A kind of production technology of polycrystalline rock sugar

A technology of polycrystalline rock sugar and production process, applied in sugar production, sucrose production, sugar products, etc., can solve the problems of poor product quality, low crystallization rate, etc., and achieve the goal of reducing color value, reducing pigment formation, and reducing temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

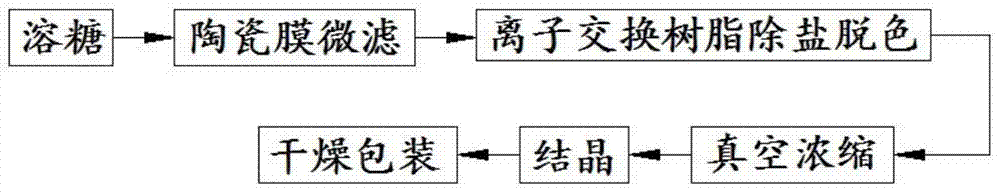

Method used

Image

Examples

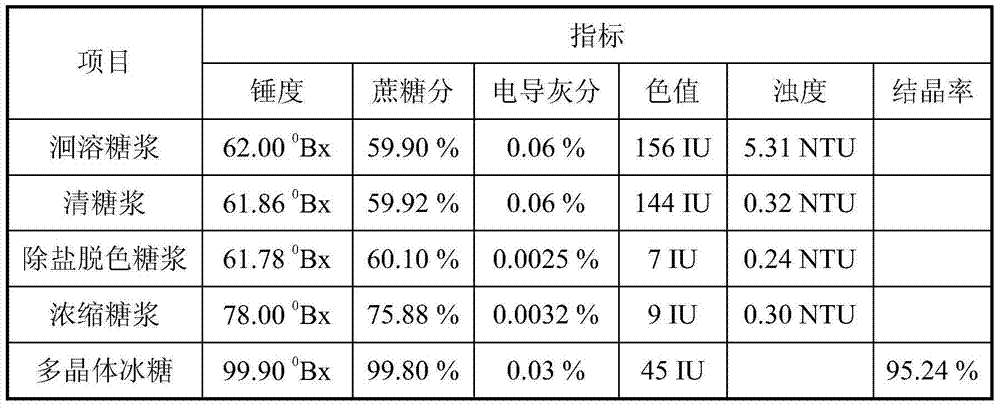

Embodiment 1

[0028] A production process of polycrystalline rock sugar, the operation steps are:

[0029] (1) Dissolving sugar: dissolve white granulated sugar in water at 85°C, stir until the white granulated sugar is completely dissolved, and obtain 62°Bx soluble syrup;

[0030] (2) Ceramic membrane microfiltration: Send the soluble syrup to the ceramic membrane microfiltration working tank, and use a ceramic membrane with a pore size of 200nm for microfiltration clarification, where the transmembrane pressure difference is 0.15MPa, and the filtration temperature is 75°C. Flow velocity is 5m / s, obtains clear syrup standby;

[0031] (3) Ion exchange resin desalination and decolorization: the clear syrup is cooled to 40°C through a plate heat exchanger, and then sent to the first ion exchange resin tower to obtain the first permeate. The flow rate in the resin is 2.0BV / h, and the diameter-to-height ratio is 1 / 3, and then the first permeate is sent to the second ion exchange resin tower to...

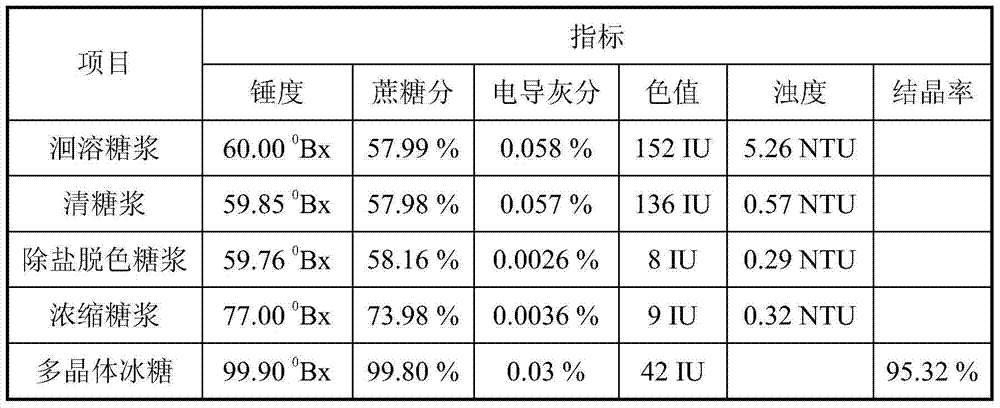

Embodiment 2

[0038] A production process of polycrystalline rock sugar, the operation steps are:

[0039] (1) Dissolving sugar: dissolving the white granulated sugar in water at 80°C, stirring until the white granulated sugar is completely dissolved, to obtain a 60°Bx soluble syrup;

[0040] (2) Ceramic membrane microfiltration: send the slurred syrup to the ceramic membrane microfiltration work tank, and use a ceramic membrane with a pore size of 500nm for microfiltration clarification, where the transmembrane pressure difference is 0.25MPa, the filtration temperature is 80°C, Flow velocity is 6m / s, obtain clear syrup for subsequent use;

[0041] (3) Ion exchange resin desalination and decolorization: the clear syrup is cooled to 43°C through a plate heat exchanger, and then sent to the first ion exchange resin tower to obtain the first permeate. The flow rate in the resin is 2.5BV / h, and the diameter-to-height ratio is 1 / 4, and then the first permeate is sent to the second ion exchange re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com