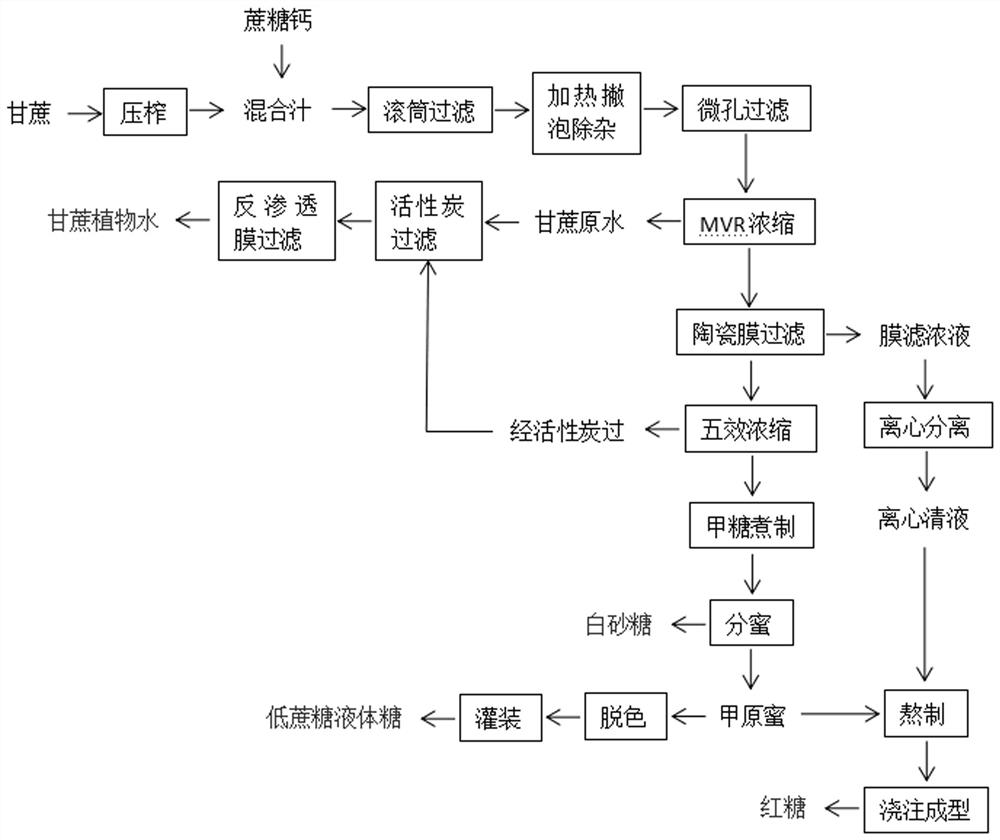

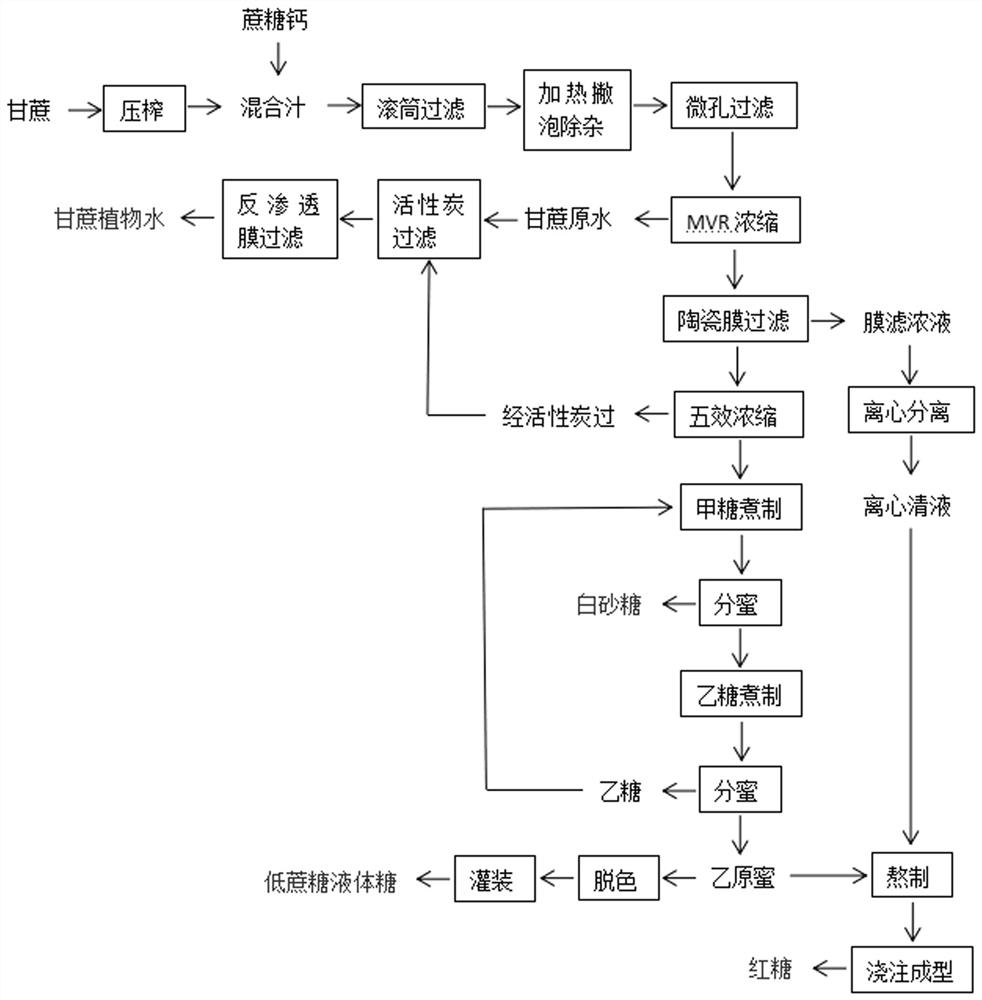

A sugar production process based on clarification of multiple co-production by membrane method

ActiveCN113462822BReduce processingLess investmentSugar productsSugar crystallisationActivated carbonSucrose

The invention discloses a sugar-making process based on membrane clarification and multiple co-production. After the mixed juice is physically removed, it is concentrated for the first time to 18-20 o Bx, the concentrated mixed juice is then physically clarified by a ceramic membrane, and the clear juice is concentrated for the second time to 55-65 o Syrup of Bx, white granulated sugar and low sucrose liquid sugar are produced according to the conventional white granulated sugar cooking process; sugarcane raw water obtained from the first and second concentration processes is filtered by activated carbon and reverse osmosis membrane to make sugarcane plant water; ceramic membrane filtration Finally, the concentrated liquid containing impurities is clarified by centrifugation and mixed with molasses to produce brown sugar. Based on the membrane clarification process without adding chemical additives, the high-value utilization of by-products can extend the product chain and increase economic benefits. The first concentration reduces the amount of mixed juice for subsequent membrane clarification, thereby reducing membrane clarification Investment in equipment reduces production costs and greatly improves the economic benefits of sugarcane sugar-making enterprises.

Owner:GUANGXI UNIV

A processing device for raw ecological brown sugar

ActiveCN104805224BTroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsAdditive ingredientUltrafiltration

An originally ecological black sugar processing device comprises a squeezing rough-filtration device, a heat exchanger, a multistage ceramic membrane ultrafiltration device, a falling-film type three-effect vacuum evaporation system, a water jet condenser, a jacketed iron pot and a graining drying forming device, which are sequentially connected, wherein a clarified sugarcane juice box is connected between the multistage ceramic membrane ultrafiltration device and the three-effect vacuum evaporation device; a syrup box is connected between the falling-film type three-effect vacuum evaporation system and the jacketed iron pot. The black sugar prepared through the device provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, sweet, delicious, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that black residues exist after the black sugar is dissolved is solved and the quality of the black sugar is improved.

Owner:广西百桂堂食品科技有限公司

A kind of processing method of sugarcane juice solid beverage

ActiveCN104824778BGuarantee green safetyExtended cleaning cycleFood scienceUltrafiltrationAdditive ingredient

A processing method of a sugarcane juice solid beverage comprises the following steps: filtering a sugarcane juice by allowing the sugarcane juice to sequentially go through a drum sieve and a curved sieve in order to obtain a coarse filtration sugarcane juice; heating the coarse filtration sugarcane juice to 90-100DEG C, maintaining the temperature for 1-2min, and rapidly cooling to obtain an enzyme killed sugarcane juice; carrying out ultrafiltration clarification on the enzyme killed sugarcane juice by adopting a multistage ceramic membrane ultrafiltration system with the membrane aperture of 0.02-0.10[mu]m; carrying out evaporative concentration on the clarified sugarcane juice to obtain a sugarcane juice concentrate; sending the sugarcane juice concentrate to a vacuum sugar boiling pan, and carrying out further evaporative concentration to obtain a massecuite; and stirring the massecuite until caster sugar appears, pouring the massecuite into a die, cooling to room temperature, cutting to form blocks, drying, and packaging to obtain a finished product. The sugarcane juice solid beverage prepared in the invention can be instantly drunk after dissolution in hot water, and the dissolved solid beverage has cleared and transparent color, rich fragrance and sweet and tasty taste, and well maintains the original nutritional components and flavor substances of sugarcane.

Owner:广西百桂堂食品科技有限公司

A kind of preparation method of eucommia seed oil microemulsion

ActiveCN108272661BGuarantee green safetyCosmetic preparationsToilet preparationsEmulsionActive agent

The invention discloses a preparation method of Eucommia ulmoides seed oil microemulsion. The Eucommia ulmoides seed oil microemulsion prepared by the method uses biosurfactant and eucommia ulmoides seed oil prepared by aqueous enzymatic method as main raw materials, and co-surfactant, emulsion , Water as auxiliary material, prepared by phase inversion emulsification method. The microemulsion prepared by the method not only solves the problem that the eucommia seed oil is not easy to store due to the high content of unsaturated fatty acids, but also reduces the application of chemical surfactants, and has green and safe characteristics. Simultaneously, the dried lyophilized powder of the eucommia seed oil microemulsion has stable properties, high encapsulation rate and wide application range.

Owner:JISHOU UNIVERSITY +1

A kind of production technology of polycrystalline rock sugar

The invention discloses a production process of poly-crystal rocky candy. The production process comprises the following six steps: by taking first-grade white sugar as a raw material, dissolving the sugar, micro-filtering and clarifying, desalting and decolorizing by using ion exchange resin, concentrating in vacuum, charging seeds for crystallization, drying and packaging to produce the poly-crystal rocky candy. The poly-crystal rocky candy produced by the method disclosed by the invention is sweet and delicious in taste and white and transparent in color and luster; no sodium hydrosulfite is added for color protection during the overall production, so the product is environmental friendly and safe; the crystallization rate of the rocky candy is above 95%; the problem of low crystallization rate during production of the poly-crystal rocky candy for a long time is solved.

Owner:GUANGXI UNIV

A method for parallel production of sugarcane concentrated juice and sugarcane drinking water by multi-stage membrane

ActiveCN104738755BGuarantee green safetyHigh permeation fluxFood scienceUltrafiltrationJuice clarification

A method for producing sugarcane concentrated juice and sugarcane drinking water in parallel with multi-stage membranes. The steps are as follows: sugarcane is blanched to kill enzymes, squeezed to extract juice, and coarsely filtered to obtain coarsely filtered sugarcane juice; the coarsely filtered sugarcane juice is passed through the first ceramic After membrane ultrafiltration clarification, sugarcane clarified juice is obtained; sugarcane clarified juice is concentrated by organic nanofiltration membrane to obtain nanofiltration clear liquid and nanofiltration concentrated liquid; nanofiltration concentrated liquid is sterilized by second ceramic membrane ultrafiltration and aseptic filling The concentrated sugarcane juice is obtained; the nanofiltration clear liquid is purified by an organic reverse osmosis membrane to obtain a reverse osmosis clear liquid; the reverse osmosis clear liquid is subjected to ultrafiltration and aseptic filling by a third ceramic membrane to obtain sugarcane drinking water. Based on the integration of membrane process separation, concentration and cold sterilization, the invention uses sugarcane as a raw material to produce high-quality sugarcane concentrated juice and sugarcane drinking water in parallel, which is beneficial to product optimization and upgrading and comprehensive utilization of sugarcane resources.

Owner:GUANGXI UNIV

Processing technology for spray evaporation type fruit and vegetable juice concentrate

A processing technology for spray evaporation type fruit and vegetable juice concentrate comprises the following steps: (1) enzyme deactivation; (2) juice squeezing; (3) rough filtration; (4) ultrafiltration through a ceramic membrane; (5) concentration: a spray dryer is used, fruit and vegetable clear juice is sprayed to vaporific fruit and vegetable liquid beads through a high-speed centrifugation mistorizer, meanwhile, hot air is introduced to a drying room to enable the vaporific fruit and vegetable liquid beads to be in contact with hot air and evaporated, vaporific fruit and vegetable liquid beads which are not completely evaporated collect together to become spray evaporation type fruit and vegetable juice concentrate to flow out from the bottom of the spray dryer, and waste gas is exhausted by a draught fan; (6) sterilization through a sterile filter membrane. The fruit and vegetable juice concentrate is clear and transparent in color and sweet and delicious in taste, maintains the original flavor and nutritional ingredients of fruits and vegetables better, and is free of precipitation and turbidity at the storage period.

Owner:GUANGXI UNIV

Process for processing ice-removed fruit and vegetable concentrated juice

InactiveCN105011272AGuarantee green safetyExtended cleaning cycleFood scienceAdditive ingredientTurbidity

The invention provides a process for processing ice-removed fruit and vegetable concentrated juice. The process sequentially comprises the following steps: (1) deactivating enzyme; (2) squeezing juice; (3) roughly filtering; (4) ultra-filtering with a ceramic membrane; (5) concentrating, namely pouring clear fruit and vegetable juice into a wide-necked flat-bottomed water tank of a freezing chamber, keeping the depth of the clear fruit and vegetable juice in the wide-necked flat-bottomed water tank being 4-6cm and the temperature in the freezing chamber being 20-30 DEG C below zero, standing to freeze the liquid surface of the clear fruit and vegetable juice in the wide-necked flat-bottomed water tank, breaking the ice layer when the thickness of the ice layer is 5mm, taking out the ice layer, and repeating the process of freezing and removing to obtain the fruit and vegetable concentrated juice; and (6) sterilizing with an aseptic filter membrane. The fruit and vegetable concentrated juice prepared by the process is clear and transparent and has sweet and delicious taste, the original flavor and nutrition of fruits and vegetables can be well maintained, and precipitate separation and turbidity generation are prevented in the storage period.

Owner:GUANGXI UNIV

A processing device for sugarcane juice solid beverage

ActiveCN104720071BGuarantee green safetyExtended cleaning cycleFood scienceAdditive ingredientSlurry

The invention discloses a processing device for a sugarcane juice solid drink. The processing device comprises sugarcane juice rough filtration equipment, a first heat exchanger, a second heat exchanger, multistage ceramic membrane ultrafiltration equipment, falling-film three-effect vacuum evaporation equipment, vacuum concentration equipment and drying-forming equipment, wherein the sugarcane juice rough filtration equipment comprises a drum sieve, a curved sieve and a roughly filtrated sugarcane juice storage box; a clarified sugarcane juice box is connected between the multistage ceramic membrane ultrafiltration equipment and the falling-film three-effect vacuum evaporation equipment; the falling-film three-effect vacuum evaporation equipment comprises a falling-film first-effect vacuum evaporation tank, a falling-film second-effect vacuum evaporation tank and a falling-film third-effect vacuum evaporation tank; a sugarcane slurry box is connected between the falling-film three-effect vacuum evaporation equipment and the vacuum concentration equipment; the vacuum concentration equipment comprises a sugarcane boiling tank and a water jet condenser. The sugarcane juice solid drink prepared by the processing device disclosed by the invention can be drunk after being dissolved with hot water, is clear and transparent in colour, strong in fragrance, and fresh, sweet and delicious in taste, as well as keeps the original nutritional ingredients and flavour substances of the sugarcane well.

Owner:广西百桂堂食品科技有限公司

Vegetable planting method for replacing chemical fertilizer and pesticide with straw compost leavening

InactiveCN112931074AComprehensive and balanced nutritionGuarantee green safetyPlant cultivationCultivating equipmentsHorticultureFertilizer

The invention discloses a vegetable planting method for replacing chemical fertilizer and pesticide with straw compost leavening, and belongs to the technical field of planting. The vegetable planting method comprises the following steps of (1) straw segmentizing treatment, (2) Chinese herbal medicine treatment, (3) mixed compost treatment, (4) field fertilization treatment, and (5) planting treatment. The vegetable planting method is simple in process, easy to popularize and apply and safe and environment-friendly to the environment, and planted vegetables are environmentally friendly and healthy and have great market competitiveness.

Owner:张量

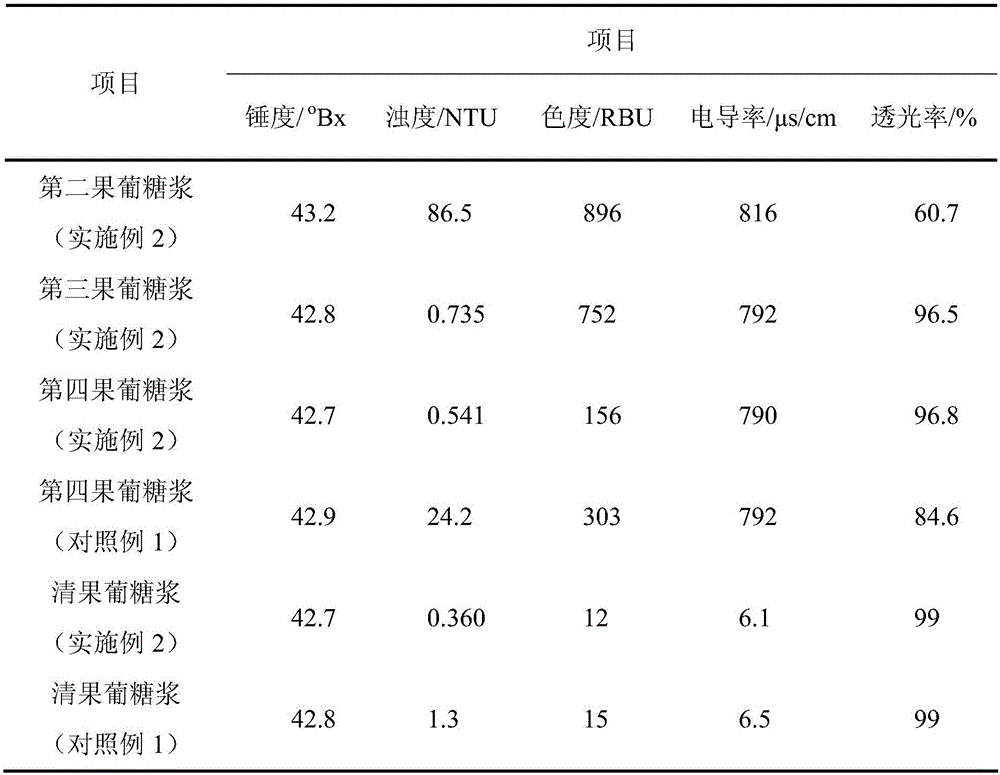

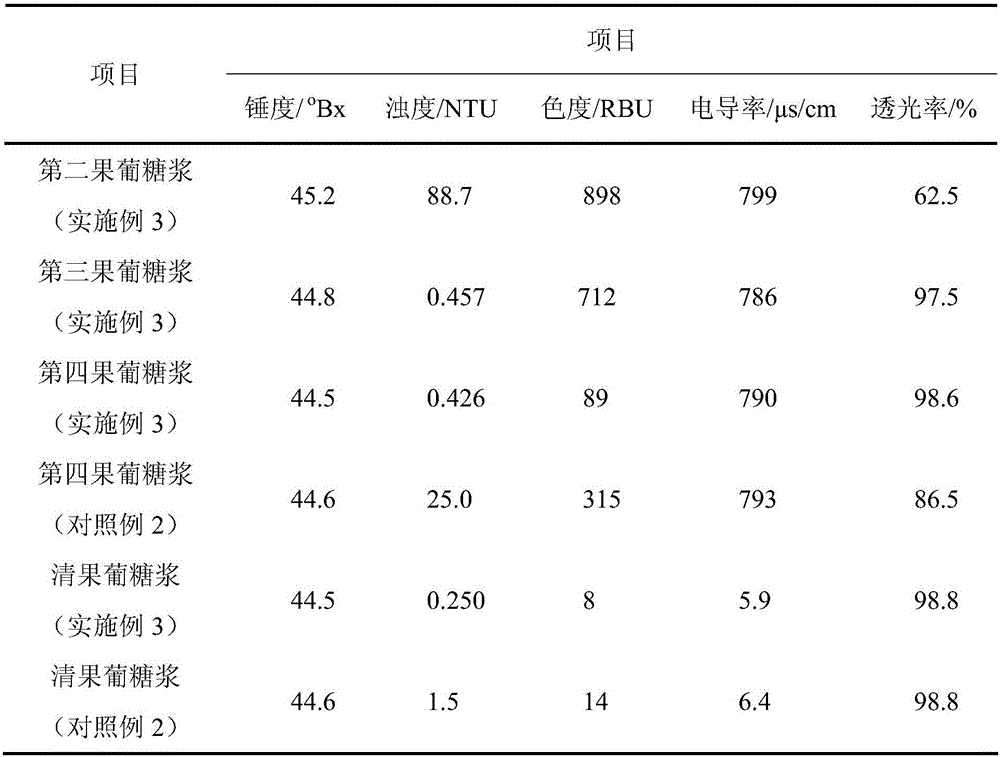

A kind of preparation method of concentrated grape juice

ActiveCN105685706BGuarantee green safetyRetain nutritionFood scienceFood additiveEnzymatic hydrolysis

The invention discloses a preparation method of concentrated grape juice. The method comprises the steps of preparing grape primary pulp, performing primary filtering and primary sterilization, cooling for reducing the temperature, carrying out enzymatic hydrolysis and clarification, and performing secondary filtering, vacuum concentration, secondary sterilization and filling. The preparation process is simple, and no any chemical reagent and food additive are added in a preparation process, so that the nutrition and flavor of grapes are kept to the maximum extent, and the green and safe properties of the food are effectively ensured; and besides, the clear grape juice after enzymatic hydrolysis, clarification and filtering has a color value of more than 90%, a turbidity of less than 2NTU, a light transmittance of more than 96%, a sugar content of 3.5-4% and an acidity degree of 35-45%; the solid content of the concentrated grape juice after vacuum concentration is 40-60%; and the concentrated grape juice has fragrance and taste of grapes, has no peculiar smell, is clear and transparent, can be stored for a long time, has no sediments and suspended solids during storage, has strong product stability and can completely meet the taste requirement of mass consumers.

Owner:曲靖市麒麟区禽蛋副食品有限公司

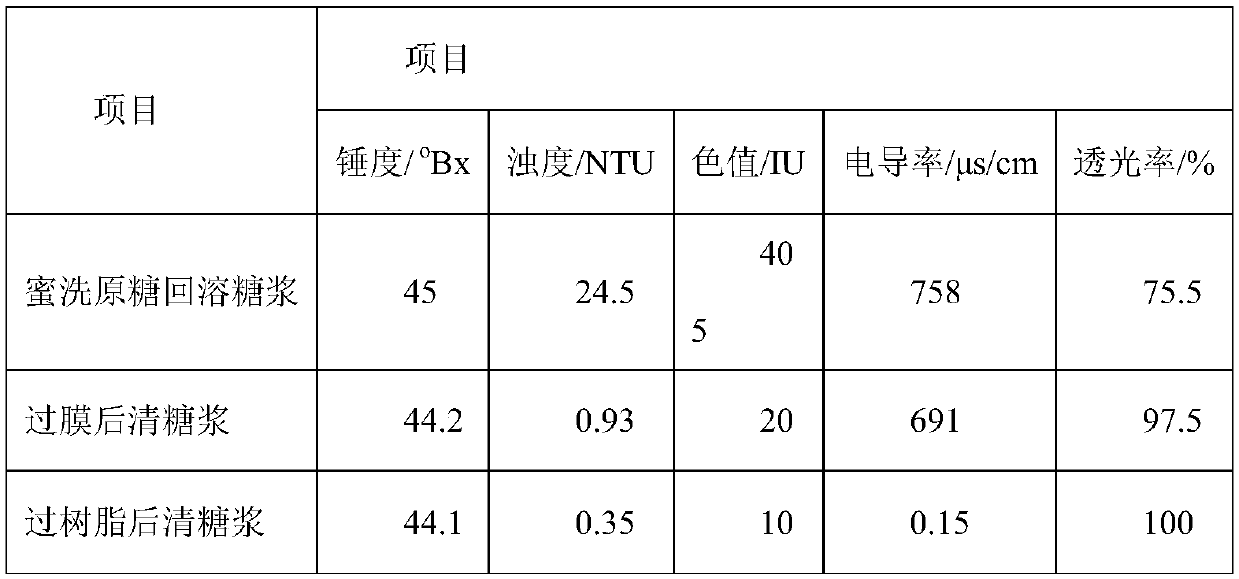

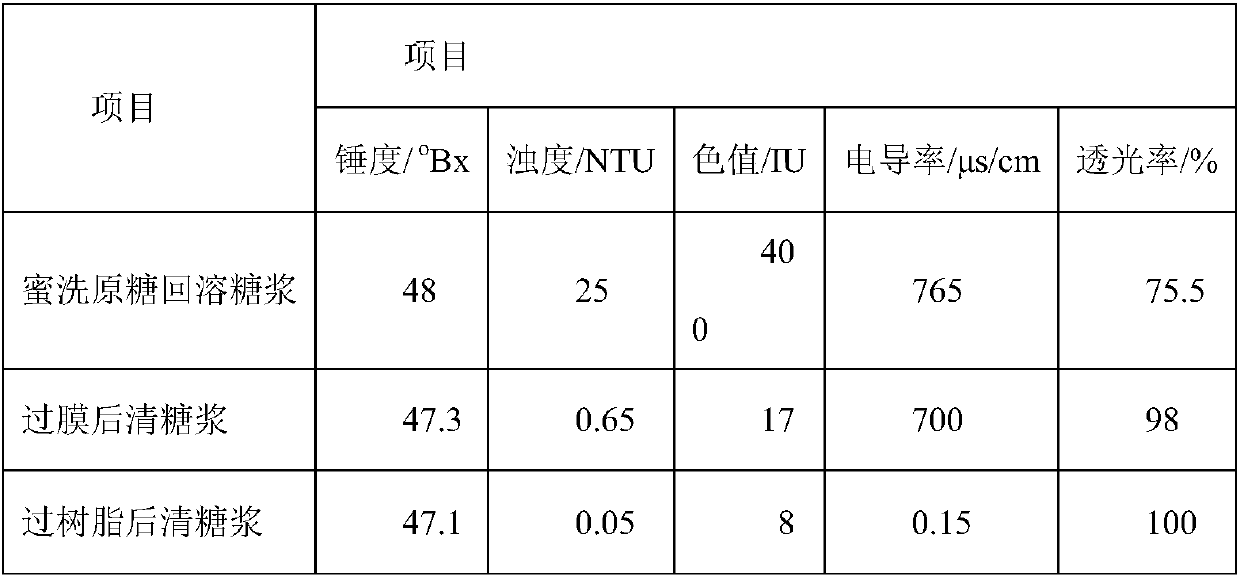

Method for clarification and decoloration of raw sugar remolten syrup

InactiveCN107937627AGuarantee green safetyImprove throughputPurification using adsorption agentsPurification using ion-exchange materialsIon-exchange resinImpurity

The invention discloses a method for clarification and decoloration of raw sugar remolten syrup. The method comprises the following steps: spraying raw sugar through a honey extractor and molasses, soas to remove large-particle impurities and part of pigment on the surface of the raw sugar; dissolving the raw sugar or the raw sugar washed by the molasses with hot water; adding activated carbon with the content being 0.1 to 2 percent relative to dry solid substance, so as to obtain remolten syrup; filtering the remolten syrup with a ceramic membrane component with the average membrane pore size being 0.005 to 0.5 micrometers, so as to obtain clear syrup; feeding the clear syrup obtained from a juice outlet of the ceramic membrane component into a first ion exchange resin tower to perform decoloration, so as to obtain first penetrating fluid; feeding the first penetrating fluid into a second ion exchange resin tower to perform desalination, so as to obtain penetrating fluid namely discolored refined syrup. The technology has the advantages that an activated carbon coupled film separation process separation is used to replace carbon dioxide carbonation and a plate and frame filteringsystem, the product quality is improved, the cost is reduced, the equipment consumption and floor space are reduced, and the load of the ion exchange resin towers is greatly reduced.

Owner:GUANGXI UNIV

Process for producing shellfish premix feed

InactiveCN102018140BReduce lossesProne to explosionFood processingClimate change adaptationFish oilMixed materials

The invention discloses a process for producing a shellfish premix feed, which is characterized in that the shellfish premix feed is prepared by using attapulgite, flours, corn husks and the like as carrier raw materials through the steps of adding bioactive peptides into the carrier raw materials by a liquid adding device through using a high-pressure atomized spraying method; drying the obtained evenly-mixed materials by air flows, then carrying out ultra-micro pulverization on the materials, and adding fish oil into the materials in the process of pulverization; then adding feed decavitamin and composite trace elements into the materials, after evenly mixing the materials, adding bioactive peptides and immune polysaccharides into the mixed materials; drying the mixed materials by air flows until the moisture content of the mixed materials is 10 to 15 percent, sieving the obtained materials so as to ensure the materials can completely pass through a 90-mesh sieve to obtain the finished product of the premix feed. The process for producing the shellfish premix feed has the advantages that the process is more reasonable, and the premix feed is ensured to be environmental friendly and safe; the losses of vitamins, microelements and other active materials can be reduced; and oil-phase, solid-phase and aqueous-phase materials in the product are added simultaneously, after the materials are mixed and dried, an envelope can be formed on the surface of the product, thereby improving the product stability.

Owner:JIANGSU TIANFULAI GROUP

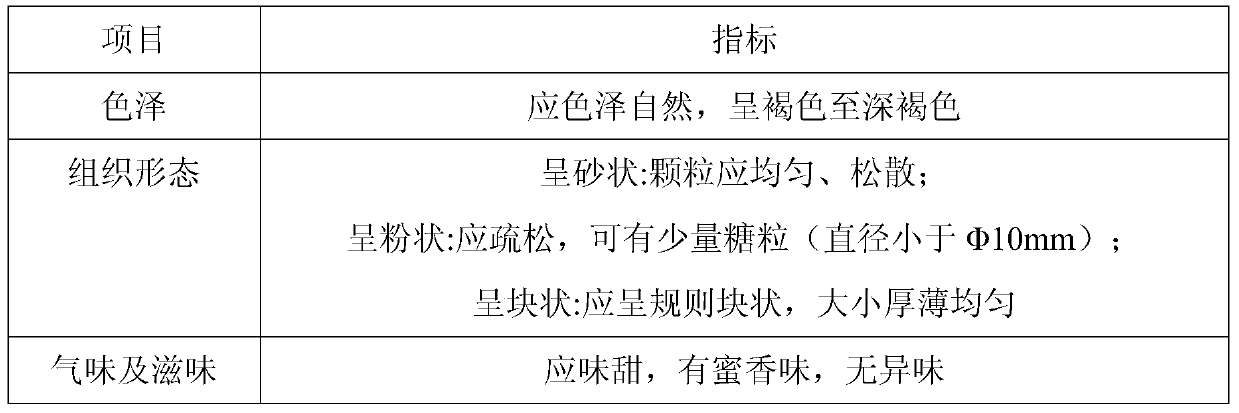

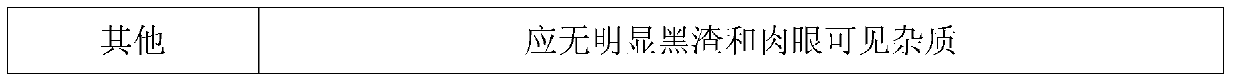

A kind of processing method of original ecological brown sugar

ActiveCN104805225BTroubleshoot filter clarification issuesEfficient removalSugar dryingSugar productsUltrafiltrationAdditive ingredient

An originally ecological black sugar processing method comprises the following steps: after sugarcane is squeezed for extracting juice, carrying out rough filtration so as to obtain sugarcane juice; heating the sugarcane juice to 90-100 DEG C and keeping heat for 1-3 min so as to obtain heated sugarcane juice; conveying the heated sugarcane juice to a multistage ceramic membrane ultrafiltration device for ultrafiltration clarification so as to obtain clarified sugarcane juice; concentrating the clarified sugarcane juice into syrup; concentrating the syrup through a jacketed iron pot so as to obtain decocted massecuite; graining, cooling and forming so as to obtain originally ecological black sugar. The originally ecological black sugar prepared through the method provided by the invention is small in grain, brown-dark brown and natural in color, contains fewer impurities, has a natural caramel charcoal burning fragrance, is rich in flavor, and fine and smooth in mouthfeel, retains the nutritional ingredients of sugarcane to the greatest extent, and has a high nutritional value; the turbidity is less than 0.5 NTU after the black sugar is dissolved to 11.5 degrees Bx, so that the problem that precipitates occur after the black sugar is dissolved for a long time is solved.

Owner:广西百桂堂食品科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com