Sulfitation syrup floatation clarification process

A sulfite method and syrup technology, applied in sugar crystallization, sugar products, sucrose production and other directions, can solve the problems of low clarification efficiency and high sulfur dioxide content, and achieve the goal of reducing nectar-making factors and pigment substances, improving quality, and improving product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

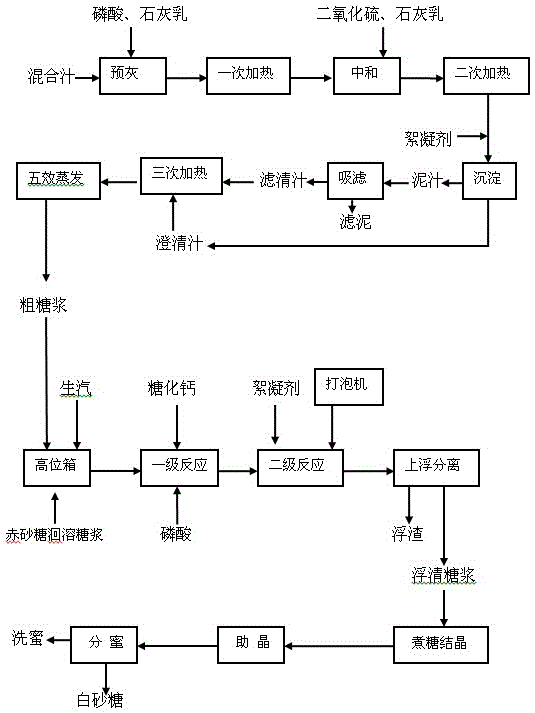

Method used

Image

Examples

Embodiment 1

[0030]First prepare the rough syrup, then pump the rough syrup to the syrup high level tank and mix it with the red sand back-dissolving syrup. At the same time, check and analyze the content of various indicators of the mixed syrup. The results are: Brix 62.6°Bx, sulfur content 405mg / kg, depending on the purity of 87.5%, pH value 7.1, and directly heat the rough syrup to 80-85°C with superheated steam in the syrup high-level box, and foam at a ratio of 15%, and add 350ppm of phosphoric acid and 10ppm of saccharified calcium for a reaction at the same time , and then add flocculant 10ppm, after mixing thoroughly, take a sample and observe before the secondary reactor flows into the floater, the scum floats up quickly and is clear, after being floated and separated by the floater, check and analyze the indicators of the float clear syrup, the result is: hammer The degree is 61.1°Bx, the sulfur content is 188mg / kg, the apparent purity is 87.7%, and the pH value is 6.3. The speci...

Embodiment 2

[0034] First prepare the rough syrup, then pump the rough syrup to the syrup high level tank and mix it with the red sand back-dissolving syrup. At the same time, check and analyze the contents of various indicators of the mixed syrup. The results are: Brix 63.8°Bx, sulfur content 413mg / kg, depending on the purity of 88.1%, pH value 7.06, and directly heat the rough syrup to 80-85°C with superheated steam in the syrup high-level box, and foam at a ratio of 15%, and add 350ppm of phosphoric acid and 10ppm of calcium saccharification for a reaction at the same time , and then add flocculant 10ppm, after mixing thoroughly, take a sample and observe before the secondary reactor flows into the floater, the scum floats up quickly and is clear, after being floated and separated by the floater, check and analyze the indicators of the float clear syrup, the result is: hammer The temperature is 61.6°Bx, the sulfur content is 198mg / kg, the apparent purity is 88.2%, and the pH value is 6.2...

Embodiment 3

[0038] First prepare the rough syrup, then pump the rough syrup to the syrup high level tank and mix it with the red sand back-dissolving syrup. At the same time, check and analyze the contents of various indicators of the mixed syrup. The results are: Brix 64.8°Bx, sulfur content 398mg / kg, depending on purity 87.2%, pH value 6.95, and directly heat the crude syrup to 80-85°C with superheated steam in the syrup high-level box, and foam at a ratio of 15%, while adding 350ppm phosphoric acid and 10ppm calcium saccharification for a reaction , and then add flocculant 10ppm, after mixing thoroughly, take a sample and observe before the secondary reactor flows into the floater, the scum floats up quickly and is clear, after being floated and separated by the floater, check and analyze the indicators of the float clear syrup, the result is: hammer The temperature is 63.5°Bx, the sulfur content is 175mg / kg, the apparent purity is 87.5%, and the pH value is 6.2. The specific situation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brix | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com