A kind of processing method of sugarcane juice solid beverage

A technology of solid beverage and processing method, which is applied in the field of food processing, can solve the problems of unfavorable storage and transportation due to excessive water content, and achieve the effects of prolonging the film cleaning cycle, low investment cost, and simple packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

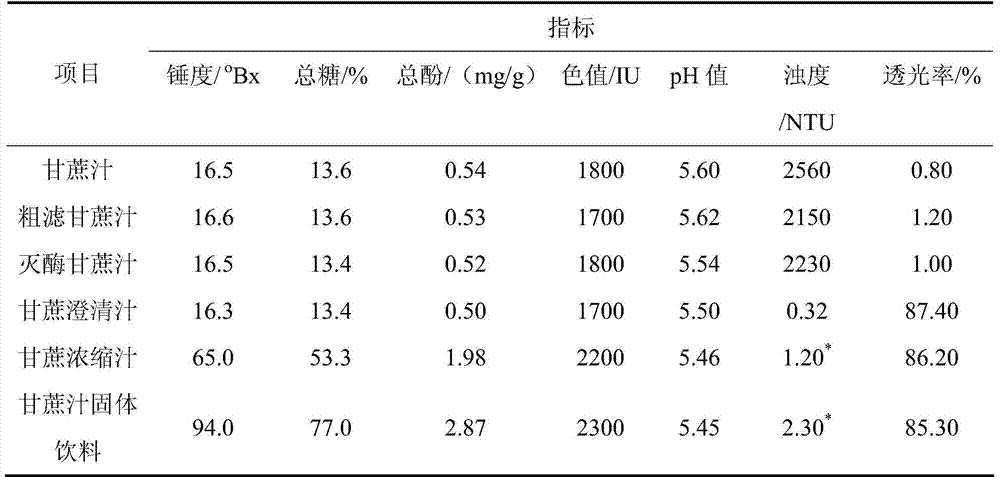

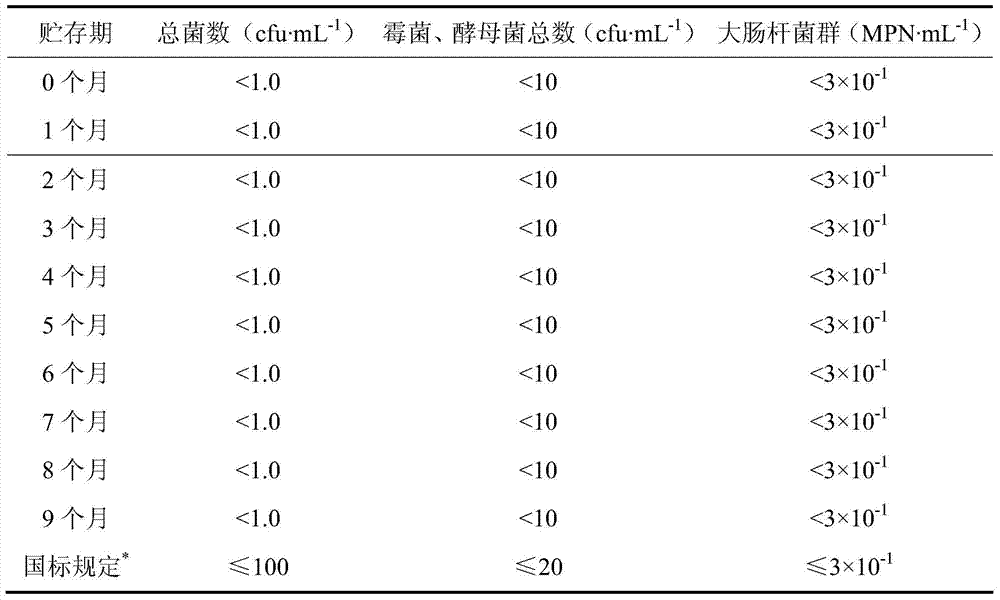

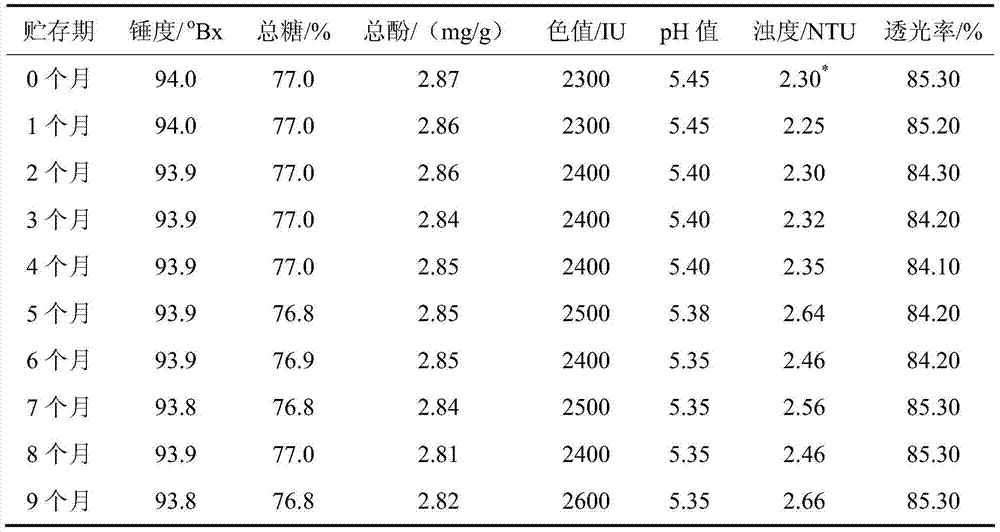

Examples

Embodiment 1

[0027] A kind of processing method of sugarcane juice solid beverage, its operation steps are:

[0028] (1) Coarse filtration: the sugarcane juice is successively filtered through a drum sieve and a sieve with a screen mesh of 100 meshes to remove large particles of impurities such as sugarcane bran and sugarcane debris in the sugarcane juice, and obtain coarsely filtered sugarcane juice;

[0029] (2) Enzyme elimination: use the first plate heat exchanger to heat the coarsely filtered sugarcane juice to 100°C, keep it for 1min, and then cool it to 70°C within 60 seconds with the second plate heat exchanger to prevent the sugarcane juice from being overheated. Loss of flavor substances and nutrients, to obtain enzyme-inactivated sugarcane juice;

[0030] (3) Ceramic membrane ultrafiltration: send the enzyme-inactivated sugarcane juice to the ceramic membrane ultrafiltration working tank, and perform ultrafiltration and clarification with a multi-stage ceramic membrane ultrafilt...

Embodiment 2

[0044] A kind of processing method of sugarcane juice solid beverage, its operation steps are:

[0045] (1) Coarse filtration: the sugarcane juice is successively filtered through a drum sieve and a sieve with a screen mesh of 80 meshes to remove large particles of impurities such as sugarcane bran and sugarcane debris in the sugarcane juice, and obtain coarsely filtered sugarcane juice;

[0046] (2) Enzyme inactivation: use the first tubular heat exchanger to heat the coarsely filtered sugarcane juice to 90°C, keep it for 2 minutes, and then cool it to 80°C within 45 seconds with the second tubular heat exchanger to prevent the temperature from being too high. High causes the loss of sugarcane juice flavor substances and nutrients, and obtains enzyme-inactivated sugarcane juice;

[0047] (3) Ceramic membrane ultrafiltration: send the enzyme-inactivated sugarcane juice to the ceramic membrane ultrafiltration working tank, and perform ultrafiltration and clarification with a mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com