Beneficiation production system of lean magnetite

A technology of lean magnetite and production system is applied in the field of beneficiation and production system of lean magnetite, which can solve the problems of equipment wear and large particle size of coarsely crushed products, and achieve the advantages of reducing wear, reducing ore transportation cost and prolonging service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

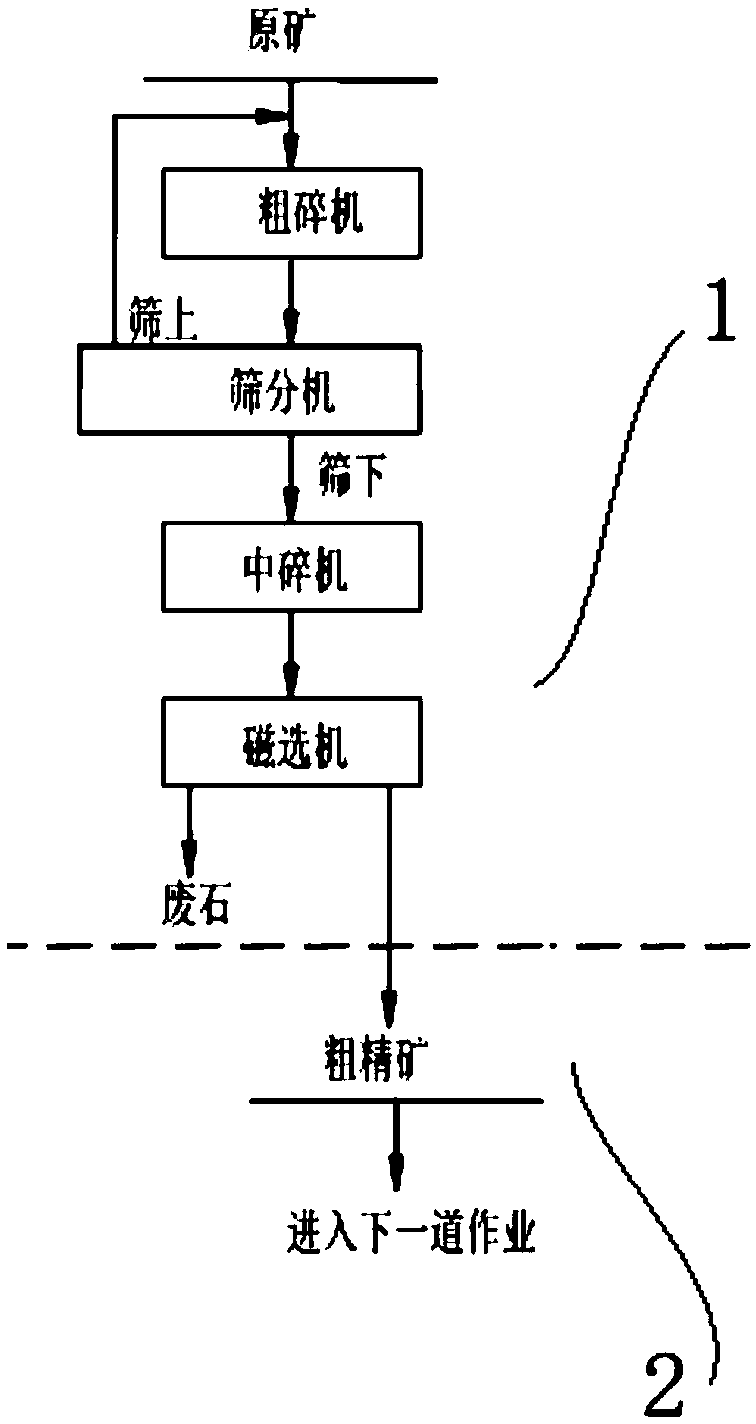

[0043] The beneficiation process of a kind of poor magnetite of the present embodiment is applied to a certain poor magnetite open-pit mine, the iron grade of raw ore is 18~22%, and iron mineral is mainly magnetite in the ore, and magnetic iron content is about 70% (accounting for total iron content), the operation steps are:

[0044] A. Coarse crushing: In the ore stope 1, the lean magnetite is coarsely crushed in the coarse crusher, and then sieved by the sieving machine after the coarse crushing;

[0045] B. Secondary crushing: In the ore stope 1, the undersieve of step A is directly entered into the secondary crusher for crushing;

[0046] C, magnetic separation: discard the waste rock after directly performing dry magnetic separation on the crushed material of step B in the ore stope 1;

[0047] D. Transfer: the coarse concentrate obtained in the previous step is transported to the fine crushing and sorting operation area of the subsequent mineral processing area 2;

...

Embodiment 2

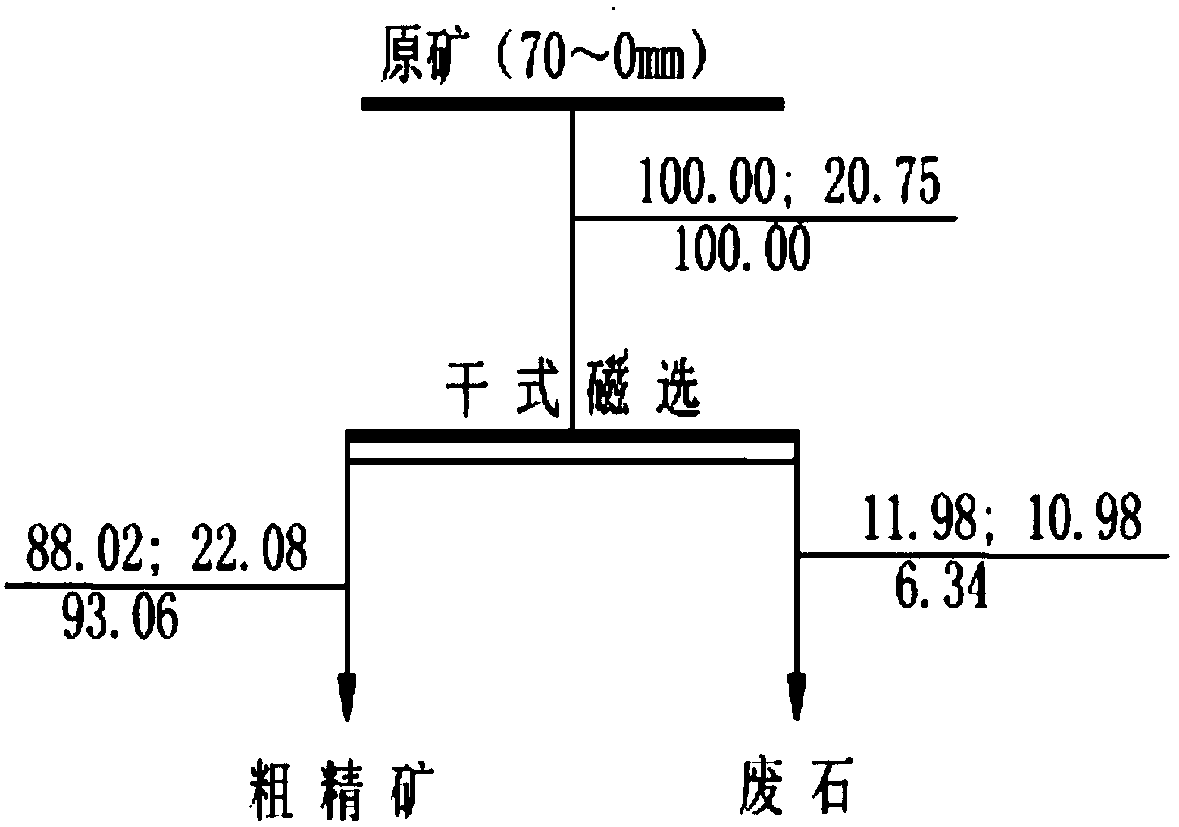

[0051] A kind of beneficiation process of lean magnetite in the present embodiment, the specific steps are basically the same as in embodiment 1, and the improvement is that: the oversize of step A is transferred to the coarse crusher for coarse crushing to improve the utilization rate of ore; coarse crushing to a particle size of 0-300mm, so as to facilitate further crushing by the secondary crusher. In step B, the intermediate crushing is crushed to a particle size of 0-70 mm, so as to facilitate the magnetic separation work of the permanent magnetic dry magnetic separator, greatly reduce the impact of the ore on the hopper and the silo of the magnetic separator, and reduce the wear of the ore on the conveyor belt ; The weak magnetic dry magnetic separation described in step C is completed by a permanent magnetic dry magnetic separator, so as to be able to adapt to the magnetic separation of ores with a maximum particle size of 70mm.

Embodiment 3

[0053] A kind of beneficiation process of lean magnetite in the present embodiment, the specific steps are the same as in embodiment 2, and the improvement is that: the field strength of the permanent magnet dry magnetic separator is 0.3T; in step B, the medium crushing particle size is The content of 40-70mm is 20%, the content of 10-40mm is 55%, and the content of less than 10mm is 25%. It is suitable for lean magnetite ore with a magnetic iron content greater than 70%. The three technical features work together to achieve a better magnetic separation effect. To achieve the purpose of improving the grade of rough concentrate in the ore stope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com