Sugar juice settle low-ash low-temperature carbonating method

A sugar juice filling technology, applied in the purification of sugar juice, sucrose production, sugar production, etc., can solve problems such as pollution, achieve the effects of reducing sugar loss, good economic benefits, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

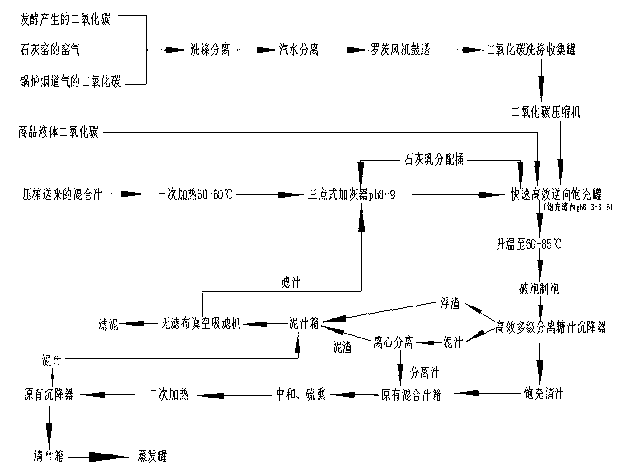

Method used

Image

Examples

Embodiment 1

[0020] Add a small amount of lime milk to the mixed juice transported from the pressing workshop to pre-lime to pH 7.2. After one heating at 50°C, the mixed juice flows into the tank quickly and efficiently in reverse, and the main ash, that is, a large amount of lime milk, is added to fill the juice effectively. Calcium oxide content reaches 0.2% of the total calcium content of cane juice to sugarcane ratio (or 0.2% to sugarcane juice ratio); at the same time, carbon dioxide is added. In addition, after the vacuum suction filter comes out of the filtered juice and refluxes, it adds lime (lime milk) to pH 8.0 through a three-point liming device, and then enters the fast and efficient reverse filling tank, and fills it together with the above mixed juice until the final pH is 7.8. . The temperature of the full-filled juice obtained after full filling reaches 60°C, after foam breaking and foam making, 1 ppm of flocculant polyacrylamide is added, and it enters the high-efficiency...

Embodiment 2

[0024] Add a small amount of lime milk to the mixed juice transported from the pressing workshop to pre-lime to pH 7.4. After one heating at 55°C, the mixed juice will flow into the tank quickly and efficiently in reverse, and add the main ash, that is, a large amount of lime milk, to effectively oxidize the full juice. The calcium content reaches 0.28% of the total calcium content of the cane juice to the cane ratio (or 0.28% to the ratio of the cane juice); at the same time, carbon dioxide is added. After the vacuum suction filter comes out, the filtered juice is refluxed and ashed to pH 8.1 through a three-point liming device, and then enters the fast and efficient reverse filling tank, and is filled together with the above mixed juice until the final pH is 8.0. The temperature of the full-filled juice obtained after full filling reaches 75°C. After breaking the foam and making foam, 2.5ppm of flocculant polyacrylamide is added, and it enters the high-efficiency multi-stage ...

Embodiment 3

[0028]Add a small amount of lime milk to the mixed juice transported from the pressing workshop to pre-lime to pH 7.6. After a heating temperature of 60°C, the mixed juice will flow into the tank quickly and efficiently, and add a large amount of lime milk, which is the main ash, to effectively oxidize the full juice. The calcium content reaches 0.35% of the total calcium content of the cane juice to the ratio of sugarcane (or 0.35% to the ratio of sugarcane juice); at the same time, carbon dioxide is added. After the vacuum suction filter comes out, the filtered juice is refluxed and ashed to pH 8.2 through a three-point liming device, and then enters the fast and efficient reverse filling tank, and is filled together with the above mixed juice until the final pH value is 8.2. The temperature of the full-filled juice obtained after full-filling reaches 85°C, after foam breaking and foam-making, 3 ppm of flocculant is added, and it enters the high-efficiency multi-stage separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com