Welding ring product flatness control process

A flatness and product technology, applied in the field of welding ring product flatness control technology, can solve the problems of uneven welding ring, flattening of welding ring, and difficulty in manual inspection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

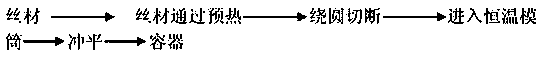

[0013] Welding ring product flatness control process, including voltage controller and heating coil, is characterized in that: the wire is wound into a circle by heating, the circle is cut and dropped into the constant temperature mold barrel, and punched down by the punching needle in the constant temperature mold barrel Leveling, after leveling, drop from the thermostatic mold barrel into the container.

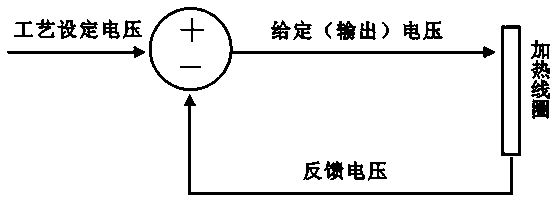

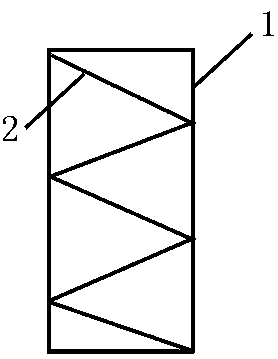

[0014] The flatness control process of welding ring products is characterized in that: the thermostatic mold cylinder is cylindrical, and a heating coil is spirally wound on its outer surface; the external voltage of the heating wire is 360 volts, and the output voltage is set to 170 volts by the voltage controller , current 2A, mold barrel preheating time is 30 minutes, continuous input current heating during the production process.

[0015] The flatness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com