Method for clarification and decoloration of raw sugar remolten syrup

A technology for syrup and raw sugar, applied in the production of sugar, purification of sugar juice, purification by physical methods, etc., can solve the problem of high cost of activated carbon, achieve high production efficiency, reduce pollution, and reduce main costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

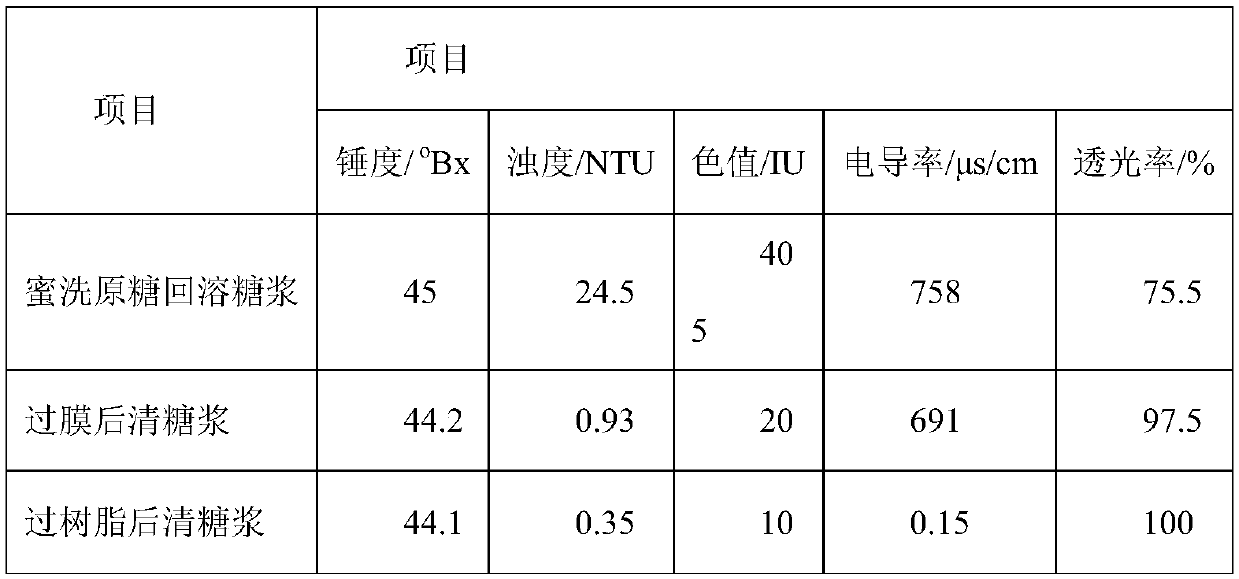

Embodiment 1

[0024] A method for clarification and decolorization of raw sugar redissolving syrup, comprising the following steps:

[0025] (1) Honey washing: use honey separator and molasses to spray and wash raw sugar to remove large particles of impurities and some pigments on the surface of raw sugar;

[0026] (2) Dissolving: dissolving raw sugar or raw sugar washed with honey to 55°Bx in hot water, heating to 70°C, and keeping warm;

[0027] (3) Activated carbon adsorption: add activated carbon with a dry solid content of 1%, and react at 60°C for 30 minutes to obtain a resolvable syrup;

[0028] (4) Ceramic membrane filtration: use a ceramic membrane module with an average membrane pore size of 0.02 μm to filter the remelted syrup to obtain clear syrup. The operating parameters of the ceramic membrane are: the transmembrane pressure difference is 0.25MPa, and the membrane surface flow rate is 3.5m / s , the operating temperature is 50°C;

[0029] (5) Decolorization and desalination o...

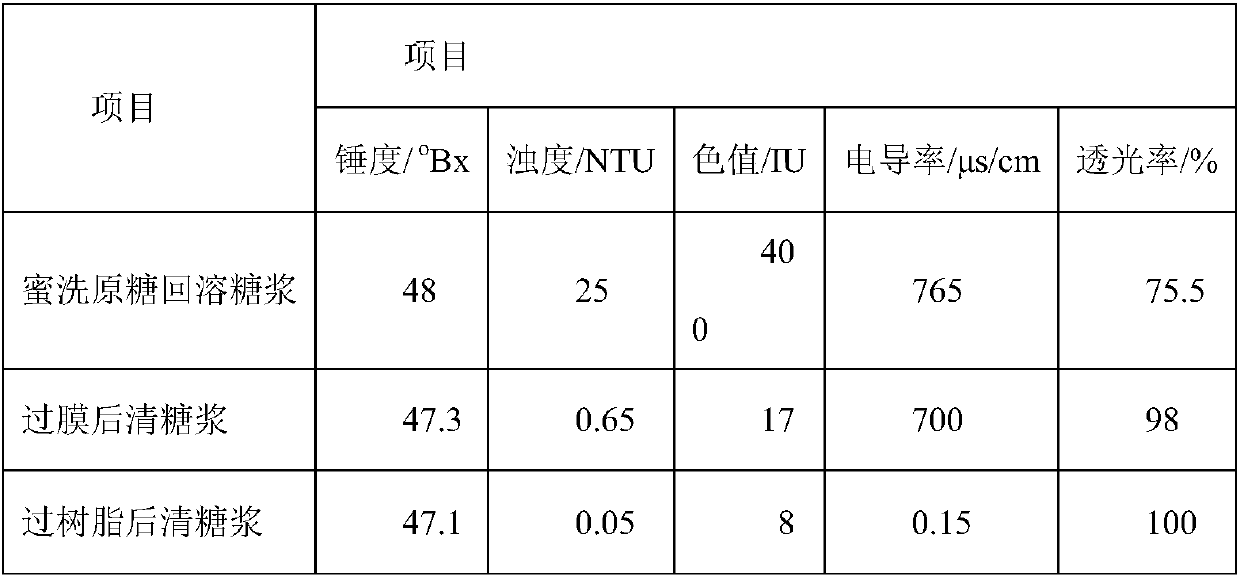

Embodiment 2

[0036] A method for clarification and decolorization of raw sugar redissolving syrup, comprising the following steps:

[0037] (1) Honey washing: use honey separator and molasses to spray and wash raw sugar to remove large particles of impurities and some pigments on the surface of raw sugar;

[0038] (2) Dissolving: dissolving raw sugar or raw sugar washed with honey to 65°Bx in hot water, heating to 80°C, and keeping warm;

[0039] (3) Activated carbon adsorption: add activated carbon with a dry solid content of 2%, and react at 80°C for 40 minutes to obtain a resolvable syrup;

[0040] (4) Ceramic membrane filtration: use a ceramic membrane module with an average membrane pore size of 0.5 μm to filter the remelted syrup to obtain clear syrup. The operating parameters of the ceramic membrane are: the transmembrane pressure difference is 0.50 MPa, and the membrane surface flow rate is 5.0m / s , the operating temperature is 80°C;

[0041] (5) Decolorization and desalination o...

Embodiment 3

[0048] A method for clarification and decolorization of raw sugar redissolving syrup, comprising the following steps:

[0049] (1) Honey washing: use honey separator and molasses to spray and wash raw sugar to remove large particles of impurities and some pigments on the surface of raw sugar;

[0050] (2) Dissolving: dissolve the raw sugar or the raw sugar washed with honey to 45°Bx in hot water, heat to 60°C, and keep warm;

[0051] (3) Activated carbon adsorption: add activated carbon with a dry solid content of 0.1%, and react at 40-80°C for 20-40 minutes to obtain a resolvable syrup;

[0052](4) Ceramic membrane filtration: use a ceramic membrane module with an average membrane pore size of 0.005 μm to filter the re-dissolved syrup to obtain clear syrup. The operating parameters of the ceramic membrane are: the transmembrane pressure difference is 0.10MPa, and the membrane surface flow rate is 2.0m / s , the operating temperature is 20°C;

[0053] (5) Decolorization and de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com