Quick assembling component type protective system of waste dump edge slope

A protection system and dump site technology, which is applied to waterway systems, drainage structures, water supply devices, etc., can solve problems such as low survival rate, failure to maintain, and difficulty in adapting to the flood discharge requirements of the dump site slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

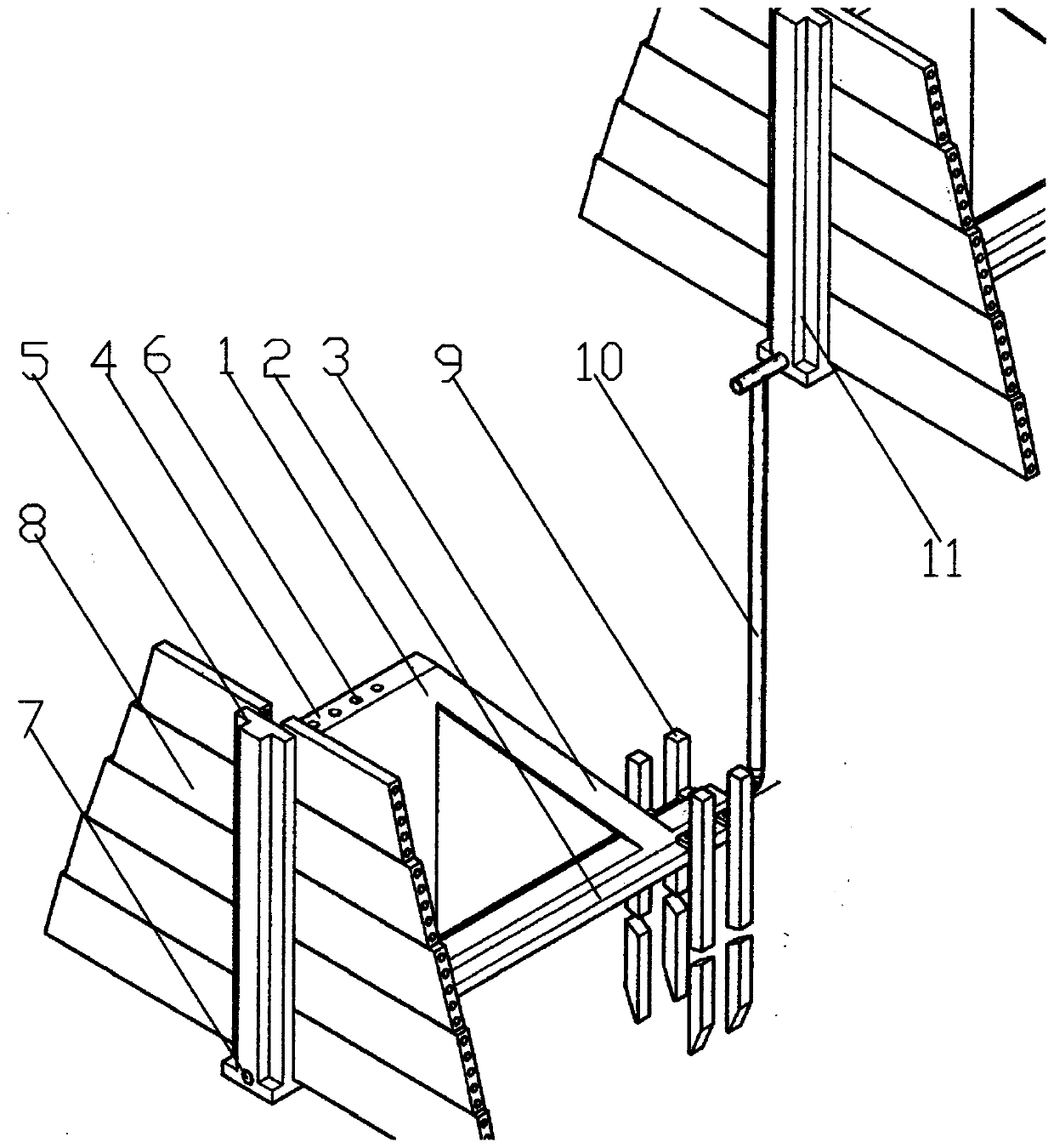

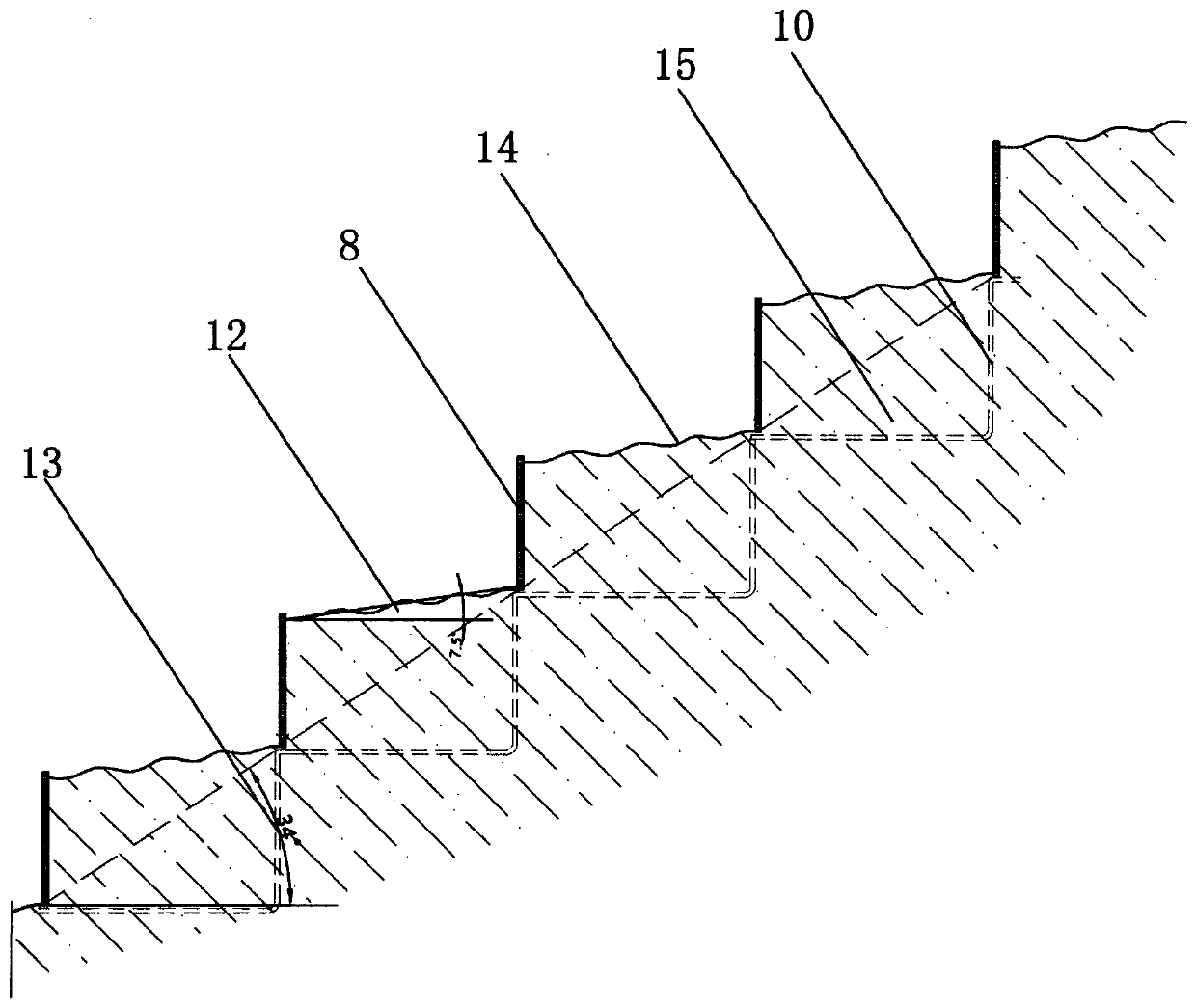

[0022] The main part of the protection system is the structural frame, and its bottom plate, shoulder plate, diagonal braces and drainage walls are poured as a whole with reinforced concrete; the recommended pouring method is: the steel bars are bound once to shape, and the horizontal drainage holes and vertical drainage holes are set simultaneously— -Pre-buried pipe method or plug-in inner formwork method, the formwork can be completed in one time or multiple times; the pouring method is recommended to be poured in multiple batches, for example: pour the bottom rectangular flat plate at the bottom of the bottom plate first (the size of this example is width × height = 420 ×90), pour the rectangular protrusion in the middle of the bottom slab after the initial setting (in this example, the size is width×height=180×90), after the initial setting, pour the drainage wall, diagonal brace and shoulder plate to the top elevation of the drainage wall, and finally The part where the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com