Anti-cracking interlayer for asphalt pavement

An asphalt pavement and interlayer technology, applied in the directions of roads, roads, pavement details, etc., can solve the problems of lack of reinforcement structure and improved drainage, failure in use, affecting the performance of asphalt pavement, etc., to prevent pavement cracks and associated diseases, prevent and Slows generation and expansion, prolongs service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

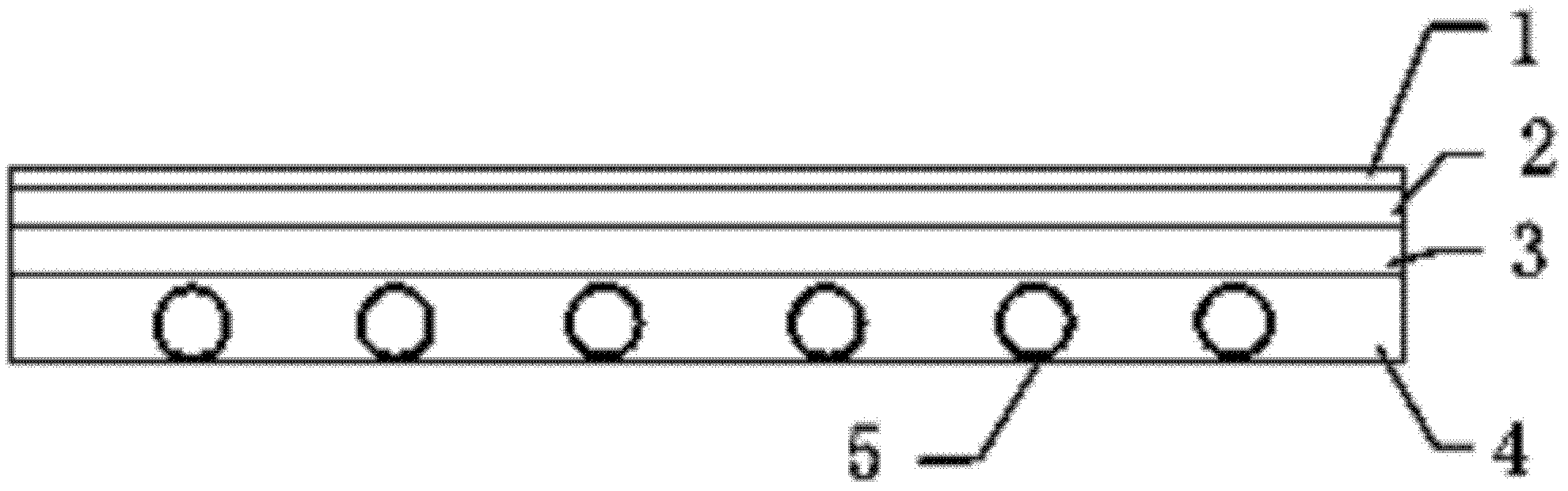

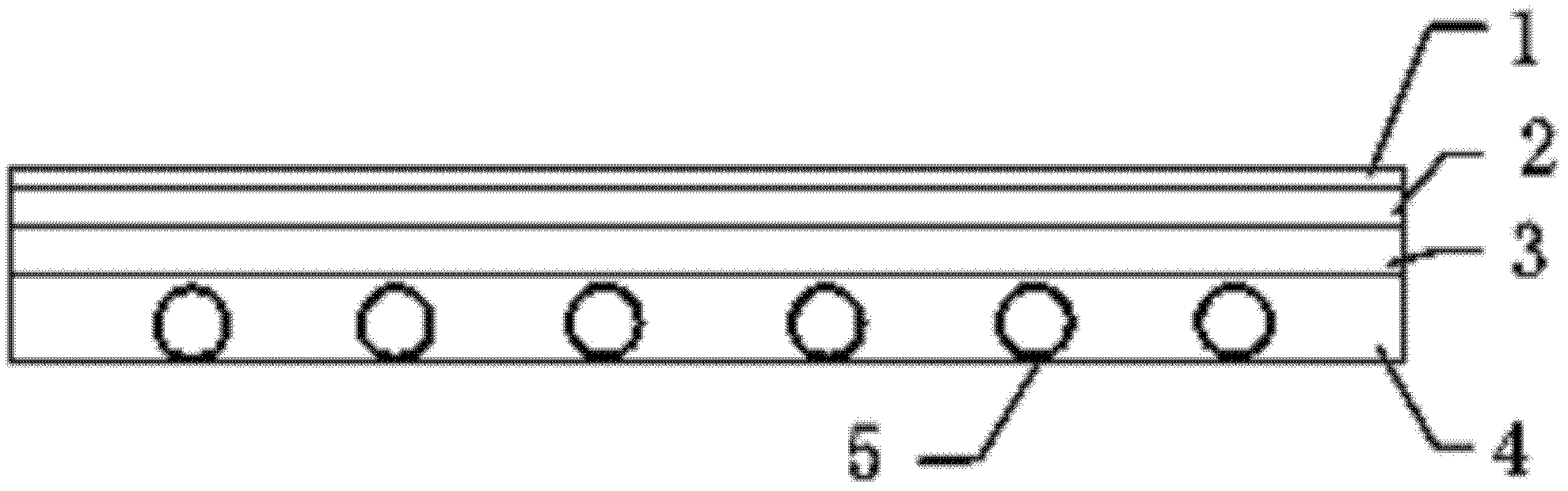

[0028] like figure 1 As shown, a kind of asphalt pavement anti-cracking interlayer of the present invention, the anti-cracking interlayer is arranged between the asphalt pavement surface layer and the base layer, and the anti-cracking interlayer is respectively a stress-absorbing film layer 1 and a polymer layer 2 from top to bottom. , high-strength tire base layer 3 and self-adhesive polymer layer 4; wherein, the stress-absorbing film layer 1 is made of polyester fiberglass cloth (fiberglass-polyester paving mat), and the polyester fiberglass cloth is made of 60% by weight of glass fiber It is a composite geosynthetic material composed of polyester fiber and 40% by weight, with a thickness of 0.03mm, high temperature resistance (250°C), high tensile strength (35kN / m), and good compatibility with asphalt mixture; high The polymer layer (high polymer soft matter) 2 is composed of polymer modified asphalt, the matrix is asphalt, the mass of rubber powder is 15-20% of the mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com