Heat-insulation performance testing device of heat-insulation coating for textile

A technology of thermal insulation coating and testing device, applied in the direction of thermal development of materials, etc., can solve the problem of not forming a closed space, and achieve the effects of uniform tension force, convenient installation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

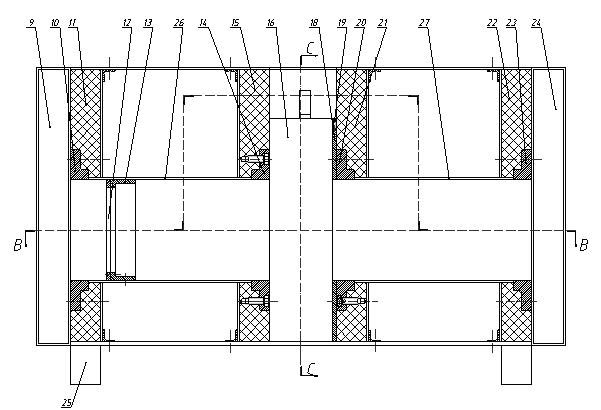

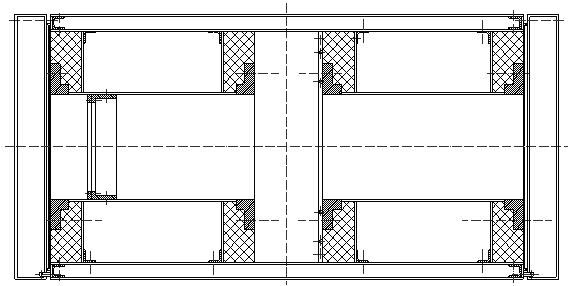

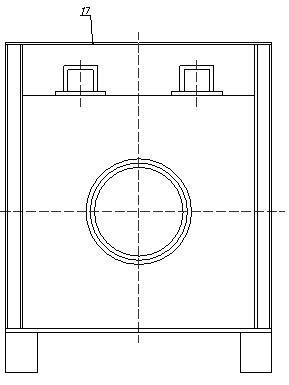

[0024] A thermal insulation performance testing device for a thermal insulation coating for fabrics, comprising an incubator and a fabric tensioning device 16 placed in the incubator during testing; Side insulation boards 4, 8, the center of the left and right side insulation boards are provided with a central hole, and a pressing plate 6 with a pressure ring 7 is arranged between the left and right side insulation boards. area, the flange nut 3 is fixed on the insulation board on the left side, the screw rod 2 is installed in the flange nut and the pressure plate, and the end of the screw rod is on the inner side of the pressure ring; the insulation box includes a box body installed on the base 25, The box body has left and right chambers separated by insulation boards 11, 15, 21, 22, a space for placing a fabric tensioning device is arranged between the left and right chambers, and a cover plate 17 is arranged on the upper part of the space for placing the fabric tensioning d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com