Clearing device for producing crystalline fructose with raw sugar as raw material

A technology for crystallizing fructose and clarifying device, applied in the production of sugar, sugar production, fructose production and other directions, can solve the problems of clogging activated carbon adsorption channel, clogging of filter cloth of plate and frame filter press, easy pollution of ion exchange resin, etc. The effect of reducing usage, reducing load, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

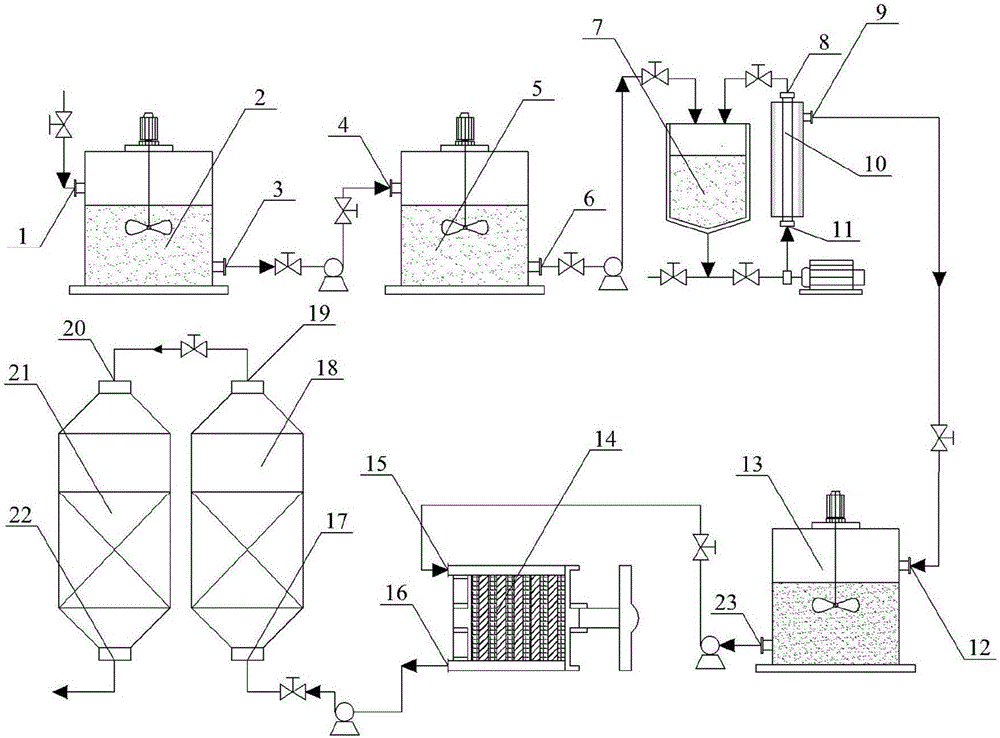

[0035] A clarification device for producing crystallized fructose from raw sugar, comprising a raw sugar dissolution tank 2, an acid hydrolysis tank 5, a first fructose syrup storage tank 7, a ceramic membrane module 10, an activated carbon pre-decolorization tank 13, a plate Frame filter press 14 , first ion exchange resin tower 18 and second ion exchange resin tower 21 .

[0036] The specific connection relationship is as follows:

[0037] The juice outlet 3 of the raw sugar dissolving box is connected to the juice inlet 4 of the acidolysis box, and the juice outlet 6 of the acidolysis box is connected to the first fructose syrup storage tank 7;

[0038] The juice inlet 11 of the ceramic membrane module is connected to the first fructose syrup storage tank 7, the retentate outlet 8 of the ceramic membrane module is connected back to the first fructose syrup storage tank 7, and the juice outlet 9 of the ceramic membrane module is connected to the activated carbon pre-decolori...

Embodiment 2

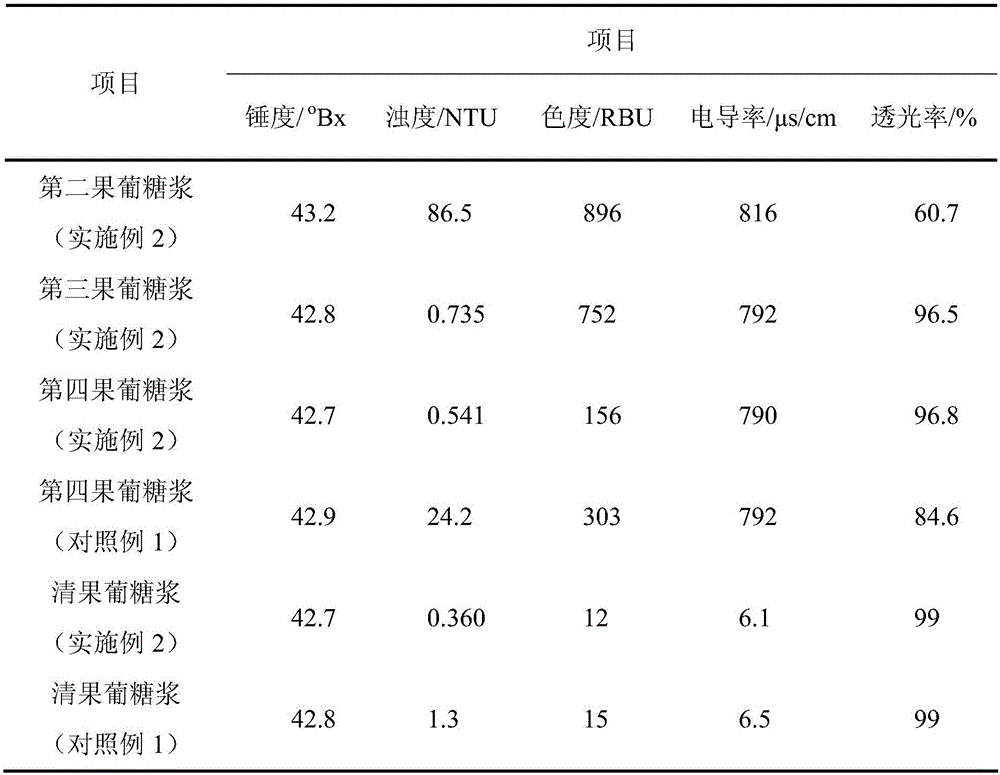

[0044] A method for producing crystallized fructose with raw sugar as raw material, the operation steps are:

[0045] (1) dissolving: the raw sugar is dissolved to 60°Bx with water to obtain the raw sugar back-dissolving syrup;

[0046] (2) Acid hydrolysis: adjust the pH of the raw sugar back-dissolving syrup to 1.0 with hydrochloric acid for acid hydrolysis to obtain the first fructose syrup;

[0047] (3) pH adjustment: adjust the pH of the first fructose syrup to 5.0 with NaOH solution to obtain the second fructose syrup;

[0048] (4) Ceramic membrane filtration: filter the second fructose syrup by using ceramic membrane components to obtain the third fructose syrup;

[0049] (5) Activated carbon pre-decolorization: add activated carbon to the third fructose syrup, filter after fully absorbing, and the filtrate is the fourth fructose syrup;

[0050] (6) Ion exchange resin decolorization and desalination:

[0051] Using the first ion exchange resin to decolorize the fourth...

Embodiment 3

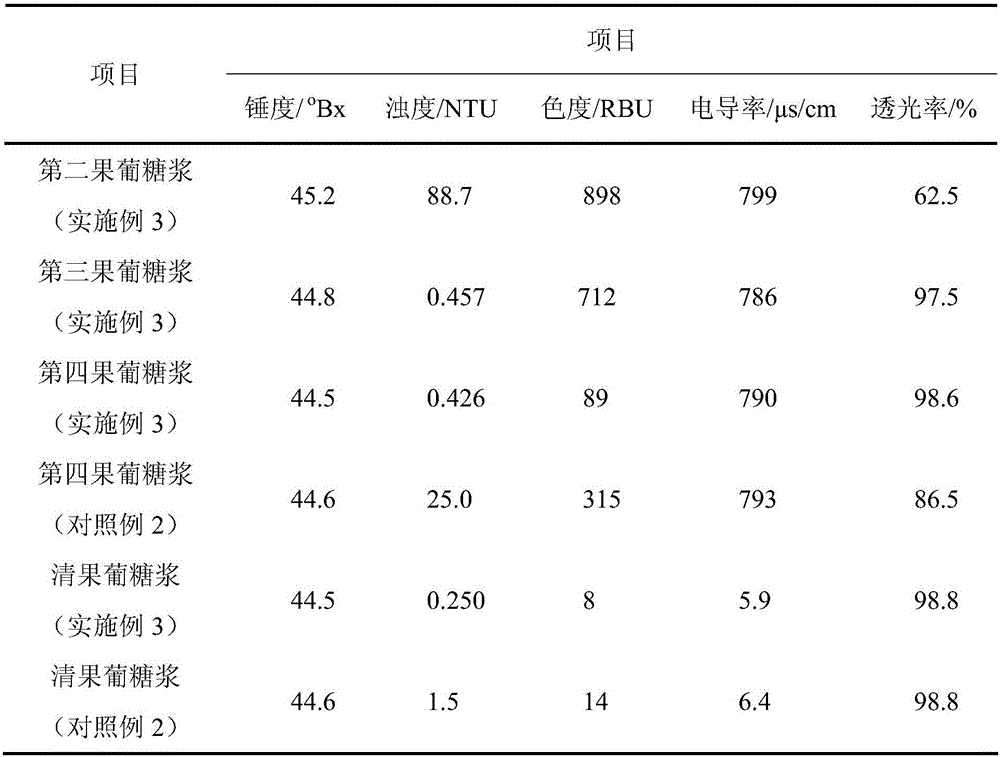

[0069] A method for producing crystallized fructose with raw sugar as raw material, the operation steps are:

[0070] (1) dissolving: the raw sugar is dissolved to 65°Bx with water to obtain the raw sugar back-dissolving syrup;

[0071] (2) Acid hydrolysis: adjust the pH of the raw sugar back-dissolving syrup to 3.0 with hydrochloric acid for acid hydrolysis to obtain the first fructose syrup;

[0072] (3) pH adjustment: adjust the pH of the first fructose syrup to 7.0 with NaOH solution to obtain the second fructose syrup;

[0073] (4) Ceramic membrane filtration: filter the second fructose syrup by using ceramic membrane components to obtain the third fructose syrup;

[0074] (5) Activated carbon pre-decolorization: add activated carbon to the third fructose syrup, filter after fully absorbing, and the filtrate is to obtain the fourth fructose syrup;

[0075] (6) Ion exchange resin decolorization and desalination:

[0076] Using the first ion exchange resin to decolorize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com