Nano-modified two-component solventless flexible packaging adhesive and preparation method thereof

A nano-modified, solvent-free technology, used in non-polymer adhesive additives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as inability to use, and reduce volatile and free substances , excellent viscosity, the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

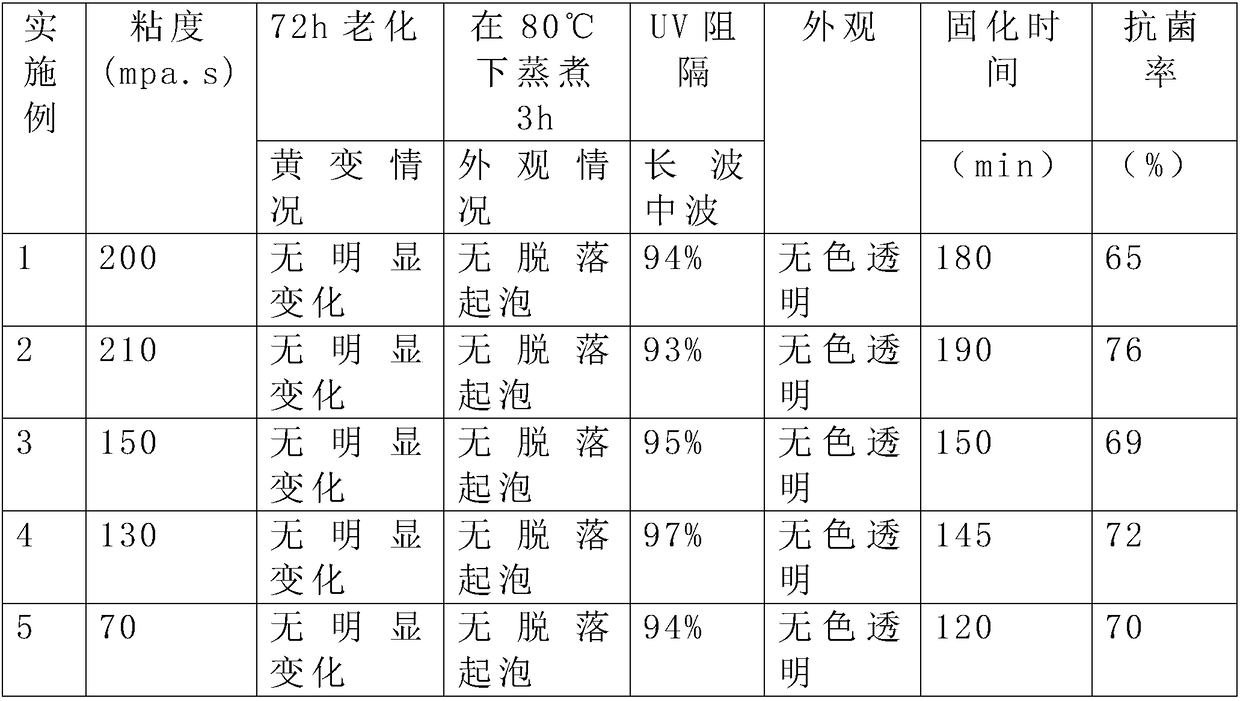

Examples

Embodiment 1

[0026] Material preparation of component A: 50 parts of castor oil, 20 parts of hexanediol, 25 parts of polyether polyol, 3 parts of additives, and 2 parts of nano-modified materials. Check the airtightness of the reactor, replace it with nitrogen to dry and remove water, and control the temperature to 10°C. Put the materials of component A into castor oil (45 parts), hexanediol, and polyether polyol in sequence, and heat and stir for 30 minutes. Graphene oxide pretreated nano-titanium dioxide (rutile type) and 5 parts of castor oil, additives, gas-phase white carbon black are dispersed at low temperature (5°C) at high speed, and the speed is 3000RPM. , keep stirring at high speed. Stir at a low speed, lower the temperature, and discharge to prepare the component A material.

[0027] Preparation of component B: 40 parts of MDI, 5 parts of TPU, 10 parts of polypropylene glycol (molecular weight 400), 30 parts of polyether polyol (molecular weight 2000-2500), 15 parts of ligni...

Embodiment 2

[0029] Material preparation of component A: 50 parts of castor oil, 20 parts of hexanediol, 25 parts of polyether polyol, 3 parts of additives, and 2 parts of nano-modified materials. Check the airtightness of the reactor, replace it with nitrogen to dry and remove water, and control the temperature to 10°C. Put the materials of component A into castor oil (45 parts), hexanediol, and polyether polyol in sequence, and heat and stir for 30 minutes. Knead and disperse nano-titanium dioxide (rutile type) pretreated by graphene oxide and high molecular weight amorphous saturated polyester resin 1:1, then add gas-phase white carbon black and knead together for 30 minutes, put it into the reactor for stirring and raise the temperature to 90°C. Keep stirring at high speed. Stir at a low speed, lower the temperature, and discharge to prepare the component A material.

[0030] Preparation of component B: 40 parts of MDI, 5 parts of TPU, 10 parts of polypropylene glycol (molecular weig...

Embodiment 3

[0032] Material preparation of component A: 50 parts of castor oil, 20 parts of hexanediol, 25 parts of polyether polyol, 3 parts of additives, and 2 parts of nano-modified materials. Check the airtightness of the reactor, replace it with nitrogen to dry and remove water, and control the temperature to 10°C. Put the materials of component A into castor oil (45 parts), hexanediol, and polyether polyol in sequence, and heat and stir for 30 minutes. Knead and disperse nano-titanium dioxide (rutile type) pretreated by graphene oxide and high molecular weight amorphous saturated polyester resin 1:1, then add gas-phase white carbon black and knead together for 30 minutes, put it into the reactor for stirring and raise the temperature to 90°C. Keep stirring at high speed. Stir at a low speed, lower the temperature, and discharge to prepare the component A material.

[0033] Preparation of component B: 40 parts of MDI, 5 parts of TPU, 10 parts of polypropylene glycol (molecular weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com