New clarification technique for refining sugar from sugar cane

A new technology, sugarcane technology, is applied in the new technology field of sugarcane sugar clarification, which can solve the problems that affect the quality of clear juice, the quality of white granulated sugar, the health of workers, and the instability of sugarcane crushing, so as to improve economic and social benefits, Good quality and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

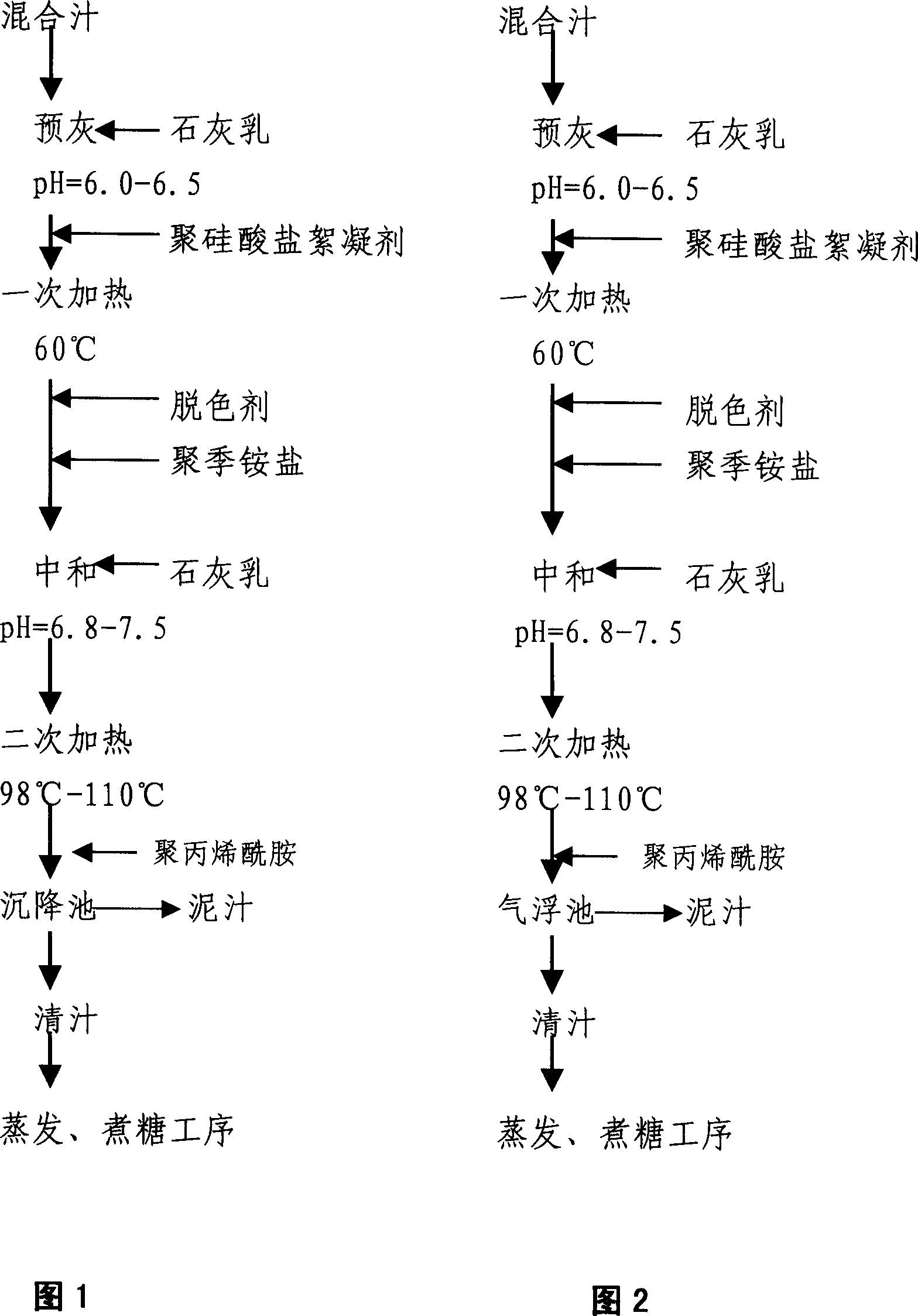

Method used

Image

Examples

Embodiment 1

[0020] Take 1000mL of sugarcane mixed juice, add Al 3+ , Zn 2+ , Ca 2+ , B 3+ Mixed ion polysilicate coagulant 0.4mL, heated to 55-65°C, then added 1.0g of sodium dithionite solid, 5.0mL of polydimethyldiallyl ammonium chloride (1%), added lime milk Neutralize to pH=6.8-7.5, heat again to 100-105°C, add 2mg / L polyacrylamide, then settle at constant temperature to separate mud juice and clear juice. After analysis, the purity difference of the clear juice increased by 1.5 percentage points, the decolorization rate was 80.5%, and the turbidity removal rate was 99%.

Embodiment 2

[0022] Take 1000mL of sugarcane mixed juice, add Al 3+ , Zn 2+ , Mg 2+ Mixed ion polysilicate coagulant 0.3mL, heated to 55-65°C, then added 1.0g of sodium metabisulfite solid, polydimethyldienyl ammonium chloride (1%) 4.0mL, added to milk of lime and to pH = 6.8-7.5, heated to 100-105°C for the second time, added 2mg / L polyacrylamide, and then settled at constant temperature to separate mud juice and clear juice. After analysis, the purity difference of the clear juice increased by 1.8 percentage points, the decolorization rate was 82.8%, and the turbidity removal rate was 99%.

Embodiment 3

[0024] Take 1000mL of sugarcane mixed juice, add Al 3+ , Mg 2+ , B 3+ Mixed ion polysilicate coagulant 0.3mL, heated to 65-70°C, then add 2.0g solid sodium bisulfite, 5.0mL polydodecyl quaternary ammonium salt (1%), add lime milk to neutralize To pH = 6.8-7.5, reheat to 105-110°C, add 2mg / L polyacrylamide, then settling at constant temperature to separate mud juice and clear juice. After analysis, the purity difference of the clear juice increased by 1.7 percentage points, the decolorization rate was 82%, and the turbidity removal rate was 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com