Reverse stacking cell guide for storing of iso shipping containers

A container and guide channel technology, which is used in transportation and packaging, storage devices, stacking of objects, etc., to achieve the effect of increased utilization and increased stacking height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

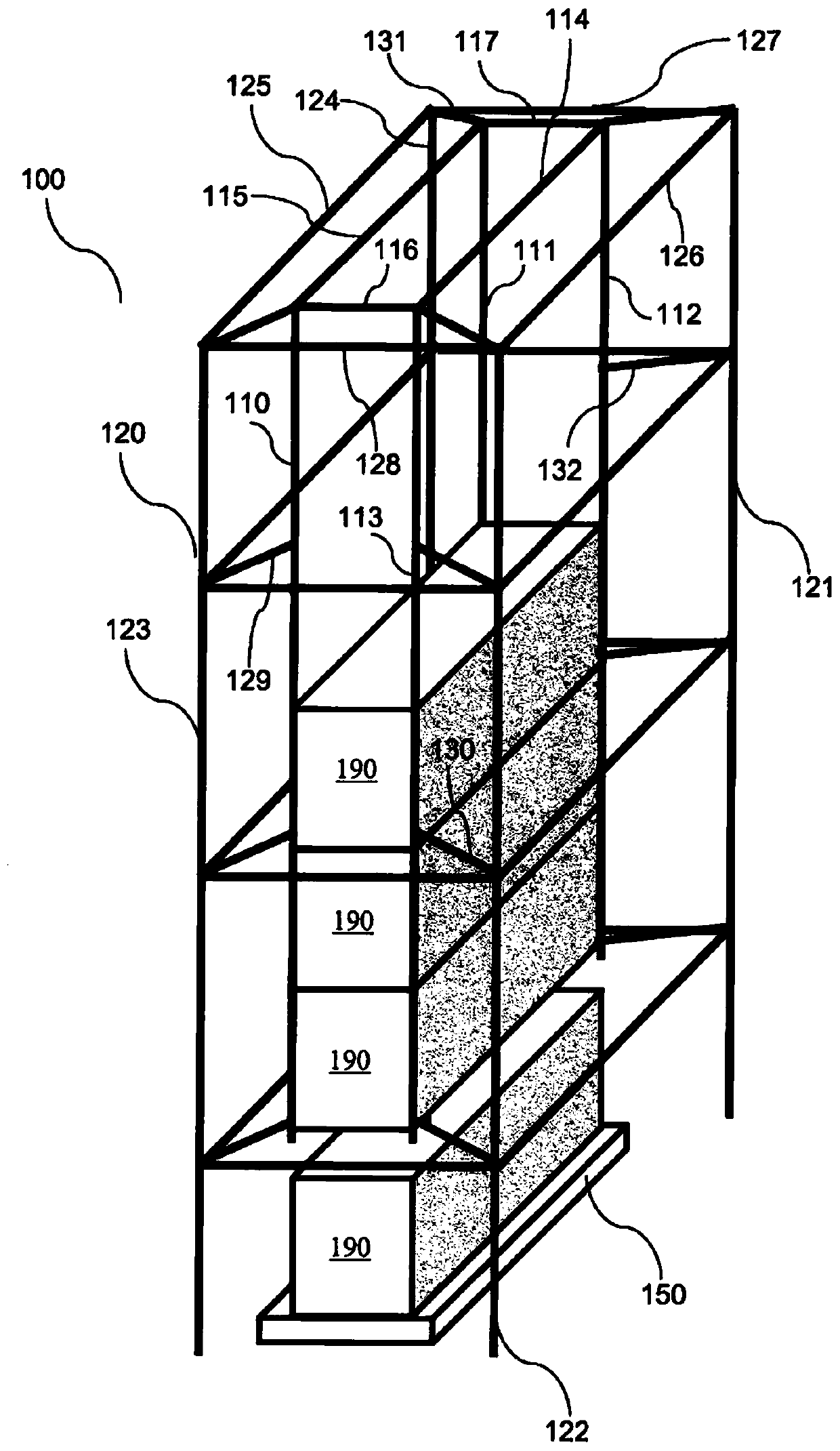

[0046] The present invention relates to methods and systems for stacking ISO shipping containers in a reverse fashion.

[0047] For the purposes of this disclosure, ISO shipping containers relate to shipping containers that have been or will be published in catalogs developed by the International Standards Organization.

[0048] Channels (also called cell guides) have been used on container ships for many years, but not on land. On board, containers are lowered from top to bottom by quay cranes, with the limitation that there can be no more than 10 containers on top of one container. It is now proposed to apply channels on land in an arrangement that enables stacking of ISO transport containers in reverse stacked fashion. In other words, instead of the conventional method of lowering the ISO shipping containers from the top down, the ISO shipping containers are stacked from the bottom up or in reverse.

[0049] figure 1 A trans-stacking channel 100 is shown. The trans-stac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com