Shaping tool and C/SiC composite structural part forming method adopting shaping tool

A molding method and technology for structural parts, applied in the field of C/SiC composite material preform molding tooling, can solve the problems of low assembly accuracy, narrow local space, difficult operation, etc., achieve convenient processing and transportation, large adjustment space, and improve the overall the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

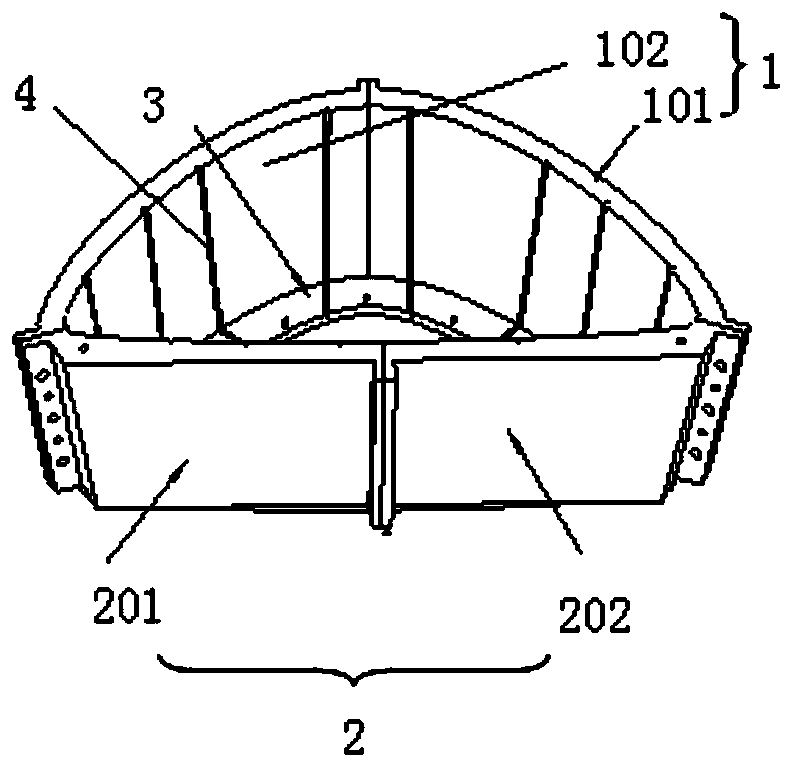

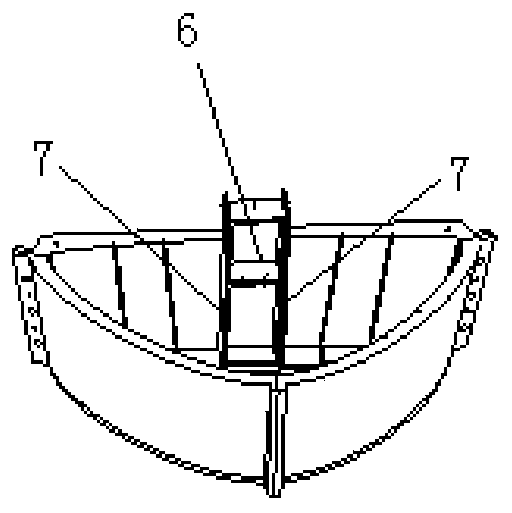

[0057] The method for forming a C / SiC composite structural part using the above-mentioned shaping tooling includes the following steps:

[0058] Step 1, box type 5 with punching holes

[0059] Take a plurality of box-shaped parts 5 with upper openings, the outer dimensions of the box-shaped parts 5 are adapted to the shaped top plate 1 or shaped bottom plate 2 between adjacent limiting grooves 4, and there is a connection relationship between each box-shaped part 5 The side walls of each are equipped with perforated holes, the hole diameter is 3mm, and the hole center distance is 6mm;

[0060] Step 2, the outer wall of the box-shaped part 5 is wrapped with carbon fiber cloth

[0061] Wrap multiple layers of carbon fiber cloth on the outer wall of each box-shaped part 5, and the edge of the carbon-fiber cloth is 5mm higher than the upper surface of the box-shaped part 5;

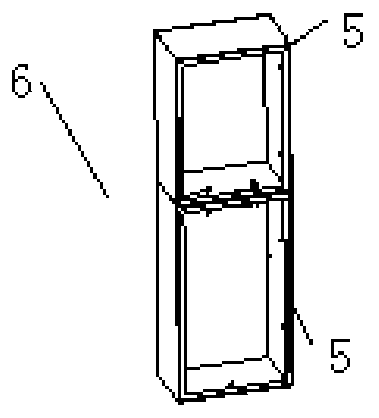

[0062] Step 3, Assembling Box Components 6

[0063] Such as figure 2 , place two box-shaped parts 5 i...

Embodiment 2

[0082] The method for forming a C / SiC composite structural part using the aforementioned sizing tooling comprises the following steps:

[0083] Step 1, box type 5 with punching holes

[0084] Take a plurality of box-shaped parts 5 with upper openings, the outer dimensions of the box-shaped parts 5 are adapted to the shaped top plate 1 or shaped bottom plate 2 between adjacent limiting grooves 4, and there is a connection relationship between each box-shaped part 5 The side walls of each are equipped with perforated holes, the hole diameter is 5mm, and the hole center distance is 9mm;

[0085] Step 2, the outer wall of the box-shaped part 5 is wrapped with carbon fiber cloth

[0086] Wrap multiple layers of carbon fiber cloth on the outer wall of each box-shaped part 5, and the edge of the carbon-fiber cloth is 8mm higher than the upper surface of the box-shaped part 5;

[0087] Step 3, Assembling Box Components 6

[0088] Place at least two box-shaped parts 5 in the same di...

Embodiment 3

[0107] The method for forming a C / SiC composite structural part using the above-mentioned shaping tooling includes the following steps:

[0108] Step 1, box type 5 with punching holes

[0109] Take a plurality of box-shaped parts 5 with upper openings, and punch holes in each side wall of each box-shaped part 5 with a connection relationship, the hole diameter is 6mm, and the distance between the holes is 10mm;

[0110] Step 2, the outer wall of the box-shaped part 5 is wrapped with carbon fiber cloth

[0111] Wrap multiple layers of carbon fiber cloth on the outer wall of each box-shaped part 5, and the edge of the carbon-fiber cloth is 10mm higher than the upper surface of the box-shaped part 5;

[0112] Step 3, Assembling Box Components 6

[0113] Place at least two box-shaped parts 5 in the same direction, and fix the adjacent surfaces of every two adjacent box-shaped parts 5 to form a box-shaped assembly 6; the height of the box-shaped assembly 6 is greater than the hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com