Mine waste dump slope water drainage system and construction method thereof

A technology for drainage system and soil dump, which is applied in the direction of waterway system, sewer pipeline system, drainage structure, etc., can solve the problem of less research, and achieve the effect of convenient construction, good drainage effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

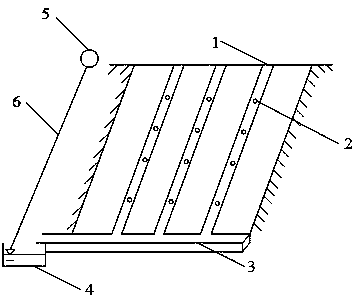

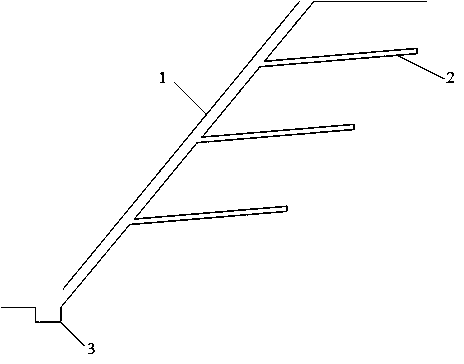

[0028] A side slope drainage system of a mine dump site comprises a rapid flow tank, a seepage pipe, a drainage tank, a water storage tank, a water pump and pipelines. The seepage pipe is buried along the inclined upward direction of the slope, and the outlet of the seepage pipe is arranged in the rapid flow tank, parallel to the bottom of the rapid flow tank, and the rapid flow tank is built from top to bottom along the slope, and the bottom of the rapid flow tank is connected The water tank is connected, the end of the drainage tank is connected with the water storage tank, and the water pump is connected with the water storage tank through a pipeline.

[0029] A construction method for a side slope drainage system of a mine dump, comprising the following steps:

[0030] (1) Use a drilling rig to drill a hole 3° above the slope with a depth of 10m;

[0031] (2) Insert the reinforced cement prefabricated seepage pipe along the drilled hole, the inner diameter of the seepage ...

Embodiment 2

[0037] A side slope drainage system of a mine dump site comprises a rapid flow tank, a seepage pipe, a drainage tank, a water storage tank, a water pump and pipelines. The seepage pipe is buried along the inclined upward direction of the slope, and the outlet of the seepage pipe is arranged in the rapid flow tank, parallel to the bottom of the rapid flow tank, and the rapid flow tank is built from top to bottom along the slope, and the bottom of the rapid flow tank is connected The water tank is connected, the end of the drainage tank is connected with the water storage tank, and the water pump is connected with the water storage tank through a pipeline.

[0038] A construction method for a side slope drainage system of a mine dump, comprising the following steps:

[0039] (1) Use a drilling rig to drill a hole 4° above the slope with a depth of 12m;

[0040] (2) Insert the reinforced cement prefabricated seepage pipe along the drilled hole. The inner diameter of the seepage ...

Embodiment 3

[0046] A side slope drainage system of a mine dump site comprises a rapid flow tank, a seepage pipe, a drainage tank, a water storage tank, a water pump and pipelines. The seepage pipe is buried along the inclined upward direction of the slope, and the outlet of the seepage pipe is arranged in the rapid flow tank, parallel to the bottom of the rapid flow tank, and the rapid flow tank is built from top to bottom along the slope, and the bottom of the rapid flow tank is connected The water tank is connected, the end of the drainage tank is connected with the water storage tank, and the water pump is connected with the water storage tank through a pipeline.

[0047] A construction method for a side slope drainage system of a mine dump, comprising the following steps:

[0048] (1) Use a drilling rig to drill a hole 5° above the slope with a depth of 15m;

[0049] (2) Insert the reinforced cement prefabricated seepage pipe along the drilled hole. The inner diameter of the seepage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elevation angle | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com