A sugar production process based on clarification of multiple co-production by membrane method

A multivariate and technological technology, applied in sugar crystallization, sugar products, sucrose production, etc., can solve the problems of low price, low added value, and single product, and achieve the effects of good product quality, increased added value, and high nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

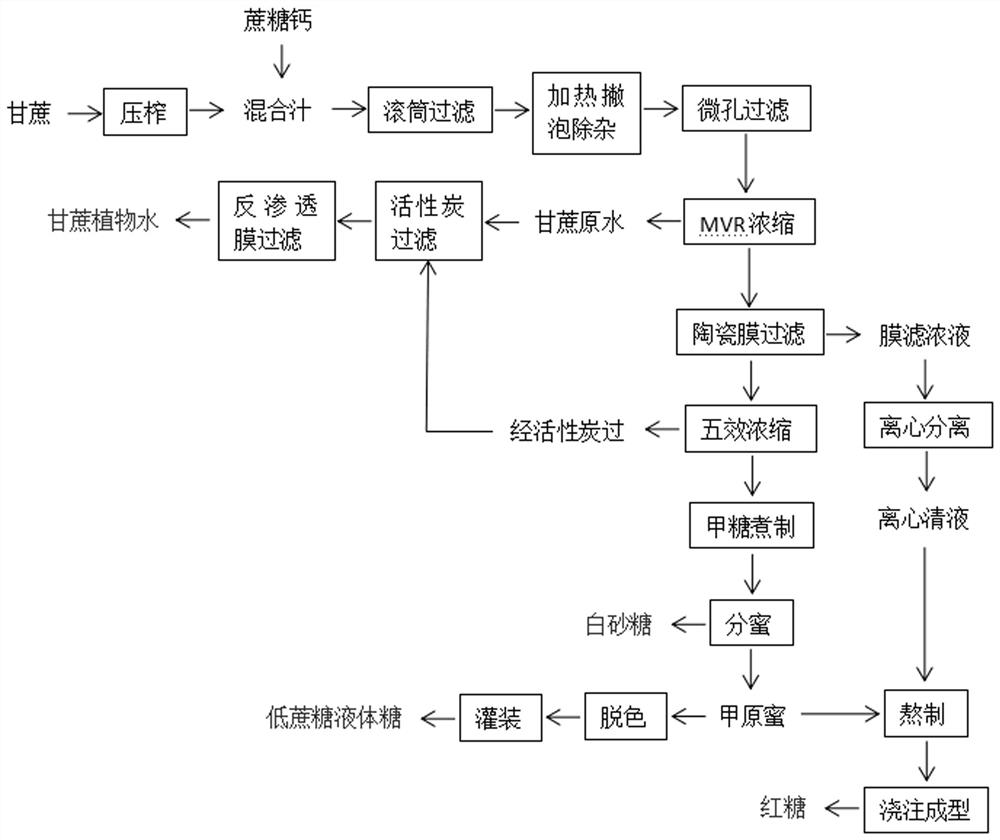

Embodiment 1

[0048] A kind of sugar making process based on membrane method clarification multiple co-production, comprises the following steps:

[0049] A. Extracting sugarcane juice: using conventional five presses to squeeze sugarcane to obtain a Brix of 13-15 o Mixture of Bx;

[0050] B. Pre-ash: add sucrose calcium to the mixed juice, and adjust the pH value to 6.8-7.2.

[0051] C. Physical impurity removal: The pre-ashed mixed juice is passed through a drum sieve, a heating skimming device, and a microporous filter in sequence for physical impurity removal to obtain filtered clear juice.

[0052] D. Concentration for the first time: Use the MVR concentrator to concentrate the filtered clear juice to obtain a Brix of 18-20 o Bx's juice concentrate and sugarcane raw water.

[0053] E. Ceramic membrane filtration: filter the concentrated juice with a ceramic membrane with a membrane pore size of 20nm to obtain membrane filtrate and membrane filtrate concentrate with turbidity less th...

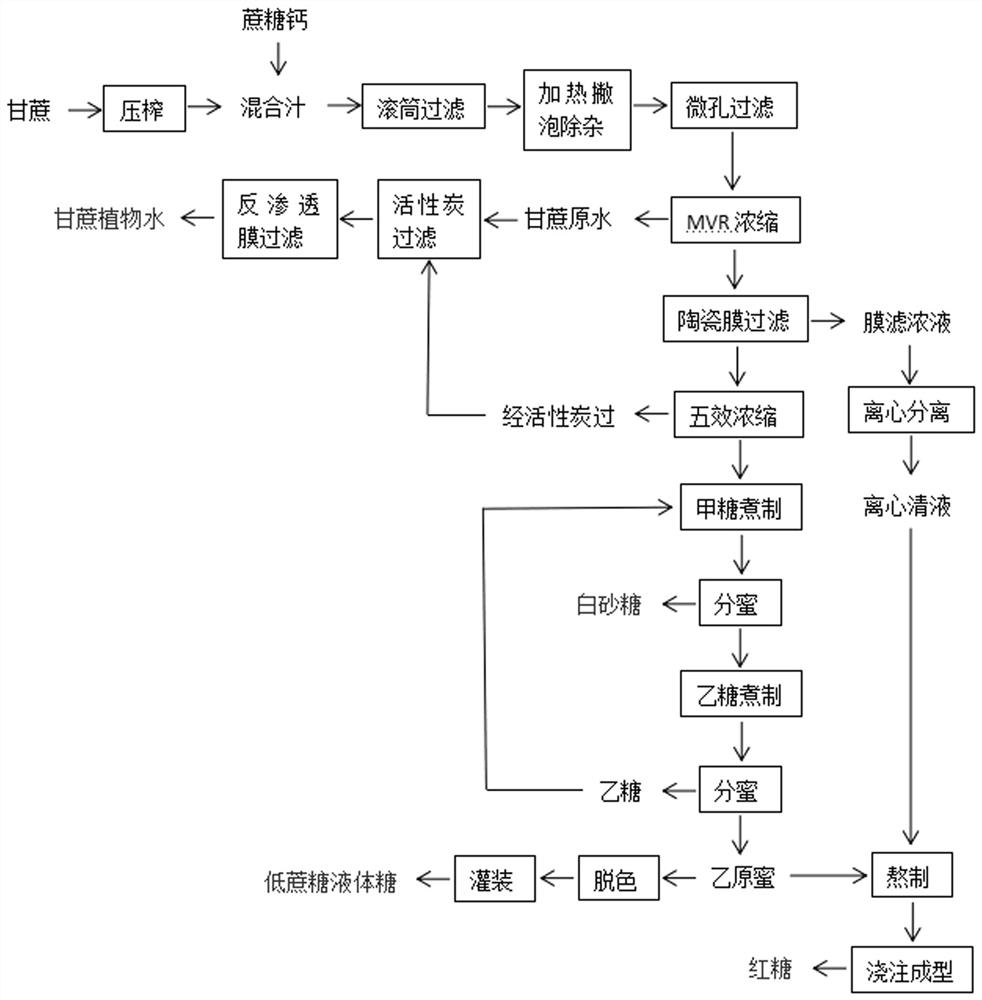

Embodiment 2

[0070] A sugar production process based on membrane method to clarify co-production sugarcane plant water, comprising the following steps:

[0071] A. Extracting sugarcane juice: using conventional five presses to squeeze sugarcane to obtain a Brix of 13-15 o Mixed juice of Bx.

[0072] B. Pre-ash: add sucrose calcium to the mixed juice, and adjust the pH value to 6.8-7.2.

[0073] C. Physical impurity removal: The pre-ashed mixed juice is passed through a drum sieve, a heating skimming device, and a microporous filter in sequence for physical impurity removal to obtain filtered clear juice.

[0074] D. Concentration for the first time: Use the MVR concentrator to concentrate the filtered clear juice to obtain a Brix of 18-20 o Bx's juice concentrate and sugarcane raw water.

[0075] E. Ceramic membrane filtration: filter the concentrated juice with a ceramic membrane with a membrane pore size of 50nm to obtain membrane filtrate and membrane filtrate concentrate with turbid...

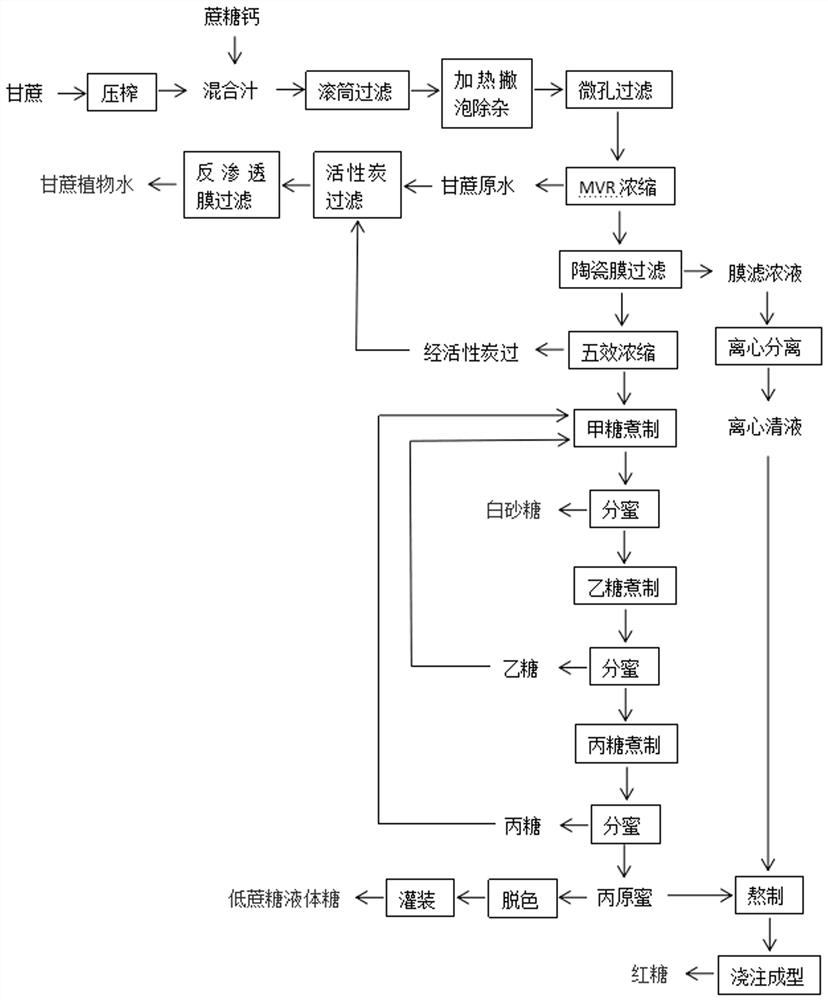

Embodiment 3

[0093] A sugar production process based on membrane method to clarify co-production sugarcane plant water, comprising the following steps:

[0094]A. Extracting sugarcane juice: using conventional five presses to squeeze sugarcane to obtain a Brix of 13-15 o Mixed juice of Bx.

[0095] B. Pre-ash: add sucrose calcium to the mixed juice, and adjust the pH value to 6.8-7.2.

[0096] C. Pretreatment: The preashed mixed juice is passed through a drum sieve, a heating skimming device, and a microporous filter in order to physically remove impurities to obtain filtered clear juice.

[0097] D. Concentration for the first time: Use the MVR concentrator to concentrate the filtered clear juice to obtain a Brix of 18-20 o Bx's juice concentrate and sugarcane raw water.

[0098] E. Ceramic membrane filtration: filter the concentrated juice with a ceramic membrane with a membrane pore size of 100nm to obtain membrane filtrate and membrane filtrate concentrate with turbidity less than 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com