Processing technology of sugarcane concentrated juice

A processing technology and a technology for concentrated juice, which is applied to the processing technology field of sugarcane concentrated juice, can solve the problems of loss of flavor substances and nutrients, browning during processing and storage, deterioration of sugarcane juice, etc., and achieves short production time and production process. Short, Scented Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

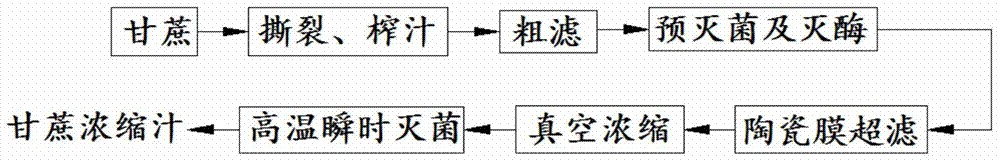

[0022] A kind of processing technology of sugarcane concentrated juice, its operation steps are:

[0023] (1) tearing and juicing: select fresh and ripe sugarcane, remove the raw materials of rotten pests, and clean the sugarcane epidermis;

[0024] (2) Coarse filtration: the raw sugarcane juice is beaten and filtered by a beater with a sieve diameter of 0.5mm, and then further filtered by a horizontal centrifuge with a sieve of 200 mesh to remove large particles such as sugarcane bran and sugarcane debris in the sugarcane juice Impurities, to obtain coarsely filtered sugarcane juice;

[0025] (3) Pre-sterilization and enzyme deactivation: heat the coarsely filtered sugarcane juice to 100°C, keep it for 3 minutes, perform pre-sterilization and deenzyme deactivation, and obtain heated sugarcane juice;

[0026] (4) Ceramic membrane ultrafiltration: send the heated sugarcane juice to the ceramic membrane ultrafiltration working tank, and perform ultrafiltration clarification wit...

Embodiment 2

[0034] A kind of processing technology of sugarcane concentrated juice, its operation steps are:

[0035] (1) Tearing and juicing: Select fresh and mature sugarcane, remove the raw materials of rotten pests, clean the sugarcane skin, use a tearing machine to tear the sugarcane into filaments, sheets, strips and other finely divided materials and send them into the Press the juicer to extract the juice. In order to increase the juice yield, you can spray a small amount of water on the bagasse obtained after the first juice extraction, and then squeeze the juice again to obtain the raw sugarcane juice;

[0036] (2) Coarse filtration: the raw sugarcane juice is beaten and filtered by a beater with a sieve diameter of 1.0 mm, and then further filtered by a horizontal centrifuge with a sieve of 400 mesh to remove large particles such as sugarcane bran and sugarcane debris in the sugarcane juice Impurities, to obtain coarsely filtered sugarcane juice;

[0037] (3) Pre-sterilization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com