A processing device for sugarcane juice solid beverage

A solid beverage and processing device technology, which is applied in the field of food processing, can solve the problems of unfavorable storage and transportation due to excessive water content, and achieve the effects of ensuring green safety, short production process, and reducing the frequency of membrane cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

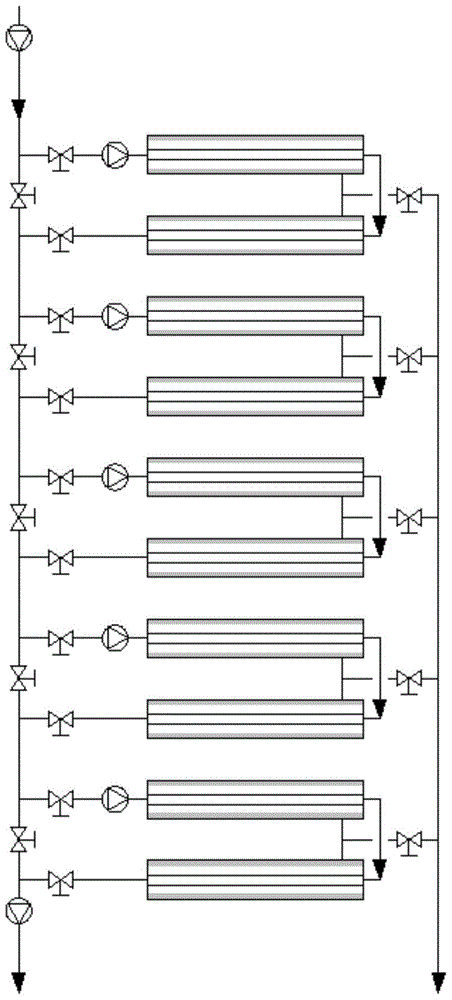

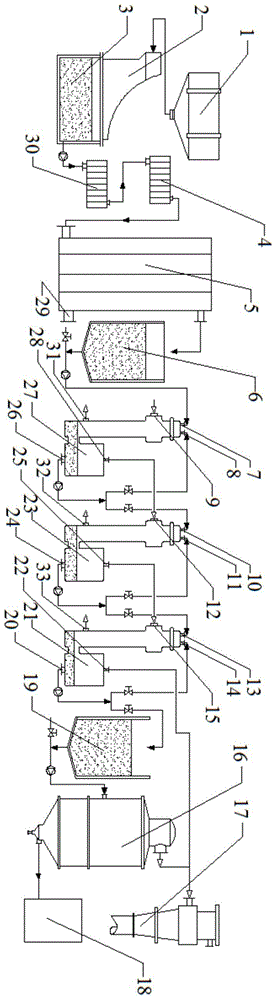

[0034] A processing device for sugarcane juice solid beverages, comprising sequentially connected coarse filtration equipment, a first heat exchanger, a second heat exchanger, multi-stage ceramic membrane ultrafiltration equipment 5, falling film type three-effect vacuum evaporation equipment, vacuum Concentrating equipment, drying forming equipment 18 and water jet condenser 17.

[0035] In the above-mentioned processing device for sugarcane juice solid beverage, the coarse filtration equipment includes a drum sieve 1, a curved sieve 2 with a screen mesh of 80 to 100 meshes, and a coarse filtration cane juice storage box 3; multi-stage ceramic membrane ultrafiltration equipment 5 and three The clarification cane juice box 6 is connected between the effect vacuum evaporation equipment; the three-effect evaporation equipment comprises a falling film type one-effect vacuum evaporation tank 27, a falling film type two-effect vacuum evaporation tank 23 and a falling film type three...

Embodiment 2

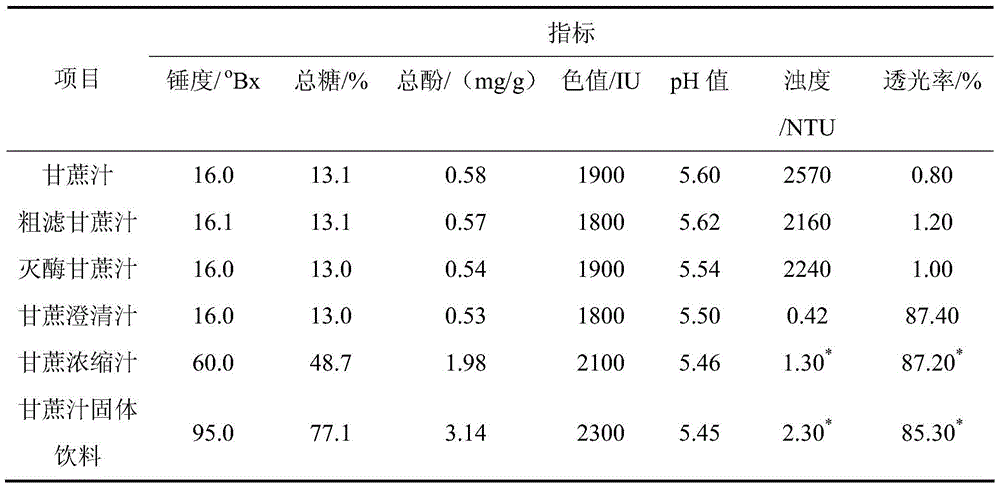

[0043] This embodiment is a specific example of utilizing the processing device of the sugarcane juice solid beverage of the present invention to produce, and the specific operation steps are:

[0044] (1) Coarse filtration: the sugarcane juice is successively filtered through a drum sieve and a sieve with a screen mesh of 80 meshes to remove large particles of impurities such as sugarcane bran and sugarcane debris in the sugarcane juice, and obtain coarsely filtered sugarcane juice;

[0045] (2) Enzyme inactivation: use the first tubular heat exchanger to heat the coarsely filtered sugarcane juice to 90°C, keep it for 5s, then cool it to 72°C with the second tubular heat exchanger to prevent the sugarcane juice from being too high. The loss of juice flavor substances and nutritional components is obtained to obtain enzyme-inactivated sugarcane juice;

[0046] (3) Ceramic membrane ultrafiltration: send the enzyme-inactivated sugarcane juice to the ceramic membrane ultrafiltrat...

Embodiment 3

[0060] This embodiment is another specific example of using the processing device of the sugarcane juice solid beverage of the present invention to produce, and the specific operation steps are:

[0061] (1) Coarse filtration: the sugarcane juice is successively filtered through a drum sieve and a sieve with a screen mesh of 100 meshes to remove large particles of impurities such as sugarcane bran and sugarcane debris in the sugarcane juice, and obtain coarsely filtered sugarcane juice;

[0062] (2) Enzyme elimination: use the first plate heat exchanger to heat the coarsely filtered sugarcane juice to 100°C, keep it for 5s, and then use the second plate heat exchanger to quickly cool it to 70°C to prevent the sugarcane juice flavor from being too high And the loss of nutritional labeling, obtain the sugarcane juice of inactivating enzyme;

[0063] (3) Ceramic membrane ultrafiltration: send the enzyme-inactivated sugarcane juice to the ceramic membrane ultrafiltration working t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com