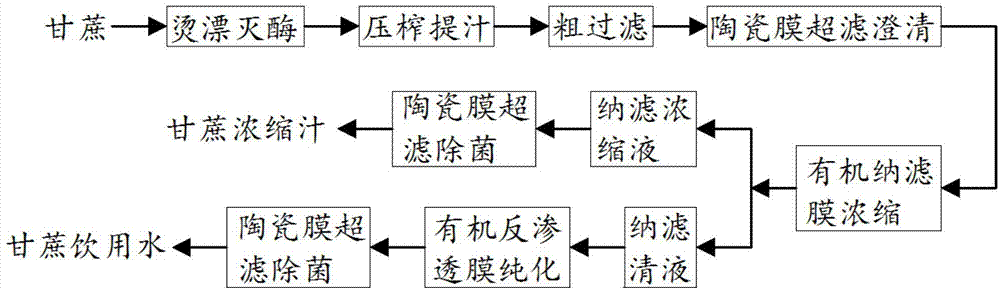

Method for parallel production of sugarcane concentrated juice and sugarcane drinking water by multi-stage films

A technology for drinking water and concentrated juice, which is applied in the field of parallel production of sugarcane juice concentrate and sugarcane drinking water with multi-stage membranes, and can solve the problems of the destruction of sugarcane juice flavor substances and nutrients, the loss of sugarcane juice nutrients and flavor substances, and the sugarcane juice aromatic substances. The problem of large loss is to avoid the decomposition of heat-sensitive substances and the loss of flavor substances and nutrients, avoid the loss of nutrients and flavor substances, and reduce the frequency of film cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

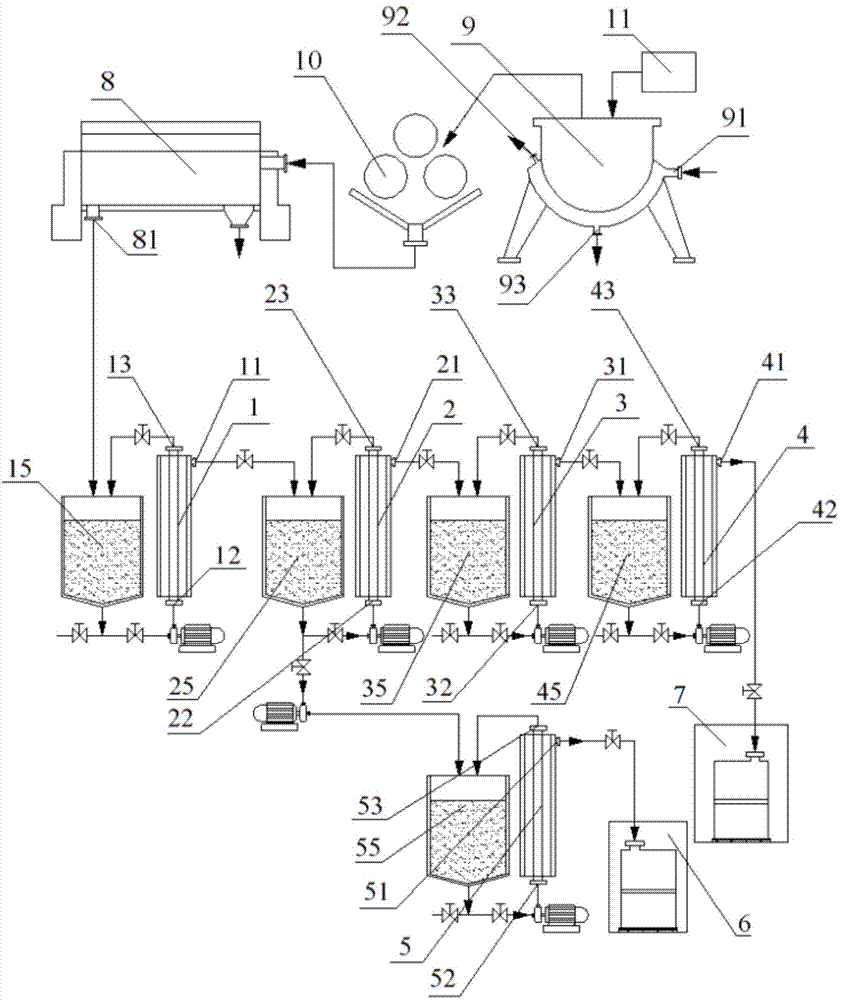

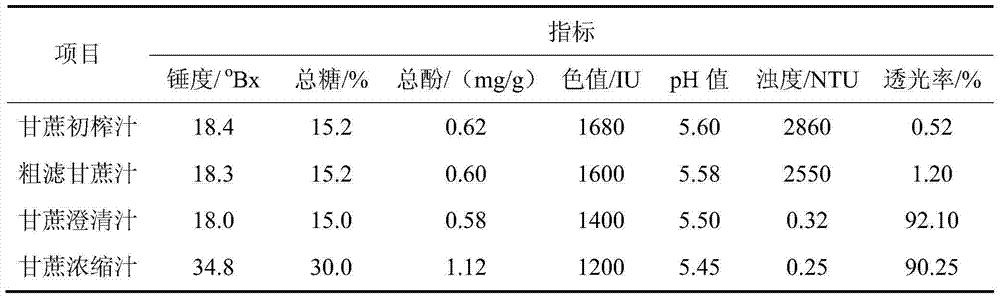

[0044] A method for producing sugarcane concentrated juice and sugarcane drinking water in parallel with multi-stage membranes, the operation steps are:

[0045] (1) Blanch and eliminate enzymes: select fresh and mature sugarcane, remove the raw materials of rotten pests, cut the sugarcane into sections, each section is 20-40cm long, and clean the sugarcane skin; then put the sugarcane into the sandwich pot adding water and boiling for 4 minutes to inactivate the oxidase in the sugarcane, prevent enzymatic browning in the processing process, and obtain the enzyme-inactivated sugarcane;

[0046] (2) Squeeze and extract juice: send the enzyme-inactivated sugarcane into a three-roller sugarcane press to squeeze out the juice to obtain virgin sugarcane juice;

[0047] (3) Coarse filtration: filtering virgin sugarcane juice through a decanter centrifuge with a pore size of 100.0 μm to obtain coarsely filtered sugarcane juice;

[0048] (4) The first ceramic membrane ultrafiltration...

Embodiment 2

[0064] A method for producing sugarcane concentrated juice and sugarcane drinking water in parallel with multi-stage membranes, the operation steps are:

[0065] (1) Blanch and eliminate enzymes: select fresh and mature sugarcane, remove the raw materials of rotten pests, cut the sugarcane into sections, each section is 20-40cm long, and clean the sugarcane skin; then put the sugarcane into the sandwich pot adding water and boiling for 5 minutes to inactivate the oxidase in the sugarcane, prevent enzymatic browning in the processing process, and obtain the enzyme-inactivated sugarcane;

[0066] (2) Squeeze and extract juice: send the enzyme-inactivated sugarcane into a three-roller sugarcane press to squeeze out the juice to obtain virgin sugarcane juice;

[0067] (3) Coarse filtration: the virgin sugarcane juice is filtered through a decanter centrifuge with a pore size of 150.0 μm to obtain coarsely filtered sugarcane juice;

[0068] (4) The first ceramic membrane ultrafilt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com